How to Achieve Tactile Improvements in Cellophane Packaging?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Tactile Enhancement: Background and Objectives

Cellophane, a thin transparent sheet made from regenerated cellulose, has been a staple in packaging since its invention in 1908. Initially used for food preservation, its applications have expanded to various industries due to its unique properties. The evolution of cellophane technology has been driven by the need for improved functionality, sustainability, and consumer experience.

In recent years, the packaging industry has witnessed a growing demand for enhanced tactile properties in materials. This trend is particularly relevant for cellophane, as consumers increasingly seek packaging that not only protects products but also provides a pleasant sensory experience. The objective of achieving tactile improvements in cellophane packaging addresses this market need while pushing the boundaries of material science.

The pursuit of tactile enhancements in cellophane packaging aims to create surfaces with specific textures, patterns, or sensations that can be perceived through touch. This goal aligns with the broader industry trend of premiumization and product differentiation through packaging. By improving the tactile qualities of cellophane, manufacturers can add value to their products and create memorable brand experiences.

Historically, cellophane's smooth and somewhat slippery surface has been both an advantage and a limitation. While it provides excellent clarity and barrier properties, it lacks the tactile appeal that some consumers associate with quality or luxury. The challenge lies in modifying the surface characteristics of cellophane without compromising its fundamental properties such as transparency, flexibility, and barrier function.

Technological advancements in material science and manufacturing processes have opened new possibilities for cellophane enhancement. These include surface treatments, coatings, and embossing techniques that can alter the texture and feel of cellophane. The integration of nanotechnology and biomimetic approaches also offers promising avenues for creating innovative tactile surfaces.

The objectives of this technological exploration are multifaceted. Primarily, it seeks to develop methods for imparting controlled and reproducible tactile properties to cellophane surfaces. This includes creating a range of textures from subtle to pronounced, and from smooth to rough, depending on the desired application and consumer preference.

Additionally, the research aims to ensure that these tactile improvements are achieved sustainably, aligning with the growing environmental concerns in the packaging industry. This involves exploring bio-based additives and environmentally friendly processing methods that can enhance cellophane's tactile properties without increasing its ecological footprint.

In recent years, the packaging industry has witnessed a growing demand for enhanced tactile properties in materials. This trend is particularly relevant for cellophane, as consumers increasingly seek packaging that not only protects products but also provides a pleasant sensory experience. The objective of achieving tactile improvements in cellophane packaging addresses this market need while pushing the boundaries of material science.

The pursuit of tactile enhancements in cellophane packaging aims to create surfaces with specific textures, patterns, or sensations that can be perceived through touch. This goal aligns with the broader industry trend of premiumization and product differentiation through packaging. By improving the tactile qualities of cellophane, manufacturers can add value to their products and create memorable brand experiences.

Historically, cellophane's smooth and somewhat slippery surface has been both an advantage and a limitation. While it provides excellent clarity and barrier properties, it lacks the tactile appeal that some consumers associate with quality or luxury. The challenge lies in modifying the surface characteristics of cellophane without compromising its fundamental properties such as transparency, flexibility, and barrier function.

Technological advancements in material science and manufacturing processes have opened new possibilities for cellophane enhancement. These include surface treatments, coatings, and embossing techniques that can alter the texture and feel of cellophane. The integration of nanotechnology and biomimetic approaches also offers promising avenues for creating innovative tactile surfaces.

The objectives of this technological exploration are multifaceted. Primarily, it seeks to develop methods for imparting controlled and reproducible tactile properties to cellophane surfaces. This includes creating a range of textures from subtle to pronounced, and from smooth to rough, depending on the desired application and consumer preference.

Additionally, the research aims to ensure that these tactile improvements are achieved sustainably, aligning with the growing environmental concerns in the packaging industry. This involves exploring bio-based additives and environmentally friendly processing methods that can enhance cellophane's tactile properties without increasing its ecological footprint.

Market Analysis for Improved Tactile Packaging

The market for improved tactile packaging, particularly in cellophane, is experiencing significant growth driven by consumer demand for enhanced sensory experiences and product differentiation. This trend is particularly evident in the food and beverage, cosmetics, and luxury goods sectors, where packaging plays a crucial role in brand perception and customer engagement.

Consumer research indicates that tactile elements in packaging can significantly influence purchasing decisions. Studies have shown that consumers are more likely to interact with and purchase products that offer a unique tactile experience. This has led to an increased focus on developing packaging solutions that not only protect the product but also provide a memorable sensory experience.

The global market for specialty films, including those with enhanced tactile properties, is projected to grow steadily over the next five years. This growth is attributed to the rising demand for premium packaging solutions across various industries. The Asia-Pacific region is expected to witness the highest growth rate, driven by the expanding middle-class population and increasing disposable incomes.

In the food and beverage industry, tactile improvements in cellophane packaging are being sought to enhance product freshness perception and create a more premium feel. Manufacturers are exploring various textures and finishes that can be applied to cellophane to mimic natural materials or create unique sensations when touched.

The cosmetics and personal care sector is another key driver for tactile improvements in packaging. Brands in this space are increasingly using textured cellophane to create a luxurious unboxing experience and differentiate their products in a crowded market. Matte finishes, embossed patterns, and soft-touch coatings are among the popular tactile enhancements being explored.

Environmental concerns are also shaping the market for improved tactile packaging. Consumers are demanding sustainable packaging solutions that do not compromise on sensory appeal. This has led to research into bio-based cellophane alternatives that can offer similar or enhanced tactile properties while being more environmentally friendly.

The competitive landscape in this market is characterized by collaborations between packaging manufacturers, material scientists, and brand owners. These partnerships aim to develop innovative tactile solutions that meet both functional and aesthetic requirements. Several patents have been filed in recent years for novel cellophane treatments that enhance tactile properties without compromising recyclability or biodegradability.

Market analysts predict that the demand for tactile improvements in cellophane packaging will continue to grow as brands seek to create more immersive and memorable product experiences. This trend is expected to drive investment in research and development, leading to new technologies and materials that can deliver enhanced tactile properties while meeting sustainability goals.

Consumer research indicates that tactile elements in packaging can significantly influence purchasing decisions. Studies have shown that consumers are more likely to interact with and purchase products that offer a unique tactile experience. This has led to an increased focus on developing packaging solutions that not only protect the product but also provide a memorable sensory experience.

The global market for specialty films, including those with enhanced tactile properties, is projected to grow steadily over the next five years. This growth is attributed to the rising demand for premium packaging solutions across various industries. The Asia-Pacific region is expected to witness the highest growth rate, driven by the expanding middle-class population and increasing disposable incomes.

In the food and beverage industry, tactile improvements in cellophane packaging are being sought to enhance product freshness perception and create a more premium feel. Manufacturers are exploring various textures and finishes that can be applied to cellophane to mimic natural materials or create unique sensations when touched.

The cosmetics and personal care sector is another key driver for tactile improvements in packaging. Brands in this space are increasingly using textured cellophane to create a luxurious unboxing experience and differentiate their products in a crowded market. Matte finishes, embossed patterns, and soft-touch coatings are among the popular tactile enhancements being explored.

Environmental concerns are also shaping the market for improved tactile packaging. Consumers are demanding sustainable packaging solutions that do not compromise on sensory appeal. This has led to research into bio-based cellophane alternatives that can offer similar or enhanced tactile properties while being more environmentally friendly.

The competitive landscape in this market is characterized by collaborations between packaging manufacturers, material scientists, and brand owners. These partnerships aim to develop innovative tactile solutions that meet both functional and aesthetic requirements. Several patents have been filed in recent years for novel cellophane treatments that enhance tactile properties without compromising recyclability or biodegradability.

Market analysts predict that the demand for tactile improvements in cellophane packaging will continue to grow as brands seek to create more immersive and memorable product experiences. This trend is expected to drive investment in research and development, leading to new technologies and materials that can deliver enhanced tactile properties while meeting sustainability goals.

Current Challenges in Cellophane Tactile Properties

Cellophane packaging, despite its widespread use, faces significant challenges in achieving desirable tactile properties. The primary issue lies in the inherent nature of cellophane, which is a smooth, thin, and relatively rigid material. This characteristic often results in a lack of tactile appeal, limiting its perceived quality and user experience.

One of the main challenges is the material's inability to provide a diverse range of textures. Unlike other packaging materials that can be easily embossed or textured, cellophane's smooth surface makes it difficult to create varied tactile sensations. This limitation restricts brand differentiation and product positioning through touch, which is increasingly important in consumer packaging.

Another significant challenge is the material's tendency to create static electricity. This property not only affects the handling of the packaging but can also lead to dust attraction, compromising the perceived cleanliness and quality of the product. The static charge can also interfere with packaging processes, causing issues in production lines and potentially damaging sensitive electronic components.

The moisture sensitivity of cellophane presents another hurdle in achieving consistent tactile properties. In high humidity environments, cellophane can become slightly tacky, altering its feel and potentially affecting the user's perception of the product. Conversely, in dry conditions, it can become brittle and lose flexibility, further impacting its tactile qualities.

The limited durability of cellophane also poses challenges in maintaining consistent tactile properties throughout the product's lifecycle. The material is prone to creasing and wrinkling, which can significantly alter its texture and feel over time. This susceptibility to physical changes can lead to a degradation of the packaging's tactile appeal, potentially affecting brand perception and product satisfaction.

Furthermore, the environmental concerns associated with traditional cellophane production methods add complexity to improving its tactile properties. As sustainability becomes increasingly important, any enhancements to cellophane's tactile qualities must also consider eco-friendly production processes and end-of-life recyclability.

Addressing these challenges requires innovative approaches that can enhance cellophane's tactile properties without compromising its fundamental characteristics or environmental sustainability. This may involve exploring new coating technologies, developing composite materials, or investigating novel surface treatment methods that can impart improved texture and feel to cellophane packaging.

One of the main challenges is the material's inability to provide a diverse range of textures. Unlike other packaging materials that can be easily embossed or textured, cellophane's smooth surface makes it difficult to create varied tactile sensations. This limitation restricts brand differentiation and product positioning through touch, which is increasingly important in consumer packaging.

Another significant challenge is the material's tendency to create static electricity. This property not only affects the handling of the packaging but can also lead to dust attraction, compromising the perceived cleanliness and quality of the product. The static charge can also interfere with packaging processes, causing issues in production lines and potentially damaging sensitive electronic components.

The moisture sensitivity of cellophane presents another hurdle in achieving consistent tactile properties. In high humidity environments, cellophane can become slightly tacky, altering its feel and potentially affecting the user's perception of the product. Conversely, in dry conditions, it can become brittle and lose flexibility, further impacting its tactile qualities.

The limited durability of cellophane also poses challenges in maintaining consistent tactile properties throughout the product's lifecycle. The material is prone to creasing and wrinkling, which can significantly alter its texture and feel over time. This susceptibility to physical changes can lead to a degradation of the packaging's tactile appeal, potentially affecting brand perception and product satisfaction.

Furthermore, the environmental concerns associated with traditional cellophane production methods add complexity to improving its tactile properties. As sustainability becomes increasingly important, any enhancements to cellophane's tactile qualities must also consider eco-friendly production processes and end-of-life recyclability.

Addressing these challenges requires innovative approaches that can enhance cellophane's tactile properties without compromising its fundamental characteristics or environmental sustainability. This may involve exploring new coating technologies, developing composite materials, or investigating novel surface treatment methods that can impart improved texture and feel to cellophane packaging.

Existing Tactile Enhancement Solutions for Cellophane

01 Surface texture modification for enhanced tactile properties

Cellophane packaging can be modified with various surface textures to enhance its tactile properties. This can include embossing, debossing, or creating micro-patterns on the surface. These modifications can improve grip, provide a unique sensory experience, and differentiate the product in the market.- Surface texture modification for enhanced tactile properties: Cellophane packaging can be modified with various surface textures to enhance its tactile properties. This can include embossing, micro-texturing, or applying coatings to create a specific feel. These modifications can improve grip, provide a luxurious touch, or create a unique sensory experience for the consumer.

- Incorporation of tactile indicators: Tactile indicators can be integrated into cellophane packaging to provide information or improve user interaction. These can include raised patterns, Braille elements, or other tactile features that allow users to identify or interact with the packaging through touch, enhancing accessibility and user experience.

- Multi-layer cellophane structures for improved feel: By combining multiple layers of cellophane or other materials, packaging can be designed with specific tactile properties. This approach allows for the creation of packaging with a soft touch, a rigid feel, or a combination of textures, enhancing the overall tactile experience of the product.

- Smart packaging with touch-sensitive elements: Integration of touch-sensitive elements into cellophane packaging can create interactive experiences. This may include capacitive touch sensors, pressure-sensitive areas, or other technologies that respond to user touch, providing a novel way for consumers to interact with the packaging and potentially access additional product information.

- Biodegradable cellophane with enhanced tactile properties: Development of biodegradable cellophane materials that maintain or enhance tactile properties. These materials can provide an environmentally friendly packaging solution while still offering desirable touch and feel characteristics, such as smoothness, flexibility, or specific textures.

02 Incorporation of tactile-enhancing additives

Additives can be incorporated into cellophane packaging to enhance its tactile properties. These may include materials that provide a soft touch, create a matte finish, or introduce a specific texture. Such additives can improve the overall feel of the packaging and create a more premium perception.Expand Specific Solutions03 Multi-layer cellophane structures for improved tactile sensation

Developing multi-layer cellophane structures can enhance the tactile properties of packaging. By combining layers with different characteristics, such as a soft outer layer and a more rigid inner layer, the packaging can provide an improved tactile experience while maintaining necessary functional properties.Expand Specific Solutions04 Smart packaging with tactile feedback

Integrating smart technologies into cellophane packaging can provide enhanced tactile feedback. This may include the use of shape-memory materials, temperature-responsive elements, or even micro-electronic components that create subtle vibrations or changes in texture when touched.Expand Specific Solutions05 Biopolymer-based cellophane with improved tactile properties

Developing cellophane packaging using biopolymers or modified cellulose materials can result in improved tactile properties. These materials can offer a more natural feel, enhanced flexibility, or unique surface characteristics that improve the overall tactile experience of the packaging.Expand Specific Solutions

Key Players in Tactile Packaging Industry

The tactile improvement of cellophane packaging is currently in a growth phase, with increasing market demand driven by consumer preferences for enhanced product experiences. The global market for advanced packaging materials is expanding, estimated to reach several billion dollars in the coming years. Technologically, this field is rapidly evolving, with companies like Mitsubishi Polyester Film GmbH, Daicel Corp., and Dow Global Technologies LLC leading innovations in surface modification and material science. These firms are developing new coatings, textures, and composite materials to enhance the tactile properties of cellophane. Procter & Gamble Co. and Corning, Inc. are also contributing significant research efforts, leveraging their expertise in consumer products and materials engineering to advance tactile packaging solutions.

Huntsman Petrochemical LLC

Technical Solution: Huntsman Petrochemical LLC has developed innovative solutions for enhancing the tactile properties of cellophane packaging. Their approach focuses on the development of specialty additives that can be incorporated into the cellophane production process to modify its surface characteristics. Huntsman has introduced a range of tactile modifiers that can create various textures, from soft-touch to high-grip surfaces[13]. They have also developed a series of reactive additives that can form micro-structures on the cellophane surface during the curing process, resulting in unique tactile properties[15]. Additionally, Huntsman has invested in research on smart materials that can change their tactile properties in response to environmental stimuli, potentially leading to cellophane packaging with adaptive tactile features[17].

Strengths: Wide range of tactile options, integration with existing production processes, potential for smart packaging solutions. Weaknesses: May require fine-tuning of production parameters, potential impact on other material properties.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed several innovative approaches to enhance the tactile properties of cellophane packaging. Their primary focus has been on creating multi-layer cellophane structures that combine different materials to achieve desired tactile effects. Dow has introduced a range of specialty resins that can be co-extruded with traditional cellophane to create unique surface textures and feels[7]. They have also developed a series of tactile coatings that can be applied to cellophane, providing a range of sensations from silky smooth to rubbery grip[9]. Additionally, Dow has invested in research on bio-based additives that can modify the surface properties of cellophane, improving its tactile qualities while maintaining its biodegradability[11].

Strengths: Versatile multi-layer solutions, wide range of tactile options, focus on maintaining material sustainability. Weaknesses: Complexity in manufacturing process, potential increase in material costs.

Innovative Approaches to Cellophane Texture Modification

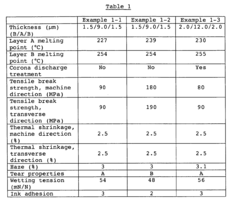

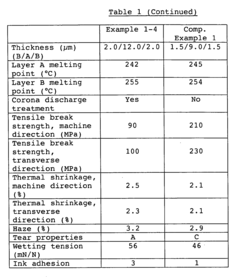

Biaxially stretched laminated polyester film and polyester film for covering

PatentInactiveUS20060073317A1

Innovation

- A biaxially stretched laminated polyester film with specific tensile break strengths, wetting tensions, surface resistivities, and barrier layers is developed, incorporating copolymeric polyethylene terephthalate and polybutyrene terephthalate layers, and antistatic agents to enhance adhesion, antistatic properties, and barrier performance.

Biaxially oriented laminated polyester film and polyester film for lid material

PatentInactiveEP1598182A1

Innovation

- A biaxially stretched laminated polyester film with specific tensile break strengths, wetting tensions, surface resistivities, and barrier layers is developed, incorporating copolymeric polyethylene terephthalate and polybutyrene terephthalate layers, along with antistatic agents and barrier coatings to enhance adhesion, antistatic properties, and barrier performance without the need for aluminum foil.

Environmental Impact of Enhanced Tactile Packaging

The enhancement of tactile properties in cellophane packaging presents a complex environmental challenge. While improved tactile features can enhance user experience and product appeal, they often come at an environmental cost. The production of enhanced tactile cellophane typically requires additional materials or processing steps, which can increase energy consumption and resource utilization. These processes may involve the application of coatings, embossing, or the incorporation of micro-textures, all of which can impact the packaging's overall environmental footprint.

One significant concern is the potential reduction in recyclability. Many tactile improvements alter the composition or structure of the cellophane, making it more difficult to recycle through conventional methods. This can lead to increased waste and contribute to the growing problem of plastic pollution. Furthermore, some tactile enhancements may involve the use of additives or chemicals that are not environmentally friendly, potentially leaching into soil or water systems when the packaging is discarded.

However, it's important to note that not all tactile improvements necessarily have negative environmental impacts. Some innovations in this field focus on creating tactile features through structural changes rather than additional materials, which may have a lower environmental impact. For instance, micro-embossing techniques can create tactile sensations without significantly altering the material's recyclability or adding harmful substances.

The lifecycle assessment of enhanced tactile cellophane packaging is crucial in understanding its true environmental impact. This includes considering the sourcing of raw materials, manufacturing processes, transportation, use phase, and end-of-life disposal or recycling. In some cases, improved tactile properties might lead to better product protection, potentially reducing food waste or extending product shelf life, which could offset some of the environmental costs associated with production.

As sustainability becomes an increasingly important factor in packaging design, there is a growing focus on developing tactile improvements that are environmentally friendly. This includes research into bio-based materials that can provide similar tactile properties to traditional cellophane while being more biodegradable or compostable. Additionally, efforts are being made to create tactile features that enhance the packaging's functionality without compromising its ability to be recycled or repurposed.

The environmental impact of enhanced tactile packaging also extends to consumer behavior. Improved tactile properties can influence purchasing decisions and brand loyalty, potentially leading to increased consumption. However, if these enhancements result in more durable or reusable packaging, it could encourage consumers to keep and repurpose the packaging, reducing overall waste.

One significant concern is the potential reduction in recyclability. Many tactile improvements alter the composition or structure of the cellophane, making it more difficult to recycle through conventional methods. This can lead to increased waste and contribute to the growing problem of plastic pollution. Furthermore, some tactile enhancements may involve the use of additives or chemicals that are not environmentally friendly, potentially leaching into soil or water systems when the packaging is discarded.

However, it's important to note that not all tactile improvements necessarily have negative environmental impacts. Some innovations in this field focus on creating tactile features through structural changes rather than additional materials, which may have a lower environmental impact. For instance, micro-embossing techniques can create tactile sensations without significantly altering the material's recyclability or adding harmful substances.

The lifecycle assessment of enhanced tactile cellophane packaging is crucial in understanding its true environmental impact. This includes considering the sourcing of raw materials, manufacturing processes, transportation, use phase, and end-of-life disposal or recycling. In some cases, improved tactile properties might lead to better product protection, potentially reducing food waste or extending product shelf life, which could offset some of the environmental costs associated with production.

As sustainability becomes an increasingly important factor in packaging design, there is a growing focus on developing tactile improvements that are environmentally friendly. This includes research into bio-based materials that can provide similar tactile properties to traditional cellophane while being more biodegradable or compostable. Additionally, efforts are being made to create tactile features that enhance the packaging's functionality without compromising its ability to be recycled or repurposed.

The environmental impact of enhanced tactile packaging also extends to consumer behavior. Improved tactile properties can influence purchasing decisions and brand loyalty, potentially leading to increased consumption. However, if these enhancements result in more durable or reusable packaging, it could encourage consumers to keep and repurpose the packaging, reducing overall waste.

Consumer Perception and Acceptance of Tactile Packaging

Consumer perception and acceptance of tactile packaging play a crucial role in the success of cellophane packaging improvements. The tactile experience of a product's packaging can significantly influence consumer behavior, brand perception, and overall product satisfaction. Research has shown that consumers often make purchasing decisions based on their sensory interactions with packaging, including touch and texture.

In recent years, there has been a growing interest in enhancing the tactile properties of cellophane packaging to create a more engaging and memorable consumer experience. This trend is driven by the increasing recognition of the importance of multisensory marketing and the desire to differentiate products in a crowded marketplace.

Studies have demonstrated that consumers tend to associate certain tactile qualities with specific product attributes. For example, smooth textures are often perceived as premium or sophisticated, while rough textures may convey a sense of naturalness or authenticity. By strategically incorporating these tactile elements into cellophane packaging, manufacturers can influence consumer perceptions and expectations of the product within.

The acceptance of tactile improvements in cellophane packaging varies across different consumer segments and product categories. Luxury goods and personal care products, for instance, have seen a higher level of consumer acceptance for enhanced tactile packaging, as it aligns with the expectation of a premium experience. In contrast, consumers may be more hesitant to embrace tactile changes in packaging for everyday household items or food products, where functionality and familiarity often take precedence.

Consumer age and cultural background also play a role in the perception and acceptance of tactile packaging. Younger consumers, particularly millennials and Gen Z, tend to be more receptive to innovative packaging designs and are more likely to appreciate tactile improvements. Cultural differences can also influence tactile preferences, with some cultures placing greater emphasis on certain textures or materials.

To ensure successful implementation of tactile improvements in cellophane packaging, manufacturers must conduct thorough market research and consumer testing. This includes gathering feedback on various tactile elements, such as embossing, debossing, or the incorporation of different surface textures. Understanding the target audience's preferences and expectations is crucial in developing packaging that resonates with consumers and enhances the overall product experience.

Moreover, educating consumers about the benefits and purpose of tactile improvements can increase acceptance and appreciation. Clear communication about how enhanced tactile properties contribute to product protection, ease of use, or sustainability can help overcome potential resistance to change and foster positive perceptions.

As the packaging industry continues to evolve, the importance of tactile elements in cellophane packaging is likely to grow. Manufacturers who successfully integrate consumer preferences and perceptions into their packaging design strategies will be better positioned to create products that not only meet functional requirements but also deliver a more engaging and memorable sensory experience.

In recent years, there has been a growing interest in enhancing the tactile properties of cellophane packaging to create a more engaging and memorable consumer experience. This trend is driven by the increasing recognition of the importance of multisensory marketing and the desire to differentiate products in a crowded marketplace.

Studies have demonstrated that consumers tend to associate certain tactile qualities with specific product attributes. For example, smooth textures are often perceived as premium or sophisticated, while rough textures may convey a sense of naturalness or authenticity. By strategically incorporating these tactile elements into cellophane packaging, manufacturers can influence consumer perceptions and expectations of the product within.

The acceptance of tactile improvements in cellophane packaging varies across different consumer segments and product categories. Luxury goods and personal care products, for instance, have seen a higher level of consumer acceptance for enhanced tactile packaging, as it aligns with the expectation of a premium experience. In contrast, consumers may be more hesitant to embrace tactile changes in packaging for everyday household items or food products, where functionality and familiarity often take precedence.

Consumer age and cultural background also play a role in the perception and acceptance of tactile packaging. Younger consumers, particularly millennials and Gen Z, tend to be more receptive to innovative packaging designs and are more likely to appreciate tactile improvements. Cultural differences can also influence tactile preferences, with some cultures placing greater emphasis on certain textures or materials.

To ensure successful implementation of tactile improvements in cellophane packaging, manufacturers must conduct thorough market research and consumer testing. This includes gathering feedback on various tactile elements, such as embossing, debossing, or the incorporation of different surface textures. Understanding the target audience's preferences and expectations is crucial in developing packaging that resonates with consumers and enhances the overall product experience.

Moreover, educating consumers about the benefits and purpose of tactile improvements can increase acceptance and appreciation. Clear communication about how enhanced tactile properties contribute to product protection, ease of use, or sustainability can help overcome potential resistance to change and foster positive perceptions.

As the packaging industry continues to evolve, the importance of tactile elements in cellophane packaging is likely to grow. Manufacturers who successfully integrate consumer preferences and perceptions into their packaging design strategies will be better positioned to create products that not only meet functional requirements but also deliver a more engaging and memorable sensory experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!