Assessing OLED Thermal Management in Compact Device Housing

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Thermal Management Evolution and Objectives

Organic Light Emitting Diode (OLED) technology has undergone significant evolution since its discovery in the 1950s, with practical applications emerging in the late 1980s. The journey from laboratory curiosity to mainstream display technology has been marked by continuous improvements in efficiency, longevity, and performance. However, thermal management has consistently remained one of the most critical challenges throughout this evolution, particularly as devices become increasingly compact and powerful.

Early OLED implementations suffered from rapid degradation due to heat accumulation, with operating temperatures significantly impacting both performance and lifespan. Research indicates that for every 10°C increase above optimal operating temperature, OLED lifetime can decrease by approximately 30-50%. This thermal sensitivity has driven continuous innovation in heat management strategies across multiple generations of OLED technology.

The miniaturization trend in consumer electronics has further complicated thermal management challenges. As device housings become more compact, the spatial constraints for traditional cooling solutions have become increasingly restrictive. Contemporary smartphones, smartwatches, and foldable devices incorporate OLED displays within enclosures that may be less than 8mm thick, creating unprecedented thermal density challenges that conventional cooling approaches struggle to address.

Current thermal management objectives focus on developing solutions that can effectively dissipate heat while maintaining the form factor advantages that make OLED technology attractive to manufacturers. These objectives include reducing thermal resistance between heat sources and dissipation pathways, implementing advanced thermal interface materials, and developing novel heat spreading technologies that can function within extremely limited spatial dimensions.

Another critical objective is the development of thermally-aware OLED panel designs that can intrinsically manage heat generation more effectively. This includes pixel architectures that distribute heat more evenly, driver circuits that minimize power consumption during operation, and materials with improved thermal conductivity properties that can channel heat away from sensitive components.

The industry is also pursuing advancements in computational thermal modeling to predict and mitigate hotspots before physical prototyping. These simulation-based approaches aim to optimize thermal pathways within the constraints of compact device housings, allowing engineers to evaluate multiple design iterations rapidly and cost-effectively.

The ultimate goal of current thermal management research is to enable OLED displays that can maintain optimal operating temperatures even under high-brightness conditions and within the most spatially constrained device architectures. Success in this domain will directly translate to extended device lifespans, improved display performance, and enhanced user experiences across the growing ecosystem of OLED-equipped devices.

Early OLED implementations suffered from rapid degradation due to heat accumulation, with operating temperatures significantly impacting both performance and lifespan. Research indicates that for every 10°C increase above optimal operating temperature, OLED lifetime can decrease by approximately 30-50%. This thermal sensitivity has driven continuous innovation in heat management strategies across multiple generations of OLED technology.

The miniaturization trend in consumer electronics has further complicated thermal management challenges. As device housings become more compact, the spatial constraints for traditional cooling solutions have become increasingly restrictive. Contemporary smartphones, smartwatches, and foldable devices incorporate OLED displays within enclosures that may be less than 8mm thick, creating unprecedented thermal density challenges that conventional cooling approaches struggle to address.

Current thermal management objectives focus on developing solutions that can effectively dissipate heat while maintaining the form factor advantages that make OLED technology attractive to manufacturers. These objectives include reducing thermal resistance between heat sources and dissipation pathways, implementing advanced thermal interface materials, and developing novel heat spreading technologies that can function within extremely limited spatial dimensions.

Another critical objective is the development of thermally-aware OLED panel designs that can intrinsically manage heat generation more effectively. This includes pixel architectures that distribute heat more evenly, driver circuits that minimize power consumption during operation, and materials with improved thermal conductivity properties that can channel heat away from sensitive components.

The industry is also pursuing advancements in computational thermal modeling to predict and mitigate hotspots before physical prototyping. These simulation-based approaches aim to optimize thermal pathways within the constraints of compact device housings, allowing engineers to evaluate multiple design iterations rapidly and cost-effectively.

The ultimate goal of current thermal management research is to enable OLED displays that can maintain optimal operating temperatures even under high-brightness conditions and within the most spatially constrained device architectures. Success in this domain will directly translate to extended device lifespans, improved display performance, and enhanced user experiences across the growing ecosystem of OLED-equipped devices.

Market Demand Analysis for Thermally Efficient Devices

The global market for thermally efficient devices has witnessed substantial growth in recent years, primarily driven by the increasing adoption of OLED technology across various consumer electronics. As devices become more compact while incorporating higher performance components, thermal management has emerged as a critical factor influencing consumer purchasing decisions and brand loyalty.

Consumer demand for slimmer, lighter, and more powerful devices continues to accelerate, with market research indicating that over 70% of smartphone users consider device thickness and weight as important purchasing factors. Simultaneously, consumers expect longer battery life and enhanced performance, creating a challenging thermal equation for manufacturers to solve.

The premium segment of the market shows particularly strong demand for thermally efficient devices, with consumers willing to pay up to 20% more for devices that maintain comfortable operating temperatures during intensive tasks. This trend is especially pronounced in gaming smartphones, ultrabooks, and high-end tablets where thermal throttling directly impacts user experience.

Enterprise customers represent another significant market segment, with IT procurement departments increasingly specifying maximum operating temperatures in their requirements. This shift reflects growing awareness of the correlation between device temperature and component longevity, with thermal management becoming a key factor in total cost of ownership calculations.

Regional analysis reveals varying market priorities, with consumers in warmer climate regions showing heightened sensitivity to device heating issues. Market surveys indicate that in Southeast Asia and the Middle East, thermal performance ranks among the top five purchasing considerations for premium smartphones, compared to eighth or ninth position in more temperate markets.

The wearable technology segment demonstrates particularly stringent thermal requirements due to direct skin contact. Market forecasts project the global wearable market to grow at a CAGR of 15.9% through 2026, with thermal comfort increasingly cited as a differentiating factor among competing products.

Industry analysts project that the market for specialized thermal management components in consumer electronics will reach $4.8 billion by 2025, representing a significant opportunity for innovation in OLED thermal solutions. This growth is further supported by regulatory trends, as several countries have introduced safety standards regarding maximum surface temperatures for consumer electronics.

The aftermarket for cooling solutions also indicates strong consumer demand, with sales of external cooling accessories for mobile devices growing by 35% annually, signaling unmet needs in built-in thermal management solutions that manufacturers could address through improved design.

Consumer demand for slimmer, lighter, and more powerful devices continues to accelerate, with market research indicating that over 70% of smartphone users consider device thickness and weight as important purchasing factors. Simultaneously, consumers expect longer battery life and enhanced performance, creating a challenging thermal equation for manufacturers to solve.

The premium segment of the market shows particularly strong demand for thermally efficient devices, with consumers willing to pay up to 20% more for devices that maintain comfortable operating temperatures during intensive tasks. This trend is especially pronounced in gaming smartphones, ultrabooks, and high-end tablets where thermal throttling directly impacts user experience.

Enterprise customers represent another significant market segment, with IT procurement departments increasingly specifying maximum operating temperatures in their requirements. This shift reflects growing awareness of the correlation between device temperature and component longevity, with thermal management becoming a key factor in total cost of ownership calculations.

Regional analysis reveals varying market priorities, with consumers in warmer climate regions showing heightened sensitivity to device heating issues. Market surveys indicate that in Southeast Asia and the Middle East, thermal performance ranks among the top five purchasing considerations for premium smartphones, compared to eighth or ninth position in more temperate markets.

The wearable technology segment demonstrates particularly stringent thermal requirements due to direct skin contact. Market forecasts project the global wearable market to grow at a CAGR of 15.9% through 2026, with thermal comfort increasingly cited as a differentiating factor among competing products.

Industry analysts project that the market for specialized thermal management components in consumer electronics will reach $4.8 billion by 2025, representing a significant opportunity for innovation in OLED thermal solutions. This growth is further supported by regulatory trends, as several countries have introduced safety standards regarding maximum surface temperatures for consumer electronics.

The aftermarket for cooling solutions also indicates strong consumer demand, with sales of external cooling accessories for mobile devices growing by 35% annually, signaling unmet needs in built-in thermal management solutions that manufacturers could address through improved design.

Current Thermal Management Challenges in Compact Devices

The thermal management of OLED displays in compact device housing presents significant engineering challenges that have intensified as devices become increasingly thinner and more powerful. Current compact devices, including smartphones, smartwatches, and foldable displays, generate substantial heat during operation while offering minimal space for traditional cooling solutions. This fundamental conflict between performance requirements and physical constraints defines the contemporary thermal management landscape.

OLED displays are particularly vulnerable to thermal issues due to their organic materials' sensitivity to temperature fluctuations. When operating temperatures exceed optimal ranges (typically 20-40°C), OLED panels experience accelerated degradation, color shifting, reduced brightness, and shortened lifespan. In extreme cases, excessive heat can cause permanent damage to display components and surrounding electronics.

The primary heat sources in OLED-equipped devices include the display panel itself, processing units, power management systems, and wireless communication modules. During intensive tasks such as gaming, video streaming, or fast charging, these components can generate heat exceeding 45°C at hotspots, creating thermal gradients that stress both the display and device structure. The challenge is compounded by consumer expectations for extended battery life, which limits the power available for active cooling systems.

Current compact device designs face several specific thermal management limitations. First, the industry trend toward seamless, unibody constructions with premium materials like glass and metal often prioritizes aesthetics over thermal efficiency. Second, the elimination of physical buttons, ports, and vents—while beneficial for water resistance and durability—severely restricts natural convection pathways. Third, the increasing integration of multiple antennas, sensors, and cameras within the device housing creates complex thermal interactions that are difficult to model and mitigate.

The miniaturization trend further exacerbates these challenges, as the volumetric density of heat-generating components continues to increase while the surface area available for heat dissipation decreases. This unfavorable scaling relationship creates fundamental thermodynamic barriers that conventional passive cooling approaches struggle to overcome. Additionally, the industry's shift toward flexible and foldable OLED displays introduces new thermal management complexities, as these displays must maintain consistent temperature across bendable surfaces with varying thermal properties.

Market pressures for rapid product development cycles often result in thermal management being addressed late in the design process, leading to suboptimal solutions. This reactive approach typically relies on throttling device performance when temperatures rise, creating a negative user experience that contradicts marketing promises of sustained high performance.

OLED displays are particularly vulnerable to thermal issues due to their organic materials' sensitivity to temperature fluctuations. When operating temperatures exceed optimal ranges (typically 20-40°C), OLED panels experience accelerated degradation, color shifting, reduced brightness, and shortened lifespan. In extreme cases, excessive heat can cause permanent damage to display components and surrounding electronics.

The primary heat sources in OLED-equipped devices include the display panel itself, processing units, power management systems, and wireless communication modules. During intensive tasks such as gaming, video streaming, or fast charging, these components can generate heat exceeding 45°C at hotspots, creating thermal gradients that stress both the display and device structure. The challenge is compounded by consumer expectations for extended battery life, which limits the power available for active cooling systems.

Current compact device designs face several specific thermal management limitations. First, the industry trend toward seamless, unibody constructions with premium materials like glass and metal often prioritizes aesthetics over thermal efficiency. Second, the elimination of physical buttons, ports, and vents—while beneficial for water resistance and durability—severely restricts natural convection pathways. Third, the increasing integration of multiple antennas, sensors, and cameras within the device housing creates complex thermal interactions that are difficult to model and mitigate.

The miniaturization trend further exacerbates these challenges, as the volumetric density of heat-generating components continues to increase while the surface area available for heat dissipation decreases. This unfavorable scaling relationship creates fundamental thermodynamic barriers that conventional passive cooling approaches struggle to overcome. Additionally, the industry's shift toward flexible and foldable OLED displays introduces new thermal management complexities, as these displays must maintain consistent temperature across bendable surfaces with varying thermal properties.

Market pressures for rapid product development cycles often result in thermal management being addressed late in the design process, leading to suboptimal solutions. This reactive approach typically relies on throttling device performance when temperatures rise, creating a negative user experience that contradicts marketing promises of sustained high performance.

Existing OLED Thermal Management Approaches

01 Heat dissipation structures for OLED displays

Various heat dissipation structures can be integrated into OLED displays to manage thermal issues. These include heat sinks, thermal interface materials, and specialized substrates that efficiently conduct heat away from the OLED components. These structures help maintain optimal operating temperatures, preventing thermal degradation and extending the lifespan of OLED devices.- Heat dissipation structures for OLED displays: Various heat dissipation structures can be integrated into OLED displays to manage thermal issues. These include heat sinks, thermal interface materials, and specialized substrates that efficiently conduct heat away from the light-emitting components. Such structures help maintain optimal operating temperatures, prevent thermal degradation, and extend the lifespan of OLED devices by reducing hotspots and thermal stress on sensitive components.

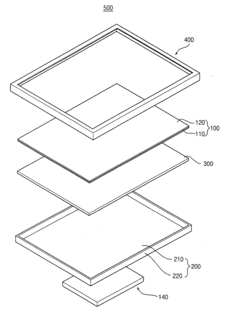

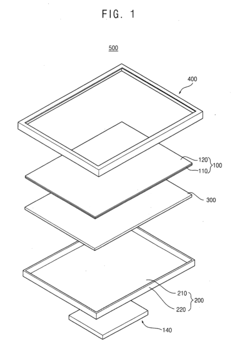

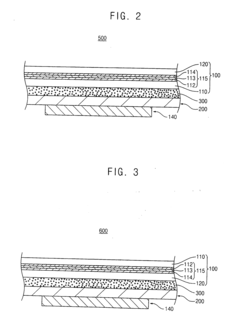

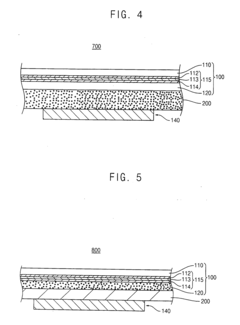

- Thermal management layers in OLED panel construction: Specialized thermal management layers can be incorporated into the multilayer structure of OLED panels. These layers may include graphene, metal foils, or composite materials with high thermal conductivity positioned strategically within the display stack. Such thermal management layers facilitate efficient heat spreading throughout the panel, reducing temperature gradients and preventing localized overheating that can lead to uneven aging and performance degradation.

- Active cooling systems for OLED devices: Active cooling systems can be implemented in OLED devices to provide enhanced thermal management. These systems may include miniaturized fans, liquid cooling channels, thermoelectric coolers, or microfluidic heat exchangers. Active cooling approaches are particularly valuable for high-brightness OLED applications or displays operating in challenging environmental conditions where passive cooling alone may be insufficient to maintain optimal operating temperatures.

- Thermal management through encapsulation and packaging: Advanced encapsulation and packaging techniques can significantly improve thermal management in OLED displays. These include thermally conductive adhesives, specialized sealants, and packaging materials that facilitate heat transfer while maintaining the hermetic seal necessary to protect sensitive organic materials. Proper encapsulation design can create thermal pathways that direct heat away from critical components while still providing the moisture and oxygen barrier properties essential for OLED longevity.

- Thermal management control systems and algorithms: Intelligent control systems and algorithms can be implemented to dynamically manage thermal conditions in OLED displays. These systems may include temperature sensors, thermal imaging, predictive modeling, and adaptive brightness control that responds to detected thermal conditions. By actively monitoring and adjusting operating parameters based on thermal feedback, these systems can prevent overheating scenarios while optimizing performance and energy efficiency under varying usage conditions.

02 Thermal management layers in OLED stack

Incorporating specialized thermal management layers within the OLED stack architecture can significantly improve heat distribution. These layers may include thermally conductive materials positioned between the light-emitting layers and substrate, or heat-spreading films that distribute heat evenly across the display area, reducing hotspots and thermal stress on sensitive components.Expand Specific Solutions03 Active cooling systems for OLED devices

Active cooling systems can be implemented to manage thermal issues in high-brightness or large-format OLED applications. These systems may include micro-fans, liquid cooling channels, or thermoelectric coolers that actively remove heat from critical components. Such active approaches are particularly valuable in applications where passive cooling alone is insufficient to maintain optimal operating temperatures.Expand Specific Solutions04 Thermal interface materials for OLED panels

Specialized thermal interface materials can be used between OLED panels and heat dissipation components to maximize thermal transfer efficiency. These materials include thermally conductive adhesives, phase change materials, and graphene-based composites that fill microscopic air gaps and ensure efficient heat conduction away from sensitive OLED components, preventing localized overheating.Expand Specific Solutions05 Thermal management algorithms and control systems

Advanced thermal management algorithms and control systems can dynamically adjust OLED operation based on temperature monitoring. These systems may include temperature sensors, predictive thermal modeling, and brightness adjustment algorithms that proactively manage heat generation. By intelligently controlling power distribution and pixel brightness based on thermal conditions, these systems prevent overheating while maintaining optimal visual performance.Expand Specific Solutions

Key Industry Players in OLED Thermal Solutions

The OLED thermal management market in compact devices is currently in a growth phase, with increasing adoption across consumer electronics. The market size is expanding rapidly due to rising demand for thinner, lighter devices with superior display quality. Technologically, the field is moderately mature but still evolving, with key players developing innovative solutions. Industry leaders like Samsung Display, LG Display, and BOE Technology are advancing thermal management techniques through proprietary technologies, while Apple and Sony drive implementation standards. Companies like OSRAM OLED and OLEDWorks focus on specialized thermal solutions, and traditional electronics manufacturers including Dell and Intel are integrating these advancements into their product ecosystems. The competitive landscape shows a mix of display specialists and device manufacturers collaborating to overcome thermal constraints in increasingly compact form factors.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed an integrated thermal management solution for OLED displays called "CoolSense" specifically designed for compact device housings. This technology incorporates multiple heat dissipation layers directly into the OLED panel structure, including graphene-enhanced heat spreading films that are less than 50μm thick yet provide thermal conductivity exceeding 1500 W/m·K. BOE's approach utilizes a network of micro heat pipes embedded within the display assembly that efficiently channel heat to the device periphery. Their solution also features specialized thermal interface materials with phase-change properties that optimize contact between heat-generating components and dissipation structures. For ultra-compact applications like smartwatches, BOE has pioneered a "thermal frame" design that integrates the structural and thermal management functions into a single component, maximizing the limited space available. Additionally, BOE implements dynamic thermal management algorithms that adjust display parameters based on real-time temperature monitoring to prevent thermal damage while maintaining optimal visual performance.

Strengths: Cost-effective thermal solutions suitable for mass production; strong integration capabilities across different device categories; innovative materials research specifically targeting compact applications. Weaknesses: Some advanced cooling technologies still in development phase; thermal solutions may require compromises in other device specifications.

Apple, Inc.

Technical Solution: Apple has developed a sophisticated multi-layered thermal management system for OLED displays in compact devices like iPhones and Apple Watches. Their approach integrates graphite heat spreaders with copper heat pipes to create efficient thermal pathways away from the OLED panel. Apple's solution incorporates a vapor chamber cooling system that utilizes phase-change materials to absorb and dissipate heat more effectively than traditional methods. The company has patented a specialized thermal interface material (TIM) that maximizes heat transfer between the OLED panel and cooling components while maintaining minimal thickness. Additionally, Apple employs algorithmic brightness management that dynamically adjusts display output based on thermal conditions to prevent hotspots and extend OLED longevity while maintaining optimal user experience.

Strengths: Exceptional integration of cooling systems within ultra-thin form factors; proprietary materials science expertise; sophisticated thermal algorithms that balance performance and protection. Weaknesses: Higher manufacturing costs; reliance on premium materials that may face supply constraints; thermal solutions add complexity to repair processes.

Critical Patents in Compact Device Heat Dissipation

OLED display having thermally conductive material

PatentWO2006002405A2

Innovation

- Incorporating a thermally conductive, conformable, and compressible material with a thickness greater than 1 micron and thermal conductivity greater than 0.25 W/mK between the OLED light-emitting elements and the encapsulating cover to facilitate uniform heat distribution and removal.

Organic light-emitting diode display device

PatentActiveUS20080007159A1

Innovation

- Incorporating a heat insulating member made of porous polymer between the display panel and the driving circuit part, or between the display panel and the receiving container, to prevent heat generated by the driving circuit from reaching the light-emitting layer, thereby maintaining a lower temperature and reducing degradation.

Material Science Advancements for Thermal Conductivity

Recent advancements in material science have revolutionized thermal management solutions for OLED displays in compact device housings. Traditional materials like aluminum and copper, while effective heat conductors, often present limitations in terms of weight, form factor flexibility, and integration capabilities within increasingly thin device profiles.

Graphene has emerged as a breakthrough material, offering thermal conductivity values exceeding 5000 W/mK, significantly outperforming conventional copper (400 W/mK). This two-dimensional carbon allotrope can be incorporated into ultra-thin films and composite structures, making it particularly suitable for space-constrained OLED implementations. Research indicates that graphene-enhanced thermal interface materials (TIMs) can reduce hotspot temperatures by up to 25% compared to standard solutions.

Carbon nanotubes (CNTs) represent another promising development, with thermal conductivity reaching 3500 W/mK for single-walled variants. When aligned in specific orientations and integrated into polymer matrices, CNT-based composites provide directional heat transfer capabilities critical for channeling thermal energy away from sensitive OLED components. These materials can be applied in thicknesses below 100μm while maintaining exceptional thermal performance.

Boron nitride nanostructures, particularly hexagonal boron nitride (h-BN), offer excellent thermal conductivity (up to 2000 W/mK) combined with electrical insulation properties. This dual characteristic makes h-BN particularly valuable for OLED applications where electrical isolation must be maintained alongside effective heat dissipation. Recent developments in h-BN aerogels and composites have demonstrated up to 40% improvement in thermal management efficiency.

Phase change materials (PCMs) represent an adaptive approach to thermal management. These materials absorb excess heat during peak operation by changing phase, typically from solid to liquid, effectively storing thermal energy that would otherwise cause temperature spikes. New microencapsulated PCMs specifically engineered for electronics applications can operate within the critical temperature range of 40-70°C where OLED degradation accelerates.

Metal-organic frameworks (MOFs) constitute an emerging class of materials with tunable thermal properties. Their porous structure can be engineered to create thermal pathways while maintaining lightweight characteristics. Recent research demonstrates that copper-based MOFs can achieve thermal conductivity values approaching 20 W/mK while adding minimal weight to device assemblies.

Diamond-based composites, including chemical vapor deposition (CVD) diamond films and diamond particle-infused polymers, offer exceptional thermal conductivity (up to 2200 W/mK) with the added benefit of optical transparency. This property is particularly valuable for front-of-display thermal management solutions that must maintain visual clarity while dissipating heat from OLED panels.

Graphene has emerged as a breakthrough material, offering thermal conductivity values exceeding 5000 W/mK, significantly outperforming conventional copper (400 W/mK). This two-dimensional carbon allotrope can be incorporated into ultra-thin films and composite structures, making it particularly suitable for space-constrained OLED implementations. Research indicates that graphene-enhanced thermal interface materials (TIMs) can reduce hotspot temperatures by up to 25% compared to standard solutions.

Carbon nanotubes (CNTs) represent another promising development, with thermal conductivity reaching 3500 W/mK for single-walled variants. When aligned in specific orientations and integrated into polymer matrices, CNT-based composites provide directional heat transfer capabilities critical for channeling thermal energy away from sensitive OLED components. These materials can be applied in thicknesses below 100μm while maintaining exceptional thermal performance.

Boron nitride nanostructures, particularly hexagonal boron nitride (h-BN), offer excellent thermal conductivity (up to 2000 W/mK) combined with electrical insulation properties. This dual characteristic makes h-BN particularly valuable for OLED applications where electrical isolation must be maintained alongside effective heat dissipation. Recent developments in h-BN aerogels and composites have demonstrated up to 40% improvement in thermal management efficiency.

Phase change materials (PCMs) represent an adaptive approach to thermal management. These materials absorb excess heat during peak operation by changing phase, typically from solid to liquid, effectively storing thermal energy that would otherwise cause temperature spikes. New microencapsulated PCMs specifically engineered for electronics applications can operate within the critical temperature range of 40-70°C where OLED degradation accelerates.

Metal-organic frameworks (MOFs) constitute an emerging class of materials with tunable thermal properties. Their porous structure can be engineered to create thermal pathways while maintaining lightweight characteristics. Recent research demonstrates that copper-based MOFs can achieve thermal conductivity values approaching 20 W/mK while adding minimal weight to device assemblies.

Diamond-based composites, including chemical vapor deposition (CVD) diamond films and diamond particle-infused polymers, offer exceptional thermal conductivity (up to 2200 W/mK) with the added benefit of optical transparency. This property is particularly valuable for front-of-display thermal management solutions that must maintain visual clarity while dissipating heat from OLED panels.

Environmental Impact of Thermal Management Solutions

The environmental implications of thermal management solutions for OLED displays in compact devices represent a growing concern as consumer electronics production continues to escalate globally. Traditional cooling methods often rely on materials and processes that carry significant ecological footprints, necessitating a comprehensive assessment of their environmental impact throughout the product lifecycle.

Metal-based heat sinks and thermal spreaders, commonly used in OLED thermal management, require energy-intensive mining and manufacturing processes. Aluminum production, for instance, generates approximately 12 tons of CO2 per ton of material produced, while copper extraction leads to substantial habitat disruption and potential water contamination. The miniaturization trend in device design further exacerbates these issues by requiring specialized alloys with rare earth elements, whose extraction often involves environmentally destructive practices.

Chemical compounds in thermal interface materials (TIMs) present additional environmental challenges. Silicone-based thermal greases contain non-biodegradable components that persist in ecosystems, while some phase-change materials incorporate potentially toxic substances that can leach into groundwater when improperly disposed. Recent studies indicate that up to 85% of electronic waste containing these materials is not properly recycled, contributing to environmental contamination.

Energy consumption during device operation represents another significant environmental factor. Inefficient thermal management solutions necessitate higher power draw, increasing carbon emissions throughout the product's operational life. Research indicates that optimized thermal design can reduce device energy consumption by 8-15%, translating to substantial emissions reductions when scaled across millions of devices.

End-of-life considerations reveal further environmental implications. The complex material composition of modern thermal solutions complicates recycling efforts, with many components classified as hazardous waste requiring specialized processing. Particularly concerning are vapor chambers and heat pipes containing working fluids that may include compounds with high global warming potential or ozone depletion properties.

Emerging sustainable alternatives show promise in reducing environmental impact. Bio-based thermal interface materials derived from renewable resources demonstrate comparable thermal performance with significantly reduced ecological footprints. Similarly, passive cooling designs that minimize material usage while maintaining thermal efficiency represent an environmentally preferable approach, potentially reducing embodied carbon by up to 30% compared to conventional solutions.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with legislation like the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives imposing stricter requirements on manufacturers regarding material selection and end-of-life management for thermal components in electronic devices.

Metal-based heat sinks and thermal spreaders, commonly used in OLED thermal management, require energy-intensive mining and manufacturing processes. Aluminum production, for instance, generates approximately 12 tons of CO2 per ton of material produced, while copper extraction leads to substantial habitat disruption and potential water contamination. The miniaturization trend in device design further exacerbates these issues by requiring specialized alloys with rare earth elements, whose extraction often involves environmentally destructive practices.

Chemical compounds in thermal interface materials (TIMs) present additional environmental challenges. Silicone-based thermal greases contain non-biodegradable components that persist in ecosystems, while some phase-change materials incorporate potentially toxic substances that can leach into groundwater when improperly disposed. Recent studies indicate that up to 85% of electronic waste containing these materials is not properly recycled, contributing to environmental contamination.

Energy consumption during device operation represents another significant environmental factor. Inefficient thermal management solutions necessitate higher power draw, increasing carbon emissions throughout the product's operational life. Research indicates that optimized thermal design can reduce device energy consumption by 8-15%, translating to substantial emissions reductions when scaled across millions of devices.

End-of-life considerations reveal further environmental implications. The complex material composition of modern thermal solutions complicates recycling efforts, with many components classified as hazardous waste requiring specialized processing. Particularly concerning are vapor chambers and heat pipes containing working fluids that may include compounds with high global warming potential or ozone depletion properties.

Emerging sustainable alternatives show promise in reducing environmental impact. Bio-based thermal interface materials derived from renewable resources demonstrate comparable thermal performance with significantly reduced ecological footprints. Similarly, passive cooling designs that minimize material usage while maintaining thermal efficiency represent an environmentally preferable approach, potentially reducing embodied carbon by up to 30% compared to conventional solutions.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with legislation like the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives imposing stricter requirements on manufacturers regarding material selection and end-of-life management for thermal components in electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!