How to Achieve High Stretchability in Cellophane Materials?

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Stretchability Background and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and various industrial applications for decades. Its unique properties, including transparency, biodegradability, and barrier characteristics, have made it a valuable material in numerous sectors. However, one of the limitations of traditional cellophane has been its relatively low stretchability, which restricts its use in applications requiring high elasticity or flexibility.

The quest for high stretchability in cellophane materials represents a significant technological challenge and opportunity. Enhancing the stretchability of cellophane could potentially revolutionize its applications, opening up new markets and improving its performance in existing ones. This technological advancement aligns with the growing demand for sustainable, bio-based materials with enhanced functional properties.

The evolution of cellophane technology has seen various attempts to improve its mechanical properties, including stretchability. Early efforts focused on chemical modifications and plasticizer additions, which yielded modest improvements. More recent approaches have explored nanotechnology, polymer blending, and advanced manufacturing techniques to push the boundaries of cellophane's stretchability.

The primary objective of this research is to develop innovative methods to significantly increase the stretchability of cellophane materials without compromising their other desirable properties. This goal encompasses several key aspects, including understanding the fundamental molecular structure of cellophane, identifying the factors that limit its current stretchability, and exploring novel approaches to overcome these limitations.

Achieving high stretchability in cellophane materials could have far-reaching implications across multiple industries. In packaging, it could lead to more flexible and durable wraps, potentially reducing material usage and improving product protection. In the medical field, highly stretchable cellophane could find applications in wound dressings or as a component in flexible biomedical devices. The textile industry might benefit from incorporating such materials into smart fabrics or high-performance sportswear.

Furthermore, this research aligns with broader trends in materials science and sustainability. As the world moves towards more eco-friendly solutions, developing enhanced bio-based materials like stretchable cellophane could contribute to reducing reliance on petroleum-based plastics. The potential for biodegradable, highly functional materials addresses both environmental concerns and performance demands in various applications.

In pursuing this technological advancement, researchers must navigate challenges such as maintaining cellophane's transparency, barrier properties, and biodegradability while enhancing its stretchability. The interplay between these properties presents a complex optimization problem that requires innovative approaches and multidisciplinary expertise.

The quest for high stretchability in cellophane materials represents a significant technological challenge and opportunity. Enhancing the stretchability of cellophane could potentially revolutionize its applications, opening up new markets and improving its performance in existing ones. This technological advancement aligns with the growing demand for sustainable, bio-based materials with enhanced functional properties.

The evolution of cellophane technology has seen various attempts to improve its mechanical properties, including stretchability. Early efforts focused on chemical modifications and plasticizer additions, which yielded modest improvements. More recent approaches have explored nanotechnology, polymer blending, and advanced manufacturing techniques to push the boundaries of cellophane's stretchability.

The primary objective of this research is to develop innovative methods to significantly increase the stretchability of cellophane materials without compromising their other desirable properties. This goal encompasses several key aspects, including understanding the fundamental molecular structure of cellophane, identifying the factors that limit its current stretchability, and exploring novel approaches to overcome these limitations.

Achieving high stretchability in cellophane materials could have far-reaching implications across multiple industries. In packaging, it could lead to more flexible and durable wraps, potentially reducing material usage and improving product protection. In the medical field, highly stretchable cellophane could find applications in wound dressings or as a component in flexible biomedical devices. The textile industry might benefit from incorporating such materials into smart fabrics or high-performance sportswear.

Furthermore, this research aligns with broader trends in materials science and sustainability. As the world moves towards more eco-friendly solutions, developing enhanced bio-based materials like stretchable cellophane could contribute to reducing reliance on petroleum-based plastics. The potential for biodegradable, highly functional materials addresses both environmental concerns and performance demands in various applications.

In pursuing this technological advancement, researchers must navigate challenges such as maintaining cellophane's transparency, barrier properties, and biodegradability while enhancing its stretchability. The interplay between these properties presents a complex optimization problem that requires innovative approaches and multidisciplinary expertise.

Market Analysis for Stretchable Cellophane

The market for stretchable cellophane materials is experiencing significant growth, driven by increasing demand across various industries. The global packaging industry, in particular, is showing keen interest in these innovative materials due to their unique properties and potential applications. Stretchable cellophane offers enhanced flexibility and durability compared to traditional cellophane, making it an attractive option for packaging solutions that require both transparency and elasticity.

The food packaging sector represents a major market opportunity for stretchable cellophane. As consumers demand more convenient and sustainable packaging options, manufacturers are seeking materials that can provide better protection while maintaining product visibility. Stretchable cellophane's ability to conform to irregular shapes and resist tearing makes it ideal for wrapping fresh produce, baked goods, and other perishable items.

In the personal care and cosmetics industry, stretchable cellophane is gaining traction for its potential in creating innovative packaging designs. The material's flexibility allows for the creation of unique shapes and structures, enhancing product presentation and user experience. This sector's focus on premium packaging and sustainability aligns well with the properties of stretchable cellophane.

The electronics industry is another promising market for stretchable cellophane materials. As flexible and wearable electronics continue to evolve, there is a growing need for transparent, stretchable substrates and protective layers. Stretchable cellophane could find applications in flexible displays, sensors, and other electronic components that require both optical clarity and mechanical flexibility.

Market analysis indicates that the Asia-Pacific region is expected to be a key growth area for stretchable cellophane materials. The region's rapidly expanding packaging industry, coupled with increasing consumer awareness of sustainable materials, is driving demand. North America and Europe are also significant markets, with a focus on high-value applications in sectors such as medical devices and advanced electronics.

The market for stretchable cellophane is characterized by intense research and development activities, as companies strive to improve material properties and expand potential applications. Key areas of focus include enhancing stretchability without compromising transparency, improving barrier properties, and developing bio-based alternatives to meet sustainability goals.

Challenges in the market include the need for scalable production methods to reduce costs and the development of standardized testing protocols for stretchable cellophane materials. Additionally, competition from other flexible packaging materials, such as stretchable plastics and advanced polymer films, may impact market growth.

Overall, the market for stretchable cellophane materials shows promising growth potential, driven by diverse industry applications and ongoing technological advancements. As research continues to improve material properties and manufacturing processes, stretchable cellophane is poised to capture an increasing share of the flexible packaging and advanced materials markets.

The food packaging sector represents a major market opportunity for stretchable cellophane. As consumers demand more convenient and sustainable packaging options, manufacturers are seeking materials that can provide better protection while maintaining product visibility. Stretchable cellophane's ability to conform to irregular shapes and resist tearing makes it ideal for wrapping fresh produce, baked goods, and other perishable items.

In the personal care and cosmetics industry, stretchable cellophane is gaining traction for its potential in creating innovative packaging designs. The material's flexibility allows for the creation of unique shapes and structures, enhancing product presentation and user experience. This sector's focus on premium packaging and sustainability aligns well with the properties of stretchable cellophane.

The electronics industry is another promising market for stretchable cellophane materials. As flexible and wearable electronics continue to evolve, there is a growing need for transparent, stretchable substrates and protective layers. Stretchable cellophane could find applications in flexible displays, sensors, and other electronic components that require both optical clarity and mechanical flexibility.

Market analysis indicates that the Asia-Pacific region is expected to be a key growth area for stretchable cellophane materials. The region's rapidly expanding packaging industry, coupled with increasing consumer awareness of sustainable materials, is driving demand. North America and Europe are also significant markets, with a focus on high-value applications in sectors such as medical devices and advanced electronics.

The market for stretchable cellophane is characterized by intense research and development activities, as companies strive to improve material properties and expand potential applications. Key areas of focus include enhancing stretchability without compromising transparency, improving barrier properties, and developing bio-based alternatives to meet sustainability goals.

Challenges in the market include the need for scalable production methods to reduce costs and the development of standardized testing protocols for stretchable cellophane materials. Additionally, competition from other flexible packaging materials, such as stretchable plastics and advanced polymer films, may impact market growth.

Overall, the market for stretchable cellophane materials shows promising growth potential, driven by diverse industry applications and ongoing technological advancements. As research continues to improve material properties and manufacturing processes, stretchable cellophane is poised to capture an increasing share of the flexible packaging and advanced materials markets.

Current Challenges in Cellophane Elasticity

Cellophane, a transparent film made from regenerated cellulose, has long been valued for its clarity, biodegradability, and barrier properties. However, its inherent rigidity and limited elasticity have restricted its applications in fields requiring flexible and stretchable materials. The pursuit of high stretchability in cellophane materials faces several significant challenges that researchers and industry professionals are actively working to overcome.

One of the primary obstacles is the fundamental molecular structure of cellophane. The strong hydrogen bonding between cellulose chains contributes to its high tensile strength but also results in a relatively brittle nature. This intrinsic property makes it difficult to achieve substantial elongation without compromising the material's integrity. Modifying the molecular structure to enhance flexibility while maintaining other desirable properties presents a complex balancing act.

Another challenge lies in the manufacturing process of cellophane. Traditional production methods involve regenerating cellulose through a viscose process, which typically yields a material with limited elasticity. Developing new production techniques or modifying existing ones to incorporate stretchability without sacrificing other key characteristics such as transparency and barrier properties is a significant hurdle.

The incorporation of plasticizers or other additives to improve flexibility has shown some promise but often comes with trade-offs. While these additives can enhance the material's ability to stretch, they may negatively impact other properties such as tensile strength, thermal stability, or biodegradability. Finding the right combination and proportion of additives that can significantly improve stretchability without compromising other essential features remains a challenge.

Surface modification techniques have been explored as a means to enhance the elastic properties of cellophane. However, achieving uniform and durable modifications that can withstand repeated stretching cycles without degradation or delamination is problematic. The development of stable, long-lasting surface treatments that can impart stretchability while preserving the core benefits of cellophane is an ongoing area of research.

The scalability of potential solutions presents another significant challenge. While laboratory-scale experiments may yield promising results, translating these findings into large-scale, cost-effective production processes that meet industry standards and consumer expectations is a complex undertaking. Bridging the gap between research innovations and practical, commercially viable applications requires substantial investment and technological advancements.

Lastly, maintaining the biodegradability and eco-friendly nature of cellophane while enhancing its stretchability is crucial, given the growing emphasis on sustainable materials. Ensuring that any modifications or additives used to improve elasticity do not compromise the material's environmental benefits adds another layer of complexity to the development process.

One of the primary obstacles is the fundamental molecular structure of cellophane. The strong hydrogen bonding between cellulose chains contributes to its high tensile strength but also results in a relatively brittle nature. This intrinsic property makes it difficult to achieve substantial elongation without compromising the material's integrity. Modifying the molecular structure to enhance flexibility while maintaining other desirable properties presents a complex balancing act.

Another challenge lies in the manufacturing process of cellophane. Traditional production methods involve regenerating cellulose through a viscose process, which typically yields a material with limited elasticity. Developing new production techniques or modifying existing ones to incorporate stretchability without sacrificing other key characteristics such as transparency and barrier properties is a significant hurdle.

The incorporation of plasticizers or other additives to improve flexibility has shown some promise but often comes with trade-offs. While these additives can enhance the material's ability to stretch, they may negatively impact other properties such as tensile strength, thermal stability, or biodegradability. Finding the right combination and proportion of additives that can significantly improve stretchability without compromising other essential features remains a challenge.

Surface modification techniques have been explored as a means to enhance the elastic properties of cellophane. However, achieving uniform and durable modifications that can withstand repeated stretching cycles without degradation or delamination is problematic. The development of stable, long-lasting surface treatments that can impart stretchability while preserving the core benefits of cellophane is an ongoing area of research.

The scalability of potential solutions presents another significant challenge. While laboratory-scale experiments may yield promising results, translating these findings into large-scale, cost-effective production processes that meet industry standards and consumer expectations is a complex undertaking. Bridging the gap between research innovations and practical, commercially viable applications requires substantial investment and technological advancements.

Lastly, maintaining the biodegradability and eco-friendly nature of cellophane while enhancing its stretchability is crucial, given the growing emphasis on sustainable materials. Ensuring that any modifications or additives used to improve elasticity do not compromise the material's environmental benefits adds another layer of complexity to the development process.

Existing Methods for Enhancing Cellophane Flexibility

01 Modification of cellophane structure for improved stretchability

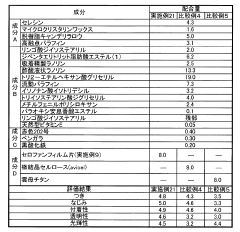

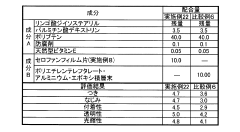

Various techniques can be employed to modify the structure of cellophane to enhance its stretchability. These may include chemical treatments, physical modifications, or the incorporation of additives that alter the molecular arrangement of cellulose chains, resulting in increased flexibility and elasticity of the material.- Modification of cellophane structure: Altering the molecular structure of cellophane through chemical treatments or additives can enhance its stretchability. This may involve incorporating plasticizers or modifying the cellulose chains to increase flexibility and elasticity.

- Lamination with elastic materials: Combining cellophane with elastic materials in a laminated structure can improve overall stretchability. This approach allows for the retention of cellophane's barrier properties while introducing elastic characteristics from the additional layers.

- Heat treatment processes: Applying controlled heat treatment to cellophane can alter its physical properties, potentially increasing stretchability. This process may involve careful temperature regulation and cooling methods to achieve the desired elastic characteristics.

- Incorporation of nanoparticles: Adding nanoparticles to cellophane during production can enhance its mechanical properties, including stretchability. These particles may interact with the cellulose structure to provide improved flexibility and elasticity.

- Biaxial orientation techniques: Employing biaxial orientation during the manufacturing process can improve the stretchability of cellophane. This technique involves stretching the material in two perpendicular directions, which can enhance its overall elastic properties.

02 Blending cellophane with other polymers

Combining cellophane with other polymeric materials can create composite films with improved stretchability. This approach allows for the synergistic combination of cellophane's properties with those of more elastic polymers, resulting in a material with enhanced flexibility and elongation characteristics.Expand Specific Solutions03 Heat treatment and plasticization of cellophane

Applying heat treatment and plasticization processes to cellophane can significantly improve its stretchability. These methods involve the use of specific temperature ranges and plasticizing agents to modify the internal structure of the material, increasing its flexibility and ability to elongate under stress.Expand Specific Solutions04 Nanocomposite cellophane materials

Incorporating nanoparticles or nanofibers into cellophane can create nanocomposite materials with enhanced stretchability. These nano-scale additives can modify the mechanical properties of cellophane, improving its elasticity and overall performance as a flexible packaging material.Expand Specific Solutions05 Surface modification techniques for cellophane

Various surface modification techniques can be applied to cellophane to improve its stretchability. These may include plasma treatment, grafting of elastic polymers onto the cellophane surface, or the application of specialized coatings that enhance the material's ability to stretch and recover.Expand Specific Solutions

Key Players in Stretchable Film Industry

The market for high stretchability cellophane materials is in a growth phase, driven by increasing demand for sustainable packaging solutions. The global market size for biodegradable films, including cellophane, is projected to reach $1.2 billion by 2025. While the technology is advancing, it's not yet fully mature, with ongoing research to improve performance. Key players like Toyobo, Corning, and AGC are investing in R&D to enhance cellophane's stretchability and functionality. Companies such as Toray Industries and Nitto Denko are leveraging their expertise in materials science to develop innovative solutions. Academic institutions like South China University of Technology and the University of Leeds are also contributing to advancements in this field.

Toyobo Co., Ltd.

Technical Solution: Toyobo has developed a highly stretchable cellophane material using a proprietary polymer blending technique. Their approach involves incorporating elastomeric polymers into the cellulose matrix, resulting in a material that can stretch up to 200% of its original length without breaking[1]. The company has also implemented a special heat treatment process that enhances the material's elastic recovery, allowing it to return to its original shape after stretching[3]. Additionally, Toyobo has developed a surface modification technique that improves the material's adhesion properties, making it suitable for various packaging applications[5].

Strengths: High stretchability, good elastic recovery, improved adhesion properties. Weaknesses: Potential reduction in transparency, higher production costs compared to traditional cellophane.

Corning, Inc.

Technical Solution: Corning has developed a novel approach to enhance the stretchability of cellophane-like materials through their proprietary "Willow Glass" technology. While not strictly cellophane, this ultra-thin, flexible glass shares similar properties and applications. The company has adapted this technology to create a hybrid material that combines the transparency of glass with the flexibility of polymers[2]. By incorporating nanoscale glass fibers into a cellulose-based matrix, Corning has achieved a material that can stretch up to 150% while maintaining optical clarity[4]. The company has also developed a specialized coating process that enhances the material's durability and resistance to environmental factors[6].

Strengths: High optical clarity, improved durability, potential for use in electronic displays. Weaknesses: Higher production costs, may not be biodegradable like traditional cellophane.

Innovative Approaches to Cellophane Stretchability

Polyester Resin Film and Process for Producing the Same

PatentInactiveUS20080193783A1

Innovation

- A production method involving mixing two polyester resin starting materials with different melting points, extruding the mixture, and stretching it in the monoaxial direction followed by heat treatment at a temperature 3°C lower than the lowest melting point, ensuring a resin proportion of 20-65 wt% with a melting point difference of at least 15°C, to achieve superior hand-tearability and twistability.

Scaly brilliant material

PatentActiveJP2009107967A

Innovation

- Utilizing cellulose resin in the form of scaly, film-like particles with specific size and aspect ratios, which are hydrophilic and transparent, to scatter visible light and enhance glossy appearance while ensuring skin compatibility.

Environmental Impact of Stretchable Cellophane Production

The production of stretchable cellophane materials presents both opportunities and challenges in terms of environmental impact. While offering potential benefits in packaging and other applications, the manufacturing process and lifecycle of these materials require careful consideration to minimize ecological footprints.

The primary environmental concern in stretchable cellophane production is the use of chemical additives to enhance elasticity. These additives, often plasticizers or elastomers, may introduce non-biodegradable components into an otherwise biodegradable material. This alteration can significantly impact the material's end-of-life disposal and decomposition characteristics, potentially increasing its environmental persistence.

Energy consumption during production is another critical factor. The additional processing steps required to impart stretchability, such as chemical treatments or mechanical stretching, typically increase the overall energy demand. This elevated energy usage contributes to higher carbon emissions if non-renewable energy sources are utilized.

Water usage and wastewater management also pose environmental challenges. The production of stretchable cellophane may require more extensive washing and treatment processes, potentially leading to increased water consumption and the generation of contaminated effluents. Proper wastewater treatment is essential to prevent the release of chemical additives and byproducts into aquatic ecosystems.

On the positive side, the enhanced functionality of stretchable cellophane could lead to reduced material usage in certain applications. Its improved flexibility and durability may result in thinner, lighter packaging solutions, potentially decreasing overall material consumption and associated transportation emissions.

The recyclability of stretchable cellophane is a complex issue. While traditional cellophane is biodegradable, the addition of stretching agents may complicate recycling processes. Developing effective recycling methods for these modified materials is crucial to mitigate their environmental impact and promote a circular economy approach.

Life cycle assessments (LCAs) are essential tools for comprehensively evaluating the environmental impact of stretchable cellophane. These assessments should consider raw material extraction, production processes, use phase, and end-of-life scenarios to provide a holistic view of the material's ecological footprint.

In conclusion, while stretchable cellophane offers functional benefits, its environmental impact is multifaceted. Balancing performance enhancements with ecological considerations is crucial. Future research and development efforts should focus on eco-friendly additives, energy-efficient production methods, and improved recyclability to minimize the environmental footprint of these innovative materials.

The primary environmental concern in stretchable cellophane production is the use of chemical additives to enhance elasticity. These additives, often plasticizers or elastomers, may introduce non-biodegradable components into an otherwise biodegradable material. This alteration can significantly impact the material's end-of-life disposal and decomposition characteristics, potentially increasing its environmental persistence.

Energy consumption during production is another critical factor. The additional processing steps required to impart stretchability, such as chemical treatments or mechanical stretching, typically increase the overall energy demand. This elevated energy usage contributes to higher carbon emissions if non-renewable energy sources are utilized.

Water usage and wastewater management also pose environmental challenges. The production of stretchable cellophane may require more extensive washing and treatment processes, potentially leading to increased water consumption and the generation of contaminated effluents. Proper wastewater treatment is essential to prevent the release of chemical additives and byproducts into aquatic ecosystems.

On the positive side, the enhanced functionality of stretchable cellophane could lead to reduced material usage in certain applications. Its improved flexibility and durability may result in thinner, lighter packaging solutions, potentially decreasing overall material consumption and associated transportation emissions.

The recyclability of stretchable cellophane is a complex issue. While traditional cellophane is biodegradable, the addition of stretching agents may complicate recycling processes. Developing effective recycling methods for these modified materials is crucial to mitigate their environmental impact and promote a circular economy approach.

Life cycle assessments (LCAs) are essential tools for comprehensively evaluating the environmental impact of stretchable cellophane. These assessments should consider raw material extraction, production processes, use phase, and end-of-life scenarios to provide a holistic view of the material's ecological footprint.

In conclusion, while stretchable cellophane offers functional benefits, its environmental impact is multifaceted. Balancing performance enhancements with ecological considerations is crucial. Future research and development efforts should focus on eco-friendly additives, energy-efficient production methods, and improved recyclability to minimize the environmental footprint of these innovative materials.

Regulatory Framework for Modified Cellophane Materials

The regulatory framework for modified cellophane materials plays a crucial role in ensuring the safety, quality, and environmental sustainability of these innovative products. As the development of highly stretchable cellophane materials progresses, it is essential to understand and navigate the complex landscape of regulations governing their production, distribution, and use.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of cellophane and modified cellophane materials, particularly when intended for food contact applications. The FDA's Code of Federal Regulations (CFR) Title 21, Part 177, Subpart B, Section 177.1200 specifically addresses cellophane, providing guidelines for its composition, manufacturing processes, and permissible additives. As new modifications are introduced to enhance stretchability, manufacturers must ensure compliance with these regulations and may need to seek FDA approval for novel additives or processing methods.

The European Union (EU) has established a comprehensive regulatory framework for food contact materials, including cellophane and its derivatives. The EU Regulation No. 1935/2004 sets out general principles for all food contact materials, while specific measures for cellophane are outlined in Commission Directive 2007/42/EC. These regulations stipulate migration limits for substances used in cellophane production and require manufacturers to demonstrate compliance through testing and documentation.

Environmental considerations are increasingly important in the regulatory landscape for modified cellophane materials. The EU's Single-Use Plastics Directive, while primarily targeting conventional plastics, may have implications for certain cellophane products. Manufacturers developing highly stretchable cellophane materials must consider end-of-life scenarios and align with circular economy principles to meet evolving regulatory requirements.

In Japan, the Ministry of Health, Labour and Welfare regulates food packaging materials, including cellophane, under the Food Sanitation Act. The act sets standards for the materials' composition and manufacturing processes, with a focus on preventing the migration of harmful substances into food. As new stretchable cellophane materials are developed, they must adhere to these standards and may require additional safety assessments.

Globally, the development of international standards for bioplastics and bio-based materials, such as those published by the International Organization for Standardization (ISO), is influencing the regulatory landscape for modified cellophane materials. These standards provide guidelines for assessing biodegradability, compostability, and bio-based content, which may become increasingly relevant as cellophane materials evolve to meet sustainability goals.

As research into highly stretchable cellophane materials advances, it is crucial for manufacturers and researchers to engage proactively with regulatory bodies. This collaboration can help shape future regulations that balance innovation with safety and environmental concerns, ensuring a supportive framework for the development and commercialization of these advanced materials.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of cellophane and modified cellophane materials, particularly when intended for food contact applications. The FDA's Code of Federal Regulations (CFR) Title 21, Part 177, Subpart B, Section 177.1200 specifically addresses cellophane, providing guidelines for its composition, manufacturing processes, and permissible additives. As new modifications are introduced to enhance stretchability, manufacturers must ensure compliance with these regulations and may need to seek FDA approval for novel additives or processing methods.

The European Union (EU) has established a comprehensive regulatory framework for food contact materials, including cellophane and its derivatives. The EU Regulation No. 1935/2004 sets out general principles for all food contact materials, while specific measures for cellophane are outlined in Commission Directive 2007/42/EC. These regulations stipulate migration limits for substances used in cellophane production and require manufacturers to demonstrate compliance through testing and documentation.

Environmental considerations are increasingly important in the regulatory landscape for modified cellophane materials. The EU's Single-Use Plastics Directive, while primarily targeting conventional plastics, may have implications for certain cellophane products. Manufacturers developing highly stretchable cellophane materials must consider end-of-life scenarios and align with circular economy principles to meet evolving regulatory requirements.

In Japan, the Ministry of Health, Labour and Welfare regulates food packaging materials, including cellophane, under the Food Sanitation Act. The act sets standards for the materials' composition and manufacturing processes, with a focus on preventing the migration of harmful substances into food. As new stretchable cellophane materials are developed, they must adhere to these standards and may require additional safety assessments.

Globally, the development of international standards for bioplastics and bio-based materials, such as those published by the International Organization for Standardization (ISO), is influencing the regulatory landscape for modified cellophane materials. These standards provide guidelines for assessing biodegradability, compostability, and bio-based content, which may become increasingly relevant as cellophane materials evolve to meet sustainability goals.

As research into highly stretchable cellophane materials advances, it is crucial for manufacturers and researchers to engage proactively with regulatory bodies. This collaboration can help shape future regulations that balance innovation with safety and environmental concerns, ensuring a supportive framework for the development and commercialization of these advanced materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!