Evaluating OLED Burn-In Lifespan Using Accelerated Testing

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Burn-In Background and Testing Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized display systems since its commercial introduction in the late 1990s. The technology offers significant advantages over traditional LCD displays, including superior contrast ratios, wider viewing angles, faster response times, and the ability to create flexible and transparent displays. However, one persistent challenge that has plagued OLED technology is the phenomenon known as "burn-in" or image persistence, where prolonged display of static content leads to permanent degradation of organic compounds, resulting in ghost images visible even when new content is displayed.

The evolution of OLED technology has seen significant improvements in addressing burn-in issues, from early passive-matrix OLEDs (PMOLEDs) to active-matrix OLEDs (AMOLEDs), and more recently to technologies like WOLED (White OLED) and TOLED (Transparent OLED). Despite these advancements, burn-in remains a critical factor limiting the lifespan and reliability of OLED displays, particularly in applications requiring sustained display of static elements such as navigation bars, channel logos, or status indicators.

Industry trends indicate growing adoption of OLED technology across multiple sectors including smartphones, televisions, automotive displays, and wearable devices. This expansion necessitates more robust solutions to the burn-in challenge, as different use cases present varying degrees of static content display requirements. The market's increasing demand for longer-lasting displays with consistent performance throughout their operational life has intensified focus on burn-in mitigation strategies.

The primary objective of accelerated testing for OLED burn-in is to develop methodologies that can accurately predict the long-term performance of displays within a compressed timeframe. Traditional lifespan testing, which might require years of observation under normal usage conditions, is impractical for product development cycles. Accelerated testing aims to simulate years of usage in weeks or months by subjecting displays to intensified conditions such as increased brightness, elevated temperatures, or concentrated static image display periods.

Secondary objectives include establishing standardized metrics for quantifying burn-in severity, identifying key factors that accelerate or mitigate burn-in effects, and developing mathematical models that can reliably extrapolate accelerated test results to real-world usage scenarios. These objectives align with the broader goal of enabling manufacturers to provide more accurate lifespan estimates and warranties for OLED products, while also informing design decisions for future display technologies.

The technical trajectory suggests continued refinement of both hardware solutions (such as improved organic materials with greater stability) and software mitigations (including pixel shifting, logo dimming, and screen savers). Accelerated testing methodologies serve as the critical bridge between laboratory innovations and market-ready products with predictable performance characteristics.

The evolution of OLED technology has seen significant improvements in addressing burn-in issues, from early passive-matrix OLEDs (PMOLEDs) to active-matrix OLEDs (AMOLEDs), and more recently to technologies like WOLED (White OLED) and TOLED (Transparent OLED). Despite these advancements, burn-in remains a critical factor limiting the lifespan and reliability of OLED displays, particularly in applications requiring sustained display of static elements such as navigation bars, channel logos, or status indicators.

Industry trends indicate growing adoption of OLED technology across multiple sectors including smartphones, televisions, automotive displays, and wearable devices. This expansion necessitates more robust solutions to the burn-in challenge, as different use cases present varying degrees of static content display requirements. The market's increasing demand for longer-lasting displays with consistent performance throughout their operational life has intensified focus on burn-in mitigation strategies.

The primary objective of accelerated testing for OLED burn-in is to develop methodologies that can accurately predict the long-term performance of displays within a compressed timeframe. Traditional lifespan testing, which might require years of observation under normal usage conditions, is impractical for product development cycles. Accelerated testing aims to simulate years of usage in weeks or months by subjecting displays to intensified conditions such as increased brightness, elevated temperatures, or concentrated static image display periods.

Secondary objectives include establishing standardized metrics for quantifying burn-in severity, identifying key factors that accelerate or mitigate burn-in effects, and developing mathematical models that can reliably extrapolate accelerated test results to real-world usage scenarios. These objectives align with the broader goal of enabling manufacturers to provide more accurate lifespan estimates and warranties for OLED products, while also informing design decisions for future display technologies.

The technical trajectory suggests continued refinement of both hardware solutions (such as improved organic materials with greater stability) and software mitigations (including pixel shifting, logo dimming, and screen savers). Accelerated testing methodologies serve as the critical bridge between laboratory innovations and market-ready products with predictable performance characteristics.

Market Analysis for OLED Display Longevity

The OLED display market has experienced significant growth over the past decade, with a market value reaching $48.5 billion in 2022 and projected to surpass $72.8 billion by 2026. This growth is primarily driven by the increasing adoption of OLED technology in smartphones, televisions, and wearable devices due to its superior visual performance, flexibility, and energy efficiency compared to traditional LCD displays.

Consumer demand for OLED displays continues to rise despite concerns about burn-in issues, which remain one of the most significant barriers to wider adoption. Market research indicates that approximately 67% of potential high-end display purchasers express concerns about OLED longevity, highlighting the critical importance of addressing this technical challenge to expand market penetration.

The premium segment of the display market shows particular sensitivity to longevity issues, with enterprise and professional users willing to pay up to 30% more for displays with verified extended lifespans. This price premium underscores the substantial market opportunity for manufacturers who can effectively address burn-in concerns through improved technology or reliable lifespan verification methods.

Regional analysis reveals varying levels of consumer awareness regarding OLED burn-in issues. North American and European markets demonstrate higher concern levels (72% and 68% of consumers respectively), while Asian markets show slightly lower concern rates (58%), possibly due to different usage patterns or market education. These regional variations suggest the need for targeted marketing strategies when introducing improved OLED longevity solutions.

Industry forecasts predict that solving the burn-in challenge could potentially increase OLED market share in the television sector from current 20% to over 35% by 2027, representing an additional $15 billion in market opportunity. Similarly, in the professional monitor segment, addressing longevity concerns could triple the current 7% OLED market share within five years.

The competitive landscape shows increasing investment in longevity research, with major display manufacturers allocating an average of 18% of their R&D budgets specifically to burn-in mitigation technologies. This investment trend indicates industry recognition of longevity as a key differentiator in the increasingly competitive display market.

Consumer willingness to adopt OLED technology shows strong correlation with perceived lifespan guarantees, with market studies indicating that extending verified lifespans from current averages of 30,000 hours to 50,000 hours could potentially convert up to 40% of hesitant buyers in premium segments.

Consumer demand for OLED displays continues to rise despite concerns about burn-in issues, which remain one of the most significant barriers to wider adoption. Market research indicates that approximately 67% of potential high-end display purchasers express concerns about OLED longevity, highlighting the critical importance of addressing this technical challenge to expand market penetration.

The premium segment of the display market shows particular sensitivity to longevity issues, with enterprise and professional users willing to pay up to 30% more for displays with verified extended lifespans. This price premium underscores the substantial market opportunity for manufacturers who can effectively address burn-in concerns through improved technology or reliable lifespan verification methods.

Regional analysis reveals varying levels of consumer awareness regarding OLED burn-in issues. North American and European markets demonstrate higher concern levels (72% and 68% of consumers respectively), while Asian markets show slightly lower concern rates (58%), possibly due to different usage patterns or market education. These regional variations suggest the need for targeted marketing strategies when introducing improved OLED longevity solutions.

Industry forecasts predict that solving the burn-in challenge could potentially increase OLED market share in the television sector from current 20% to over 35% by 2027, representing an additional $15 billion in market opportunity. Similarly, in the professional monitor segment, addressing longevity concerns could triple the current 7% OLED market share within five years.

The competitive landscape shows increasing investment in longevity research, with major display manufacturers allocating an average of 18% of their R&D budgets specifically to burn-in mitigation technologies. This investment trend indicates industry recognition of longevity as a key differentiator in the increasingly competitive display market.

Consumer willingness to adopt OLED technology shows strong correlation with perceived lifespan guarantees, with market studies indicating that extending verified lifespans from current averages of 30,000 hours to 50,000 hours could potentially convert up to 40% of hesitant buyers in premium segments.

Current Challenges in OLED Burn-In Assessment

Despite significant advancements in OLED technology, burn-in assessment remains a complex challenge for manufacturers, researchers, and quality assurance teams. The primary difficulty lies in the time-dependent nature of burn-in phenomena, which typically manifests over months or years of normal usage. This temporal disconnect creates substantial obstacles for timely product development cycles and reliability predictions.

Traditional burn-in testing methodologies often fail to accurately simulate real-world usage patterns. Static image retention tests may overestimate burn-in severity, while dynamic content tests might underestimate long-term effects. This inconsistency leads to significant variability in test results across different laboratories and testing protocols, making standardization extremely difficult.

Another critical challenge is the multi-factorial nature of OLED degradation. Burn-in is influenced by numerous variables including brightness levels, image content, ambient temperature, panel materials, and driving schemes. The complex interactions between these factors create a high-dimensional problem space that is difficult to model comprehensively, particularly when attempting to compress testing timeframes.

Accelerated testing methodologies, while necessary for practical development timelines, introduce their own set of complications. The fundamental question remains whether accelerated aging truly represents natural degradation pathways or potentially triggers alternative failure mechanisms not present in normal usage. The validation of acceleration factors requires extensive correlation studies between accelerated and real-time aging, which few organizations have comprehensively conducted.

Current measurement and quantification techniques also present limitations. Visual assessment remains subjective, while instrumental measurements may not align with human perception of display quality. The industry lacks consensus on burn-in metrics that meaningfully correlate with user experience and satisfaction, creating challenges in establishing acceptance criteria.

The diversity of OLED materials and structures further complicates assessment efforts. Different OLED technologies (RGB vs. WOLED), material systems, and panel architectures exhibit varying burn-in characteristics, necessitating customized testing approaches. This heterogeneity makes it difficult to develop universal testing standards applicable across the industry.

Finally, there exists a significant gap between laboratory testing and field performance. Environmental factors, usage patterns, and maintenance practices in real-world scenarios introduce variables that laboratory testing struggles to replicate. This disconnect often results in unexpected field failures despite products passing laboratory qualification tests, undermining confidence in current assessment methodologies.

Traditional burn-in testing methodologies often fail to accurately simulate real-world usage patterns. Static image retention tests may overestimate burn-in severity, while dynamic content tests might underestimate long-term effects. This inconsistency leads to significant variability in test results across different laboratories and testing protocols, making standardization extremely difficult.

Another critical challenge is the multi-factorial nature of OLED degradation. Burn-in is influenced by numerous variables including brightness levels, image content, ambient temperature, panel materials, and driving schemes. The complex interactions between these factors create a high-dimensional problem space that is difficult to model comprehensively, particularly when attempting to compress testing timeframes.

Accelerated testing methodologies, while necessary for practical development timelines, introduce their own set of complications. The fundamental question remains whether accelerated aging truly represents natural degradation pathways or potentially triggers alternative failure mechanisms not present in normal usage. The validation of acceleration factors requires extensive correlation studies between accelerated and real-time aging, which few organizations have comprehensively conducted.

Current measurement and quantification techniques also present limitations. Visual assessment remains subjective, while instrumental measurements may not align with human perception of display quality. The industry lacks consensus on burn-in metrics that meaningfully correlate with user experience and satisfaction, creating challenges in establishing acceptance criteria.

The diversity of OLED materials and structures further complicates assessment efforts. Different OLED technologies (RGB vs. WOLED), material systems, and panel architectures exhibit varying burn-in characteristics, necessitating customized testing approaches. This heterogeneity makes it difficult to develop universal testing standards applicable across the industry.

Finally, there exists a significant gap between laboratory testing and field performance. Environmental factors, usage patterns, and maintenance practices in real-world scenarios introduce variables that laboratory testing struggles to replicate. This disconnect often results in unexpected field failures despite products passing laboratory qualification tests, undermining confidence in current assessment methodologies.

Accelerated Testing Methodologies for OLED Panels

01 Material composition to extend OLED lifespan

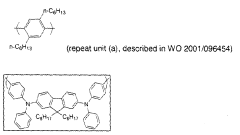

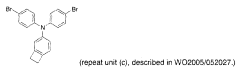

Various material compositions can significantly extend the lifespan of OLED displays and reduce burn-in effects. These include specialized organic light-emitting materials, improved electrode materials, and novel encapsulation techniques that protect against moisture and oxygen degradation. By optimizing the chemical structure of emissive layers and incorporating stabilizing additives, manufacturers can create more durable displays that maintain brightness uniformity over extended periods of operation.- Material composition to extend OLED lifespan: Specific material compositions can significantly extend the lifespan of OLED displays and reduce burn-in effects. These include improved organic light-emitting materials, novel electrode materials, and specialized encapsulation layers that protect against moisture and oxygen degradation. Advanced materials can maintain luminance efficiency over longer periods, resulting in displays that resist image retention and maintain consistent brightness throughout their operational life.

- Compensation algorithms for burn-in prevention: Software-based compensation algorithms can detect and mitigate burn-in effects in OLED displays. These algorithms monitor pixel usage, adjust pixel brightness based on cumulative usage data, and implement pixel shifting techniques to distribute wear evenly across the display. Advanced systems may incorporate machine learning to predict potential burn-in areas and proactively adjust display parameters to extend the overall lifespan of the OLED panel.

- Thermal management solutions for OLED longevity: Effective thermal management systems can significantly extend OLED display lifespan by preventing heat-accelerated degradation. These solutions include advanced heat dissipation structures, thermal interface materials, and active cooling systems that maintain optimal operating temperatures. By controlling thermal conditions, these innovations slow the chemical degradation processes that lead to burn-in, particularly in high-brightness applications where heat generation is more pronounced.

- Display driving techniques to reduce burn-in: Specialized display driving techniques can extend OLED lifespan by optimizing how pixels are activated and controlled. These include variable refresh rates, dynamic voltage adjustment based on content, and advanced pulse width modulation schemes that reduce stress on organic materials. Some systems implement content-adaptive brightness control that automatically adjusts luminance levels based on displayed content to prevent uneven wear across the panel.

- Testing and measurement methods for OLED lifespan prediction: Advanced testing and measurement methodologies enable accurate prediction of OLED display lifespan and burn-in susceptibility. These include accelerated aging tests, precise luminance degradation measurements, and specialized optical analysis techniques that can detect early signs of material degradation. Some systems employ real-time monitoring of electrical characteristics to estimate remaining useful life, allowing for preventive measures before visible burn-in occurs.

02 Pixel compensation techniques for burn-in prevention

Advanced pixel compensation algorithms can detect and mitigate burn-in effects in OLED displays. These techniques involve monitoring pixel usage, adjusting voltage or current levels to compensate for aging pixels, and implementing pixel shifting or rotation strategies. By dynamically adjusting the driving signals based on historical usage patterns, these systems can equalize wear across the display and significantly extend the effective lifespan of OLED panels before visible burn-in occurs.Expand Specific Solutions03 Thermal management solutions for OLED longevity

Effective thermal management is crucial for extending OLED display lifespan and preventing premature burn-in. Innovative heat dissipation structures, thermally conductive materials, and active cooling systems help maintain optimal operating temperatures. By preventing localized heating and thermal stress, these solutions slow down the degradation processes that lead to differential aging of pixels, thereby preserving display uniformity and extending the overall functional lifespan of OLED panels.Expand Specific Solutions04 Display driving methods to distribute pixel wear

Specialized display driving methods can significantly extend OLED lifespan by distributing pixel wear more evenly. These include variable refresh rates, adaptive brightness control, and content-aware pixel management algorithms. Some systems implement periodic pixel refreshing cycles or compensate for static image elements by subtly adjusting surrounding pixels. By intelligently managing how and when pixels are activated, these methods minimize the cumulative stress on any particular area of the display, reducing burn-in effects and extending useful device life.Expand Specific Solutions05 Testing and prediction methods for OLED lifespan

Advanced testing and prediction methods help manufacturers and users understand and optimize OLED display lifespan. These include accelerated aging tests, real-time monitoring systems, and predictive algorithms that can forecast burn-in patterns based on usage data. By analyzing degradation characteristics under various conditions, these methods enable more accurate lifespan estimates and inform the development of targeted mitigation strategies. Some systems can even provide users with personalized recommendations to maximize their specific display's longevity.Expand Specific Solutions

Leading OLED Manufacturers and Research Institutions

The OLED burn-in lifespan testing market is currently in a growth phase, with increasing demand for reliable accelerated testing methodologies as OLED technology becomes mainstream in consumer electronics. The global market for OLED display testing is projected to expand significantly as manufacturers seek to address durability concerns. Leading display manufacturers Samsung Display, LG Display, and BOE Technology are at the forefront of technological innovation, with Universal Display Corporation providing critical OLED materials technology. Companies like Cambridge Display Technology and Kyulux are advancing TADF (Thermally Activated Delayed Fluorescence) technology to improve OLED lifespan. Meanwhile, consumer electronics giants including Samsung Electronics, Sony, and Xiaomi are driving demand for improved burn-in testing solutions as they integrate OLED displays across their product lines. The testing methodologies are approaching maturity, though standardization remains a challenge across the industry.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has implemented a comprehensive accelerated testing framework for OLED burn-in evaluation that combines environmental stress testing with advanced optical characterization. Their methodology employs a multi-stage approach beginning with high-temperature operational testing (typically at 40-65°C) combined with elevated brightness levels to accelerate aging mechanisms. BOE's testing protocols include specialized image patterns designed to stress different sub-pixel configurations based on statistical analysis of common user interfaces. The company has developed an automated optical measurement system that captures microscopic luminance changes across the panel at regular intervals during accelerated testing. Their approach incorporates both static image retention tests and dynamic content simulation with programmed duty cycles. BOE's data analysis platform employs regression models to extrapolate accelerated test results to normal usage conditions, with claimed accuracy within 15% of actual field performance data.

Strengths: Comprehensive testing infrastructure with high-precision optical measurement capabilities; strong correlation models between accelerated and normal usage conditions; testing methodology adaptable to different OLED structural designs. Weaknesses: Relatively newer to OLED manufacturing compared to some competitors; correlation models may have less historical validation data compared to longer-established manufacturers.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed comprehensive accelerated testing methodologies for OLED burn-in evaluation that simulate years of usage in weeks. Their approach combines high-temperature operational life (HTOL) testing with increased brightness levels to accelerate aging factors. The company employs cumulative stress models that correlate pixel degradation rates across different usage patterns and environmental conditions. Samsung's proprietary Artificial Aging Chamber technology can simulate up to 5 years of normal usage in approximately 500 hours by controlling temperature, humidity, and operational parameters with precision. Their testing protocols include specialized image retention measurement tools that can detect sub-pixel degradation at early stages before visible to the human eye. Samsung has also implemented machine learning algorithms to predict long-term performance based on short-term accelerated test data.

Strengths: Industry-leading testing facilities with highly controlled environmental chambers; proprietary algorithms for translating accelerated test results to real-world lifespan predictions; comprehensive sub-pixel level analysis capabilities. Weaknesses: Testing methodologies may be optimized specifically for Samsung's panel technologies and may not translate perfectly to other manufacturers' OLED structures; accelerated testing still involves some uncertainty in correlation factors.

Critical Patents in OLED Lifespan Prediction

Display device

PatentActiveUS12125440B2

Innovation

- The OLED display device calculates the cumulative current of each pixel, estimates the expected deterioration time based on consumed current, and operates in a burn-in prevention mode by reducing the luminance of pixels expected to burn-in, thereby extending the display's lifespan and preventing user discomfort.

OLED display device having some of the pixels containing two diodes with organic layers of different thickness

PatentWO2013045869A1

Innovation

- Incorporating a smaller, thinner 'sacrificial' diode in parallel with the main diode, which is driven harder and ages faster, increasing current to the main diode as it degrades, thus slowing down the luminance decay and reducing image burn-in, while maintaining high panel efficiency.

Standardization Efforts in OLED Reliability Testing

The standardization of OLED reliability testing has become increasingly crucial as these displays gain prominence across consumer electronics, automotive interfaces, and professional equipment. Currently, several international organizations are actively developing comprehensive standards to address the specific challenges of OLED burn-in evaluation through accelerated testing methodologies.

The International Electrotechnical Commission (IEC) has established the IEC 62341 series specifically for OLED displays, with section 62341-5 focusing on environmental testing methods. This framework provides foundational guidelines, though it continues to evolve to better address accelerated lifetime prediction models for burn-in phenomena.

VESA (Video Electronics Standards Association) has introduced the DisplayHDR True Black certification, which incorporates specific testing protocols for OLED displays. While primarily focused on performance characteristics, these standards increasingly include reliability metrics that manufacturers must meet, creating de facto industry benchmarks for burn-in resistance.

The Society for Information Display (SID) has formed dedicated working groups to establish standardized accelerated testing protocols specifically targeting OLED degradation mechanisms. These efforts aim to create testing methodologies that can reliably compress years of normal usage into manageable testing periods while maintaining predictive accuracy.

In Asia, the Korean Standards Association (KSA) has been particularly active, developing KS C IEC standards that adapt international frameworks to the specific manufacturing environments prevalent in Korea, where much of global OLED production is concentrated. Similarly, Japan's JEITA (Japan Electronics and Information Technology Industries Association) has published testing guidelines that have gained significant industry adoption.

A key challenge in standardization efforts remains the correlation between accelerated testing conditions and real-world usage patterns. Current standards typically specify test conditions using elevated temperatures (typically 40-85°C), increased brightness levels (150-200% of typical usage), and static image patterns designed to maximize stress on vulnerable pixels.

The emerging trend in standardization is moving toward more sophisticated testing regimes that incorporate variable content testing, duty cycle variations, and advanced statistical models to better predict real-world performance. These next-generation standards aim to address the limitations of current approaches, which sometimes fail to accurately model the complex degradation mechanisms in different OLED technologies.

Cross-industry collaboration between display manufacturers, device makers, and standards bodies is increasingly recognized as essential for developing meaningful reliability standards that balance rigorous evaluation with practical testing timeframes and costs.

The International Electrotechnical Commission (IEC) has established the IEC 62341 series specifically for OLED displays, with section 62341-5 focusing on environmental testing methods. This framework provides foundational guidelines, though it continues to evolve to better address accelerated lifetime prediction models for burn-in phenomena.

VESA (Video Electronics Standards Association) has introduced the DisplayHDR True Black certification, which incorporates specific testing protocols for OLED displays. While primarily focused on performance characteristics, these standards increasingly include reliability metrics that manufacturers must meet, creating de facto industry benchmarks for burn-in resistance.

The Society for Information Display (SID) has formed dedicated working groups to establish standardized accelerated testing protocols specifically targeting OLED degradation mechanisms. These efforts aim to create testing methodologies that can reliably compress years of normal usage into manageable testing periods while maintaining predictive accuracy.

In Asia, the Korean Standards Association (KSA) has been particularly active, developing KS C IEC standards that adapt international frameworks to the specific manufacturing environments prevalent in Korea, where much of global OLED production is concentrated. Similarly, Japan's JEITA (Japan Electronics and Information Technology Industries Association) has published testing guidelines that have gained significant industry adoption.

A key challenge in standardization efforts remains the correlation between accelerated testing conditions and real-world usage patterns. Current standards typically specify test conditions using elevated temperatures (typically 40-85°C), increased brightness levels (150-200% of typical usage), and static image patterns designed to maximize stress on vulnerable pixels.

The emerging trend in standardization is moving toward more sophisticated testing regimes that incorporate variable content testing, duty cycle variations, and advanced statistical models to better predict real-world performance. These next-generation standards aim to address the limitations of current approaches, which sometimes fail to accurately model the complex degradation mechanisms in different OLED technologies.

Cross-industry collaboration between display manufacturers, device makers, and standards bodies is increasingly recognized as essential for developing meaningful reliability standards that balance rigorous evaluation with practical testing timeframes and costs.

Environmental Factors Affecting OLED Degradation

OLED degradation is significantly influenced by various environmental factors, with temperature being one of the most critical. Research indicates that elevated temperatures accelerate the chemical reactions responsible for OLED material decomposition, with degradation rates approximately doubling for every 10°C increase above room temperature. This temperature sensitivity makes thermal management a crucial consideration in both accelerated testing protocols and real-world device design.

Humidity represents another substantial environmental stressor for OLED displays. Water molecules can penetrate encapsulation barriers and react with the organic materials and electrodes, leading to dark spots, delamination, and accelerated degradation of the emissive layers. Studies have shown that relative humidity levels above 60% can dramatically reduce OLED lifespan, particularly when combined with elevated temperatures.

Light exposure, especially in the ultraviolet spectrum, contributes significantly to OLED degradation through photochemical reactions. These reactions can break molecular bonds within the organic materials, altering their electronic properties and reducing luminous efficiency. This factor is particularly relevant when considering outdoor applications or devices used in high-brightness environments.

Oxygen exposure represents a critical degradation pathway for OLED materials. When oxygen molecules penetrate the device structure, they can react with the organic compounds, forming non-emissive oxidized species. This process, known as photo-oxidation when combined with light exposure, is one of the primary mechanisms behind luminance loss and color shift in OLED displays.

Electrical stress patterns significantly impact degradation rates, with higher current densities accelerating burn-in effects. Voltage spikes and inconsistent power delivery can create localized hot spots within the display, leading to uneven aging across the panel. This factor is particularly important when designing accelerated testing protocols that accurately reflect real-world usage patterns.

Mechanical stress, including bending, twisting, or pressure application, can compromise encapsulation integrity and create pathways for environmental contaminants. This consideration becomes increasingly important for flexible OLED applications, where repeated folding or rolling actions may accelerate degradation processes through microfractures in barrier layers.

The interaction between these environmental factors often produces synergistic effects that exceed the sum of individual stressors. For example, the combination of high temperature and humidity creates particularly aggressive degradation conditions, accelerating failure mechanisms beyond what either factor would produce independently. Understanding these complex interactions is essential for developing meaningful accelerated testing protocols that can accurately predict real-world OLED lifespan.

Humidity represents another substantial environmental stressor for OLED displays. Water molecules can penetrate encapsulation barriers and react with the organic materials and electrodes, leading to dark spots, delamination, and accelerated degradation of the emissive layers. Studies have shown that relative humidity levels above 60% can dramatically reduce OLED lifespan, particularly when combined with elevated temperatures.

Light exposure, especially in the ultraviolet spectrum, contributes significantly to OLED degradation through photochemical reactions. These reactions can break molecular bonds within the organic materials, altering their electronic properties and reducing luminous efficiency. This factor is particularly relevant when considering outdoor applications or devices used in high-brightness environments.

Oxygen exposure represents a critical degradation pathway for OLED materials. When oxygen molecules penetrate the device structure, they can react with the organic compounds, forming non-emissive oxidized species. This process, known as photo-oxidation when combined with light exposure, is one of the primary mechanisms behind luminance loss and color shift in OLED displays.

Electrical stress patterns significantly impact degradation rates, with higher current densities accelerating burn-in effects. Voltage spikes and inconsistent power delivery can create localized hot spots within the display, leading to uneven aging across the panel. This factor is particularly important when designing accelerated testing protocols that accurately reflect real-world usage patterns.

Mechanical stress, including bending, twisting, or pressure application, can compromise encapsulation integrity and create pathways for environmental contaminants. This consideration becomes increasingly important for flexible OLED applications, where repeated folding or rolling actions may accelerate degradation processes through microfractures in barrier layers.

The interaction between these environmental factors often produces synergistic effects that exceed the sum of individual stressors. For example, the combination of high temperature and humidity creates particularly aggressive degradation conditions, accelerating failure mechanisms beyond what either factor would produce independently. Understanding these complex interactions is essential for developing meaningful accelerated testing protocols that can accurately predict real-world OLED lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!