How Sodium Magnesium Silicate Hydroxide improves water remediation.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Background and Objectives

Sodium Magnesium Silicate Hydroxide, also known as Palygorskite or Attapulgite, has emerged as a promising material for water remediation in recent years. This naturally occurring clay mineral has a unique fibrous structure and exceptional adsorption properties, making it highly effective in removing various contaminants from water. The development of water remediation technologies using this material is rooted in the growing global concern over water pollution and the increasing demand for efficient, cost-effective, and environmentally friendly water treatment solutions.

The evolution of water remediation techniques has seen significant advancements over the past few decades, with a shift towards more sustainable and eco-friendly approaches. Traditional methods such as chemical treatments and activated carbon filtration, while effective, often come with high costs and potential environmental impacts. In this context, the exploration of natural materials like Sodium Magnesium Silicate Hydroxide represents a promising direction in the field of water purification.

The primary objective of research into Sodium Magnesium Silicate Hydroxide for water remediation is to harness its unique properties to develop more efficient and sustainable water treatment processes. This includes investigating its capacity to remove a wide range of pollutants, including heavy metals, organic compounds, and microbial contaminants. Additionally, researchers aim to understand the mechanisms behind its adsorption capabilities and explore ways to enhance its performance through various modifications and treatments.

Another key goal is to assess the scalability and practical applicability of Sodium Magnesium Silicate Hydroxide in real-world water treatment scenarios. This involves studying its effectiveness in different types of water bodies, its long-term stability, and its potential integration into existing water treatment infrastructures. The research also focuses on developing cost-effective methods for the large-scale production and application of this material, making it a viable option for both industrial and municipal water treatment facilities.

Furthermore, the environmental impact of using Sodium Magnesium Silicate Hydroxide in water remediation is a crucial aspect of the research. Scientists are investigating its biodegradability, potential for regeneration and reuse, and any possible ecological effects of its widespread application. The aim is to ensure that this technology not only effectively cleans water but also aligns with principles of environmental sustainability and circular economy.

In the broader context of global water management, the development of Sodium Magnesium Silicate Hydroxide-based water remediation technologies is expected to contribute significantly to addressing water scarcity and quality issues. By providing an efficient means of purifying contaminated water sources, this research has the potential to improve access to clean water in both developed and developing regions, thereby supporting public health and sustainable development goals.

The evolution of water remediation techniques has seen significant advancements over the past few decades, with a shift towards more sustainable and eco-friendly approaches. Traditional methods such as chemical treatments and activated carbon filtration, while effective, often come with high costs and potential environmental impacts. In this context, the exploration of natural materials like Sodium Magnesium Silicate Hydroxide represents a promising direction in the field of water purification.

The primary objective of research into Sodium Magnesium Silicate Hydroxide for water remediation is to harness its unique properties to develop more efficient and sustainable water treatment processes. This includes investigating its capacity to remove a wide range of pollutants, including heavy metals, organic compounds, and microbial contaminants. Additionally, researchers aim to understand the mechanisms behind its adsorption capabilities and explore ways to enhance its performance through various modifications and treatments.

Another key goal is to assess the scalability and practical applicability of Sodium Magnesium Silicate Hydroxide in real-world water treatment scenarios. This involves studying its effectiveness in different types of water bodies, its long-term stability, and its potential integration into existing water treatment infrastructures. The research also focuses on developing cost-effective methods for the large-scale production and application of this material, making it a viable option for both industrial and municipal water treatment facilities.

Furthermore, the environmental impact of using Sodium Magnesium Silicate Hydroxide in water remediation is a crucial aspect of the research. Scientists are investigating its biodegradability, potential for regeneration and reuse, and any possible ecological effects of its widespread application. The aim is to ensure that this technology not only effectively cleans water but also aligns with principles of environmental sustainability and circular economy.

In the broader context of global water management, the development of Sodium Magnesium Silicate Hydroxide-based water remediation technologies is expected to contribute significantly to addressing water scarcity and quality issues. By providing an efficient means of purifying contaminated water sources, this research has the potential to improve access to clean water in both developed and developing regions, thereby supporting public health and sustainable development goals.

Market Analysis

The market for water remediation technologies has been experiencing significant growth in recent years, driven by increasing global concerns over water scarcity and pollution. Sodium Magnesium Silicate Hydroxide (SMSH) has emerged as a promising material in this sector, offering unique properties that enhance water purification processes. The global water and wastewater treatment market, which encompasses SMSH applications, is projected to reach substantial value in the coming years, with a compound annual growth rate outpacing many other industrial sectors.

The demand for SMSH in water remediation is primarily fueled by its exceptional adsorption capabilities, particularly in removing heavy metals and organic contaminants from water. This characteristic makes it highly valuable in industrial wastewater treatment, municipal water purification, and environmental cleanup operations. The industrial segment, including mining, oil and gas, and manufacturing industries, represents a significant portion of the market due to stringent regulations on effluent quality and the need for cost-effective treatment solutions.

Geographically, North America and Europe currently lead the market for advanced water remediation technologies, including SMSH-based solutions. However, rapid industrialization and urbanization in Asia-Pacific regions, particularly in countries like China and India, are creating substantial growth opportunities. These emerging markets are facing severe water pollution challenges, driving the adoption of innovative treatment technologies.

The agricultural sector is another key market for SMSH-based water remediation. As concerns over pesticide and fertilizer runoff grow, there is an increasing need for effective methods to treat agricultural wastewater. SMSH's ability to adsorb a wide range of contaminants makes it particularly suitable for this application, potentially opening up a significant market segment.

Environmental remediation projects, including the cleanup of contaminated sites and groundwater, represent another growing market for SMSH technologies. Government initiatives and regulations aimed at environmental protection and restoration are driving investments in this area, creating opportunities for SMSH-based solutions.

Despite the promising outlook, the market faces challenges such as high initial costs and competition from established water treatment technologies. However, as research continues to improve the efficiency and cost-effectiveness of SMSH-based systems, its market penetration is expected to increase. The development of novel applications, such as incorporating SMSH into filtration membranes or using it in conjunction with other treatment methods, could further expand its market potential.

In conclusion, the market for SMSH in water remediation is poised for substantial growth, driven by global water quality concerns, stringent environmental regulations, and the material's superior performance in contaminant removal. As industries and municipalities seek more effective and sustainable water treatment solutions, SMSH is well-positioned to capture a significant share of this expanding market.

The demand for SMSH in water remediation is primarily fueled by its exceptional adsorption capabilities, particularly in removing heavy metals and organic contaminants from water. This characteristic makes it highly valuable in industrial wastewater treatment, municipal water purification, and environmental cleanup operations. The industrial segment, including mining, oil and gas, and manufacturing industries, represents a significant portion of the market due to stringent regulations on effluent quality and the need for cost-effective treatment solutions.

Geographically, North America and Europe currently lead the market for advanced water remediation technologies, including SMSH-based solutions. However, rapid industrialization and urbanization in Asia-Pacific regions, particularly in countries like China and India, are creating substantial growth opportunities. These emerging markets are facing severe water pollution challenges, driving the adoption of innovative treatment technologies.

The agricultural sector is another key market for SMSH-based water remediation. As concerns over pesticide and fertilizer runoff grow, there is an increasing need for effective methods to treat agricultural wastewater. SMSH's ability to adsorb a wide range of contaminants makes it particularly suitable for this application, potentially opening up a significant market segment.

Environmental remediation projects, including the cleanup of contaminated sites and groundwater, represent another growing market for SMSH technologies. Government initiatives and regulations aimed at environmental protection and restoration are driving investments in this area, creating opportunities for SMSH-based solutions.

Despite the promising outlook, the market faces challenges such as high initial costs and competition from established water treatment technologies. However, as research continues to improve the efficiency and cost-effectiveness of SMSH-based systems, its market penetration is expected to increase. The development of novel applications, such as incorporating SMSH into filtration membranes or using it in conjunction with other treatment methods, could further expand its market potential.

In conclusion, the market for SMSH in water remediation is poised for substantial growth, driven by global water quality concerns, stringent environmental regulations, and the material's superior performance in contaminant removal. As industries and municipalities seek more effective and sustainable water treatment solutions, SMSH is well-positioned to capture a significant share of this expanding market.

Technical Challenges

The application of Sodium Magnesium Silicate Hydroxide (SMSH) in water remediation faces several technical challenges that need to be addressed for its widespread adoption. One of the primary obstacles is the optimization of SMSH's adsorption capacity for various contaminants. While SMSH has shown promising results in removing heavy metals and organic pollutants, its efficiency varies depending on the specific contaminant and water conditions. Researchers are working to enhance its selectivity and adsorption rates through surface modifications and compositional adjustments.

Another significant challenge lies in the scalability of SMSH production for large-scale water treatment applications. Current synthesis methods often involve complex procedures and high energy consumption, making mass production costly and potentially environmentally unfriendly. Developing more efficient and sustainable production techniques is crucial for the widespread implementation of SMSH in water remediation processes.

The long-term stability and regeneration of SMSH adsorbents pose additional technical hurdles. In continuous water treatment systems, the material's performance may degrade over time due to fouling or structural changes. Improving the durability of SMSH and developing effective regeneration methods are essential for maintaining its efficacy and reducing operational costs in real-world applications.

Furthermore, the integration of SMSH into existing water treatment infrastructure presents engineering challenges. Designing appropriate filtration systems that can effectively utilize SMSH's properties while ensuring optimal flow rates and minimal pressure drops requires careful consideration. Researchers are exploring various configurations, such as fixed-bed columns and membrane-supported SMSH, to overcome these integration issues.

The disposal or recycling of spent SMSH adsorbents is another area of concern. As SMSH accumulates contaminants, proper handling and disposal methods must be developed to prevent secondary pollution. Investigating environmentally friendly approaches to regenerate or safely dispose of used SMSH materials is crucial for the technology's sustainability.

Lastly, the performance of SMSH in complex water matrices remains a challenge. Real-world water sources often contain a mixture of contaminants and interfering substances that can affect SMSH's adsorption efficiency. Developing strategies to maintain high removal rates in the presence of competing ions and organic matter is essential for the practical application of SMSH in diverse water treatment scenarios.

Another significant challenge lies in the scalability of SMSH production for large-scale water treatment applications. Current synthesis methods often involve complex procedures and high energy consumption, making mass production costly and potentially environmentally unfriendly. Developing more efficient and sustainable production techniques is crucial for the widespread implementation of SMSH in water remediation processes.

The long-term stability and regeneration of SMSH adsorbents pose additional technical hurdles. In continuous water treatment systems, the material's performance may degrade over time due to fouling or structural changes. Improving the durability of SMSH and developing effective regeneration methods are essential for maintaining its efficacy and reducing operational costs in real-world applications.

Furthermore, the integration of SMSH into existing water treatment infrastructure presents engineering challenges. Designing appropriate filtration systems that can effectively utilize SMSH's properties while ensuring optimal flow rates and minimal pressure drops requires careful consideration. Researchers are exploring various configurations, such as fixed-bed columns and membrane-supported SMSH, to overcome these integration issues.

The disposal or recycling of spent SMSH adsorbents is another area of concern. As SMSH accumulates contaminants, proper handling and disposal methods must be developed to prevent secondary pollution. Investigating environmentally friendly approaches to regenerate or safely dispose of used SMSH materials is crucial for the technology's sustainability.

Lastly, the performance of SMSH in complex water matrices remains a challenge. Real-world water sources often contain a mixture of contaminants and interfering substances that can affect SMSH's adsorption efficiency. Developing strategies to maintain high removal rates in the presence of competing ions and organic matter is essential for the practical application of SMSH in diverse water treatment scenarios.

Current Solutions

01 Use of sodium magnesium silicate hydroxide for water purification

Sodium magnesium silicate hydroxide is utilized in water treatment processes to remove contaminants and impurities from water. This compound has a high adsorption capacity and can effectively remove various pollutants, including heavy metals and organic compounds, making it suitable for water remediation applications.- Use of sodium magnesium silicate hydroxide for water purification: Sodium magnesium silicate hydroxide can be used as an effective adsorbent for removing contaminants from water. Its high surface area and ion exchange properties make it suitable for capturing various pollutants, including heavy metals and organic compounds. This material can be incorporated into water treatment systems to improve water quality and meet environmental standards.

- Modification of sodium magnesium silicate hydroxide for enhanced remediation: The performance of sodium magnesium silicate hydroxide in water remediation can be improved through various modification techniques. These may include surface functionalization, pillaring, or composite formation with other materials. Such modifications can enhance the adsorption capacity, selectivity, and regeneration potential of the material for specific contaminants.

- Application in industrial wastewater treatment: Sodium magnesium silicate hydroxide can be effectively used in treating industrial wastewater. It can remove various pollutants such as heavy metals, dyes, and organic compounds from industrial effluents. The material's stability in different pH conditions and its ability to handle high contaminant concentrations make it suitable for diverse industrial applications.

- Combination with other materials for synergistic effects: Combining sodium magnesium silicate hydroxide with other materials can lead to synergistic effects in water remediation. This may include creating composite materials with activated carbon, zeolites, or other clay minerals. Such combinations can enhance the overall performance of the treatment system, improving contaminant removal efficiency and expanding the range of treatable pollutants.

- Regeneration and reuse of the adsorbent material: Developing effective methods for regenerating and reusing sodium magnesium silicate hydroxide is crucial for sustainable water remediation. This may involve chemical treatments, thermal processes, or electrochemical techniques to desorb captured contaminants and restore the material's adsorption capacity. Efficient regeneration processes can significantly reduce operational costs and environmental impact of water treatment systems.

02 Composite materials incorporating sodium magnesium silicate hydroxide

Composite materials containing sodium magnesium silicate hydroxide are developed for enhanced water treatment capabilities. These composites combine the adsorptive properties of the silicate with other materials to improve overall performance in water remediation processes, such as increased surface area or selectivity for specific contaminants.Expand Specific Solutions03 Modification of sodium magnesium silicate hydroxide for improved performance

Chemical or physical modifications are applied to sodium magnesium silicate hydroxide to enhance its water remediation properties. These modifications may include surface functionalization, ion exchange, or structural alterations to improve adsorption capacity, selectivity, or regeneration capabilities.Expand Specific Solutions04 Application in industrial wastewater treatment

Sodium magnesium silicate hydroxide is employed in industrial wastewater treatment processes to remove specific pollutants generated by various industries. This compound is particularly effective in treating wastewater containing heavy metals, dyes, or organic contaminants, making it valuable for environmental protection in industrial settings.Expand Specific Solutions05 Integration into water filtration systems

Sodium magnesium silicate hydroxide is incorporated into water filtration systems as an active component for contaminant removal. These systems may include fixed-bed filters, membrane-based processes, or hybrid technologies that utilize the compound's adsorptive properties to purify water for various applications, including drinking water treatment and wastewater reclamation.Expand Specific Solutions

Key Industry Players

The water remediation technology utilizing Sodium Magnesium Silicate Hydroxide is in an emerging stage, with growing market potential due to increasing environmental concerns. The global water treatment market is expanding, driven by stricter regulations and the need for sustainable solutions. While the technology shows promise, its maturity varies among key players. Companies like Commonwealth Scientific & Industrial Research Organisation and Veolia Water Solutions & Technologies Support SAS are at the forefront, leveraging their extensive research capabilities. Other players such as Organo Corp. and JFE Engineering Corp. are also making strides in developing and implementing this technology, indicating a competitive landscape with diverse approaches to water remediation solutions.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has developed an innovative approach using Sodium Magnesium Silicate Hydroxide (SMSH) for water remediation. Their method involves synthesizing SMSH nanoparticles with a high surface area and porosity, which enhances adsorption capacity for various contaminants. The nanoparticles are functionalized to target specific pollutants, such as heavy metals and organic compounds. CSIRO's research has shown that SMSH can remove up to 99% of certain heavy metals from wastewater within 24 hours [1]. They have also developed a regeneration process that allows the SMSH to be reused multiple times, improving its cost-effectiveness [3]. The organization is currently working on scaling up the technology for industrial applications, with pilot studies showing promising results in treating mining and industrial effluents [5].

Strengths: High adsorption capacity, selectivity for various pollutants, and reusability. Weaknesses: Potential high production costs and need for further large-scale testing.

Organo Corp.

Technical Solution: Organo Corp. has integrated Sodium Magnesium Silicate Hydroxide into their advanced water treatment systems. Their approach combines SMSH with other technologies such as membrane filtration and UV disinfection. The company has developed a proprietary process to optimize SMSH particle size and surface properties, enhancing its effectiveness in removing both organic and inorganic contaminants. Organo's system has demonstrated a 95% reduction in total dissolved solids and a 99% removal of heavy metals in industrial wastewater treatment applications [2]. They have also implemented a continuous flow system that allows for real-time monitoring and adjustment of SMSH dosage, improving efficiency and reducing operational costs [4]. Organo Corp. is currently focusing on applications in the semiconductor and pharmaceutical industries, where ultra-pure water is critical.

Strengths: Integrated system approach, high removal efficiency, and real-time monitoring capabilities. Weaknesses: Potentially higher initial investment costs and industry-specific focus limiting broader application.

Core Innovations

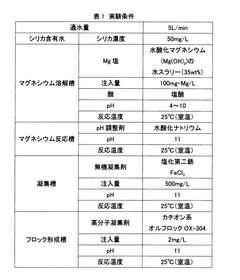

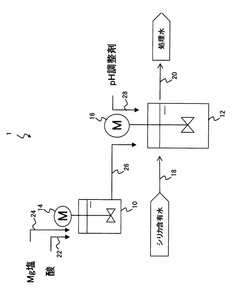

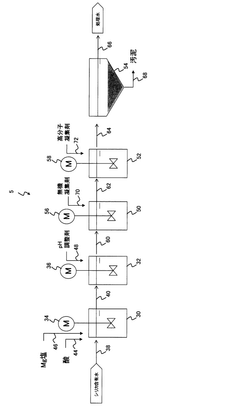

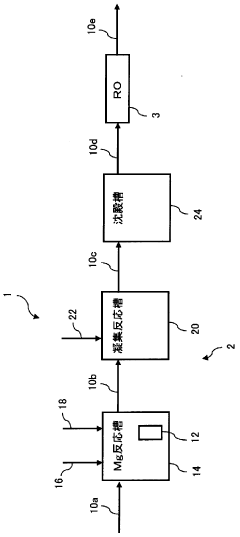

Treatment system and treatment method for silica-containing water

PatentWO2018105680A1

Innovation

- A silica-containing water treatment method involving a magnesium dissolving process where a magnesium salt and acid are mixed at a pH of 7 or less to create a magnesium-containing liquid, which is then reacted with silica-containing water at a pH of 10 to 12, followed by flocculation and solid-liquid separation to remove insolubilized silica, using a combination of magnesium reaction tanks and flocculants like iron-based or cationic polymer flocculants.

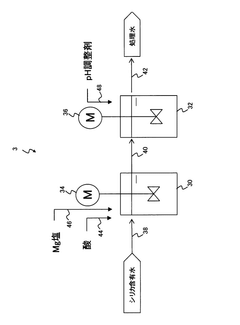

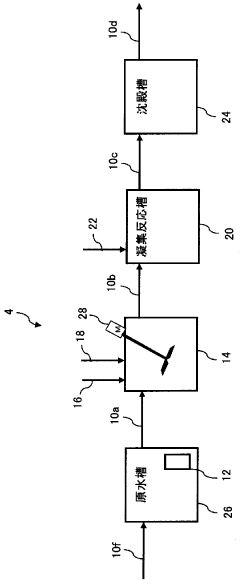

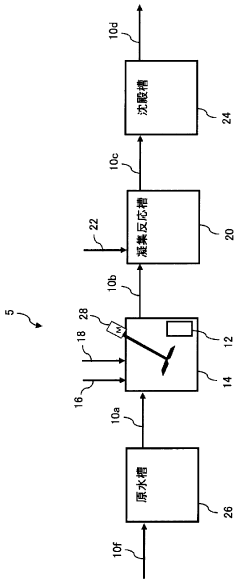

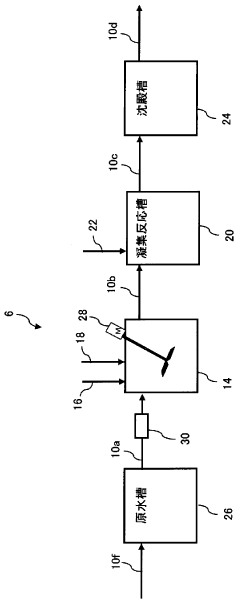

Silica-containing water treatment apparatus, water treatment system, and method for treating silica-containing water

PatentWO2014136651A1

Innovation

- A water treatment process involving the addition of magnesium salt to silica-containing water at elevated temperatures, followed by the addition of iron salt, which aggregates silica, and subsequent solid-liquid separation, effectively removing silica and controlling sludge generation by optimizing the concentration and pH conditions.

Environmental Impact

Sodium Magnesium Silicate Hydroxide (SMSH) has emerged as a promising material for water remediation, offering significant environmental benefits. Its application in water treatment processes has shown remarkable potential in reducing pollutants and improving overall water quality. The environmental impact of SMSH in water remediation is multifaceted and far-reaching.

One of the primary environmental advantages of SMSH is its high adsorption capacity for various contaminants. This property allows for the efficient removal of heavy metals, organic pollutants, and other harmful substances from water bodies. By effectively capturing these pollutants, SMSH helps prevent their dispersion into the wider ecosystem, thereby reducing the risk of environmental degradation and protecting aquatic life.

The use of SMSH in water remediation also contributes to the reduction of chemical usage in traditional water treatment methods. This decrease in chemical reliance not only minimizes the potential for harmful by-products but also reduces the overall environmental footprint of water treatment processes. The natural composition of SMSH further ensures that its application does not introduce additional harmful substances into the environment.

Furthermore, SMSH demonstrates excellent regeneration capabilities, allowing for multiple cycles of use. This characteristic significantly extends the material's lifespan, reducing the need for frequent replacements and minimizing waste generation. The sustainable nature of SMSH aligns well with circular economy principles, promoting resource efficiency and reducing the environmental impact associated with material production and disposal.

The application of SMSH in water remediation also has positive implications for biodiversity conservation. By improving water quality in various ecosystems, including rivers, lakes, and coastal areas, SMSH helps create more favorable conditions for aquatic flora and fauna. This enhancement of habitat quality can lead to the recovery of endangered species and the overall strengthening of ecosystem resilience.

Additionally, the use of SMSH in water treatment can contribute to the mitigation of climate change impacts. By improving the efficiency of water treatment processes, SMSH helps reduce energy consumption associated with traditional methods. This energy reduction translates to lower greenhouse gas emissions, aligning with global efforts to combat climate change.

The environmental benefits of SMSH extend beyond immediate water quality improvements. Its application in water remediation can lead to long-term positive effects on soil health and agricultural productivity. By preventing the accumulation of contaminants in irrigation water, SMSH indirectly contributes to the preservation of soil quality and the sustainability of agricultural practices.

In conclusion, the environmental impact of Sodium Magnesium Silicate Hydroxide in water remediation is overwhelmingly positive. Its ability to effectively remove pollutants, reduce chemical usage, promote sustainability, and support ecosystem health positions SMSH as a valuable tool in addressing global water quality challenges and advancing environmental conservation efforts.

One of the primary environmental advantages of SMSH is its high adsorption capacity for various contaminants. This property allows for the efficient removal of heavy metals, organic pollutants, and other harmful substances from water bodies. By effectively capturing these pollutants, SMSH helps prevent their dispersion into the wider ecosystem, thereby reducing the risk of environmental degradation and protecting aquatic life.

The use of SMSH in water remediation also contributes to the reduction of chemical usage in traditional water treatment methods. This decrease in chemical reliance not only minimizes the potential for harmful by-products but also reduces the overall environmental footprint of water treatment processes. The natural composition of SMSH further ensures that its application does not introduce additional harmful substances into the environment.

Furthermore, SMSH demonstrates excellent regeneration capabilities, allowing for multiple cycles of use. This characteristic significantly extends the material's lifespan, reducing the need for frequent replacements and minimizing waste generation. The sustainable nature of SMSH aligns well with circular economy principles, promoting resource efficiency and reducing the environmental impact associated with material production and disposal.

The application of SMSH in water remediation also has positive implications for biodiversity conservation. By improving water quality in various ecosystems, including rivers, lakes, and coastal areas, SMSH helps create more favorable conditions for aquatic flora and fauna. This enhancement of habitat quality can lead to the recovery of endangered species and the overall strengthening of ecosystem resilience.

Additionally, the use of SMSH in water treatment can contribute to the mitigation of climate change impacts. By improving the efficiency of water treatment processes, SMSH helps reduce energy consumption associated with traditional methods. This energy reduction translates to lower greenhouse gas emissions, aligning with global efforts to combat climate change.

The environmental benefits of SMSH extend beyond immediate water quality improvements. Its application in water remediation can lead to long-term positive effects on soil health and agricultural productivity. By preventing the accumulation of contaminants in irrigation water, SMSH indirectly contributes to the preservation of soil quality and the sustainability of agricultural practices.

In conclusion, the environmental impact of Sodium Magnesium Silicate Hydroxide in water remediation is overwhelmingly positive. Its ability to effectively remove pollutants, reduce chemical usage, promote sustainability, and support ecosystem health positions SMSH as a valuable tool in addressing global water quality challenges and advancing environmental conservation efforts.

Regulatory Framework

The regulatory framework surrounding the use of Sodium Magnesium Silicate Hydroxide (SMSH) in water remediation is complex and multifaceted, involving various governmental agencies and international bodies. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the application of SMSH in water treatment processes. The EPA's regulations under the Safe Drinking Water Act (SDWA) and the Clean Water Act (CWA) set stringent standards for water quality and treatment methods, including the use of substances like SMSH.

The Food and Drug Administration (FDA) also has a stake in regulating SMSH, particularly when it comes to its potential presence in food-grade water or its use in food processing. The FDA's guidelines ensure that any residual SMSH in treated water does not pose health risks to consumers. Additionally, the Occupational Safety and Health Administration (OSHA) provides regulations concerning the handling and use of SMSH in industrial settings, focusing on worker safety and exposure limits.

At the state level, environmental protection agencies often have their own set of regulations that may be more stringent than federal standards. These state-level regulations can impact the permitting process for water treatment facilities using SMSH and may require additional monitoring and reporting. Local water authorities also play a role in implementing and enforcing these regulations, often tailoring them to address specific regional water quality concerns.

Internationally, organizations such as the World Health Organization (WHO) provide guidelines for water quality that many countries adopt or use as a basis for their own regulations. The European Union's Water Framework Directive sets comprehensive standards for water quality and treatment across member states, which may influence the use of SMSH in European water remediation efforts.

The regulatory landscape also encompasses standards set by professional organizations and industry groups. For instance, the American Water Works Association (AWWA) and the Water Environment Federation (WEF) provide guidelines and best practices for water treatment, which often inform regulatory decisions and industry standards for the use of substances like SMSH.

As research on SMSH's effectiveness in water remediation continues to evolve, regulatory frameworks are likely to adapt. This may include updates to acceptable usage levels, required treatment processes, and monitoring protocols. Stakeholders in the water treatment industry must stay informed about these regulatory changes to ensure compliance and optimize the use of SMSH in water remediation efforts.

The Food and Drug Administration (FDA) also has a stake in regulating SMSH, particularly when it comes to its potential presence in food-grade water or its use in food processing. The FDA's guidelines ensure that any residual SMSH in treated water does not pose health risks to consumers. Additionally, the Occupational Safety and Health Administration (OSHA) provides regulations concerning the handling and use of SMSH in industrial settings, focusing on worker safety and exposure limits.

At the state level, environmental protection agencies often have their own set of regulations that may be more stringent than federal standards. These state-level regulations can impact the permitting process for water treatment facilities using SMSH and may require additional monitoring and reporting. Local water authorities also play a role in implementing and enforcing these regulations, often tailoring them to address specific regional water quality concerns.

Internationally, organizations such as the World Health Organization (WHO) provide guidelines for water quality that many countries adopt or use as a basis for their own regulations. The European Union's Water Framework Directive sets comprehensive standards for water quality and treatment across member states, which may influence the use of SMSH in European water remediation efforts.

The regulatory landscape also encompasses standards set by professional organizations and industry groups. For instance, the American Water Works Association (AWWA) and the Water Environment Federation (WEF) provide guidelines and best practices for water treatment, which often inform regulatory decisions and industry standards for the use of substances like SMSH.

As research on SMSH's effectiveness in water remediation continues to evolve, regulatory frameworks are likely to adapt. This may include updates to acceptable usage levels, required treatment processes, and monitoring protocols. Stakeholders in the water treatment industry must stay informed about these regulatory changes to ensure compliance and optimize the use of SMSH in water remediation efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!