How to Conduct OLED Emission Wavelength Consistency Tests

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Emission Wavelength Testing Background and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized display and lighting industries since its commercial introduction in the late 1990s. The technology's evolution has been marked by significant improvements in efficiency, color accuracy, and manufacturing processes. OLED displays offer superior contrast ratios, wider viewing angles, and faster response times compared to traditional LCD technology, making them increasingly prevalent in consumer electronics, automotive displays, and lighting applications.

Emission wavelength consistency represents a critical quality parameter in OLED manufacturing, directly impacting color accuracy, display uniformity, and overall product performance. Inconsistencies in emission wavelengths can lead to color variations across displays, affecting brand perception and user experience. The primary objective of OLED emission wavelength consistency testing is to ensure that manufactured panels maintain precise color reproduction within established tolerances throughout their operational lifetime.

Historical testing methodologies have evolved from basic spectrophotometric measurements to sophisticated integrated testing systems. Early approaches focused primarily on end-product verification, while modern techniques emphasize in-line process monitoring and statistical process control. This evolution reflects the industry's growing emphasis on quality assurance and manufacturing efficiency.

Current testing objectives encompass multiple dimensions: quantifying wavelength variations across individual panels, ensuring batch-to-batch consistency, predicting color stability over time, and correlating manufacturing parameters with emission characteristics. These objectives align with broader industry trends toward higher resolution displays, wider color gamuts, and more stringent quality standards.

The technological landscape for emission wavelength testing continues to evolve, with emerging methodologies incorporating machine learning algorithms for predictive quality control and automated defect classification. Advanced spectral analysis techniques now enable sub-nanometer precision in wavelength measurements, allowing manufacturers to detect subtle variations that would have been undetectable with previous generation equipment.

Regulatory frameworks and industry standards further shape testing objectives, with organizations like the International Electrotechnical Commission (IEC) and Society for Information Display (SID) establishing standardized testing protocols and performance metrics. These standards ensure consistency across the industry while driving continuous improvement in testing methodologies.

As OLED technology expands into new application domains such as flexible displays, transparent panels, and micro-displays for augmented reality, emission wavelength testing faces new challenges and requirements. Testing objectives must now address novel form factors, substrate materials, and operating conditions while maintaining backward compatibility with established quality control systems.

Emission wavelength consistency represents a critical quality parameter in OLED manufacturing, directly impacting color accuracy, display uniformity, and overall product performance. Inconsistencies in emission wavelengths can lead to color variations across displays, affecting brand perception and user experience. The primary objective of OLED emission wavelength consistency testing is to ensure that manufactured panels maintain precise color reproduction within established tolerances throughout their operational lifetime.

Historical testing methodologies have evolved from basic spectrophotometric measurements to sophisticated integrated testing systems. Early approaches focused primarily on end-product verification, while modern techniques emphasize in-line process monitoring and statistical process control. This evolution reflects the industry's growing emphasis on quality assurance and manufacturing efficiency.

Current testing objectives encompass multiple dimensions: quantifying wavelength variations across individual panels, ensuring batch-to-batch consistency, predicting color stability over time, and correlating manufacturing parameters with emission characteristics. These objectives align with broader industry trends toward higher resolution displays, wider color gamuts, and more stringent quality standards.

The technological landscape for emission wavelength testing continues to evolve, with emerging methodologies incorporating machine learning algorithms for predictive quality control and automated defect classification. Advanced spectral analysis techniques now enable sub-nanometer precision in wavelength measurements, allowing manufacturers to detect subtle variations that would have been undetectable with previous generation equipment.

Regulatory frameworks and industry standards further shape testing objectives, with organizations like the International Electrotechnical Commission (IEC) and Society for Information Display (SID) establishing standardized testing protocols and performance metrics. These standards ensure consistency across the industry while driving continuous improvement in testing methodologies.

As OLED technology expands into new application domains such as flexible displays, transparent panels, and micro-displays for augmented reality, emission wavelength testing faces new challenges and requirements. Testing objectives must now address novel form factors, substrate materials, and operating conditions while maintaining backward compatibility with established quality control systems.

Market Demand for Wavelength Consistency in Display Industry

The global display industry has witnessed a significant shift towards OLED technology in recent years, with market demand for consistent emission wavelength becoming increasingly critical. This demand is primarily driven by high-end consumer electronics manufacturers who require precise color reproduction across their product lines. According to industry reports, the OLED display market reached approximately $38 billion in 2022 and is projected to grow at a CAGR of 14.7% through 2028, with wavelength consistency being a key quality differentiator.

Consumer expectations for visual fidelity have risen dramatically, particularly in premium smartphones, televisions, and professional monitors. End users now demand perfect color matching between devices of the same model, creating substantial pressure on manufacturers to implement rigorous wavelength consistency testing. This trend is especially pronounced in the luxury smartphone segment, where even minor color variations between units can trigger consumer complaints and warranty claims.

The automotive industry represents another significant market driver, as OLED displays increasingly appear in vehicle dashboards and entertainment systems. Here, wavelength consistency is not merely an aesthetic concern but also a safety consideration, as inconsistent color reproduction could potentially affect driver information interpretation. Automotive OEMs typically specify wavelength tolerances below ±2 nm, creating substantial technical challenges for display manufacturers.

Professional markets, including medical imaging, color-critical design work, and scientific visualization, demand even tighter wavelength consistency. In medical displays, for instance, diagnostic accuracy depends on precise color reproduction, with some applications requiring wavelength variations under ±1 nm. This specialized segment, though smaller in volume, commands premium pricing and influences technical standards across the broader industry.

Regional market analysis reveals varying demands for wavelength consistency. Asian markets, particularly Japan and South Korea, show the highest sensitivity to color accuracy, while North American and European markets emphasize consistency across product batches. This regional variation creates complex supply chain requirements for global manufacturers.

The economic impact of wavelength inconsistency is substantial. Manufacturing yields can drop by 15-20% when strict wavelength parameters are implemented without appropriate testing methodologies. Conversely, manufacturers who master consistency testing can command price premiums of 5-8% for their display components, according to industry consultants. This economic incentive has accelerated investment in advanced testing equipment and methodologies.

Future market projections indicate that wavelength consistency will become even more critical as microLED technology enters mass production, potentially creating new testing challenges while simultaneously raising consumer expectations for color accuracy across all display technologies.

Consumer expectations for visual fidelity have risen dramatically, particularly in premium smartphones, televisions, and professional monitors. End users now demand perfect color matching between devices of the same model, creating substantial pressure on manufacturers to implement rigorous wavelength consistency testing. This trend is especially pronounced in the luxury smartphone segment, where even minor color variations between units can trigger consumer complaints and warranty claims.

The automotive industry represents another significant market driver, as OLED displays increasingly appear in vehicle dashboards and entertainment systems. Here, wavelength consistency is not merely an aesthetic concern but also a safety consideration, as inconsistent color reproduction could potentially affect driver information interpretation. Automotive OEMs typically specify wavelength tolerances below ±2 nm, creating substantial technical challenges for display manufacturers.

Professional markets, including medical imaging, color-critical design work, and scientific visualization, demand even tighter wavelength consistency. In medical displays, for instance, diagnostic accuracy depends on precise color reproduction, with some applications requiring wavelength variations under ±1 nm. This specialized segment, though smaller in volume, commands premium pricing and influences technical standards across the broader industry.

Regional market analysis reveals varying demands for wavelength consistency. Asian markets, particularly Japan and South Korea, show the highest sensitivity to color accuracy, while North American and European markets emphasize consistency across product batches. This regional variation creates complex supply chain requirements for global manufacturers.

The economic impact of wavelength inconsistency is substantial. Manufacturing yields can drop by 15-20% when strict wavelength parameters are implemented without appropriate testing methodologies. Conversely, manufacturers who master consistency testing can command price premiums of 5-8% for their display components, according to industry consultants. This economic incentive has accelerated investment in advanced testing equipment and methodologies.

Future market projections indicate that wavelength consistency will become even more critical as microLED technology enters mass production, potentially creating new testing challenges while simultaneously raising consumer expectations for color accuracy across all display technologies.

Current Challenges in OLED Emission Wavelength Testing

Despite significant advancements in OLED technology, ensuring consistent emission wavelengths across displays remains a formidable challenge. Current testing methodologies face several critical limitations that impede quality control in manufacturing environments. The primary challenge lies in the inherent variability of organic materials used in OLED fabrication, which can exhibit different emission characteristics even within the same production batch, resulting in color inconsistencies across panels.

Measurement precision presents another significant hurdle. Conventional spectrometers often lack the necessary resolution to detect subtle wavelength shifts that can significantly impact perceived color quality. This limitation becomes particularly problematic when testing high-resolution displays where pixel-level variations must be identified with extreme accuracy. The industry currently struggles with a trade-off between measurement speed and precision, with high-precision equipment typically requiring longer testing times incompatible with mass production requirements.

Environmental factors further complicate testing procedures. OLED emission wavelengths are notably sensitive to temperature fluctuations, with shifts of up to 2-3nm observed with just a 10°C change. This necessitates strictly controlled testing environments that are difficult to maintain consistently in production settings. Additionally, humidity variations can accelerate degradation processes in organic materials, potentially altering emission characteristics during extended testing procedures.

The aging behavior of OLED materials introduces temporal challenges to wavelength consistency testing. Emission wavelengths typically shift over device lifetime, with different rates of change for different color components. Current testing protocols struggle to predict these long-term changes based on initial measurements, creating a disconnect between factory quality control and real-world performance.

Calibration standardization across the industry remains inadequate, with different manufacturers employing varied reference standards and measurement protocols. This lack of uniformity makes cross-comparison between different testing systems problematic and hampers the establishment of universal quality benchmarks for emission wavelength consistency.

For micro-displays and transparent OLED applications, existing testing equipment often proves insufficient due to unique form factors and optical properties. The miniaturization trend in display technology has outpaced the development of corresponding testing methodologies, creating a technological gap in quality assurance capabilities.

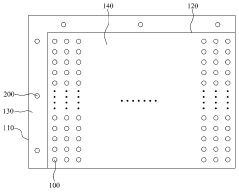

Finally, current testing approaches typically focus on average wavelength measurements across display areas rather than pixel-level precision. This statistical approach masks localized inconsistencies that can significantly impact image quality, particularly in applications requiring high color accuracy such as medical imaging or professional content creation.

Measurement precision presents another significant hurdle. Conventional spectrometers often lack the necessary resolution to detect subtle wavelength shifts that can significantly impact perceived color quality. This limitation becomes particularly problematic when testing high-resolution displays where pixel-level variations must be identified with extreme accuracy. The industry currently struggles with a trade-off between measurement speed and precision, with high-precision equipment typically requiring longer testing times incompatible with mass production requirements.

Environmental factors further complicate testing procedures. OLED emission wavelengths are notably sensitive to temperature fluctuations, with shifts of up to 2-3nm observed with just a 10°C change. This necessitates strictly controlled testing environments that are difficult to maintain consistently in production settings. Additionally, humidity variations can accelerate degradation processes in organic materials, potentially altering emission characteristics during extended testing procedures.

The aging behavior of OLED materials introduces temporal challenges to wavelength consistency testing. Emission wavelengths typically shift over device lifetime, with different rates of change for different color components. Current testing protocols struggle to predict these long-term changes based on initial measurements, creating a disconnect between factory quality control and real-world performance.

Calibration standardization across the industry remains inadequate, with different manufacturers employing varied reference standards and measurement protocols. This lack of uniformity makes cross-comparison between different testing systems problematic and hampers the establishment of universal quality benchmarks for emission wavelength consistency.

For micro-displays and transparent OLED applications, existing testing equipment often proves insufficient due to unique form factors and optical properties. The miniaturization trend in display technology has outpaced the development of corresponding testing methodologies, creating a technological gap in quality assurance capabilities.

Finally, current testing approaches typically focus on average wavelength measurements across display areas rather than pixel-level precision. This statistical approach masks localized inconsistencies that can significantly impact image quality, particularly in applications requiring high color accuracy such as medical imaging or professional content creation.

Current Methodologies for Emission Wavelength Consistency Testing

01 Material composition for wavelength consistency

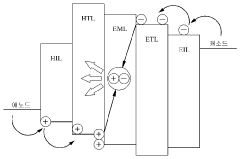

Specific material compositions can be used to achieve consistent emission wavelengths in OLEDs. These include carefully selected host materials, dopants, and emitter compounds that maintain stable spectral characteristics over time and operating conditions. The molecular structure of these materials is engineered to provide narrow emission bands and reduce wavelength shifts due to aging or temperature variations.- Material composition for wavelength stability: Specific organic and inorganic materials can be incorporated into OLED structures to maintain consistent emission wavelengths. These materials include specially designed host-dopant systems and phosphorescent compounds that minimize wavelength shifts during operation. By carefully selecting materials with stable electronic properties, manufacturers can reduce variations in color output across different operating conditions and over the device lifetime.

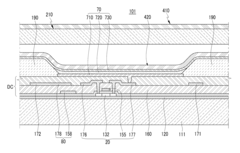

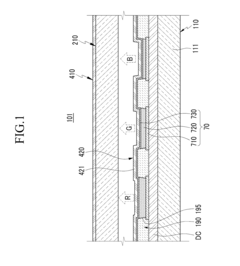

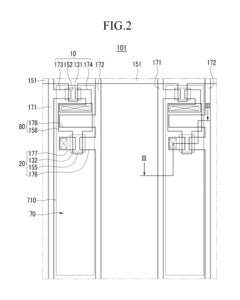

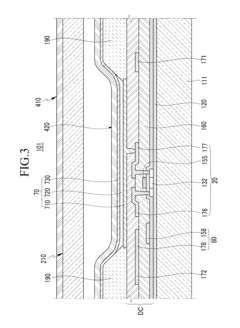

- Device structure optimization for emission consistency: The physical structure of OLED devices can be engineered to improve wavelength consistency. This includes optimizing layer thicknesses, implementing optical microcavities, and designing specialized electrode configurations. Multi-layer structures with carefully controlled interfaces help maintain stable charge injection and recombination zones, resulting in more consistent emission wavelengths across the display and during operation.

- Feedback control systems for wavelength monitoring: Advanced feedback control systems can be implemented to monitor and adjust OLED emission wavelengths in real-time. These systems use optical sensors to detect wavelength shifts and apply corrective measures through driving circuit adjustments. By continuously monitoring emission characteristics and making compensatory adjustments, these systems maintain consistent wavelength output despite variations in temperature, aging, or other operational factors.

- Thermal management techniques: Thermal management solutions are critical for maintaining wavelength consistency in OLEDs, as temperature fluctuations can cause significant shifts in emission wavelength. These techniques include heat dissipation structures, thermal isolation layers, and temperature-compensated driving schemes. By stabilizing the operating temperature of the emissive materials, these approaches minimize thermally-induced wavelength variations and ensure more consistent color output.

- Laser-based OLED emission stabilization: Laser technology can be integrated with OLED systems to achieve highly stable emission wavelengths. These approaches include laser-assisted deposition of emissive materials, laser-induced crystallization for improved molecular ordering, and hybrid laser-OLED architectures. The inherent wavelength stability of laser systems helps to establish reference points for OLED emission, resulting in more consistent and precisely controlled wavelength output across different operating conditions.

02 Device structure optimization for emission stability

The physical structure of OLED devices can be optimized to maintain wavelength consistency. This includes multi-layer designs with specialized transport layers, optical cavity tuning, and electrode configurations that minimize wavelength shifts. Structural elements like microcavities and quantum wells can be incorporated to constrain emission wavelengths within desired ranges regardless of driving conditions.Expand Specific Solutions03 Feedback control systems for wavelength stabilization

Advanced feedback control systems can be implemented to monitor and adjust OLED emission wavelengths in real-time. These systems use sensors to detect spectral shifts and apply compensating adjustments to driving parameters. Algorithms process the feedback data to maintain consistent wavelength output despite variations in temperature, current density, or device aging.Expand Specific Solutions04 Laser-based OLED emission techniques

Laser-based approaches can be used to achieve highly consistent emission wavelengths in OLED devices. These techniques include organic semiconductor lasers, stimulated emission configurations, and resonant cavity designs that produce coherent light with narrow spectral width. The laser mechanisms provide inherently more stable wavelength characteristics compared to traditional spontaneous emission OLEDs.Expand Specific Solutions05 Thermal management for wavelength stability

Thermal management solutions can significantly improve emission wavelength consistency in OLEDs. These include heat dissipation structures, temperature-compensating circuits, and thermally conductive substrates that minimize temperature gradients across the device. By maintaining uniform operating temperatures, these approaches prevent thermal-induced wavelength shifts that commonly affect OLED emission characteristics.Expand Specific Solutions

Key Industry Players in OLED Testing Equipment

The OLED emission wavelength consistency testing market is currently in a growth phase, driven by increasing demand for high-quality displays in consumer electronics. The global market size is expanding rapidly, estimated to reach several billion dollars by 2025 as OLED technology becomes more prevalent in smartphones, TVs, and automotive displays. From a technical maturity perspective, the field shows varying levels of advancement among key players. Samsung Display and LG Display lead with sophisticated testing methodologies, while BOE Technology and TCL China Star are rapidly closing the gap with significant R&D investments. Companies like Visionox, Tianma Microelectronics, and Innolux are developing competitive testing solutions, while specialized equipment manufacturers including Agilent Technologies and TSE Co. provide critical testing instruments. The ecosystem is becoming increasingly sophisticated as wavelength consistency becomes a crucial quality differentiator in premium OLED applications.

BOE Technology Group Co., Ltd.

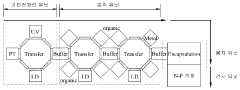

Technical Solution: BOE has developed a sophisticated OLED emission wavelength consistency testing system that combines spectrophotometric analysis with AI-powered quality control. Their approach utilizes an array of calibrated spectrophotometers positioned at strategic points along the production line to continuously monitor emission wavelength characteristics. BOE's testing methodology incorporates reference standards that are traceable to international metrology institutes, ensuring measurement accuracy and repeatability. The company employs a dual-stage testing protocol: first conducting high-speed screening measurements across entire panels, then performing detailed spectral analysis on identified regions of interest. Their system can detect wavelength variations of approximately 0.3nm while maintaining production efficiency. BOE has also implemented an automated feedback mechanism that adjusts manufacturing parameters in real-time based on test results, helping to maintain consistency throughout production runs. The company's testing facilities operate under ISO-certified clean room conditions with controlled temperature, humidity, and particulate levels to ensure measurement reliability.

Strengths: Seamless integration with production systems allowing for real-time adjustments; AI-enhanced detection algorithms that improve over time; high throughput without sacrificing necessary precision. Weaknesses: Slightly lower precision compared to some competitors (0.3nm vs 0.1-0.2nm); system requires regular validation against external standards; significant computational resources required for real-time analysis.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed a comprehensive OLED emission wavelength consistency testing methodology that combines spectroradiometric measurements with proprietary algorithms. Their approach utilizes high-precision spectroradiometers to capture the complete emission spectrum across multiple points of OLED panels. The company employs a multi-stage testing protocol that includes initial calibration, in-process monitoring, and final quality verification. Samsung's system can detect wavelength variations as small as 0.2nm across panels, ensuring color uniformity in mass production. Their methodology incorporates temperature-controlled testing environments to account for thermal effects on emission characteristics, as temperature fluctuations can significantly impact OLED emission wavelengths. Additionally, Samsung has implemented automated optical inspection systems with machine learning algorithms that can identify subtle wavelength inconsistencies that might be missed by conventional testing methods.

Strengths: Industry-leading precision with detection capability down to 0.2nm variations; integrated production line testing allowing real-time adjustments; proprietary algorithms for compensating minor variations. Weaknesses: Highly sophisticated equipment requires significant capital investment; testing process is time-intensive which may impact production throughput; system requires frequent recalibration to maintain accuracy standards.

Critical Patents and Innovations in Spectral Analysis

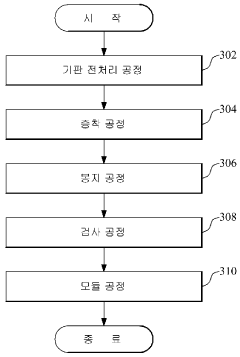

Method for testing an organic light emitting diode panel

PatentActiveKR1020120077791A

Innovation

- A noise measurement method is employed to inspect OLED panels before or after encapsulation, using a lookup table to correlate noise characteristics with lifespan, allowing real-time quality assessment by comparing measured noise with predefined criteria.

Organic light emitting diode display and method for manufacturing the same

PatentActiveUS20110204388A1

Innovation

- The implementation of a phase delay capping layer with a refractive index between 1.8 and 2.7, formed through thermal deposition at an inclined angle, which converts linearly polarized external light to circularly polarized light and back to linearly polarized light, is used in conjunction with a polarizing plate to minimize external light reflection. This layer is made of materials like titanium oxide or zinc oxide and has a thickness of 0.9 to 1.3 μm, incorporating double refraction characteristics and cylindrical microelements.

Quality Control Standards and Specifications for OLED Displays

Quality control standards for OLED displays are essential to ensure consistent performance across production batches. These standards encompass various parameters, with emission wavelength consistency being particularly critical for color accuracy and display uniformity. Industry specifications typically require wavelength variations to remain within ±2nm for premium displays and ±3-5nm for standard consumer products.

The International Electrotechnical Commission (IEC) has established standard 62341 specifically for OLED display modules, which includes detailed requirements for spectral emission characteristics. Similarly, the Video Electronics Standards Association (VESA) provides DisplayHDR True Black certification with strict color accuracy requirements that necessitate precise wavelength control.

Manufacturers must adhere to ISO 9241-307 standards for ergonomic requirements of electronic visual displays, which specify acceptable limits for color uniformity across the display surface. These standards are complemented by JEDEC's reliability testing protocols that ensure wavelength stability under various environmental conditions.

For production environments, Statistical Process Control (SPC) methodologies are implemented to monitor wavelength consistency, with control limits typically set at ±1.5nm to provide early warning before products exceed customer specifications. Six Sigma quality initiatives in leading manufacturers aim to achieve defect rates below 3.4 parts per million for wavelength variations.

Testing protocols must comply with CIE standards for colorimetry, particularly CIE 1976 (L*a*b*) color space measurements, which provide a perceptually uniform color space for evaluating human-perceived color differences. The Just Noticeable Difference (JND) threshold, approximately 2-3 ΔE units in this color space, serves as a reference point for establishing acceptable wavelength variation limits.

Equipment calibration standards are equally important, with spectroradiometers requiring NIST-traceable calibration at minimum six-month intervals. Measurement uncertainty must be documented according to ISO/IEC Guide 98-3, with target expanded uncertainty values (k=2) not exceeding 0.5nm for wavelength measurements.

These comprehensive quality control standards create a framework that enables manufacturers to consistently produce OLED displays with precise color reproduction, ensuring that consumers experience accurate and uniform visual performance across all devices utilizing this technology.

The International Electrotechnical Commission (IEC) has established standard 62341 specifically for OLED display modules, which includes detailed requirements for spectral emission characteristics. Similarly, the Video Electronics Standards Association (VESA) provides DisplayHDR True Black certification with strict color accuracy requirements that necessitate precise wavelength control.

Manufacturers must adhere to ISO 9241-307 standards for ergonomic requirements of electronic visual displays, which specify acceptable limits for color uniformity across the display surface. These standards are complemented by JEDEC's reliability testing protocols that ensure wavelength stability under various environmental conditions.

For production environments, Statistical Process Control (SPC) methodologies are implemented to monitor wavelength consistency, with control limits typically set at ±1.5nm to provide early warning before products exceed customer specifications. Six Sigma quality initiatives in leading manufacturers aim to achieve defect rates below 3.4 parts per million for wavelength variations.

Testing protocols must comply with CIE standards for colorimetry, particularly CIE 1976 (L*a*b*) color space measurements, which provide a perceptually uniform color space for evaluating human-perceived color differences. The Just Noticeable Difference (JND) threshold, approximately 2-3 ΔE units in this color space, serves as a reference point for establishing acceptable wavelength variation limits.

Equipment calibration standards are equally important, with spectroradiometers requiring NIST-traceable calibration at minimum six-month intervals. Measurement uncertainty must be documented according to ISO/IEC Guide 98-3, with target expanded uncertainty values (k=2) not exceeding 0.5nm for wavelength measurements.

These comprehensive quality control standards create a framework that enables manufacturers to consistently produce OLED displays with precise color reproduction, ensuring that consumers experience accurate and uniform visual performance across all devices utilizing this technology.

Environmental Factors Affecting Emission Wavelength Stability

The stability of OLED emission wavelength is significantly influenced by various environmental factors, which must be carefully controlled during consistency testing to ensure reliable results. Temperature stands as one of the most critical factors, with OLED devices exhibiting notable shifts in emission wavelength as operating temperatures fluctuate. Research indicates that for many OLED materials, wavelength shifts of 0.1-0.3 nm per degree Celsius can occur, potentially causing significant color variations in high-precision applications.

Humidity represents another crucial environmental variable affecting wavelength stability. Moisture ingress into OLED devices can accelerate degradation mechanisms, particularly in devices with inadequate encapsulation. Studies have shown that relative humidity levels exceeding 50% can accelerate degradation rates by 2-3 times compared to controlled environments, leading to progressive shifts in emission characteristics over time.

Ambient light exposure during testing can introduce measurement artifacts through photobleaching effects or by triggering photochemical reactions within the organic materials. This is particularly relevant for blue-emitting materials, which typically demonstrate higher photosensitivity than their red or green counterparts. Testing protocols must therefore incorporate appropriate light shielding measures.

Atmospheric composition, particularly oxygen concentration, plays a significant role in emission stability. Oxygen molecules can diffuse into the emissive layers and form quenching complexes with excited state molecules, reducing quantum efficiency and altering spectral characteristics. Even trace amounts of oxidizing gases can accelerate degradation pathways that manifest as wavelength instability.

Electrical operating conditions, while not strictly environmental, interact significantly with environmental factors. Voltage fluctuations of even ±0.1V can produce measurable shifts in emission wavelength, with these effects becoming more pronounced at elevated temperatures. The relationship between driving current density and spectral stability is non-linear, with higher current densities typically accelerating wavelength drift.

Barometric pressure variations, though often overlooked, can affect measurement accuracy in high-precision spectroscopic systems through subtle changes in refractive indices of optical components. For ultra-precise measurements below 0.1nm resolution, pressure stabilization may be necessary.

Establishing standardized environmental control parameters is essential for meaningful cross-comparison of test results across different facilities and timeframes. Industry standards typically recommend temperature control of ±1°C, humidity control of ±5% RH, and stable power supplies with less than 0.1% fluctuation to ensure measurement repeatability.

Humidity represents another crucial environmental variable affecting wavelength stability. Moisture ingress into OLED devices can accelerate degradation mechanisms, particularly in devices with inadequate encapsulation. Studies have shown that relative humidity levels exceeding 50% can accelerate degradation rates by 2-3 times compared to controlled environments, leading to progressive shifts in emission characteristics over time.

Ambient light exposure during testing can introduce measurement artifacts through photobleaching effects or by triggering photochemical reactions within the organic materials. This is particularly relevant for blue-emitting materials, which typically demonstrate higher photosensitivity than their red or green counterparts. Testing protocols must therefore incorporate appropriate light shielding measures.

Atmospheric composition, particularly oxygen concentration, plays a significant role in emission stability. Oxygen molecules can diffuse into the emissive layers and form quenching complexes with excited state molecules, reducing quantum efficiency and altering spectral characteristics. Even trace amounts of oxidizing gases can accelerate degradation pathways that manifest as wavelength instability.

Electrical operating conditions, while not strictly environmental, interact significantly with environmental factors. Voltage fluctuations of even ±0.1V can produce measurable shifts in emission wavelength, with these effects becoming more pronounced at elevated temperatures. The relationship between driving current density and spectral stability is non-linear, with higher current densities typically accelerating wavelength drift.

Barometric pressure variations, though often overlooked, can affect measurement accuracy in high-precision spectroscopic systems through subtle changes in refractive indices of optical components. For ultra-precise measurements below 0.1nm resolution, pressure stabilization may be necessary.

Establishing standardized environmental control parameters is essential for meaningful cross-comparison of test results across different facilities and timeframes. Industry standards typically recommend temperature control of ±1°C, humidity control of ±5% RH, and stable power supplies with less than 0.1% fluctuation to ensure measurement repeatability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!