How to Address Common Solar Inverter Failures?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Failure Background and Objectives

Solar inverter failures have become a critical concern in the renewable energy sector, particularly as solar power installations continue to grow globally. These failures not only impact the efficiency and reliability of solar energy systems but also pose significant economic challenges for both residential and commercial users. The evolution of solar inverter technology has been marked by continuous improvements in efficiency, durability, and functionality, yet failures remain a persistent issue.

The primary objective of addressing common solar inverter failures is to enhance the overall performance and longevity of solar power systems. This involves identifying the root causes of failures, developing more robust components, and implementing advanced monitoring and predictive maintenance strategies. By tackling these challenges, the industry aims to reduce downtime, minimize repair costs, and ultimately increase the return on investment for solar energy installations.

Solar inverter technology has progressed significantly since its inception, with advancements in power electronics, control systems, and materials science contributing to more efficient and reliable designs. However, as solar installations are exposed to diverse environmental conditions and varying operational demands, inverters continue to face a range of failure modes. These include thermal stress, component degradation, grid instability issues, and software malfunctions.

The current technological landscape presents both opportunities and challenges in addressing inverter failures. On one hand, the integration of smart monitoring systems and the advent of Internet of Things (IoT) technologies offer new possibilities for real-time diagnostics and predictive maintenance. On the other hand, the increasing complexity of inverter designs and the push for higher power densities introduce new potential points of failure that must be carefully managed.

As the solar energy industry matures, there is a growing emphasis on developing standardized testing protocols and reliability metrics for inverters. This trend is driven by the need to provide more accurate lifetime predictions and performance guarantees to consumers and investors. Additionally, regulatory bodies and industry associations are working towards establishing more stringent quality standards and certification processes to ensure the reliability and safety of solar inverter technologies.

The path forward in addressing solar inverter failures involves a multifaceted approach, combining advances in materials science, thermal management, power electronics, and software engineering. Research efforts are focused on developing more resilient components, implementing advanced fault detection algorithms, and designing inverters with enhanced self-diagnostic capabilities. These technological advancements aim to not only reduce the frequency of failures but also to minimize their impact when they do occur.

The primary objective of addressing common solar inverter failures is to enhance the overall performance and longevity of solar power systems. This involves identifying the root causes of failures, developing more robust components, and implementing advanced monitoring and predictive maintenance strategies. By tackling these challenges, the industry aims to reduce downtime, minimize repair costs, and ultimately increase the return on investment for solar energy installations.

Solar inverter technology has progressed significantly since its inception, with advancements in power electronics, control systems, and materials science contributing to more efficient and reliable designs. However, as solar installations are exposed to diverse environmental conditions and varying operational demands, inverters continue to face a range of failure modes. These include thermal stress, component degradation, grid instability issues, and software malfunctions.

The current technological landscape presents both opportunities and challenges in addressing inverter failures. On one hand, the integration of smart monitoring systems and the advent of Internet of Things (IoT) technologies offer new possibilities for real-time diagnostics and predictive maintenance. On the other hand, the increasing complexity of inverter designs and the push for higher power densities introduce new potential points of failure that must be carefully managed.

As the solar energy industry matures, there is a growing emphasis on developing standardized testing protocols and reliability metrics for inverters. This trend is driven by the need to provide more accurate lifetime predictions and performance guarantees to consumers and investors. Additionally, regulatory bodies and industry associations are working towards establishing more stringent quality standards and certification processes to ensure the reliability and safety of solar inverter technologies.

The path forward in addressing solar inverter failures involves a multifaceted approach, combining advances in materials science, thermal management, power electronics, and software engineering. Research efforts are focused on developing more resilient components, implementing advanced fault detection algorithms, and designing inverters with enhanced self-diagnostic capabilities. These technological advancements aim to not only reduce the frequency of failures but also to minimize their impact when they do occur.

Market Analysis for Reliable Solar Inverters

The solar inverter market has witnessed significant growth in recent years, driven by the increasing adoption of solar energy systems worldwide. As the demand for reliable and efficient solar power generation continues to rise, the market for dependable solar inverters has expanded accordingly. The global solar inverter market was valued at approximately $7.7 billion in 2020 and is projected to reach $12.3 billion by 2026, growing at a CAGR of 8.1% during the forecast period.

The market for reliable solar inverters is primarily driven by the growing installation of solar photovoltaic (PV) systems in both residential and commercial sectors. Governments across various countries have implemented favorable policies and incentives to promote solar energy adoption, further fueling market growth. Additionally, the increasing focus on renewable energy sources to reduce carbon emissions and combat climate change has contributed to the expanding market for solar inverters.

In terms of regional analysis, Asia Pacific dominates the solar inverter market, with China and India being the major contributors. Europe and North America follow closely, with countries like Germany, Italy, and the United States showing significant market potential. The Middle East and Africa region is also experiencing rapid growth in solar energy adoption, presenting new opportunities for solar inverter manufacturers.

The market landscape for reliable solar inverters is highly competitive, with several key players vying for market share. Some of the prominent companies in this space include SMA Solar Technology, Huawei, Sungrow Power Supply, and ABB. These companies are continuously investing in research and development to improve inverter efficiency, reliability, and overall performance.

One of the key trends in the market is the shift towards smart and connected solar inverters. These advanced inverters offer features such as remote monitoring, predictive maintenance, and grid integration capabilities, enhancing the overall efficiency and reliability of solar power systems. The integration of artificial intelligence and machine learning technologies in solar inverters is also gaining traction, enabling better fault detection and performance optimization.

The increasing focus on grid stability and power quality has led to the development of advanced grid-support features in solar inverters. This includes capabilities such as reactive power control, voltage regulation, and low voltage ride-through, which are becoming essential requirements in many markets.

As the solar energy industry continues to mature, there is a growing emphasis on the total cost of ownership rather than just the initial investment. This shift has led to increased demand for reliable and long-lasting solar inverters that can minimize maintenance costs and maximize energy production over the system's lifetime.

The market for reliable solar inverters is primarily driven by the growing installation of solar photovoltaic (PV) systems in both residential and commercial sectors. Governments across various countries have implemented favorable policies and incentives to promote solar energy adoption, further fueling market growth. Additionally, the increasing focus on renewable energy sources to reduce carbon emissions and combat climate change has contributed to the expanding market for solar inverters.

In terms of regional analysis, Asia Pacific dominates the solar inverter market, with China and India being the major contributors. Europe and North America follow closely, with countries like Germany, Italy, and the United States showing significant market potential. The Middle East and Africa region is also experiencing rapid growth in solar energy adoption, presenting new opportunities for solar inverter manufacturers.

The market landscape for reliable solar inverters is highly competitive, with several key players vying for market share. Some of the prominent companies in this space include SMA Solar Technology, Huawei, Sungrow Power Supply, and ABB. These companies are continuously investing in research and development to improve inverter efficiency, reliability, and overall performance.

One of the key trends in the market is the shift towards smart and connected solar inverters. These advanced inverters offer features such as remote monitoring, predictive maintenance, and grid integration capabilities, enhancing the overall efficiency and reliability of solar power systems. The integration of artificial intelligence and machine learning technologies in solar inverters is also gaining traction, enabling better fault detection and performance optimization.

The increasing focus on grid stability and power quality has led to the development of advanced grid-support features in solar inverters. This includes capabilities such as reactive power control, voltage regulation, and low voltage ride-through, which are becoming essential requirements in many markets.

As the solar energy industry continues to mature, there is a growing emphasis on the total cost of ownership rather than just the initial investment. This shift has led to increased demand for reliable and long-lasting solar inverters that can minimize maintenance costs and maximize energy production over the system's lifetime.

Current Challenges in Solar Inverter Reliability

Solar inverter reliability remains a critical challenge in the photovoltaic industry, impacting system performance, energy yield, and overall cost-effectiveness. Despite significant advancements in inverter technology, several persistent issues continue to plague these essential components of solar power systems.

One of the primary challenges is thermal management. Inverters generate substantial heat during operation, and inadequate cooling can lead to premature component failure. High temperatures stress electronic components, particularly capacitors and semiconductors, reducing their lifespan and efficiency. Manufacturers are constantly seeking innovative cooling solutions, including advanced heat sink designs and active cooling systems, to mitigate these thermal issues.

Another significant concern is the vulnerability of inverters to environmental factors. Exposure to dust, humidity, and extreme temperatures can compromise the integrity of internal components. Ingress protection is crucial, yet achieving a balance between effective sealing and proper ventilation remains a complex engineering challenge. Additionally, in coastal areas, salt corrosion poses a severe threat to inverter longevity, necessitating specialized protective measures.

Power quality issues present another set of challenges. Grid instability, voltage fluctuations, and harmonic distortions can stress inverter components and lead to failures. Developing robust control algorithms and protective circuitry to handle these grid anomalies without compromising performance is an ongoing area of research and development.

The reliability of power electronic components, particularly IGBTs (Insulated Gate Bipolar Transistors) and capacitors, continues to be a focal point. These components are subject to high stress and are often the first to fail in inverter systems. Improving the quality and durability of these components, as well as implementing more effective fault detection and isolation mechanisms, is crucial for enhancing overall inverter reliability.

Software and firmware issues also contribute to inverter failures. Complex control algorithms can sometimes lead to unexpected behaviors or inefficiencies. Regular updates and patches are necessary to address bugs and improve performance, but the update process itself can introduce new vulnerabilities if not managed properly.

Lastly, the challenge of predictive maintenance and real-time monitoring cannot be overstated. Developing accurate models for predicting inverter failures and implementing effective monitoring systems to detect early signs of degradation are essential for preventing unexpected downtime and optimizing maintenance schedules.

Addressing these challenges requires a multifaceted approach, combining advancements in materials science, thermal engineering, power electronics, software development, and data analytics. As the solar industry continues to grow, overcoming these reliability issues will be crucial for improving the overall efficiency and cost-effectiveness of photovoltaic systems.

One of the primary challenges is thermal management. Inverters generate substantial heat during operation, and inadequate cooling can lead to premature component failure. High temperatures stress electronic components, particularly capacitors and semiconductors, reducing their lifespan and efficiency. Manufacturers are constantly seeking innovative cooling solutions, including advanced heat sink designs and active cooling systems, to mitigate these thermal issues.

Another significant concern is the vulnerability of inverters to environmental factors. Exposure to dust, humidity, and extreme temperatures can compromise the integrity of internal components. Ingress protection is crucial, yet achieving a balance between effective sealing and proper ventilation remains a complex engineering challenge. Additionally, in coastal areas, salt corrosion poses a severe threat to inverter longevity, necessitating specialized protective measures.

Power quality issues present another set of challenges. Grid instability, voltage fluctuations, and harmonic distortions can stress inverter components and lead to failures. Developing robust control algorithms and protective circuitry to handle these grid anomalies without compromising performance is an ongoing area of research and development.

The reliability of power electronic components, particularly IGBTs (Insulated Gate Bipolar Transistors) and capacitors, continues to be a focal point. These components are subject to high stress and are often the first to fail in inverter systems. Improving the quality and durability of these components, as well as implementing more effective fault detection and isolation mechanisms, is crucial for enhancing overall inverter reliability.

Software and firmware issues also contribute to inverter failures. Complex control algorithms can sometimes lead to unexpected behaviors or inefficiencies. Regular updates and patches are necessary to address bugs and improve performance, but the update process itself can introduce new vulnerabilities if not managed properly.

Lastly, the challenge of predictive maintenance and real-time monitoring cannot be overstated. Developing accurate models for predicting inverter failures and implementing effective monitoring systems to detect early signs of degradation are essential for preventing unexpected downtime and optimizing maintenance schedules.

Addressing these challenges requires a multifaceted approach, combining advancements in materials science, thermal engineering, power electronics, software development, and data analytics. As the solar industry continues to grow, overcoming these reliability issues will be crucial for improving the overall efficiency and cost-effectiveness of photovoltaic systems.

Existing Solutions for Inverter Failure Prevention

01 Fault detection and diagnosis in solar inverters

Advanced fault detection and diagnosis systems are implemented in solar inverters to identify and analyze various types of failures. These systems use sensors, data analysis, and machine learning algorithms to monitor inverter performance, detect anomalies, and predict potential failures before they occur. This proactive approach helps in minimizing downtime and improving overall system reliability.- Fault detection and diagnosis in solar inverters: Advanced fault detection and diagnosis systems are implemented in solar inverters to identify and analyze various types of failures. These systems use sensors, data analysis, and machine learning algorithms to monitor inverter performance, detect anomalies, and predict potential failures before they occur. This proactive approach helps in maintaining system reliability and reducing downtime.

- Thermal management and cooling systems: Effective thermal management and cooling systems are crucial for preventing solar inverter failures caused by overheating. These systems may include advanced heat sinks, liquid cooling, or forced air cooling mechanisms. Proper thermal management helps extend the lifespan of inverter components and maintain optimal performance under various environmental conditions.

- Grid integration and protection mechanisms: Solar inverters incorporate sophisticated grid integration and protection mechanisms to prevent failures caused by grid instabilities or abnormalities. These mechanisms include anti-islanding protection, voltage and frequency ride-through capabilities, and grid synchronization features. Such protections ensure the inverter's safe operation and compliance with grid codes.

- Component reliability and quality control: Improving the reliability of individual components and implementing stringent quality control measures are essential for reducing solar inverter failures. This includes using high-quality capacitors, semiconductors, and other critical components, as well as implementing robust testing and validation processes during manufacturing.

- Remote monitoring and predictive maintenance: Remote monitoring systems and predictive maintenance strategies are employed to minimize solar inverter failures. These systems collect and analyze real-time data from inverters, allowing for early detection of potential issues and scheduling of preventive maintenance. This approach helps reduce unexpected failures and optimize inverter performance over time.

02 Thermal management and cooling solutions

Effective thermal management is crucial for preventing solar inverter failures caused by overheating. Various cooling solutions are employed, including passive cooling techniques, active cooling systems with fans or liquid cooling, and advanced heat sink designs. These methods help dissipate heat efficiently, maintain optimal operating temperatures, and extend the lifespan of inverter components.Expand Specific Solutions03 Grid integration and protection mechanisms

Solar inverters incorporate sophisticated grid integration and protection mechanisms to prevent failures caused by grid instabilities or abnormalities. These include anti-islanding protection, voltage and frequency ride-through capabilities, and grid synchronization algorithms. Such features ensure the inverter can safely disconnect from the grid during faults and reconnect when conditions normalize, protecting both the inverter and the grid infrastructure.Expand Specific Solutions04 Component reliability and quality control

Improving the reliability of individual components and implementing stringent quality control measures are essential for reducing solar inverter failures. This includes using high-quality capacitors, robust semiconductor devices, and durable circuit boards. Advanced manufacturing techniques, thorough testing procedures, and rigorous quality assurance processes are employed to ensure the longevity and reliability of inverter components.Expand Specific Solutions05 Software and firmware updates

Regular software and firmware updates play a crucial role in preventing and addressing solar inverter failures. These updates can improve system performance, fix bugs, enhance compatibility with new grid requirements, and introduce new features. Remote update capabilities allow for efficient maintenance and troubleshooting without the need for on-site visits, reducing downtime and improving overall system reliability.Expand Specific Solutions

Key Players in Solar Inverter Manufacturing

The solar inverter market is in a mature growth phase, with a global market size expected to reach $27 billion by 2026. The technology has evolved significantly, with major players like SolarEdge Technologies, Tesla, and Enphase Energy leading innovation in module-level power electronics and smart inverter solutions. These companies, along with established manufacturers such as SMA Solar Technology and Sungrow Power Supply, are driving advancements in efficiency, reliability, and grid integration capabilities. The competitive landscape is characterized by a mix of specialized solar technology firms and diversified industrial conglomerates like Siemens and GE, indicating the technology's growing importance in the broader energy sector.

SolarEdge Technologies, Inc.

Technical Solution: SolarEdge addresses common solar inverter failures through their HD-Wave technology, which uses distributed switching and advanced digital processing to synthesize a clean sine wave. This approach reduces the size and number of magnetic components, leading to a 99% weighted efficiency[1]. Their inverters incorporate advanced thermal management systems and use film capacitors instead of electrolytic ones, significantly extending the inverter's lifespan[2]. SolarEdge also employs a unique power optimizer architecture, where each solar panel has its own power optimizer, allowing for individual panel monitoring and mitigation of panel-level issues without affecting the entire system[3].

Strengths: High efficiency, extended lifespan, and granular control. Weaknesses: Higher initial cost compared to traditional string inverters, and reliance on proprietary components.

Tesla, Inc.

Technical Solution: Tesla's approach to addressing solar inverter failures focuses on integration and simplification. Their Powerwall system combines a battery, inverter, and energy management software into a single unit. The inverter uses advanced switching technologies and sophisticated control algorithms to manage power flow between solar panels, battery, and the grid[4]. Tesla's inverters incorporate active cooling systems and use high-quality components to enhance reliability. They also implement over-the-air updates to continuously improve performance and address potential issues before they lead to failures[5]. Tesla's inverters are designed with a focus on ease of installation and maintenance, reducing the likelihood of installation-related failures.

Strengths: Integrated system design, continuous improvement through software updates, and simplified installation. Weaknesses: Limited flexibility for system customization and potential for system-wide issues if the integrated inverter fails.

Core Innovations in Inverter Reliability

Solar Photovoltaic Inverters

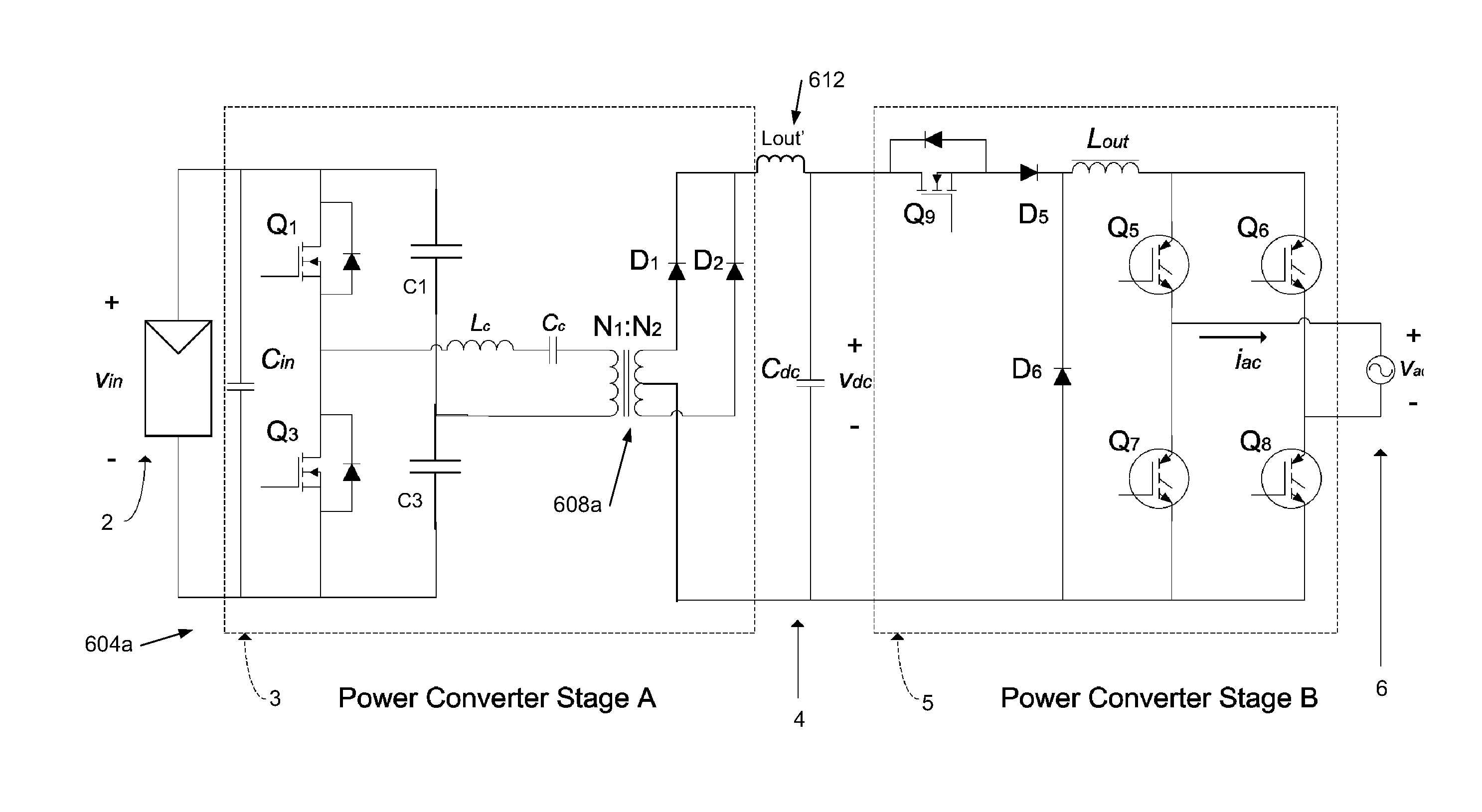

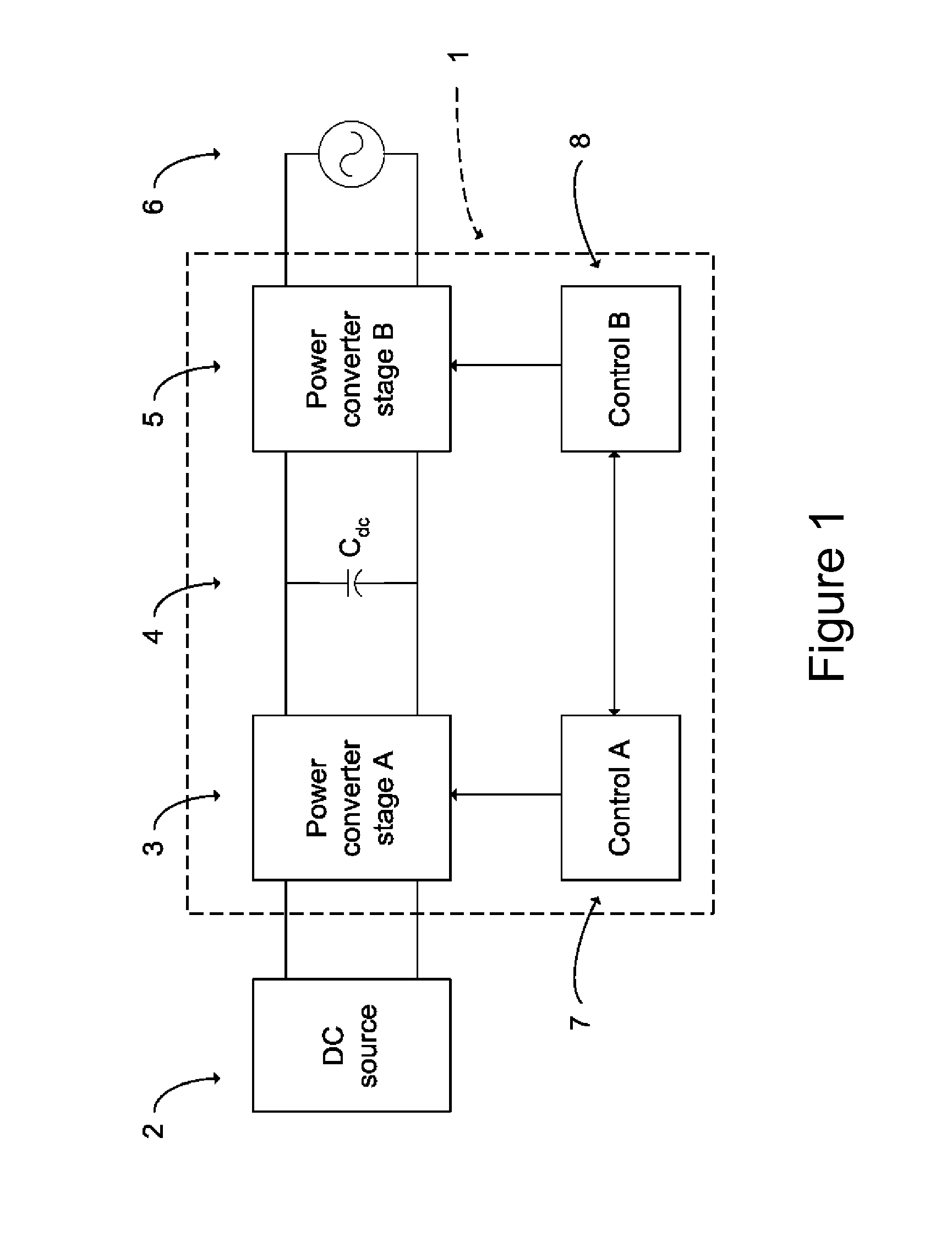

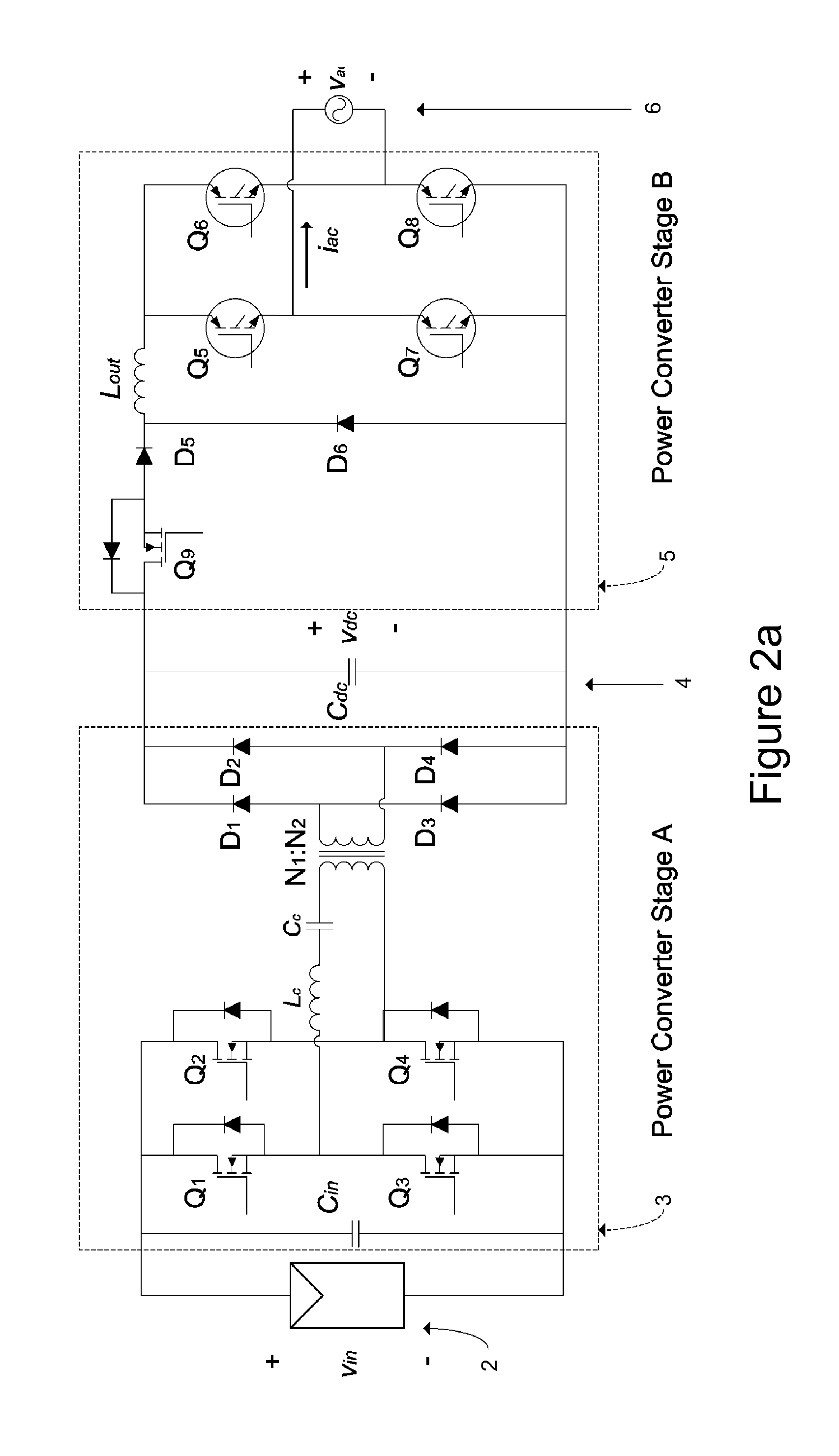

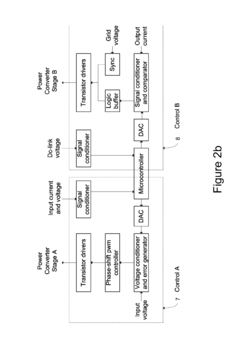

PatentActiveUS20120057388A1

Innovation

- A solar photovoltaic inverter design featuring a power conditioning circuit on a circuit board enclosed by an electrically conductive shield with holes for a plastic overmould, providing a sealed, solid housing that facilitates heat dissipation and environmental protection, along with pre-coating magnetic components with elastic materials to manage thermal expansion, and using a modular connector system for dc input to ensure compatibility with various PV panels.

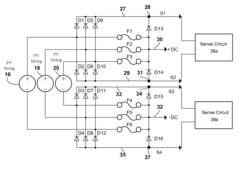

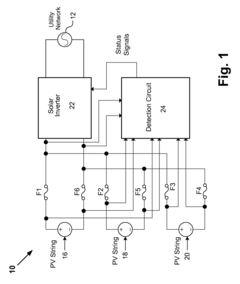

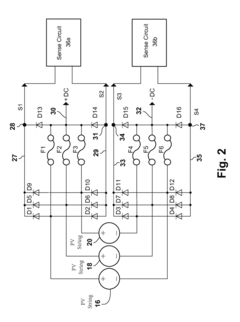

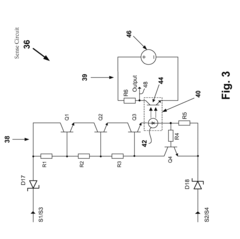

Open fuse detection system for a solar inverter

PatentActiveUS9843192B2

Innovation

- A fault detection circuit is implemented, utilizing positive and negative bypass lines, sense circuits, and diodes to generate signals when potential differences exceed predetermined voltages, indicating open fuses, allowing for real-time monitoring and indication of fuse status.

Environmental Impact of Inverter Failures

Solar inverter failures not only impact the efficiency and reliability of photovoltaic systems but also have significant environmental implications. The production, replacement, and disposal of faulty inverters contribute to increased carbon emissions and resource depletion. When inverters fail prematurely, it necessitates the manufacturing of replacement units, which involves energy-intensive processes and the consumption of raw materials. This additional production leads to increased greenhouse gas emissions and places further strain on natural resources.

Moreover, the disposal of failed inverters poses environmental challenges. Many inverters contain electronic components and materials that can be harmful if not properly managed. Improper disposal can result in the release of toxic substances into soil and water systems, potentially causing long-term ecological damage. The presence of heavy metals and other hazardous materials in inverters requires specialized recycling processes to mitigate environmental risks.

The transportation of replacement inverters and technicians for on-site repairs also contributes to the environmental footprint. Frequent maintenance visits and equipment replacements increase vehicle emissions, particularly in remote or widely distributed solar installations. This aspect of inverter failures adds to the overall carbon footprint of solar energy systems, partially offsetting their environmental benefits.

Inverter failures can lead to extended periods of system downtime, reducing the overall energy production of solar installations. This loss of clean energy generation may result in increased reliance on conventional power sources, potentially leading to higher fossil fuel consumption and associated emissions. The environmental impact is particularly significant in regions where the grid mix heavily relies on non-renewable energy sources.

From a lifecycle perspective, premature inverter failures shorten the effective lifespan of solar energy systems, reducing their long-term environmental benefits. The energy payback time of the entire solar installation is extended when components like inverters require frequent replacement, diminishing the net positive environmental impact of the system over its operational life.

Addressing inverter failures is crucial for maximizing the environmental benefits of solar energy. Improving inverter reliability and longevity can significantly reduce the need for replacements, thereby minimizing the associated environmental impacts. Additionally, designing inverters with recyclability and ease of repair in mind can facilitate more sustainable end-of-life management, reducing waste and promoting a circular economy approach in the solar industry.

Moreover, the disposal of failed inverters poses environmental challenges. Many inverters contain electronic components and materials that can be harmful if not properly managed. Improper disposal can result in the release of toxic substances into soil and water systems, potentially causing long-term ecological damage. The presence of heavy metals and other hazardous materials in inverters requires specialized recycling processes to mitigate environmental risks.

The transportation of replacement inverters and technicians for on-site repairs also contributes to the environmental footprint. Frequent maintenance visits and equipment replacements increase vehicle emissions, particularly in remote or widely distributed solar installations. This aspect of inverter failures adds to the overall carbon footprint of solar energy systems, partially offsetting their environmental benefits.

Inverter failures can lead to extended periods of system downtime, reducing the overall energy production of solar installations. This loss of clean energy generation may result in increased reliance on conventional power sources, potentially leading to higher fossil fuel consumption and associated emissions. The environmental impact is particularly significant in regions where the grid mix heavily relies on non-renewable energy sources.

From a lifecycle perspective, premature inverter failures shorten the effective lifespan of solar energy systems, reducing their long-term environmental benefits. The energy payback time of the entire solar installation is extended when components like inverters require frequent replacement, diminishing the net positive environmental impact of the system over its operational life.

Addressing inverter failures is crucial for maximizing the environmental benefits of solar energy. Improving inverter reliability and longevity can significantly reduce the need for replacements, thereby minimizing the associated environmental impacts. Additionally, designing inverters with recyclability and ease of repair in mind can facilitate more sustainable end-of-life management, reducing waste and promoting a circular economy approach in the solar industry.

Cost-Benefit Analysis of Inverter Maintenance Strategies

Conducting a cost-benefit analysis of inverter maintenance strategies is crucial for optimizing the performance and longevity of solar power systems. This analysis involves evaluating the financial implications of different maintenance approaches to address common solar inverter failures.

Preventive maintenance strategies typically involve regular inspections, cleaning, and component replacements based on predetermined schedules. While these strategies incur upfront costs, they can significantly reduce the likelihood of unexpected failures and extend the inverter's lifespan. The benefits include minimized downtime, improved system reliability, and potentially lower long-term repair costs.

On the other hand, reactive maintenance strategies focus on addressing issues as they arise. This approach may seem cost-effective initially due to lower upfront expenses. However, it often leads to higher repair costs, extended downtime, and potential damage to other system components when failures occur unexpectedly.

Condition-based maintenance represents a middle ground, utilizing real-time monitoring and data analysis to predict potential failures and schedule maintenance accordingly. While this strategy requires investment in monitoring equipment and software, it can optimize maintenance timing and reduce unnecessary interventions.

When comparing these strategies, it's essential to consider factors such as the inverter's age, environmental conditions, and the system's overall importance. For critical systems, the cost of downtime may outweigh the expenses of preventive maintenance. In contrast, for smaller or less critical installations, a more reactive approach might be justified.

The analysis should also account for the costs associated with each strategy, including labor, replacement parts, diagnostic tools, and potential production losses during maintenance or unexpected failures. Additionally, the impact on the inverter's efficiency and lifespan should be factored into the long-term cost calculations.

It's important to note that the optimal maintenance strategy may evolve over the inverter's lifecycle. As the equipment ages, the frequency and intensity of maintenance activities may need to increase to maintain performance and reliability.

Ultimately, the cost-benefit analysis should aim to strike a balance between minimizing maintenance costs and maximizing system uptime and longevity. This balance will vary depending on the specific circumstances of each solar installation, including its size, location, and operational requirements.

Preventive maintenance strategies typically involve regular inspections, cleaning, and component replacements based on predetermined schedules. While these strategies incur upfront costs, they can significantly reduce the likelihood of unexpected failures and extend the inverter's lifespan. The benefits include minimized downtime, improved system reliability, and potentially lower long-term repair costs.

On the other hand, reactive maintenance strategies focus on addressing issues as they arise. This approach may seem cost-effective initially due to lower upfront expenses. However, it often leads to higher repair costs, extended downtime, and potential damage to other system components when failures occur unexpectedly.

Condition-based maintenance represents a middle ground, utilizing real-time monitoring and data analysis to predict potential failures and schedule maintenance accordingly. While this strategy requires investment in monitoring equipment and software, it can optimize maintenance timing and reduce unnecessary interventions.

When comparing these strategies, it's essential to consider factors such as the inverter's age, environmental conditions, and the system's overall importance. For critical systems, the cost of downtime may outweigh the expenses of preventive maintenance. In contrast, for smaller or less critical installations, a more reactive approach might be justified.

The analysis should also account for the costs associated with each strategy, including labor, replacement parts, diagnostic tools, and potential production losses during maintenance or unexpected failures. Additionally, the impact on the inverter's efficiency and lifespan should be factored into the long-term cost calculations.

It's important to note that the optimal maintenance strategy may evolve over the inverter's lifecycle. As the equipment ages, the frequency and intensity of maintenance activities may need to increase to maintain performance and reliability.

Ultimately, the cost-benefit analysis should aim to strike a balance between minimizing maintenance costs and maximizing system uptime and longevity. This balance will vary depending on the specific circumstances of each solar installation, including its size, location, and operational requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!