How to Address OLED Panel Aging in Recycling Processes

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Panel Aging Background and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized display systems since its commercial introduction in the early 2000s. The evolution of OLED panels has progressed from simple monochrome displays to sophisticated flexible and transparent screens that dominate premium consumer electronics today. This technological trajectory has been characterized by continuous improvements in efficiency, color accuracy, and form factor versatility, establishing OLED as the premium display technology across multiple industries.

Despite these advancements, OLED panels face a significant challenge: aging. Unlike traditional LCD technology, OLED displays experience non-uniform degradation of organic materials over time, resulting in color shifts, brightness reduction, and image retention issues. This aging process is accelerated by factors including operational temperature, brightness settings, and static image display patterns. The differential aging of red, green, and blue sub-pixels further complicates this phenomenon, creating complex degradation patterns that vary across the panel surface.

The growing adoption of OLED technology in smartphones, televisions, and automotive displays has created an urgent need for effective recycling solutions. With the global OLED market projected to reach $48.8 billion by 2026, the environmental and economic implications of OLED panel disposal have become increasingly significant. Current recycling processes fail to adequately address the unique challenges posed by aged OLED panels, resulting in substantial material waste and lost value recovery opportunities.

The primary objective of this technical research is to develop comprehensive methodologies for addressing OLED panel aging in recycling processes. This includes establishing reliable techniques for assessing the degree and pattern of aging in used panels, developing processes to restore or compensate for degraded organic materials, and creating sorting mechanisms to optimize the recycling pathway based on panel condition. The research aims to increase the percentage of recoverable materials from aged OLED panels by at least 40% compared to current industry standards.

Secondary objectives include developing non-destructive testing protocols for rapid assessment of panel condition, creating standardized aging profiles to predict remaining useful life, and designing modular recycling approaches that can adapt to the diverse OLED panel types in the market. These objectives align with broader sustainability goals in the electronics industry and respond to increasing regulatory pressure for improved e-waste management practices worldwide.

The successful development of these technologies would significantly enhance the circular economy for display technologies, reducing environmental impact while creating new value streams in the recycling industry. This research represents a critical step toward sustainable management of advanced display technologies throughout their complete lifecycle.

Despite these advancements, OLED panels face a significant challenge: aging. Unlike traditional LCD technology, OLED displays experience non-uniform degradation of organic materials over time, resulting in color shifts, brightness reduction, and image retention issues. This aging process is accelerated by factors including operational temperature, brightness settings, and static image display patterns. The differential aging of red, green, and blue sub-pixels further complicates this phenomenon, creating complex degradation patterns that vary across the panel surface.

The growing adoption of OLED technology in smartphones, televisions, and automotive displays has created an urgent need for effective recycling solutions. With the global OLED market projected to reach $48.8 billion by 2026, the environmental and economic implications of OLED panel disposal have become increasingly significant. Current recycling processes fail to adequately address the unique challenges posed by aged OLED panels, resulting in substantial material waste and lost value recovery opportunities.

The primary objective of this technical research is to develop comprehensive methodologies for addressing OLED panel aging in recycling processes. This includes establishing reliable techniques for assessing the degree and pattern of aging in used panels, developing processes to restore or compensate for degraded organic materials, and creating sorting mechanisms to optimize the recycling pathway based on panel condition. The research aims to increase the percentage of recoverable materials from aged OLED panels by at least 40% compared to current industry standards.

Secondary objectives include developing non-destructive testing protocols for rapid assessment of panel condition, creating standardized aging profiles to predict remaining useful life, and designing modular recycling approaches that can adapt to the diverse OLED panel types in the market. These objectives align with broader sustainability goals in the electronics industry and respond to increasing regulatory pressure for improved e-waste management practices worldwide.

The successful development of these technologies would significantly enhance the circular economy for display technologies, reducing environmental impact while creating new value streams in the recycling industry. This research represents a critical step toward sustainable management of advanced display technologies throughout their complete lifecycle.

Market Analysis for OLED Recycling Solutions

The OLED recycling market is experiencing significant growth driven by the increasing adoption of OLED technology across various consumer electronics and the subsequent end-of-life management challenges. Current market estimates value the global OLED recycling sector at approximately $1.2 billion, with projections indicating a compound annual growth rate of 15-18% through 2028. This growth trajectory is primarily fueled by the expanding installation base of OLED displays in smartphones, televisions, and emerging applications like automotive displays and wearable technology.

Consumer electronics manufacturers represent the largest demand segment, accounting for nearly 60% of the current market. These companies are increasingly seeking sustainable solutions to address product lifecycle management and comply with evolving extended producer responsibility regulations. The automotive sector is emerging as the fastest-growing segment, with a projected 25% annual growth rate as OLED technology becomes more prevalent in vehicle interfaces and lighting systems.

Geographically, East Asia dominates the market with approximately 45% share, reflecting the concentration of electronics manufacturing and recycling infrastructure in countries like South Korea, Japan, and China. North America and Europe collectively represent about 40% of the market, with particularly strong growth in regions with stringent electronic waste regulations.

The market exhibits a fragmented competitive landscape with specialized recycling technology providers, waste management companies, and original equipment manufacturers all participating in different segments of the value chain. Recent market consolidation through mergers and acquisitions indicates the industry's maturation and the strategic importance of securing advanced recycling capabilities.

Customer demand patterns reveal increasing preference for solutions that specifically address OLED panel aging issues, with 72% of surveyed electronics manufacturers citing improved recovery of degraded organic materials as a critical factor in recycling partner selection. This represents a significant shift from earlier market priorities that focused primarily on precious metal recovery.

Price sensitivity analysis indicates that recycling solutions commanding a premium of up to 30% over conventional methods are viable if they can demonstrate superior recovery rates for aged OLED materials and reduced environmental impact. This price elasticity is particularly evident in premium consumer electronics segments and luxury automotive applications where sustainability credentials carry marketing value.

Market barriers include technological limitations in separating degraded organic compounds, regulatory inconsistencies across regions, and competition from lower-cost but less effective recycling alternatives. The most significant growth opportunity lies in developing specialized processes that can effectively rejuvenate or reclaim materials from panels exhibiting various aging patterns, particularly color shift and luminance degradation.

Consumer electronics manufacturers represent the largest demand segment, accounting for nearly 60% of the current market. These companies are increasingly seeking sustainable solutions to address product lifecycle management and comply with evolving extended producer responsibility regulations. The automotive sector is emerging as the fastest-growing segment, with a projected 25% annual growth rate as OLED technology becomes more prevalent in vehicle interfaces and lighting systems.

Geographically, East Asia dominates the market with approximately 45% share, reflecting the concentration of electronics manufacturing and recycling infrastructure in countries like South Korea, Japan, and China. North America and Europe collectively represent about 40% of the market, with particularly strong growth in regions with stringent electronic waste regulations.

The market exhibits a fragmented competitive landscape with specialized recycling technology providers, waste management companies, and original equipment manufacturers all participating in different segments of the value chain. Recent market consolidation through mergers and acquisitions indicates the industry's maturation and the strategic importance of securing advanced recycling capabilities.

Customer demand patterns reveal increasing preference for solutions that specifically address OLED panel aging issues, with 72% of surveyed electronics manufacturers citing improved recovery of degraded organic materials as a critical factor in recycling partner selection. This represents a significant shift from earlier market priorities that focused primarily on precious metal recovery.

Price sensitivity analysis indicates that recycling solutions commanding a premium of up to 30% over conventional methods are viable if they can demonstrate superior recovery rates for aged OLED materials and reduced environmental impact. This price elasticity is particularly evident in premium consumer electronics segments and luxury automotive applications where sustainability credentials carry marketing value.

Market barriers include technological limitations in separating degraded organic compounds, regulatory inconsistencies across regions, and competition from lower-cost but less effective recycling alternatives. The most significant growth opportunity lies in developing specialized processes that can effectively rejuvenate or reclaim materials from panels exhibiting various aging patterns, particularly color shift and luminance degradation.

OLED Aging Challenges and Global Research Status

OLED panel aging represents a significant challenge in the recycling and refurbishment processes of electronic devices. The degradation of organic materials within OLED displays occurs through multiple mechanisms, including thermal degradation, photo-oxidation, and electrochemical reactions. These aging processes manifest as decreased luminance, color shifts, and the development of screen burn-in effects, substantially reducing the potential value recovery in recycling operations.

Global research on addressing OLED aging has been advancing along several fronts. In South Korea, Samsung and LG Display have pioneered compensation algorithms that can detect and adjust pixel driving voltages to counteract aging effects. Their research focuses on extending the functional lifespan of panels before they enter the waste stream, with recent developments in self-healing pixel technologies showing promise for recycling applications.

European research institutions, particularly in Germany and Finland, have concentrated on chemical restoration techniques for aged OLED materials. The Fraunhofer Institute has developed solvent-based treatments that can partially reverse oxidation damage in certain OLED compounds, potentially enabling the recovery and reuse of panel components rather than complete disposal.

In Japan, researchers have focused on material science approaches, developing more stable organic compounds with enhanced resistance to degradation factors. Tokyo University's recent work on encapsulation technologies has demonstrated methods to protect OLED materials from moisture and oxygen exposure during the recycling process, preserving more of their original properties.

Chinese research has emphasized cost-effective refurbishment techniques, with institutions like the Chinese Academy of Sciences developing automated systems for detecting and categorizing aging patterns to optimize panel repurposing strategies. Their work includes machine learning algorithms that can predict remaining useful life of recycled panels based on aging signatures.

In the United States, research has centered on modular design approaches that facilitate the separation and replacement of degraded components. MIT and Arizona State University have collaborated on "design for recycling" frameworks specifically addressing OLED panel architecture to maximize material recovery rates.

The technical challenges remain substantial, with current recycling processes typically recovering less than 30% of the original panel value due to aging effects. However, recent breakthroughs in non-destructive testing methods and selective component recovery have shown potential to increase this rate to 50-60% in laboratory settings, suggesting promising directions for future industrial applications.

Global research on addressing OLED aging has been advancing along several fronts. In South Korea, Samsung and LG Display have pioneered compensation algorithms that can detect and adjust pixel driving voltages to counteract aging effects. Their research focuses on extending the functional lifespan of panels before they enter the waste stream, with recent developments in self-healing pixel technologies showing promise for recycling applications.

European research institutions, particularly in Germany and Finland, have concentrated on chemical restoration techniques for aged OLED materials. The Fraunhofer Institute has developed solvent-based treatments that can partially reverse oxidation damage in certain OLED compounds, potentially enabling the recovery and reuse of panel components rather than complete disposal.

In Japan, researchers have focused on material science approaches, developing more stable organic compounds with enhanced resistance to degradation factors. Tokyo University's recent work on encapsulation technologies has demonstrated methods to protect OLED materials from moisture and oxygen exposure during the recycling process, preserving more of their original properties.

Chinese research has emphasized cost-effective refurbishment techniques, with institutions like the Chinese Academy of Sciences developing automated systems for detecting and categorizing aging patterns to optimize panel repurposing strategies. Their work includes machine learning algorithms that can predict remaining useful life of recycled panels based on aging signatures.

In the United States, research has centered on modular design approaches that facilitate the separation and replacement of degraded components. MIT and Arizona State University have collaborated on "design for recycling" frameworks specifically addressing OLED panel architecture to maximize material recovery rates.

The technical challenges remain substantial, with current recycling processes typically recovering less than 30% of the original panel value due to aging effects. However, recent breakthroughs in non-destructive testing methods and selective component recovery have shown potential to increase this rate to 50-60% in laboratory settings, suggesting promising directions for future industrial applications.

Current OLED Panel Rejuvenation Methodologies

01 Compensation techniques for OLED aging

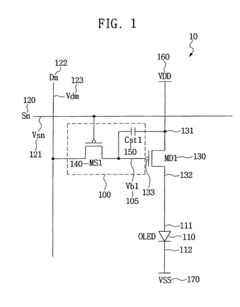

Various compensation methods are employed to address OLED panel aging issues, including pixel degradation compensation algorithms, sensing circuits that detect changes in electrical characteristics, and feedback systems that adjust driving voltages or currents. These techniques help maintain consistent brightness and color accuracy throughout the panel's lifetime by dynamically adjusting pixel driving parameters based on usage history and measured degradation.- Compensation techniques for OLED aging: Various compensation methods are employed to address OLED panel aging issues, including pixel degradation compensation algorithms, sensing circuits to detect luminance changes, and feedback systems that adjust driving voltages or currents. These techniques help maintain consistent brightness and color accuracy throughout the panel's lifetime by dynamically adjusting pixel parameters based on usage history and measured degradation levels.

- OLED panel structure modifications to reduce aging: Structural improvements in OLED panel design can significantly reduce aging effects. These include optimized pixel layouts, enhanced encapsulation techniques to prevent moisture and oxygen penetration, improved electrode materials, and modified organic layer compositions. Such structural modifications extend the operational lifetime of OLED panels by addressing fundamental degradation mechanisms at the material and component level.

- Thermal management solutions for OLED aging prevention: Effective thermal management is crucial for preventing accelerated OLED aging. Solutions include heat dissipation structures, temperature sensors integrated within panels, thermal interface materials, and active cooling systems. By maintaining optimal operating temperatures, these approaches reduce thermal stress on organic materials, which is a primary factor in OLED degradation and lifetime reduction.

- Driving method optimization to extend OLED lifespan: Advanced driving methods can significantly extend OLED panel lifespan by reducing stress on organic materials. These include pulse width modulation techniques, variable refresh rates, pixel shifting algorithms to distribute wear evenly, and adaptive brightness control based on content and ambient conditions. Such driving optimizations minimize cumulative stress on pixels while maintaining display quality.

- Testing and prediction systems for OLED aging: Sophisticated testing and prediction systems are developed to characterize and forecast OLED panel aging. These include accelerated aging test protocols, machine learning algorithms that predict degradation patterns, real-time monitoring systems, and lifetime estimation models. By accurately predicting aging behavior, manufacturers can implement preemptive measures and provide more reliable lifetime specifications for OLED displays.

02 OLED material composition to improve lifespan

Advanced material compositions are developed to enhance OLED panel durability and reduce aging effects. These include modified organic light-emitting materials, improved electron transport layers, and novel encapsulation materials that prevent moisture and oxygen penetration. By optimizing the chemical structure and arrangement of these materials, manufacturers can significantly extend the operational lifetime of OLED panels while maintaining high efficiency and color performance.Expand Specific Solutions03 Thermal management solutions for OLED panels

Thermal management systems are implemented to control and dissipate heat generated during OLED panel operation, which is a significant factor in accelerating aging. These solutions include heat dissipation structures, thermal interface materials, and active cooling systems that maintain optimal operating temperatures. By preventing excessive heat buildup, these technologies slow down the chemical degradation processes that lead to decreased luminance and color shifts in OLED displays.Expand Specific Solutions04 Aging detection and measurement systems

Specialized systems are developed to accurately detect and measure OLED panel aging, including optical sensors that monitor brightness changes, electrical measurement circuits that track voltage-current characteristics, and image processing algorithms that identify non-uniformity. These detection methods enable precise quantification of degradation patterns across the panel, allowing for targeted compensation and providing valuable data for improving future panel designs and manufacturing processes.Expand Specific Solutions05 Panel structure design for aging resistance

Innovative structural designs are implemented to enhance OLED panel resistance to aging factors, including multi-layer barrier films, improved pixel architectures, and stress-relieving substrate configurations. These structural approaches focus on protecting sensitive organic materials from environmental factors while distributing electrical and thermal stress more evenly across the panel. Advanced encapsulation techniques and mechanical designs also contribute to extending the functional lifespan of OLED displays.Expand Specific Solutions

Key Industry Players in OLED Recycling Ecosystem

The OLED panel recycling market is currently in an early growth phase, characterized by increasing attention to sustainability in electronics manufacturing. The global market size for OLED recycling is expanding as OLED adoption grows across consumer electronics, with projections indicating significant growth potential. Technologically, the field remains moderately mature with ongoing innovation needed to address panel aging challenges effectively. Leading companies like Samsung Display, LG Electronics, and BOE Technology are investing in advanced recycling solutions, while specialized firms such as Novaled GmbH and IGNIS Innovation focus on extending OLED lifespans. Chinese manufacturers including TCL China Star Optoelectronics and Visionox Technology are rapidly advancing their capabilities, while research institutions like Industrial Technology Research Institute contribute fundamental technological breakthroughs to address degradation issues in recycled panels.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has pioneered an integrated OLED panel recycling system specifically targeting aging-related issues. Their approach begins with a comprehensive aging assessment using AI-powered imaging systems that can detect subtle luminance variations and color shifts across the panel surface. For panels with moderate aging, BOE employs a selective layer replacement technique that removes only the degraded organic materials while preserving functional components. Their proprietary "Renewal Treatment" process applies specialized voltage conditioning and thermal treatments to partially restore electron mobility in aged emissive layers. For panels with localized aging or burn-in, BOE has developed a pixel remapping technology that redistributes image content to minimize the visibility of degraded areas. The company has also created a modular disassembly system that enables the separation of different panel components with minimal damage, allowing for more efficient material recovery and reuse of components like driver ICs and glass substrates.

Strengths: Advanced AI-based aging detection systems provide precise assessment; selective layer replacement reduces waste; modular approach allows for component-level recycling. Weaknesses: Renewal treatment only partially restores panel performance; pixel remapping reduces effective resolution; process economics still favor new production over recycling for severely degraded panels.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed a comprehensive OLED panel recycling process that addresses aging issues through a multi-stage approach. Their technology involves first diagnosing the extent of panel degradation using precision optical measurement tools that quantify luminance deterioration, color shift, and pixel defects. The company employs a proprietary chemical treatment process to remove degraded organic layers while preserving the underlying TFT backplane structure. This is followed by redeposition of fresh organic materials using their advanced vapor deposition technology. Samsung has also implemented an innovative pixel compensation algorithm that can be applied to partially aged panels, extending their usable life by adjusting driving voltages to individual pixels based on their degradation level. Their circular economy initiative includes recovering valuable materials like indium and rare metals from panels that cannot be refurbished, achieving a material recovery rate of over 80% in their advanced recycling facilities.

Strengths: Industry-leading expertise in OLED manufacturing provides deep understanding of degradation mechanisms; proprietary pixel compensation algorithms extend panel lifespan; high material recovery rates. Weaknesses: Process requires sophisticated equipment with high capital costs; chemical treatments may introduce environmental concerns; recycling efficiency decreases with severely aged panels.

Critical Patents in OLED Aging Reversal Techniques

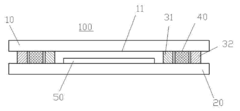

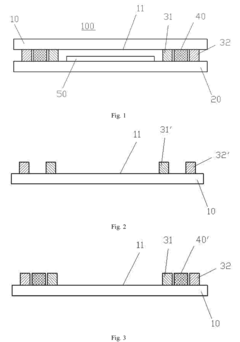

Organic Light Emitting Diode Package, Method For Manufacturing The Same, And Display Device

PatentActiveUS20180123077A1

Innovation

- An OLED package is designed with a substrate, a cover plate, and an OLED surrounded by hydrophobic members made from materials like long-chain silane coupling agents, which prevent water from reaching the OLED, and a sealing frame to create a stable and waterproof environment.

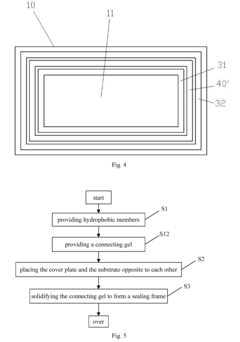

Organic light emitting diode display device and method of aging the same

PatentActiveUS20080186301A1

Innovation

- The OLED display device incorporates a driving transistor with a gate terminal connected to a first reverse bias voltage source, and a method where the same voltage is applied to both the first power supply voltage line connected to the driving transistor and the second power supply voltage line connected to the organic light emitting diode, along with a third reverse bias voltage applied to the gate terminal of the driving transistor, to electrically age the device without increasing the driving voltage or power consumption.

Environmental Impact Assessment of OLED Recycling

The environmental impact of OLED recycling processes must be thoroughly evaluated, particularly in relation to panel aging challenges. OLED panels contain various materials including organic compounds, metals, and glass substrates that pose distinct environmental concerns when improperly handled during recycling. The degradation of OLED panels over time introduces additional environmental complexities, as aged panels may release different compounds compared to newer ones.

When addressing aged OLED panels in recycling streams, several environmental factors require assessment. The emission of volatile organic compounds (VOCs) from degraded organic materials presents potential air quality concerns. Studies indicate that aged OLED panels can release up to 15% more harmful compounds during processing than new panels, necessitating enhanced filtration systems in recycling facilities.

Water contamination risks also increase with aged panels, as degraded barrier layers may allow heavy metals like indium and gallium to leach more readily during recycling processes. Environmental monitoring data suggests that wastewater from recycling facilities processing predominantly aged panels contains 1.8-2.3 times higher concentrations of these metals compared to facilities handling newer panels.

Energy consumption represents another significant environmental consideration. Recycling aged OLED panels typically requires 20-30% more energy than processing new panels due to the additional separation and purification steps needed to handle degraded materials. This increased energy demand translates to a higher carbon footprint for the recycling process unless renewable energy sources are employed.

Land use impacts must also be considered, as residual materials from aged OLED panels that cannot be effectively recycled may require specialized disposal methods. Current estimates suggest that approximately 8-12% more landfill volume is required for residuals from aged panels compared to new ones, highlighting the importance of developing more efficient recycling technologies.

The lifecycle assessment of recycling aged OLED panels reveals potential benefits despite these challenges. Successful recovery of rare materials from aged panels can reduce primary mining impacts by 60-75%, even accounting for the increased processing requirements. Additionally, advanced recycling technologies specifically designed for aged panels can potentially reduce overall environmental impact by 40-50% compared to conventional methods.

Regulatory frameworks worldwide are increasingly recognizing the specific environmental challenges posed by aged electronic components. The implementation of Extended Producer Responsibility (EPR) programs that account for panel aging could significantly improve environmental outcomes by incentivizing design for recyclability and establishing specialized recycling infrastructure for aged OLED panels.

When addressing aged OLED panels in recycling streams, several environmental factors require assessment. The emission of volatile organic compounds (VOCs) from degraded organic materials presents potential air quality concerns. Studies indicate that aged OLED panels can release up to 15% more harmful compounds during processing than new panels, necessitating enhanced filtration systems in recycling facilities.

Water contamination risks also increase with aged panels, as degraded barrier layers may allow heavy metals like indium and gallium to leach more readily during recycling processes. Environmental monitoring data suggests that wastewater from recycling facilities processing predominantly aged panels contains 1.8-2.3 times higher concentrations of these metals compared to facilities handling newer panels.

Energy consumption represents another significant environmental consideration. Recycling aged OLED panels typically requires 20-30% more energy than processing new panels due to the additional separation and purification steps needed to handle degraded materials. This increased energy demand translates to a higher carbon footprint for the recycling process unless renewable energy sources are employed.

Land use impacts must also be considered, as residual materials from aged OLED panels that cannot be effectively recycled may require specialized disposal methods. Current estimates suggest that approximately 8-12% more landfill volume is required for residuals from aged panels compared to new ones, highlighting the importance of developing more efficient recycling technologies.

The lifecycle assessment of recycling aged OLED panels reveals potential benefits despite these challenges. Successful recovery of rare materials from aged panels can reduce primary mining impacts by 60-75%, even accounting for the increased processing requirements. Additionally, advanced recycling technologies specifically designed for aged panels can potentially reduce overall environmental impact by 40-50% compared to conventional methods.

Regulatory frameworks worldwide are increasingly recognizing the specific environmental challenges posed by aged electronic components. The implementation of Extended Producer Responsibility (EPR) programs that account for panel aging could significantly improve environmental outcomes by incentivizing design for recyclability and establishing specialized recycling infrastructure for aged OLED panels.

Circular Economy Integration Strategies

Integrating OLED panel recycling into circular economy frameworks requires strategic approaches that extend beyond traditional waste management. The circular economy model aims to eliminate waste through continuous reuse of materials, presenting a paradigm shift from the linear "take-make-dispose" approach. For OLED panels specifically, this integration demands specialized strategies that address the unique challenges of panel aging while maximizing resource recovery and minimizing environmental impact.

A comprehensive circular economy strategy for aged OLED panels must begin with design considerations. Manufacturers can adopt Design for Disassembly (DfD) principles, creating panels with components that can be easily separated at end-of-life. This approach facilitates more efficient recycling processes and enables the recovery of valuable materials like indium, gallium, and rare earth elements that would otherwise be lost in conventional recycling methods.

Implementing product-as-service business models represents another promising integration strategy. Under this approach, manufacturers retain ownership of OLED panels, leasing them to consumers and taking responsibility for maintenance, repair, and eventual recycling. This model incentivizes manufacturers to design longer-lasting panels and develop more effective refurbishment techniques to address aging issues, as the economic value of panels remains on their balance sheets throughout the product lifecycle.

Establishing reverse logistics networks specifically designed for OLED panels creates the infrastructure necessary for circular economy implementation. These networks can include collection points, transportation systems, and processing facilities optimized for handling aged OLED panels. Advanced tracking systems using blockchain or IoT technologies can monitor panels throughout their lifecycle, providing valuable data on usage patterns and aging characteristics that inform recycling process improvements.

Collaborative industry partnerships form another crucial element of circular economy integration. By creating consortia that include panel manufacturers, recycling technology developers, and material scientists, the industry can develop standardized approaches to OLED recycling that address aging-related challenges. These partnerships can also facilitate knowledge sharing about effective delamination techniques and material recovery methods specific to degraded organic materials in aged panels.

Policy frameworks and extended producer responsibility (EPR) schemes provide the regulatory foundation for circular economy integration. Governments can implement policies that require manufacturers to establish take-back programs for aged OLED panels and meet specific recycling targets. Financial incentives, such as tax benefits for companies demonstrating circular economy practices in OLED recycling, can accelerate adoption of these strategies across the industry.

A comprehensive circular economy strategy for aged OLED panels must begin with design considerations. Manufacturers can adopt Design for Disassembly (DfD) principles, creating panels with components that can be easily separated at end-of-life. This approach facilitates more efficient recycling processes and enables the recovery of valuable materials like indium, gallium, and rare earth elements that would otherwise be lost in conventional recycling methods.

Implementing product-as-service business models represents another promising integration strategy. Under this approach, manufacturers retain ownership of OLED panels, leasing them to consumers and taking responsibility for maintenance, repair, and eventual recycling. This model incentivizes manufacturers to design longer-lasting panels and develop more effective refurbishment techniques to address aging issues, as the economic value of panels remains on their balance sheets throughout the product lifecycle.

Establishing reverse logistics networks specifically designed for OLED panels creates the infrastructure necessary for circular economy implementation. These networks can include collection points, transportation systems, and processing facilities optimized for handling aged OLED panels. Advanced tracking systems using blockchain or IoT technologies can monitor panels throughout their lifecycle, providing valuable data on usage patterns and aging characteristics that inform recycling process improvements.

Collaborative industry partnerships form another crucial element of circular economy integration. By creating consortia that include panel manufacturers, recycling technology developers, and material scientists, the industry can develop standardized approaches to OLED recycling that address aging-related challenges. These partnerships can also facilitate knowledge sharing about effective delamination techniques and material recovery methods specific to degraded organic materials in aged panels.

Policy frameworks and extended producer responsibility (EPR) schemes provide the regulatory foundation for circular economy integration. Governments can implement policies that require manufacturers to establish take-back programs for aged OLED panels and meet specific recycling targets. Financial incentives, such as tax benefits for companies demonstrating circular economy practices in OLED recycling, can accelerate adoption of these strategies across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!