OLED Phosphorescent Lifetimes vs Fluorescent: Performance Study

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Emission Technology Background and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized display and lighting industries since its inception in the late 1980s. The evolution of OLED emission technologies has progressed through several distinct phases, from the early fluorescent-based systems to the more efficient phosphorescent emitters and recent developments in thermally activated delayed fluorescence (TADF). This technological progression has been driven by the fundamental need to improve energy efficiency, color purity, and operational lifetime of OLED devices.

The fundamental difference between fluorescent and phosphorescent emission mechanisms lies in their quantum mechanical properties. Fluorescent emitters utilize singlet excitons only, theoretically limiting their internal quantum efficiency to 25%, while phosphorescent materials can harvest both singlet and triplet excitons, potentially achieving 100% internal quantum efficiency. This efficiency gap represents one of the most significant technological hurdles that has shaped research directions in the field.

Market demands for higher display resolution, reduced power consumption, and extended device lifetimes have accelerated research into understanding and improving the operational stability of different emission technologies. Phosphorescent materials, while offering superior efficiency, have historically struggled with shorter operational lifetimes compared to their fluorescent counterparts, particularly in blue emission regions.

The current technological landscape shows a hybrid approach in commercial applications, with phosphorescent materials dominating green and red emission layers, while fluorescent materials remain prevalent for blue emission due to stability concerns. This dichotomy highlights the critical importance of understanding the relationship between emission mechanism and operational lifetime.

Recent advancements in molecular design, host materials, and device architectures have narrowed the lifetime gap between these technologies. Developments in exciton management strategies, such as triplet-triplet annihilation control and excited-state quenching prevention, have shown promising results in extending phosphorescent emitter lifetimes.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of phosphorescent and fluorescent OLED technologies, with specific focus on their operational lifetimes under various driving conditions. This study aims to identify the fundamental degradation mechanisms affecting each technology, quantify the performance trade-offs between efficiency and stability, and establish predictive models for lifetime estimation based on molecular structure and device architecture.

Additionally, this research seeks to explore emerging hybrid approaches that combine the advantages of both emission mechanisms, potentially offering pathways to overcome current limitations. The findings will inform future material design strategies and device optimization techniques to achieve the ideal balance of efficiency and longevity in next-generation OLED displays and lighting solutions.

The fundamental difference between fluorescent and phosphorescent emission mechanisms lies in their quantum mechanical properties. Fluorescent emitters utilize singlet excitons only, theoretically limiting their internal quantum efficiency to 25%, while phosphorescent materials can harvest both singlet and triplet excitons, potentially achieving 100% internal quantum efficiency. This efficiency gap represents one of the most significant technological hurdles that has shaped research directions in the field.

Market demands for higher display resolution, reduced power consumption, and extended device lifetimes have accelerated research into understanding and improving the operational stability of different emission technologies. Phosphorescent materials, while offering superior efficiency, have historically struggled with shorter operational lifetimes compared to their fluorescent counterparts, particularly in blue emission regions.

The current technological landscape shows a hybrid approach in commercial applications, with phosphorescent materials dominating green and red emission layers, while fluorescent materials remain prevalent for blue emission due to stability concerns. This dichotomy highlights the critical importance of understanding the relationship between emission mechanism and operational lifetime.

Recent advancements in molecular design, host materials, and device architectures have narrowed the lifetime gap between these technologies. Developments in exciton management strategies, such as triplet-triplet annihilation control and excited-state quenching prevention, have shown promising results in extending phosphorescent emitter lifetimes.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of phosphorescent and fluorescent OLED technologies, with specific focus on their operational lifetimes under various driving conditions. This study aims to identify the fundamental degradation mechanisms affecting each technology, quantify the performance trade-offs between efficiency and stability, and establish predictive models for lifetime estimation based on molecular structure and device architecture.

Additionally, this research seeks to explore emerging hybrid approaches that combine the advantages of both emission mechanisms, potentially offering pathways to overcome current limitations. The findings will inform future material design strategies and device optimization techniques to achieve the ideal balance of efficiency and longevity in next-generation OLED displays and lighting solutions.

Market Analysis for Phosphorescent vs Fluorescent OLED Applications

The OLED display market has witnessed significant growth over the past decade, with phosphorescent and fluorescent technologies competing for dominance across various application segments. Currently, the global OLED market is valued at approximately 48 billion USD, with projections indicating growth to reach 72 billion USD by 2026, representing a compound annual growth rate of 8.5%.

Phosphorescent OLED (PHOLED) technology has captured substantial market share in premium display applications, particularly in high-end smartphones and televisions. This dominance stems from PHOLED's superior energy efficiency, with devices utilizing this technology consuming 25-40% less power than their fluorescent counterparts. Major smartphone manufacturers have increasingly adopted PHOLED displays, with the technology now present in over 70% of flagship devices.

Fluorescent OLED technology, despite its efficiency limitations, maintains relevance in specific market segments where cost considerations outweigh performance requirements. The technology holds approximately 30% market share in mid-range consumer electronics and continues to serve as an entry-level solution for manufacturers seeking to transition from LCD to OLED displays without significant cost increases.

Market segmentation analysis reveals distinct application preferences between these technologies. The automotive industry has shown growing interest in PHOLED technology, with premium vehicle manufacturers incorporating these displays into dashboard systems and entertainment consoles. Industry reports indicate that the automotive OLED market segment is growing at 12% annually, with phosphorescent technology accounting for 65% of implementations.

Consumer electronics beyond smartphones and televisions represent an expanding market for both technologies. Wearable devices favor phosphorescent technology due to battery life considerations, while home appliances and secondary displays often utilize fluorescent technology where extended operational lifetimes are less critical.

Regional market analysis shows Asia-Pacific dominating OLED manufacturing, with South Korea and China accounting for 78% of global production capacity. North American and European markets primarily serve as consumption regions, with higher adoption rates for phosphorescent technology due to consumer preference for premium products with enhanced energy efficiency.

The pricing differential between phosphorescent and fluorescent technologies has narrowed from 40% in 2015 to approximately 15% in 2023, accelerating market penetration for phosphorescent displays. This convergence has particularly impacted the mid-range smartphone segment, where manufacturers increasingly opt for phosphorescent technology to differentiate their products.

Future market projections indicate phosphorescent technology will continue expanding its market share, potentially reaching 85% of the OLED display market by 2028. This growth trajectory is supported by ongoing improvements in manufacturing processes that continue to reduce production costs while maintaining performance advantages.

Phosphorescent OLED (PHOLED) technology has captured substantial market share in premium display applications, particularly in high-end smartphones and televisions. This dominance stems from PHOLED's superior energy efficiency, with devices utilizing this technology consuming 25-40% less power than their fluorescent counterparts. Major smartphone manufacturers have increasingly adopted PHOLED displays, with the technology now present in over 70% of flagship devices.

Fluorescent OLED technology, despite its efficiency limitations, maintains relevance in specific market segments where cost considerations outweigh performance requirements. The technology holds approximately 30% market share in mid-range consumer electronics and continues to serve as an entry-level solution for manufacturers seeking to transition from LCD to OLED displays without significant cost increases.

Market segmentation analysis reveals distinct application preferences between these technologies. The automotive industry has shown growing interest in PHOLED technology, with premium vehicle manufacturers incorporating these displays into dashboard systems and entertainment consoles. Industry reports indicate that the automotive OLED market segment is growing at 12% annually, with phosphorescent technology accounting for 65% of implementations.

Consumer electronics beyond smartphones and televisions represent an expanding market for both technologies. Wearable devices favor phosphorescent technology due to battery life considerations, while home appliances and secondary displays often utilize fluorescent technology where extended operational lifetimes are less critical.

Regional market analysis shows Asia-Pacific dominating OLED manufacturing, with South Korea and China accounting for 78% of global production capacity. North American and European markets primarily serve as consumption regions, with higher adoption rates for phosphorescent technology due to consumer preference for premium products with enhanced energy efficiency.

The pricing differential between phosphorescent and fluorescent technologies has narrowed from 40% in 2015 to approximately 15% in 2023, accelerating market penetration for phosphorescent displays. This convergence has particularly impacted the mid-range smartphone segment, where manufacturers increasingly opt for phosphorescent technology to differentiate their products.

Future market projections indicate phosphorescent technology will continue expanding its market share, potentially reaching 85% of the OLED display market by 2028. This growth trajectory is supported by ongoing improvements in manufacturing processes that continue to reduce production costs while maintaining performance advantages.

Current Technical Limitations and Challenges in OLED Lifetime

Despite significant advancements in OLED technology, several critical limitations continue to challenge the improvement of device lifetimes, particularly when comparing phosphorescent and fluorescent emitters. The operational lifetime of OLEDs remains a primary concern for commercial applications, with phosphorescent devices typically exhibiting shorter lifetimes than their fluorescent counterparts despite superior efficiency.

The degradation mechanisms in phosphorescent OLEDs (PhOLEDs) present complex challenges. The triplet exciton, which enables the high efficiency of phosphorescent materials, paradoxically contributes to accelerated degradation. These long-lived triplet states increase the probability of detrimental interactions with charge carriers and other excited states, leading to molecular decomposition of the emitter complexes.

Thermal stability represents another significant limitation, particularly for blue phosphorescent emitters. The high energy required for blue emission often leads to bond breaking within the organometallic complexes, resulting in rapid degradation under operational conditions. This thermal instability is exacerbated by Joule heating during device operation, creating a self-accelerating degradation cycle.

Exciton-polaron interactions constitute a major degradation pathway in PhOLEDs. When triplet excitons interact with polarons (charged carriers), they can form highly reactive species that attack the emitter molecules and host materials. This process is particularly problematic in phosphorescent systems due to the extended lifetime of triplet states, which increases the probability of such interactions.

Chemical stability of the iridium complexes commonly used in phosphorescent emitters presents another challenge. The metal-ligand bonds in these complexes can undergo irreversible chemical changes during operation, particularly under high current densities or elevated temperatures. These changes alter the emission properties and reduce quantum efficiency over time.

Interface degradation between the various functional layers in OLEDs significantly impacts device lifetime. The accumulation of charges at interfaces can lead to electrochemical reactions, material mixing, and morphological changes that compromise device performance. This effect is often more pronounced in phosphorescent devices due to their complex multi-layer architectures.

Blue phosphorescent emitters face particularly severe lifetime limitations compared to green and red counterparts. The high-energy triplet states in blue emitters are more susceptible to non-radiative deactivation pathways and chemical degradation. Despite extensive research efforts, the development of stable deep blue phosphorescent emitters with acceptable lifetimes remains one of the most significant challenges in OLED technology.

The degradation mechanisms in phosphorescent OLEDs (PhOLEDs) present complex challenges. The triplet exciton, which enables the high efficiency of phosphorescent materials, paradoxically contributes to accelerated degradation. These long-lived triplet states increase the probability of detrimental interactions with charge carriers and other excited states, leading to molecular decomposition of the emitter complexes.

Thermal stability represents another significant limitation, particularly for blue phosphorescent emitters. The high energy required for blue emission often leads to bond breaking within the organometallic complexes, resulting in rapid degradation under operational conditions. This thermal instability is exacerbated by Joule heating during device operation, creating a self-accelerating degradation cycle.

Exciton-polaron interactions constitute a major degradation pathway in PhOLEDs. When triplet excitons interact with polarons (charged carriers), they can form highly reactive species that attack the emitter molecules and host materials. This process is particularly problematic in phosphorescent systems due to the extended lifetime of triplet states, which increases the probability of such interactions.

Chemical stability of the iridium complexes commonly used in phosphorescent emitters presents another challenge. The metal-ligand bonds in these complexes can undergo irreversible chemical changes during operation, particularly under high current densities or elevated temperatures. These changes alter the emission properties and reduce quantum efficiency over time.

Interface degradation between the various functional layers in OLEDs significantly impacts device lifetime. The accumulation of charges at interfaces can lead to electrochemical reactions, material mixing, and morphological changes that compromise device performance. This effect is often more pronounced in phosphorescent devices due to their complex multi-layer architectures.

Blue phosphorescent emitters face particularly severe lifetime limitations compared to green and red counterparts. The high-energy triplet states in blue emitters are more susceptible to non-radiative deactivation pathways and chemical degradation. Despite extensive research efforts, the development of stable deep blue phosphorescent emitters with acceptable lifetimes remains one of the most significant challenges in OLED technology.

Comparative Analysis of Current Lifetime Extension Solutions

01 Material composition for improved OLED lifetime

Specific organic materials and compositions can significantly enhance OLED device lifetimes. These include optimized host-dopant systems, novel emitter materials with improved stability, and specialized transport layers that reduce degradation mechanisms. The selection of materials with appropriate energy levels and molecular structures can minimize operational stress and extend the functional lifespan of OLED devices.- Material composition for improved OLED lifetime: Specific organic materials and compounds can significantly enhance OLED lifetime. These include optimized host materials, dopants, and transport layers that reduce degradation mechanisms. Novel material compositions with improved thermal stability and resistance to electrochemical degradation help maintain luminance efficiency over extended periods. Advanced emitter materials, particularly phosphorescent and thermally activated delayed fluorescence (TADF) compounds, contribute to longer operational lifetimes while maintaining color purity.

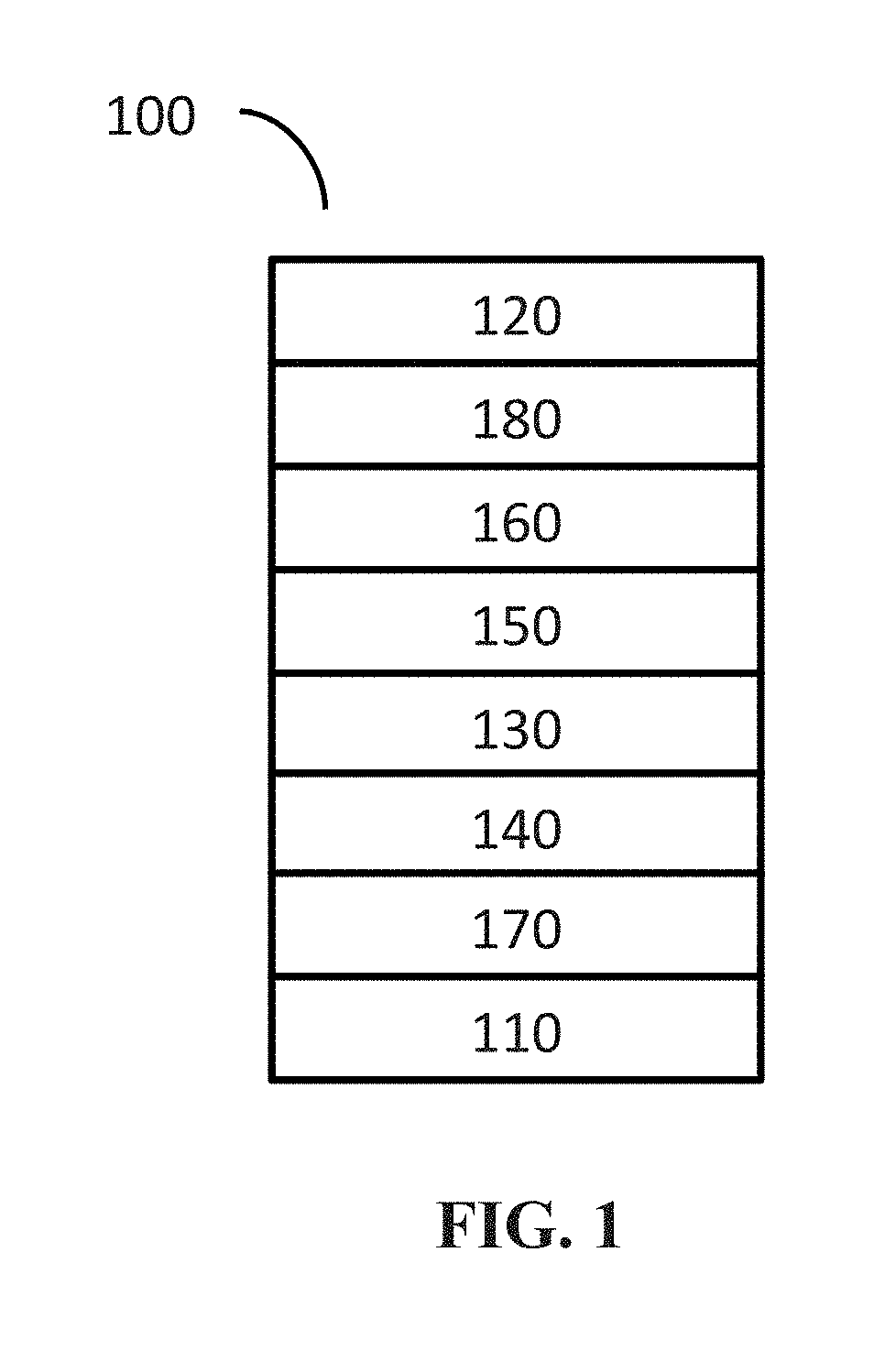

- Device structure optimization for longevity: The physical architecture of OLED devices plays a crucial role in determining operational lifetime. Multi-layer structures with optimized thickness ratios between emission, transport, and blocking layers can reduce driving voltage and current density, thereby extending device lifespan. Specialized buffer layers and interface engineering techniques minimize charge accumulation and exciton quenching at layer boundaries. Advanced encapsulation methods protect sensitive organic materials from moisture and oxygen, which are primary causes of OLED degradation.

- Driving and compensation techniques: Sophisticated driving schemes and compensation algorithms can significantly extend OLED lifetime by addressing uneven aging and degradation. Adaptive current control methods adjust pixel driving parameters based on usage history and measured degradation. Compensation circuits detect changes in OLED electrical characteristics over time and modify driving signals accordingly. Pulse-width modulation and variable refresh rate techniques reduce thermal stress and current-induced degradation while maintaining perceived brightness and image quality.

- Thermal management solutions: Effective thermal management is critical for extending OLED lifetime as elevated operating temperatures accelerate degradation mechanisms. Heat dissipation structures integrated into device architecture help maintain optimal operating temperatures. Thermally conductive materials and substrates efficiently transfer heat away from emission layers. Advanced thermal interface materials between OLED panels and device housings improve overall thermal performance. Intelligent brightness control systems adjust power consumption based on temperature monitoring to prevent overheating during extended operation.

- Testing and prediction methodologies: Accelerated testing protocols and lifetime prediction models enable accurate assessment of OLED durability. Advanced measurement techniques quantify degradation mechanisms under various operating conditions. Machine learning algorithms analyze performance data to predict lifetime characteristics and failure modes. Real-time monitoring systems track changes in electrical and optical parameters to estimate remaining useful life. Standardized testing frameworks allow comparison between different OLED technologies and manufacturing processes, facilitating continuous improvement in lifetime performance.

02 Device structure optimization for longevity

The physical architecture of OLED devices plays a crucial role in determining operational lifetime. Multi-layer structures with optimized thicknesses, specialized barrier and encapsulation technologies, and novel electrode configurations can protect sensitive organic materials from degradation factors. Structural innovations such as tandem OLEDs and microcavity designs can distribute operational stress and enhance device durability.Expand Specific Solutions03 Driving methods and circuit designs for lifetime extension

Advanced driving schemes and circuit designs can significantly extend OLED lifetimes by managing operational stress. These include compensation circuits that adjust for aging effects, pulse-width modulation techniques that reduce peak current stress, and temperature-compensated driving methods. Intelligent power management systems can dynamically adjust operating parameters based on usage patterns and environmental conditions to minimize degradation.Expand Specific Solutions04 Degradation mechanisms and lifetime prediction models

Understanding the fundamental mechanisms of OLED degradation enables the development of accurate lifetime prediction models. Research has identified key factors including exciton-polaron interactions, chemical transformations of organic materials, and interfacial degradation processes. Advanced analytical techniques and accelerated testing protocols help quantify these effects, allowing for lifetime estimation under various operating conditions and enabling targeted improvements in device design.Expand Specific Solutions05 Encapsulation and environmental protection technologies

Protection from environmental factors such as moisture and oxygen is critical for extending OLED lifetimes. Advanced encapsulation technologies including thin-film barriers with alternating organic and inorganic layers, edge sealing techniques, and getter materials that absorb contaminants can effectively shield sensitive organic materials. These protective measures significantly reduce extrinsic degradation mechanisms and enhance long-term stability under various operating conditions.Expand Specific Solutions

Key Industry Players in OLED Material Development

The OLED phosphorescent vs. fluorescent technology landscape is currently in a mature growth phase, with the global OLED market valued at approximately $48 billion and expanding at 13.4% CAGR. Phosphorescent OLEDs dominate due to their superior efficiency and longer lifetimes compared to fluorescent variants. Universal Display Corporation holds key phosphorescent OLED patents, while companies like Merck, Novaled, and Idemitsu Kosan lead in material development. Major display manufacturers including Samsung Display, LG Display, and BOE Technology have heavily invested in phosphorescent technology. Academic institutions such as USC and Tsinghua University continue advancing fundamental research, while emerging players like Beijing Xiahe Technology and Changchun Hyperions are developing competitive materials, particularly in China's rapidly growing OLED ecosystem.

Universal Display Corp.

Technical Solution: Universal Display Corporation (UDC) has pioneered phosphorescent OLED (PHOLED) technology, which offers significant advantages over traditional fluorescent OLEDs. Their proprietary PHOLED technology harnesses both singlet and triplet excitons, achieving nearly 100% internal quantum efficiency compared to fluorescent OLEDs' 25% limitation. UDC has developed a comprehensive portfolio of phosphorescent emitter materials, particularly excelling in red and green phosphorescent systems with lifetimes exceeding 900,000 hours at practical luminance levels. Their latest generation materials demonstrate color coordinates meeting display industry standards while maintaining high efficiency. UDC's approach involves using host materials doped with phosphorescent emitters, often iridium-based complexes, which enable efficient energy transfer and emission. The company has also made significant progress in blue phosphorescent materials, historically the most challenging color, with recent developments showing operational lifetimes suitable for commercial applications. Their materials are designed with specific molecular structures that minimize non-radiative decay pathways, thereby extending operational lifetimes significantly beyond fluorescent counterparts.

Strengths: Industry-leading phosphorescent efficiency (nearly 4x that of fluorescent OLEDs); exceptional red and green emitter lifetimes; comprehensive IP portfolio covering key phosphorescent technologies. Weaknesses: Blue phosphorescent emitters still face lifetime challenges compared to fluorescent blues; higher material costs compared to some fluorescent systems; requires more complex device structures for optimal performance.

LG Display Co., Ltd.

Technical Solution: LG Display has developed a hybrid OLED technology approach that strategically combines phosphorescent and fluorescent materials to optimize both performance and lifetime. Their WOLED (White OLED) technology utilizes a multi-layer emission structure where phosphorescent red and green emitters are combined with fluorescent or advanced delayed fluorescent blue emitters. This architecture allows LG to achieve high efficiency from the phosphorescent components while addressing the lifetime limitations of blue phosphorescent materials. Their panels typically demonstrate 150,000+ hour lifetimes at standard brightness levels, significantly outperforming pure fluorescent displays. LG has further enhanced their technology with advanced optical designs including color filters and micro-lens arrays that improve light extraction efficiency by approximately 20%. Their latest generation panels incorporate deuterium-based phosphorescent materials that show improved stability under high current conditions, addressing one of the key degradation mechanisms in phosphorescent systems. LG has also pioneered tandem OLED structures that effectively double the emission efficiency while distributing current load to extend operational lifetime beyond what single-stack designs can achieve.

Strengths: Hybrid approach maximizes efficiency while mitigating lifetime limitations; mature manufacturing processes for large-area displays; excellent color reproduction across wide viewing angles. Weaknesses: More complex manufacturing process compared to pure fluorescent displays; higher production costs; color filter approach reduces some efficiency gains from phosphorescent materials.

Critical Patents and Research in Phosphorescent Materials

Phosphorescent emitters and extrinsic method for increasing stability thereof

PatentActiveUS20190044084A1

Innovation

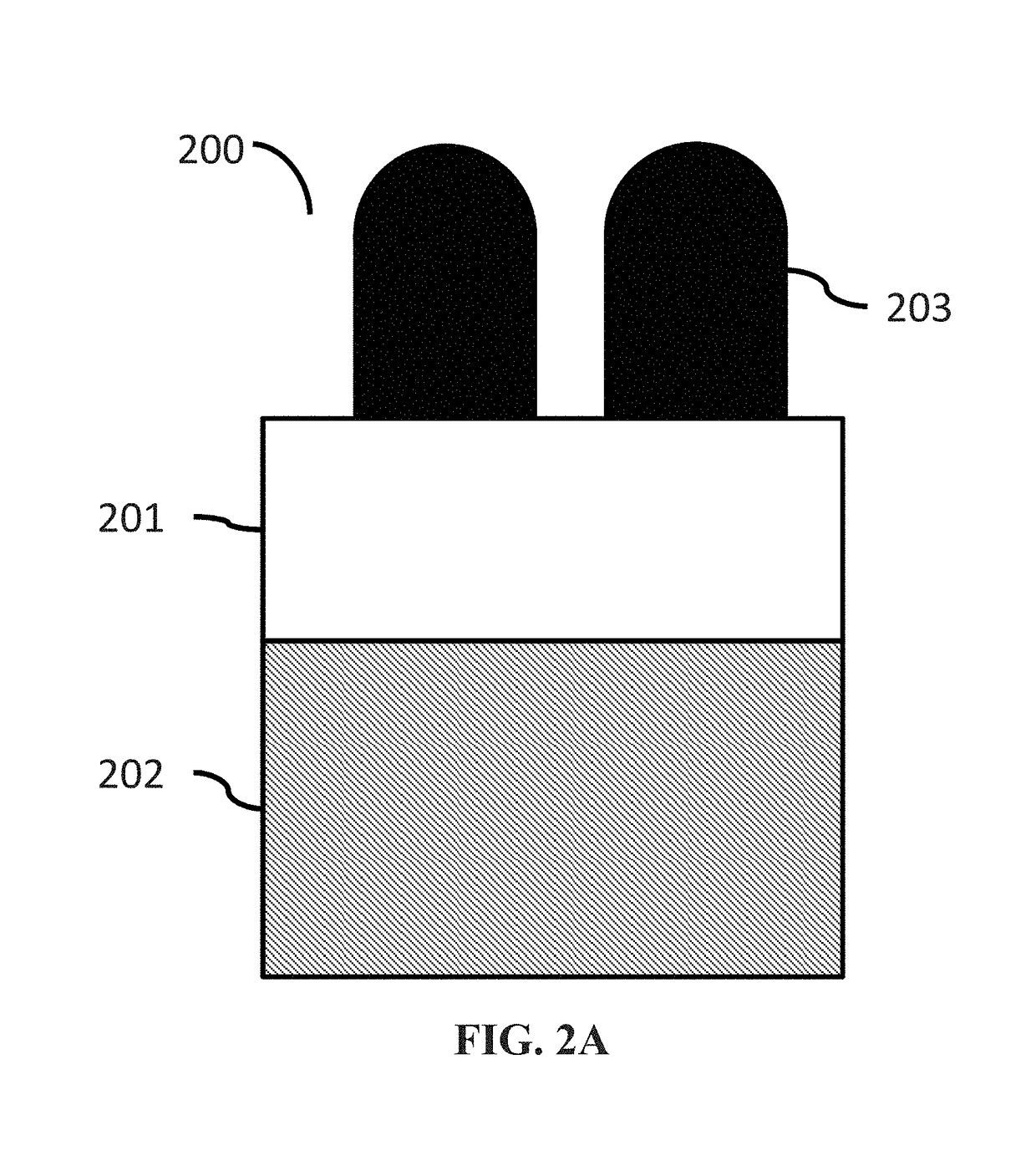

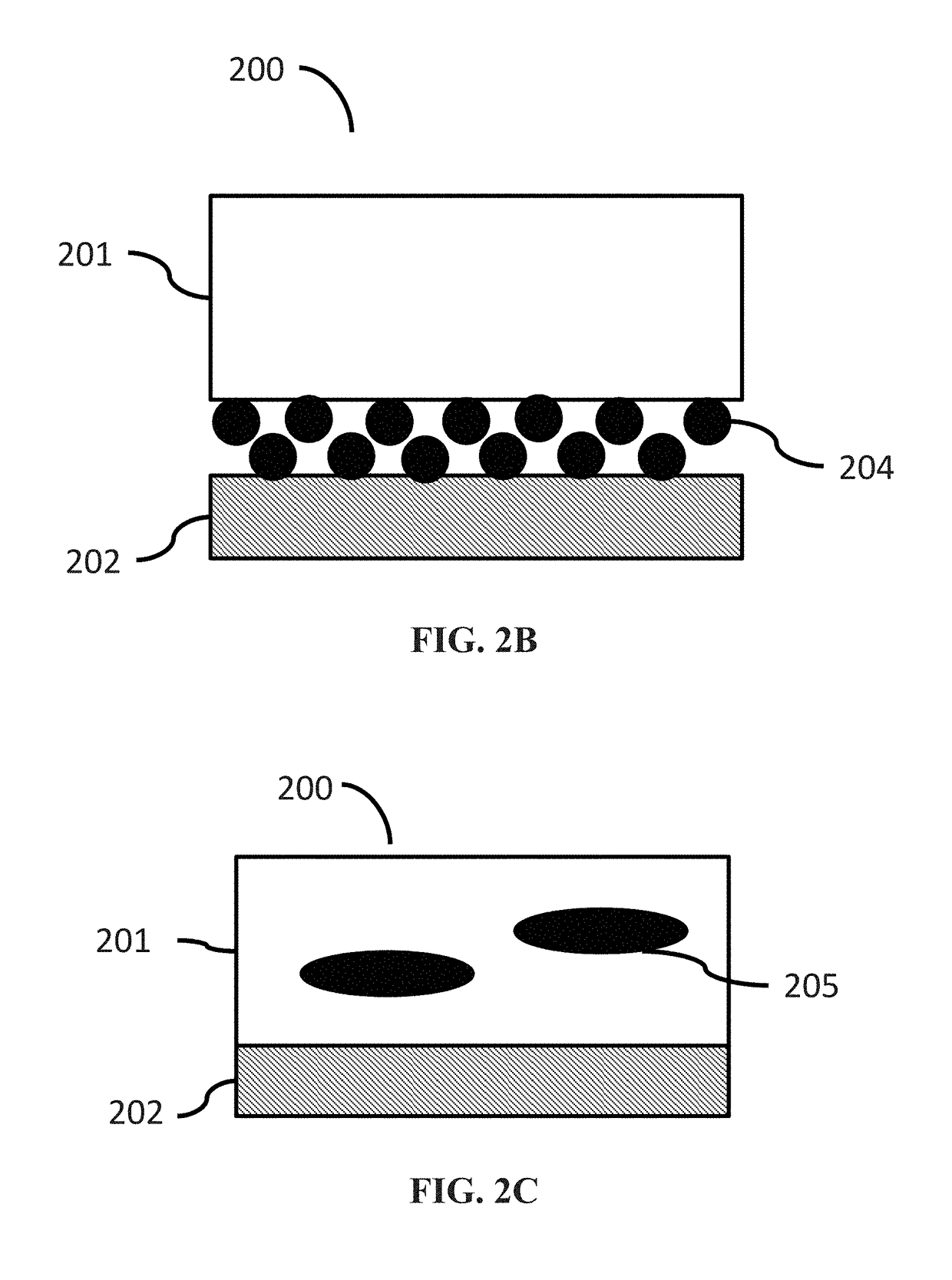

- Incorporating a nanostructure with local electric fields that spectrally and spatially overlap with the light-emitting organic or organometallic material to enhance radiative decay rates, thereby preventing the buildup of triplet excited states and improving stability, using materials like dielectric or plasmonic nanostructures such as Al, Ag, SiO2, or ZnO, and configuring the emitting layer with materials like bis[2-(4,6-difluorophenyl)pyridinato-C2,N](picolinato)iridium(III) or polyvinylcarabzole (PVK) to facilitate faster light emission from triplet states.

Phosphorescent emitters and extrinsic method for increasing stability thereof

PatentWO2019028243A1

Innovation

- Incorporating a nanostructure with local electric fields that spectrally and spatially overlap with the light-emitting organic or organometallic material, such as dielectric or plasmonic materials like Al, Ag, or TiO2, to enhance radiative decay rates and prevent triplet state buildup, thereby stabilizing the emission.

Energy Efficiency Comparison Between Emission Technologies

The energy efficiency of OLED displays represents a critical performance metric that significantly impacts device battery life, operational costs, and environmental footprint. When comparing phosphorescent and fluorescent emission technologies, substantial differences emerge in their fundamental energy conversion mechanisms and resulting efficiency profiles.

Phosphorescent OLEDs (PHOLEDs) demonstrate markedly superior energy efficiency, with internal quantum efficiencies (IQE) approaching 100% compared to the theoretical 25% maximum for fluorescent systems. This efficiency advantage stems from phosphorescent emitters' ability to harvest both singlet and triplet excitons for light emission, whereas traditional fluorescent materials utilize only singlet states, wasting approximately 75% of electrical energy as heat.

In practical applications, phosphorescent systems typically achieve 4-5 times greater power efficiency than their fluorescent counterparts when operating at comparable brightness levels. This translates to external quantum efficiencies (EQE) of 20-30% for commercial phosphorescent displays versus 4-8% for fluorescent alternatives. The efficiency gap becomes particularly pronounced at lower brightness settings, where phosphorescent systems maintain higher relative efficiency.

Energy consumption measurements reveal that phosphorescent OLED panels require approximately 1.8-2.5W for a standard 6-inch display operating at 500 nits brightness, while equivalent fluorescent panels demand 3.5-4.2W under identical conditions. This efficiency differential directly impacts device battery life, with phosphorescent displays extending operational time by 30-45% in mobile applications.

The efficiency advantage of phosphorescent systems does diminish somewhat at extremely high brightness levels (>1000 nits) due to exciton-polaron quenching effects that become more pronounced at higher current densities. Additionally, blue phosphorescent emitters still lag behind their green and red counterparts in efficiency metrics, presenting an ongoing development challenge.

Thermographic analysis demonstrates that fluorescent displays generate significantly more waste heat during operation, with surface temperatures measuring 5-8°C higher than phosphorescent equivalents under standardized test conditions. This thermal difference impacts not only energy efficiency but also device longevity and thermal management requirements.

Recent advancements in TADF (Thermally Activated Delayed Fluorescence) technology are beginning to bridge the efficiency gap, achieving intermediate performance levels between traditional fluorescent and phosphorescent systems while potentially offering manufacturing advantages and reduced reliance on precious metals used in phosphorescent emitters.

Phosphorescent OLEDs (PHOLEDs) demonstrate markedly superior energy efficiency, with internal quantum efficiencies (IQE) approaching 100% compared to the theoretical 25% maximum for fluorescent systems. This efficiency advantage stems from phosphorescent emitters' ability to harvest both singlet and triplet excitons for light emission, whereas traditional fluorescent materials utilize only singlet states, wasting approximately 75% of electrical energy as heat.

In practical applications, phosphorescent systems typically achieve 4-5 times greater power efficiency than their fluorescent counterparts when operating at comparable brightness levels. This translates to external quantum efficiencies (EQE) of 20-30% for commercial phosphorescent displays versus 4-8% for fluorescent alternatives. The efficiency gap becomes particularly pronounced at lower brightness settings, where phosphorescent systems maintain higher relative efficiency.

Energy consumption measurements reveal that phosphorescent OLED panels require approximately 1.8-2.5W for a standard 6-inch display operating at 500 nits brightness, while equivalent fluorescent panels demand 3.5-4.2W under identical conditions. This efficiency differential directly impacts device battery life, with phosphorescent displays extending operational time by 30-45% in mobile applications.

The efficiency advantage of phosphorescent systems does diminish somewhat at extremely high brightness levels (>1000 nits) due to exciton-polaron quenching effects that become more pronounced at higher current densities. Additionally, blue phosphorescent emitters still lag behind their green and red counterparts in efficiency metrics, presenting an ongoing development challenge.

Thermographic analysis demonstrates that fluorescent displays generate significantly more waste heat during operation, with surface temperatures measuring 5-8°C higher than phosphorescent equivalents under standardized test conditions. This thermal difference impacts not only energy efficiency but also device longevity and thermal management requirements.

Recent advancements in TADF (Thermally Activated Delayed Fluorescence) technology are beginning to bridge the efficiency gap, achieving intermediate performance levels between traditional fluorescent and phosphorescent systems while potentially offering manufacturing advantages and reduced reliance on precious metals used in phosphorescent emitters.

Manufacturing Cost Analysis and Scalability Considerations

The manufacturing cost structure of OLED displays varies significantly between phosphorescent and fluorescent technologies, with phosphorescent materials generally commanding higher prices due to their complex synthesis processes and intellectual property constraints. Current market analysis indicates that phosphorescent emitter materials cost approximately 30-40% more than their fluorescent counterparts, primarily due to the precious metal complexes (particularly iridium) required for phosphorescent compounds. However, this cost differential is partially offset by the higher efficiency of phosphorescent OLEDs, which require less material per unit area to achieve equivalent brightness levels.

Production scaling presents distinct challenges for both technologies. Fluorescent OLED manufacturing benefits from decades of process optimization and established supply chains, allowing for more predictable yield rates averaging 85-90% in mature production lines. Phosphorescent technology, while offering superior performance characteristics, typically experiences lower initial yields (70-80%) during mass production implementation, requiring additional quality control measures that increase overall manufacturing costs by approximately 15-25%.

Equipment requirements also differ substantially between the two technologies. Vacuum thermal evaporation (VTE) systems for phosphorescent materials demand more precise deposition control and often require specialized shadow masks to achieve accurate patterning, increasing capital expenditure by 20-30% compared to fluorescent-only production lines. Solution-processing methods, while promising for cost reduction, have achieved limited commercial success due to challenges in maintaining consistent film morphology for phosphorescent materials.

Supply chain considerations reveal another dimension of cost analysis. The phosphorescent material market remains relatively concentrated, with a small number of suppliers controlling key patents and production capabilities. This market structure has maintained higher material costs despite increasing production volumes. Conversely, fluorescent materials benefit from a more diversified supplier ecosystem, creating greater price competition and stability.

Long-term economic modeling suggests that phosphorescent technology will achieve cost parity with fluorescent systems within 3-5 years as manufacturing processes mature and key patents expire. Current data indicates that the total cost of ownership for phosphorescent OLED displays becomes favorable in applications where device lifetime exceeds 10,000 hours, primarily due to their reduced power consumption offsetting higher initial manufacturing costs. For high-volume consumer electronics, the manufacturing cost premium for phosphorescent technology currently ranges from $8-15 per square meter of display area, representing a 12-18% premium over fluorescent-only production.

Production scaling presents distinct challenges for both technologies. Fluorescent OLED manufacturing benefits from decades of process optimization and established supply chains, allowing for more predictable yield rates averaging 85-90% in mature production lines. Phosphorescent technology, while offering superior performance characteristics, typically experiences lower initial yields (70-80%) during mass production implementation, requiring additional quality control measures that increase overall manufacturing costs by approximately 15-25%.

Equipment requirements also differ substantially between the two technologies. Vacuum thermal evaporation (VTE) systems for phosphorescent materials demand more precise deposition control and often require specialized shadow masks to achieve accurate patterning, increasing capital expenditure by 20-30% compared to fluorescent-only production lines. Solution-processing methods, while promising for cost reduction, have achieved limited commercial success due to challenges in maintaining consistent film morphology for phosphorescent materials.

Supply chain considerations reveal another dimension of cost analysis. The phosphorescent material market remains relatively concentrated, with a small number of suppliers controlling key patents and production capabilities. This market structure has maintained higher material costs despite increasing production volumes. Conversely, fluorescent materials benefit from a more diversified supplier ecosystem, creating greater price competition and stability.

Long-term economic modeling suggests that phosphorescent technology will achieve cost parity with fluorescent systems within 3-5 years as manufacturing processes mature and key patents expire. Current data indicates that the total cost of ownership for phosphorescent OLED displays becomes favorable in applications where device lifetime exceeds 10,000 hours, primarily due to their reduced power consumption offsetting higher initial manufacturing costs. For high-volume consumer electronics, the manufacturing cost premium for phosphorescent technology currently ranges from $8-15 per square meter of display area, representing a 12-18% premium over fluorescent-only production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!