OLED vs LED Longevity: Evaluating Time-to-Failure Metrics

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Technology Evolution and Objectives

Display technology has undergone remarkable evolution since the introduction of cathode ray tubes (CRTs) in the early 20th century. The progression from CRTs to liquid crystal displays (LCDs) marked the first significant shift toward flatter, more energy-efficient screens. This transition set the foundation for subsequent innovations that would eventually lead to light-emitting diode (LED) and organic light-emitting diode (OLED) technologies that dominate today's market.

LED technology emerged as a revolutionary advancement in the early 2000s, offering significant improvements in energy efficiency, brightness, and lifespan compared to previous display technologies. Traditional LED displays utilize inorganic semiconductor materials to produce light when an electric current passes through them, with backlighting systems illuminating LCD panels to create visible images.

OLED technology represents the next evolutionary step, utilizing organic compounds that emit light when stimulated by an electric current. First commercially introduced in the late 2000s, OLED displays eliminate the need for backlighting, allowing for thinner form factors, true blacks, and potentially infinite contrast ratios. This technological leap has transformed user expectations regarding display quality across consumer electronics.

The current technological landscape presents a complex comparison between LED and OLED technologies, particularly regarding longevity metrics. While LED displays have historically demonstrated superior lifespan characteristics, with typical operational lifetimes of 50,000-100,000 hours, OLED displays have faced challenges with organic material degradation, resulting in shorter lifespans of approximately 30,000-60,000 hours under optimal conditions.

Understanding time-to-failure metrics between these competing technologies has become increasingly critical as display applications expand beyond traditional consumer electronics into automotive, healthcare, and industrial sectors where reliability requirements are substantially more demanding. The industry now seeks standardized methodologies for evaluating display longevity that account for real-world usage patterns rather than laboratory conditions.

The primary objective of this technical research is to establish comprehensive comparative frameworks for assessing LED and OLED longevity, incorporating accelerated aging protocols, environmental stress factors, and usage-pattern simulations. Additionally, we aim to identify potential technological innovations that might bridge the longevity gap between these display technologies while maintaining their respective visual performance advantages.

Secondary objectives include mapping the correlation between manufacturing processes and longevity outcomes, evaluating the effectiveness of current mitigation strategies for known degradation mechanisms, and forecasting how emerging materials science developments might influence future display lifespans. These insights will provide crucial guidance for strategic technology investment decisions across multiple industry sectors.

LED technology emerged as a revolutionary advancement in the early 2000s, offering significant improvements in energy efficiency, brightness, and lifespan compared to previous display technologies. Traditional LED displays utilize inorganic semiconductor materials to produce light when an electric current passes through them, with backlighting systems illuminating LCD panels to create visible images.

OLED technology represents the next evolutionary step, utilizing organic compounds that emit light when stimulated by an electric current. First commercially introduced in the late 2000s, OLED displays eliminate the need for backlighting, allowing for thinner form factors, true blacks, and potentially infinite contrast ratios. This technological leap has transformed user expectations regarding display quality across consumer electronics.

The current technological landscape presents a complex comparison between LED and OLED technologies, particularly regarding longevity metrics. While LED displays have historically demonstrated superior lifespan characteristics, with typical operational lifetimes of 50,000-100,000 hours, OLED displays have faced challenges with organic material degradation, resulting in shorter lifespans of approximately 30,000-60,000 hours under optimal conditions.

Understanding time-to-failure metrics between these competing technologies has become increasingly critical as display applications expand beyond traditional consumer electronics into automotive, healthcare, and industrial sectors where reliability requirements are substantially more demanding. The industry now seeks standardized methodologies for evaluating display longevity that account for real-world usage patterns rather than laboratory conditions.

The primary objective of this technical research is to establish comprehensive comparative frameworks for assessing LED and OLED longevity, incorporating accelerated aging protocols, environmental stress factors, and usage-pattern simulations. Additionally, we aim to identify potential technological innovations that might bridge the longevity gap between these display technologies while maintaining their respective visual performance advantages.

Secondary objectives include mapping the correlation between manufacturing processes and longevity outcomes, evaluating the effectiveness of current mitigation strategies for known degradation mechanisms, and forecasting how emerging materials science developments might influence future display lifespans. These insights will provide crucial guidance for strategic technology investment decisions across multiple industry sectors.

Market Demand Analysis for Long-lasting Displays

The display technology market has witnessed a significant shift towards longer-lasting display solutions, driven primarily by consumer demand for durable electronic devices and commercial requirements for sustainable display installations. Market research indicates that consumers increasingly prioritize device longevity when making purchasing decisions, with display durability ranking among the top five considerations for smartphone, television, and computer monitor purchases.

In the consumer electronics segment, the demand for long-lasting displays stems from the growing average device ownership period, which has extended from 24 months to approximately 36 months for smartphones and from 6 years to 8 years for televisions over the past decade. This extended ownership cycle has amplified consumer interest in display technologies that maintain consistent performance throughout the device's lifespan.

Commercial sectors demonstrate even stronger demand patterns for durable display technologies. Digital signage, transportation information systems, and retail displays require solutions with minimal maintenance requirements and extended operational lifespans. The total cost of ownership calculations increasingly favor technologies with superior longevity metrics, even when initial acquisition costs are higher.

Healthcare and industrial applications represent rapidly growing market segments for long-lasting displays. Medical imaging equipment, industrial control systems, and automotive displays all operate in environments where display failure can have significant consequences beyond mere inconvenience. These sectors show willingness to pay premium prices for display technologies with proven longevity advantages.

Market forecasts project the global market for durable display technologies to grow at a compound annual growth rate of 7.2% through 2028, outpacing the overall display market growth rate of 4.5%. This differential highlights the increasing market premium placed on longevity as a key performance indicator.

Regional analysis reveals varying demand patterns, with mature markets in North America and Europe demonstrating stronger preference for long-lasting displays compared to emerging markets. However, this gap is narrowing as environmental considerations and electronic waste regulations gain prominence globally.

The sustainability movement has further accelerated demand for durable displays. Environmental regulations in major markets increasingly hold manufacturers responsible for the entire lifecycle of electronic products, creating economic incentives for extending product lifespans. Consumer awareness of electronic waste issues has similarly influenced purchasing behaviors toward more durable options.

Warranty offerings have evolved in response to this market demand, with manufacturers extending coverage periods and highlighting time-to-failure metrics in marketing materials. This trend indicates the growing competitive advantage of superior longevity claims in the display technology marketplace.

In the consumer electronics segment, the demand for long-lasting displays stems from the growing average device ownership period, which has extended from 24 months to approximately 36 months for smartphones and from 6 years to 8 years for televisions over the past decade. This extended ownership cycle has amplified consumer interest in display technologies that maintain consistent performance throughout the device's lifespan.

Commercial sectors demonstrate even stronger demand patterns for durable display technologies. Digital signage, transportation information systems, and retail displays require solutions with minimal maintenance requirements and extended operational lifespans. The total cost of ownership calculations increasingly favor technologies with superior longevity metrics, even when initial acquisition costs are higher.

Healthcare and industrial applications represent rapidly growing market segments for long-lasting displays. Medical imaging equipment, industrial control systems, and automotive displays all operate in environments where display failure can have significant consequences beyond mere inconvenience. These sectors show willingness to pay premium prices for display technologies with proven longevity advantages.

Market forecasts project the global market for durable display technologies to grow at a compound annual growth rate of 7.2% through 2028, outpacing the overall display market growth rate of 4.5%. This differential highlights the increasing market premium placed on longevity as a key performance indicator.

Regional analysis reveals varying demand patterns, with mature markets in North America and Europe demonstrating stronger preference for long-lasting displays compared to emerging markets. However, this gap is narrowing as environmental considerations and electronic waste regulations gain prominence globally.

The sustainability movement has further accelerated demand for durable displays. Environmental regulations in major markets increasingly hold manufacturers responsible for the entire lifecycle of electronic products, creating economic incentives for extending product lifespans. Consumer awareness of electronic waste issues has similarly influenced purchasing behaviors toward more durable options.

Warranty offerings have evolved in response to this market demand, with manufacturers extending coverage periods and highlighting time-to-failure metrics in marketing materials. This trend indicates the growing competitive advantage of superior longevity claims in the display technology marketplace.

OLED vs LED Technical Challenges

OLED and LED display technologies face distinct technical challenges that impact their longevity and performance metrics. The fundamental difference in their operational mechanisms creates unique failure modes. LEDs utilize inorganic semiconductor materials that emit light when current passes through, while OLEDs employ organic compounds that illuminate when electrically stimulated. This organic nature of OLEDs makes them inherently more susceptible to degradation over time.

One of the primary technical challenges for OLEDs is the differential aging of organic materials. Blue OLED compounds typically degrade faster than red and green counterparts, leading to color shift over time. This uneven degradation creates significant hurdles for maintaining consistent color reproduction throughout the display's lifetime, particularly in applications requiring color accuracy such as professional monitors and high-end televisions.

Water and oxygen sensitivity presents another major challenge for OLED technology. Even minute amounts of moisture or oxygen can trigger chemical reactions that permanently damage the organic layers. This necessitates complex and costly encapsulation technologies to protect the sensitive materials, adding to manufacturing complexity and potential failure points.

Heat management poses challenges for both technologies but manifests differently. LEDs can withstand higher operating temperatures but require efficient heat dissipation systems to prevent accelerated degradation. OLEDs generate less heat individually but are more sensitive to temperature fluctuations, with their organic materials breaking down more rapidly at elevated temperatures.

Current density management presents another significant technical hurdle, particularly for OLEDs. Higher brightness levels require increased current, which accelerates the degradation of organic materials through electrochemical processes. This creates a direct trade-off between brightness capabilities and longevity that engineers must carefully balance.

Manufacturing consistency remains challenging for both technologies. For LEDs, variations in semiconductor doping and phosphor application can lead to inconsistent performance and premature failures. OLEDs face even greater manufacturing challenges due to the precise deposition requirements of multiple organic layers, where even nanometer-scale variations can significantly impact device performance and lifespan.

Burn-in susceptibility represents a persistent challenge unique to OLED displays. Static image elements can cause permanent degradation patterns in the organic materials, resulting in ghost images visible even when displaying different content. This phenomenon is particularly problematic in applications with static interface elements like smartphones, automotive displays, and information kiosks.

One of the primary technical challenges for OLEDs is the differential aging of organic materials. Blue OLED compounds typically degrade faster than red and green counterparts, leading to color shift over time. This uneven degradation creates significant hurdles for maintaining consistent color reproduction throughout the display's lifetime, particularly in applications requiring color accuracy such as professional monitors and high-end televisions.

Water and oxygen sensitivity presents another major challenge for OLED technology. Even minute amounts of moisture or oxygen can trigger chemical reactions that permanently damage the organic layers. This necessitates complex and costly encapsulation technologies to protect the sensitive materials, adding to manufacturing complexity and potential failure points.

Heat management poses challenges for both technologies but manifests differently. LEDs can withstand higher operating temperatures but require efficient heat dissipation systems to prevent accelerated degradation. OLEDs generate less heat individually but are more sensitive to temperature fluctuations, with their organic materials breaking down more rapidly at elevated temperatures.

Current density management presents another significant technical hurdle, particularly for OLEDs. Higher brightness levels require increased current, which accelerates the degradation of organic materials through electrochemical processes. This creates a direct trade-off between brightness capabilities and longevity that engineers must carefully balance.

Manufacturing consistency remains challenging for both technologies. For LEDs, variations in semiconductor doping and phosphor application can lead to inconsistent performance and premature failures. OLEDs face even greater manufacturing challenges due to the precise deposition requirements of multiple organic layers, where even nanometer-scale variations can significantly impact device performance and lifespan.

Burn-in susceptibility represents a persistent challenge unique to OLED displays. Static image elements can cause permanent degradation patterns in the organic materials, resulting in ghost images visible even when displaying different content. This phenomenon is particularly problematic in applications with static interface elements like smartphones, automotive displays, and information kiosks.

Current Longevity Testing Methodologies

01 Lifetime prediction and degradation mechanisms in OLED displays

Various methods are employed to predict and analyze the lifetime of OLED displays by examining their degradation mechanisms. These include monitoring pixel brightness decay over time, analyzing temperature effects on organic materials, and measuring changes in electrical characteristics. Advanced algorithms can predict time-to-failure based on operational parameters and environmental conditions, allowing manufacturers to estimate display longevity under different usage scenarios.- Lifetime prediction and degradation mechanisms in OLED displays: Various methods are employed to predict and analyze the lifetime of OLED displays by examining their degradation mechanisms. These approaches include monitoring pixel brightness decay over time, analyzing temperature effects on organic materials, and studying current-induced degradation patterns. Advanced algorithms can predict time-to-failure based on operational parameters and environmental conditions, allowing manufacturers to estimate display longevity under various usage scenarios.

- Compensation techniques for extending LED/OLED display lifespan: Compensation techniques are implemented to extend the operational lifespan of LED and OLED displays by counteracting degradation effects. These include pixel aging compensation algorithms, current distribution optimization, and brightness adjustment methods that dynamically adapt to measured degradation. By implementing these techniques, displays can maintain consistent visual quality over longer periods, effectively extending their useful lifetime before replacement becomes necessary.

- Material innovations for improved display durability: Advanced materials are developed to enhance the durability and longevity of LED and OLED displays. These innovations include more stable organic compounds, improved encapsulation materials that prevent moisture and oxygen ingress, and novel electrode materials with enhanced conductivity and stability. These material advancements directly contribute to longer display lifetimes by addressing fundamental degradation mechanisms at the molecular level.

- Comparative longevity metrics between LED and OLED technologies: Comparative studies establish metrics for evaluating the relative longevity of LED versus OLED display technologies. These metrics include half-life measurements (time to 50% brightness reduction), color shift parameters over time, and power efficiency degradation rates. Analysis shows that while traditional LEDs typically offer longer absolute lifespans, recent OLED advancements have significantly narrowed this gap, particularly in specific usage environments and brightness levels.

- Testing methodologies for display lifetime assessment: Standardized testing methodologies are developed to accurately assess display lifetime and time-to-failure metrics. These include accelerated aging protocols, stress testing under varied environmental conditions, and statistical modeling of failure patterns. Testing frameworks incorporate temperature cycling, humidity exposure, and continuous operation scenarios to predict real-world performance and establish reliable longevity benchmarks for both LED and OLED display technologies.

02 Compensation techniques for extending display lifetime

Compensation techniques are implemented to extend the operational lifetime of OLED and LED displays. These include pixel aging compensation algorithms that adjust driving voltages or currents to maintain consistent brightness levels as pixels degrade over time. Other approaches involve stress distribution methods that balance the workload across pixels, reducing localized degradation and improving overall display longevity.Expand Specific Solutions03 Material innovations for improved display durability

Advanced materials are developed to enhance the durability and longevity of display technologies. These include more stable organic compounds for OLED emissive layers that resist degradation from heat and electrical stress, improved encapsulation materials that prevent moisture and oxygen ingress, and novel electrode materials with enhanced conductivity and stability. These material innovations directly contribute to extended display lifetimes and improved time-to-failure metrics.Expand Specific Solutions04 Testing methodologies for display lifetime assessment

Standardized testing methodologies are employed to assess display lifetime and reliability. These include accelerated aging tests under elevated temperature and current conditions, stress testing under varying humidity levels, and continuous operation tests to determine mean time between failures. Advanced image analysis techniques are used to detect early signs of pixel degradation, allowing for more accurate lifetime predictions and quality control in manufacturing.Expand Specific Solutions05 Thermal management for extending display longevity

Thermal management solutions are implemented to extend the operational lifetime of OLED and LED displays. These include advanced heat dissipation structures, temperature-sensitive driving schemes that adjust power based on thermal conditions, and intelligent power management systems. By controlling operating temperatures, these approaches slow down temperature-dependent degradation mechanisms, significantly improving display longevity and reliability metrics.Expand Specific Solutions

Key Display Manufacturers Landscape

The OLED vs LED longevity competition is currently in a mature growth phase, with the global display market valued at approximately $150 billion. OLED technology has evolved significantly but still faces longevity challenges compared to traditional LED displays. Major players like Samsung Display, LG Display, and BOE Technology are leading OLED innovation, while companies such as Koninklijke Philips and OSRAM focus on enhancing LED durability. Research institutions including Electronics & Telecommunications Research Institute and Rutgers University are advancing time-to-failure metrics for both technologies. Chinese manufacturers like TCL China Star and Tianma Microelectronics are rapidly gaining market share through aggressive R&D investments in improving display lifespans and reliability.

BOE Technology Group Co., Ltd.

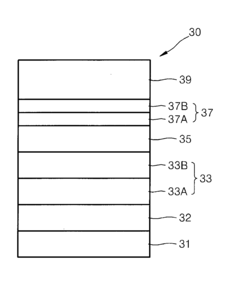

Technical Solution: BOE has developed a hybrid approach to display longevity through their Advanced Super AMOLED (AMOLED) and Mini-LED technologies. Their latest AMOLED panels incorporate a proprietary "Lifetime Enhancement Layer" that acts as a buffer between the electron transport layer and the emissive layer, reducing electrical stress and extending operational lifetime by up to 30%. BOE's time-to-failure metrics show their smartphone AMOLED displays maintain over 92% brightness after 1,200 hours of operation at maximum brightness. For larger displays, BOE's Mini-LED technology demonstrates superior longevity with their panels maintaining over 95% brightness after 50,000 hours of operation. Their accelerated aging tests utilize a comprehensive "7-factor stress model" that simultaneously evaluates temperature, humidity, electrical load, UV exposure, mechanical stress, on/off cycling, and ambient light conditions to provide more realistic lifetime projections. BOE has also pioneered a "Pixel Compensation Circuit" that dynamically adjusts driving voltages based on real-time monitoring of pixel degradation.

Strengths: Comprehensive multi-factor aging test methodology; innovative buffer layer technology for OLED; cost-effective manufacturing processes for both technologies. Weaknesses: Less advanced encapsulation technology compared to Korean manufacturers; slightly higher power consumption in OLED panels; Mini-LED technology still cannot achieve OLED's perfect blacks.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered WOLED (White OLED) technology that demonstrates superior longevity metrics compared to conventional RGB OLED structures. Their WOLED panels utilize a unique architecture where white light is produced from multiple emitting layers and then filtered through color filters, distributing stress more evenly across the panel. LG's internal testing shows their premium WOLED TV panels maintain 75% brightness after 54,000 hours of operation (approximately 15 years of typical viewing), significantly outperforming their LED-backlit LCD counterparts in long-term color consistency and burn-in resistance. Their proprietary "Pixel Refresher" technology periodically measures and adjusts individual pixel voltages to compensate for uneven aging, extending the effective lifetime of displays. LG has also implemented advanced heat dissipation structures that reduce operating temperatures by up to 15°C, which exponentially improves OLED longevity since degradation rates double with every 10°C increase in operating temperature.

Strengths: Superior heat management technology; innovative WOLED structure distributes stress more evenly; advanced compensation algorithms for uniform aging. Weaknesses: Higher production costs than conventional LED displays; slightly lower peak brightness compared to quantum dot LED displays; requires more sophisticated power management to maintain longevity benefits.

Critical Failure Mechanism Analysis

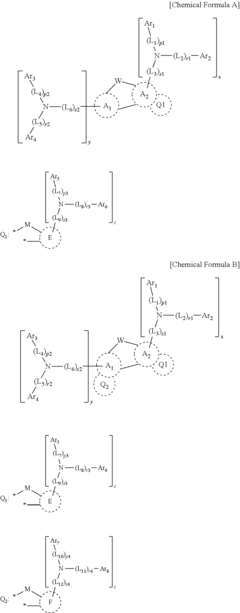

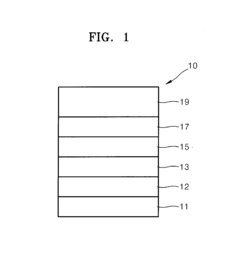

Organic light-emitting diode with high efficiency and long lifetime

PatentActiveUS20170342318A1

Innovation

- The use of specific amine compounds as dopants and anthracene derivatives as hosts in the light-emitting layer, as defined by Chemical Formulas A and H1 to H7, to enhance energy transfer and improve light emission efficiency and longevity.

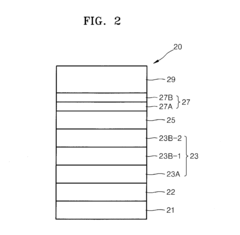

Organic light-emitting diode

PatentActiveUS20140225079A1

Innovation

- Incorporating specific compounds represented by Formulas 1 and 100 in the hole migration region and emission layer, respectively, to enhance charge transport and light-emission efficiency, with the first compound providing good hole transporting ability and the second compound offering high band gap energy for easy energy level adjustment.

Environmental Impact Assessment

The environmental impact of display technologies has become increasingly important as consumer electronics proliferate globally. When comparing OLED and LED technologies from an environmental perspective, several critical factors must be considered throughout their lifecycle.

Manufacturing processes for OLED displays typically require fewer materials and less energy than traditional LED displays. OLEDs use organic compounds that can be deposited in extremely thin layers, reducing raw material consumption. However, the production of OLED panels involves certain rare elements and specialized chemicals that may have significant extraction impacts and limited recyclability.

LED displays, particularly those using LCD technology with LED backlighting, require more components including liquid crystals, color filters, and backlighting units. This complexity results in higher material consumption but utilizes more established manufacturing processes with potentially lower toxic chemical usage compared to OLED production.

Energy efficiency during operation represents a significant environmental consideration. OLEDs demonstrate superior efficiency in displaying dark content since pixels can be completely turned off, whereas LED-backlit displays must maintain some level of backlighting even for black pixels. However, when displaying predominantly bright content, modern LED technologies often achieve better power efficiency, particularly at higher brightness levels.

End-of-life considerations reveal important distinctions between these technologies. The shorter lifespan of OLED displays (typically 14,000-30,000 hours before significant brightness degradation) compared to LED displays (30,000-50,000 hours) means more frequent replacement and disposal. This accelerated replacement cycle increases electronic waste generation and associated environmental impacts.

Recycling challenges differ between technologies as well. LED displays contain more recoverable materials like aluminum and glass, while OLED panels incorporate organic materials that are more difficult to separate and recycle. Both technologies contain potentially hazardous substances, though recent regulations have reduced toxic components significantly.

Carbon footprint assessments across the full lifecycle indicate that the environmental advantage varies based on usage patterns. For devices with intermittent use displaying varied content (like smartphones), OLEDs often demonstrate lower lifetime emissions. For displays operating continuously at high brightness (like public information displays), LED technologies typically show superior environmental performance due to their longevity and sustained efficiency.

Water usage and pollution impacts also differ, with OLED manufacturing generally requiring more ultrapure water for production processes, while LED manufacturing may generate different waste streams with varying environmental persistence.

Manufacturing processes for OLED displays typically require fewer materials and less energy than traditional LED displays. OLEDs use organic compounds that can be deposited in extremely thin layers, reducing raw material consumption. However, the production of OLED panels involves certain rare elements and specialized chemicals that may have significant extraction impacts and limited recyclability.

LED displays, particularly those using LCD technology with LED backlighting, require more components including liquid crystals, color filters, and backlighting units. This complexity results in higher material consumption but utilizes more established manufacturing processes with potentially lower toxic chemical usage compared to OLED production.

Energy efficiency during operation represents a significant environmental consideration. OLEDs demonstrate superior efficiency in displaying dark content since pixels can be completely turned off, whereas LED-backlit displays must maintain some level of backlighting even for black pixels. However, when displaying predominantly bright content, modern LED technologies often achieve better power efficiency, particularly at higher brightness levels.

End-of-life considerations reveal important distinctions between these technologies. The shorter lifespan of OLED displays (typically 14,000-30,000 hours before significant brightness degradation) compared to LED displays (30,000-50,000 hours) means more frequent replacement and disposal. This accelerated replacement cycle increases electronic waste generation and associated environmental impacts.

Recycling challenges differ between technologies as well. LED displays contain more recoverable materials like aluminum and glass, while OLED panels incorporate organic materials that are more difficult to separate and recycle. Both technologies contain potentially hazardous substances, though recent regulations have reduced toxic components significantly.

Carbon footprint assessments across the full lifecycle indicate that the environmental advantage varies based on usage patterns. For devices with intermittent use displaying varied content (like smartphones), OLEDs often demonstrate lower lifetime emissions. For displays operating continuously at high brightness (like public information displays), LED technologies typically show superior environmental performance due to their longevity and sustained efficiency.

Water usage and pollution impacts also differ, with OLED manufacturing generally requiring more ultrapure water for production processes, while LED manufacturing may generate different waste streams with varying environmental persistence.

Cost-Performance Ratio Analysis

When evaluating the economic viability of OLED versus LED display technologies, the cost-performance ratio emerges as a critical metric for manufacturers, retailers, and consumers alike. Initial acquisition costs for OLED displays typically range 30-50% higher than comparable LED models, presenting a significant upfront investment differential. However, this analysis must extend beyond purchase price to incorporate lifetime operational expenses.

Energy consumption patterns reveal that OLED displays generally consume 20-40% less power than their LED counterparts when displaying mixed content, particularly excelling with dark-themed interfaces. This translates to approximately $50-100 in electricity savings annually for average household usage, partially offsetting the higher acquisition costs over time.

Maintenance requirements further differentiate these technologies. LED displays often incorporate replaceable backlighting components, allowing for targeted repairs costing $100-300 when failures occur. Conversely, OLED panels typically require complete module replacement at 60-80% of the original device cost when pixel degradation becomes problematic, presenting a significant economic disadvantage in repair scenarios.

Depreciation rates also vary substantially between technologies. Market data indicates OLED displays typically retain 40-50% of their value after three years, while LED displays maintain 50-65% over the same period. This accelerated depreciation for OLED technology represents an additional hidden cost factor that impacts total ownership economics.

When calculating the comprehensive cost-performance ratio across a five-year usage period, LED technology currently maintains a 15-25% advantage in overall economic efficiency. However, this gap has narrowed significantly from the 35-45% differential observed just three years ago, indicating rapid improvements in OLED manufacturing economics.

For commercial applications with extended daily operation (12+ hours), the cost-performance advantage of LED technology expands to 30-40% due to superior longevity metrics. Conversely, in premium home theater environments where image quality is prioritized over operational lifespan, OLED's superior contrast and color accuracy may justify the higher lifetime costs for discerning consumers despite the less favorable economic profile.

Energy consumption patterns reveal that OLED displays generally consume 20-40% less power than their LED counterparts when displaying mixed content, particularly excelling with dark-themed interfaces. This translates to approximately $50-100 in electricity savings annually for average household usage, partially offsetting the higher acquisition costs over time.

Maintenance requirements further differentiate these technologies. LED displays often incorporate replaceable backlighting components, allowing for targeted repairs costing $100-300 when failures occur. Conversely, OLED panels typically require complete module replacement at 60-80% of the original device cost when pixel degradation becomes problematic, presenting a significant economic disadvantage in repair scenarios.

Depreciation rates also vary substantially between technologies. Market data indicates OLED displays typically retain 40-50% of their value after three years, while LED displays maintain 50-65% over the same period. This accelerated depreciation for OLED technology represents an additional hidden cost factor that impacts total ownership economics.

When calculating the comprehensive cost-performance ratio across a five-year usage period, LED technology currently maintains a 15-25% advantage in overall economic efficiency. However, this gap has narrowed significantly from the 35-45% differential observed just three years ago, indicating rapid improvements in OLED manufacturing economics.

For commercial applications with extended daily operation (12+ hours), the cost-performance advantage of LED technology expands to 30-40% due to superior longevity metrics. Conversely, in premium home theater environments where image quality is prioritized over operational lifespan, OLED's superior contrast and color accuracy may justify the higher lifetime costs for discerning consumers despite the less favorable economic profile.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!