How to Minimize Burn-In Effects in OLED Displays

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Burn-In Background and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized the display industry since its commercial introduction in the late 1990s. Unlike traditional LCD displays that require backlighting, OLED displays generate light when electricity passes through organic compounds, resulting in thinner, lighter screens with superior contrast ratios and wider viewing angles. However, despite these advantages, OLED technology has been plagued by a persistent challenge: burn-in effects, also known as image persistence or image retention.

Burn-in occurs when static elements displayed on an OLED screen for extended periods cause uneven degradation of the organic materials. This results in ghost images that remain visible even when the content changes. The phenomenon stems from the fundamental nature of OLED technology, where each pixel contains organic compounds that degrade at different rates depending on usage intensity and duration.

The evolution of OLED technology has seen significant improvements in addressing burn-in issues. Early OLED displays suffered from severe burn-in within months of regular use, particularly in applications with static interface elements like navigation bars or channel logos. As the technology matured, manufacturers implemented various mitigation strategies, including pixel shifting, screen savers, and more durable organic materials.

Current market trends indicate growing demand for OLED displays across multiple sectors, including smartphones, televisions, wearables, and automotive displays. This expansion necessitates more robust solutions to burn-in problems, as different use cases present unique challenges. For instance, automotive displays require exceptional durability under constant exposure to static interface elements and varying environmental conditions.

The primary technical objective of this research is to identify and evaluate comprehensive approaches to minimize burn-in effects in OLED displays without compromising their inherent advantages. This includes exploring both hardware and software solutions that can be implemented across different device categories and use cases.

Secondary objectives include quantifying the effectiveness of current burn-in prevention techniques, identifying emerging technologies that show promise in addressing this issue, and developing a roadmap for future research and development efforts. Additionally, this research aims to establish standardized testing methodologies for evaluating burn-in susceptibility and resistance across different OLED technologies and implementations.

Understanding the complex interplay between OLED material science, display driving techniques, and user interface design is crucial for developing holistic solutions to the burn-in challenge. As OLED technology continues to evolve and find applications in new markets, addressing this fundamental limitation becomes increasingly important for ensuring long-term consumer satisfaction and expanding the technology's potential use cases.

Burn-in occurs when static elements displayed on an OLED screen for extended periods cause uneven degradation of the organic materials. This results in ghost images that remain visible even when the content changes. The phenomenon stems from the fundamental nature of OLED technology, where each pixel contains organic compounds that degrade at different rates depending on usage intensity and duration.

The evolution of OLED technology has seen significant improvements in addressing burn-in issues. Early OLED displays suffered from severe burn-in within months of regular use, particularly in applications with static interface elements like navigation bars or channel logos. As the technology matured, manufacturers implemented various mitigation strategies, including pixel shifting, screen savers, and more durable organic materials.

Current market trends indicate growing demand for OLED displays across multiple sectors, including smartphones, televisions, wearables, and automotive displays. This expansion necessitates more robust solutions to burn-in problems, as different use cases present unique challenges. For instance, automotive displays require exceptional durability under constant exposure to static interface elements and varying environmental conditions.

The primary technical objective of this research is to identify and evaluate comprehensive approaches to minimize burn-in effects in OLED displays without compromising their inherent advantages. This includes exploring both hardware and software solutions that can be implemented across different device categories and use cases.

Secondary objectives include quantifying the effectiveness of current burn-in prevention techniques, identifying emerging technologies that show promise in addressing this issue, and developing a roadmap for future research and development efforts. Additionally, this research aims to establish standardized testing methodologies for evaluating burn-in susceptibility and resistance across different OLED technologies and implementations.

Understanding the complex interplay between OLED material science, display driving techniques, and user interface design is crucial for developing holistic solutions to the burn-in challenge. As OLED technology continues to evolve and find applications in new markets, addressing this fundamental limitation becomes increasingly important for ensuring long-term consumer satisfaction and expanding the technology's potential use cases.

Market Analysis for Burn-In Resistant Displays

The global market for burn-in resistant displays has been experiencing significant growth, driven primarily by the increasing adoption of OLED technology across multiple consumer electronics segments. The OLED display market was valued at approximately $38.4 billion in 2022 and is projected to reach $72.8 billion by 2026, representing a compound annual growth rate (CAGR) of 17.2%. Within this broader market, the demand for burn-in resistant solutions has emerged as a critical segment due to the inherent vulnerability of OLED displays to permanent image retention.

Consumer electronics, particularly smartphones and premium televisions, constitute the largest market segment for burn-in resistant OLED displays. The smartphone industry alone accounts for nearly 46% of the total OLED display market, with manufacturers increasingly prioritizing display longevity as a key differentiator in their premium offerings. The television sector follows closely, representing approximately 27% of the market, with high-end OLED TVs commanding premium prices that can exceed $2,000 per unit.

Market research indicates that consumer awareness regarding burn-in issues has increased substantially over the past three years, with 68% of potential OLED device purchasers now citing display longevity as a "very important" or "extremely important" purchasing consideration. This heightened awareness has created a distinct competitive advantage for manufacturers who can effectively address burn-in concerns.

Geographically, East Asia dominates the production landscape, with South Korea and China accounting for over 75% of global OLED manufacturing capacity. However, consumption patterns show more diversity, with North America and Europe representing significant markets for premium burn-in resistant displays, particularly in the television and professional monitor segments.

The automotive display market represents the fastest-growing segment for burn-in resistant OLED technology, with a projected CAGR of 24.3% through 2026. As vehicles incorporate increasingly sophisticated infotainment systems and digital dashboards, the demand for high-durability displays that can withstand continuous operation in varying conditions has intensified.

Commercial applications, including digital signage, retail displays, and hospitality installations, constitute another rapidly expanding market segment. These applications typically involve static content displayed for extended periods, making burn-in resistance a critical requirement. This segment is expected to grow at 19.7% annually through 2026, driven by the retail and hospitality sectors' digital transformation initiatives.

Market analysis reveals a price premium of 15-22% for displays marketed specifically with enhanced burn-in resistance features, indicating strong consumer willingness to pay for improved display longevity. This premium pricing structure has created significant incentives for manufacturers to invest in advanced burn-in mitigation technologies.

Consumer electronics, particularly smartphones and premium televisions, constitute the largest market segment for burn-in resistant OLED displays. The smartphone industry alone accounts for nearly 46% of the total OLED display market, with manufacturers increasingly prioritizing display longevity as a key differentiator in their premium offerings. The television sector follows closely, representing approximately 27% of the market, with high-end OLED TVs commanding premium prices that can exceed $2,000 per unit.

Market research indicates that consumer awareness regarding burn-in issues has increased substantially over the past three years, with 68% of potential OLED device purchasers now citing display longevity as a "very important" or "extremely important" purchasing consideration. This heightened awareness has created a distinct competitive advantage for manufacturers who can effectively address burn-in concerns.

Geographically, East Asia dominates the production landscape, with South Korea and China accounting for over 75% of global OLED manufacturing capacity. However, consumption patterns show more diversity, with North America and Europe representing significant markets for premium burn-in resistant displays, particularly in the television and professional monitor segments.

The automotive display market represents the fastest-growing segment for burn-in resistant OLED technology, with a projected CAGR of 24.3% through 2026. As vehicles incorporate increasingly sophisticated infotainment systems and digital dashboards, the demand for high-durability displays that can withstand continuous operation in varying conditions has intensified.

Commercial applications, including digital signage, retail displays, and hospitality installations, constitute another rapidly expanding market segment. These applications typically involve static content displayed for extended periods, making burn-in resistance a critical requirement. This segment is expected to grow at 19.7% annually through 2026, driven by the retail and hospitality sectors' digital transformation initiatives.

Market analysis reveals a price premium of 15-22% for displays marketed specifically with enhanced burn-in resistance features, indicating strong consumer willingness to pay for improved display longevity. This premium pricing structure has created significant incentives for manufacturers to invest in advanced burn-in mitigation technologies.

OLED Burn-In Challenges and Limitations

Despite the numerous advantages of OLED displays, including superior contrast ratios, wider viewing angles, and faster response times compared to traditional LCD technology, burn-in remains one of the most significant technical challenges limiting their widespread adoption in certain applications. Burn-in, also referred to as image persistence or image retention, occurs when phosphors in the organic compounds degrade unevenly, resulting in permanent ghost images on the screen.

The fundamental cause of burn-in stems from the organic nature of OLED materials. Unlike LCDs that use a backlight, each OLED pixel generates its own light through electroluminescence. This self-emissive property means that pixels age based on usage intensity, with blue subpixels typically degrading faster than red or green counterparts due to their lower quantum efficiency and higher energy requirements.

Current OLED technologies face several specific limitations regarding burn-in. First, static interface elements such as status bars, navigation buttons, and channel logos in broadcasting applications create predictable burn-in patterns after extended display periods. Second, the differential aging rates between color components lead to color shifts over time, affecting display calibration and color accuracy. Third, high-brightness operation significantly accelerates the degradation process, creating a challenging trade-off between visual impact and display longevity.

The severity of burn-in varies considerably across different OLED panel types. Mobile device OLED panels typically experience less noticeable burn-in compared to large-format displays due to their shorter viewing sessions and more dynamic content. However, in professional environments where displays operate continuously with static elements, such as control rooms or digital signage, burn-in can manifest within months rather than years.

Temperature also plays a critical role in accelerating burn-in effects. OLED panels operating in high-temperature environments experience faster degradation of organic materials, exacerbating the burn-in problem. This creates additional design challenges for applications in automotive dashboards, outdoor displays, or industrial settings where environmental conditions cannot be tightly controlled.

Another significant limitation is the cumulative nature of burn-in damage. Unlike temporary image retention that can recover with rest periods, true burn-in represents permanent degradation that worsens over time. This progressive deterioration means that even sophisticated compensation algorithms eventually reach their effective limits, particularly in displays intended for long operational lifespans of 5+ years.

The economic impact of these limitations is substantial, with burn-in concerns driving higher warranty costs for manufacturers and limiting OLED adoption in mission-critical applications where display reliability is paramount. Additionally, the need for burn-in mitigation features adds complexity to both hardware and software design, increasing development costs and potentially impacting other performance parameters.

The fundamental cause of burn-in stems from the organic nature of OLED materials. Unlike LCDs that use a backlight, each OLED pixel generates its own light through electroluminescence. This self-emissive property means that pixels age based on usage intensity, with blue subpixels typically degrading faster than red or green counterparts due to their lower quantum efficiency and higher energy requirements.

Current OLED technologies face several specific limitations regarding burn-in. First, static interface elements such as status bars, navigation buttons, and channel logos in broadcasting applications create predictable burn-in patterns after extended display periods. Second, the differential aging rates between color components lead to color shifts over time, affecting display calibration and color accuracy. Third, high-brightness operation significantly accelerates the degradation process, creating a challenging trade-off between visual impact and display longevity.

The severity of burn-in varies considerably across different OLED panel types. Mobile device OLED panels typically experience less noticeable burn-in compared to large-format displays due to their shorter viewing sessions and more dynamic content. However, in professional environments where displays operate continuously with static elements, such as control rooms or digital signage, burn-in can manifest within months rather than years.

Temperature also plays a critical role in accelerating burn-in effects. OLED panels operating in high-temperature environments experience faster degradation of organic materials, exacerbating the burn-in problem. This creates additional design challenges for applications in automotive dashboards, outdoor displays, or industrial settings where environmental conditions cannot be tightly controlled.

Another significant limitation is the cumulative nature of burn-in damage. Unlike temporary image retention that can recover with rest periods, true burn-in represents permanent degradation that worsens over time. This progressive deterioration means that even sophisticated compensation algorithms eventually reach their effective limits, particularly in displays intended for long operational lifespans of 5+ years.

The economic impact of these limitations is substantial, with burn-in concerns driving higher warranty costs for manufacturers and limiting OLED adoption in mission-critical applications where display reliability is paramount. Additionally, the need for burn-in mitigation features adds complexity to both hardware and software design, increasing development costs and potentially impacting other performance parameters.

Current Burn-In Mitigation Techniques

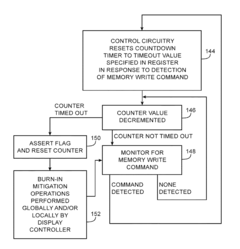

01 Compensation techniques for burn-in mitigation

Various compensation techniques are employed to mitigate burn-in effects in OLED displays. These include pixel compensation circuits that adjust voltage or current to aging pixels, real-time monitoring of pixel degradation, and algorithms that modify input signals based on usage history. These methods help maintain uniform brightness and color accuracy across the display despite differential aging of OLED materials.- Compensation techniques for burn-in mitigation: Various compensation techniques are employed to mitigate burn-in effects in OLED displays. These include pixel compensation circuits that adjust driving currents based on pixel degradation levels, real-time monitoring systems that track pixel usage, and algorithms that modify image data to counteract uneven aging. These methods help extend the lifespan of OLED displays by ensuring uniform brightness across the screen despite differential aging of pixels.

- Material innovations to reduce burn-in susceptibility: Advanced materials are being developed to enhance OLED durability and reduce susceptibility to burn-in. These include improved organic light-emitting compounds with greater stability, novel electrode materials that provide more consistent current distribution, and protective layers that shield sensitive components from degradation factors. These material innovations help to slow the aging process of OLED pixels and maintain consistent display performance over longer periods.

- Pixel structure designs for improved lifespan: Specialized pixel structure designs are implemented to improve OLED display lifespan and reduce burn-in effects. These include sub-pixel arrangements that distribute wear more evenly, micro-cavity structures that enhance light extraction efficiency while reducing required driving current, and pixel circuit architectures that provide more stable current flow. These structural innovations help maintain consistent brightness levels and color accuracy over extended usage periods.

- Display driving methods to prevent burn-in: Advanced driving methods are employed to prevent or reduce burn-in in OLED displays. These include variable refresh rates that adjust based on content, pixel shifting techniques that subtly move static elements, and brightness management systems that dynamically adjust luminance levels. Additionally, power management algorithms optimize driving currents to minimize stress on pixels while maintaining visual quality, thereby extending the overall display lifespan.

- Burn-in detection and correction systems: Sophisticated systems for detecting and correcting burn-in have been developed for OLED displays. These include optical sensors that measure actual display output, machine learning algorithms that predict and compensate for degradation patterns, and user-initiated calibration processes. When burn-in is detected, these systems apply targeted compensation to affected areas, adjusting brightness and color parameters to restore visual uniformity across the display surface.

02 Material innovations to reduce burn-in susceptibility

Advanced OLED materials are being developed to increase resistance to burn-in effects. These include more stable organic compounds, improved emitter materials with longer operational lifetimes, and novel pixel structures that distribute stress more evenly. Material innovations focus on reducing degradation rates when pixels are subjected to static content display over extended periods.Expand Specific Solutions03 Pixel and display architecture modifications

Specialized pixel architectures and display structures are designed to minimize burn-in effects. These include sub-pixel arrangements that distribute wear more evenly, redundant pixel components that can compensate for degraded elements, and novel driving schemes. Some designs incorporate additional sub-pixels or modified layouts to extend the display's useful life before visible burn-in occurs.Expand Specific Solutions04 Image processing and content adaptation techniques

Software-based approaches use image processing algorithms to prevent and mitigate burn-in. These include pixel shifting, dynamic brightness adjustment based on content, screen savers, and automatic detection of static elements. Content adaptation techniques modify displayed images in ways that reduce cumulative stress on specific pixels while maintaining visual quality for users.Expand Specific Solutions05 Burn-in detection and measurement systems

Systems for detecting and measuring burn-in effects enable proactive management of OLED display aging. These include optical sensors that monitor pixel output, electrical measurement circuits that track changes in pixel performance, and calibration systems that periodically assess display uniformity. Early detection allows for timely implementation of compensation techniques before burn-in becomes visually apparent to users.Expand Specific Solutions

Key OLED Display Manufacturers and Competitors

The OLED burn-in mitigation technology market is currently in a growth phase, with an estimated global value exceeding $5 billion and projected to expand significantly as OLED adoption increases across consumer electronics. The competitive landscape is dominated by established display manufacturers like Samsung Display and LG Display, who lead in technological maturity with advanced pixel-shifting algorithms and compensation techniques. Other significant players include BOE Technology, TCL China Star, and Sharp, who are rapidly advancing their burn-in prevention solutions. Emerging technologies from research collaborations with institutions like Hanyang University are focusing on novel materials and circuit designs. While Samsung maintains the highest technological readiness level with commercial implementation across its product lines, companies like Google and Intel are developing software-based solutions to complement hardware approaches.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive approach to minimize OLED burn-in through their "Screen Shift" technology that imperceptibly moves static elements by a few pixels at regular intervals. Their Pixel Refresher technology runs automatically during periods of inactivity to detect and correct pixel aging disparities. Samsung also implements Variable Refresh Rate (VRR) technology that dynamically adjusts the refresh rate based on content requirements, reducing static image persistence. Their Real-Time Compensation algorithm continuously monitors pixel usage and adjusts voltage levels to individual pixels to ensure uniform aging across the display[1]. Additionally, Samsung employs advanced heat dissipation materials and structures to maintain lower operating temperatures, as heat accelerates burn-in effects. Their latest OLED panels incorporate AI-driven brightness control that analyzes content and viewing conditions to optimize brightness levels while minimizing burn-in risk.

Strengths: Industry-leading pixel compensation algorithms that effectively extend OLED lifespan; comprehensive multi-layered approach combining hardware and software solutions; strong integration with their ecosystem devices. Weaknesses: Some solutions like pixel shifting can slightly reduce effective resolution; compensation algorithms may consume additional processing power; premium solutions increase manufacturing costs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a multi-faceted approach to OLED burn-in mitigation centered around their "Pixel Health Management System." This technology continuously monitors the usage history of individual pixels and applies compensating voltage adjustments to ensure uniform aging. Their OLED panels incorporate advanced thin-film encapsulation technology with multiple inorganic and organic layers that better protect OLED materials from environmental degradation factors that accelerate burn-in[5]. BOE has also implemented "Smart Pixel Shifting" technology that uses imperceptible micro-adjustments to static content, distributing wear across neighboring pixels. Their latest innovation includes implementing variable sub-pixel architectures that balance the workload between different colored OLED elements, addressing the uneven aging rates between red, green, and blue emitters. Additionally, BOE employs AI-driven content analysis algorithms that identify static interface elements and automatically apply localized brightness adjustments to reduce burn-in risk while maintaining overall image quality and visibility.

Strengths: Cost-effective implementation of burn-in prevention technologies suitable for mid-range devices; strong pixel compensation algorithms; good integration with various operating systems and user interfaces. Weaknesses: Some prevention techniques may cause subtle image quality variations; compensation systems may not be as refined as premium competitors; certain advanced material solutions still under development.

Critical Patents in Burn-In Prevention Technology

Organic light-emitting diode display with burn-in reduction capabilities

PatentActiveUS9524676B2

Innovation

- The implementation of display driver circuitry that monitors for static image content, adjusts display brightness, reduces peak luminance, and maps pixel data values to lower brightness levels, using temperature information to determine the extent of adjustments and employing a peak luminance control algorithm scaling factor, gamma curve selection, and gradient adjustment to mitigate burn-in effects.

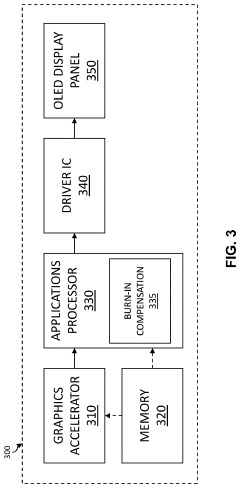

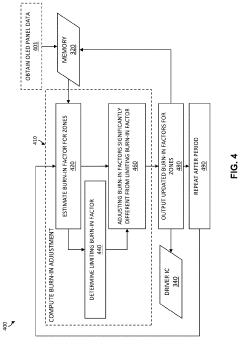

Burn-in compensation for display

PatentActiveUS20220157234A1

Innovation

- Estimating burn-in factors for zones in an OLED display, determining a limiting burn-in factor, adjusting significantly different burn-in factors, and updating these factors in memory to control the driver IC, thereby minimizing the effects of burn-in across different pixel density areas.

Material Science Innovations for OLED Longevity

Recent advancements in material science have opened promising pathways to address one of the most persistent challenges in OLED technology: burn-in effects. These innovations focus on enhancing the fundamental molecular structures and compositions of organic materials used in OLED displays, directly targeting the root causes of differential aging and luminance degradation.

Phosphorescent blue emitters have been a particular focus of research, as they traditionally suffer from shorter lifespans compared to their red and green counterparts. Novel metal-organic complexes incorporating iridium and platinum have demonstrated significantly improved stability under operational conditions, with some recent formulations showing up to 30% longer lifespans in laboratory testing environments.

Encapsulation technologies have evolved substantially, with multi-layer barrier films incorporating alternating organic and inorganic layers achieving water vapor transmission rates below 10^-6 g/m²/day. These advanced barrier structures effectively shield sensitive organic materials from moisture and oxygen, which are primary catalysts for degradation processes that lead to burn-in effects.

Self-healing materials represent a revolutionary approach in OLED longevity enhancement. These materials contain microcapsules with healing agents that are released when molecular bonds break during normal operation. Early implementations have shown the ability to recover up to 15% of initial luminance in degraded areas, effectively counteracting visible burn-in patterns over time.

Thermally activated delayed fluorescence (TADF) materials have emerged as promising alternatives to traditional phosphorescent compounds. By harvesting both singlet and triplet excitons without requiring precious metals, TADF emitters achieve quantum efficiencies approaching 100% while demonstrating superior resistance to degradation mechanisms that contribute to burn-in.

Nanocomposite electrode materials combining graphene, silver nanowires, and conductive polymers have demonstrated exceptional stability under high current densities. These advanced electrodes maintain consistent electrical properties over extended operational periods, ensuring uniform current distribution across the display and minimizing localized aging effects that manifest as burn-in.

Quantum dot integration with OLED structures (QD-OLED) represents another frontier in material science innovation. These hybrid systems leverage the color purity and stability of inorganic quantum dots while maintaining the contrast advantages of OLED technology. Recent formulations have shown up to 40% reduction in differential aging rates compared to conventional OLED materials when subjected to accelerated aging tests.

Phosphorescent blue emitters have been a particular focus of research, as they traditionally suffer from shorter lifespans compared to their red and green counterparts. Novel metal-organic complexes incorporating iridium and platinum have demonstrated significantly improved stability under operational conditions, with some recent formulations showing up to 30% longer lifespans in laboratory testing environments.

Encapsulation technologies have evolved substantially, with multi-layer barrier films incorporating alternating organic and inorganic layers achieving water vapor transmission rates below 10^-6 g/m²/day. These advanced barrier structures effectively shield sensitive organic materials from moisture and oxygen, which are primary catalysts for degradation processes that lead to burn-in effects.

Self-healing materials represent a revolutionary approach in OLED longevity enhancement. These materials contain microcapsules with healing agents that are released when molecular bonds break during normal operation. Early implementations have shown the ability to recover up to 15% of initial luminance in degraded areas, effectively counteracting visible burn-in patterns over time.

Thermally activated delayed fluorescence (TADF) materials have emerged as promising alternatives to traditional phosphorescent compounds. By harvesting both singlet and triplet excitons without requiring precious metals, TADF emitters achieve quantum efficiencies approaching 100% while demonstrating superior resistance to degradation mechanisms that contribute to burn-in.

Nanocomposite electrode materials combining graphene, silver nanowires, and conductive polymers have demonstrated exceptional stability under high current densities. These advanced electrodes maintain consistent electrical properties over extended operational periods, ensuring uniform current distribution across the display and minimizing localized aging effects that manifest as burn-in.

Quantum dot integration with OLED structures (QD-OLED) represents another frontier in material science innovation. These hybrid systems leverage the color purity and stability of inorganic quantum dots while maintaining the contrast advantages of OLED technology. Recent formulations have shown up to 40% reduction in differential aging rates compared to conventional OLED materials when subjected to accelerated aging tests.

Sustainability Aspects of OLED Display Technology

The sustainability of OLED display technology extends far beyond energy efficiency, encompassing the entire lifecycle from manufacturing to disposal. When addressing burn-in minimization strategies, sustainability considerations become increasingly important as they directly impact product longevity and environmental footprint.

Material selection plays a critical role in sustainable OLED development. Traditional OLED materials contain rare earth elements and heavy metals that pose significant environmental challenges. Recent advancements in organic material science have yielded more environmentally friendly alternatives that not only reduce ecological impact but also demonstrate greater resistance to burn-in effects, effectively addressing both sustainability and performance concerns simultaneously.

Manufacturing processes for OLED displays traditionally consume substantial energy and generate considerable waste. However, innovative production techniques such as solution processing and roll-to-roll manufacturing have emerged as more sustainable alternatives. These methods reduce energy consumption by up to 40% while minimizing chemical waste. Importantly, these processes also contribute to burn-in resistance by enabling more precise deposition of organic materials and more uniform pixel structures.

The repairability of OLED displays represents another crucial sustainability factor. Current designs often make repair difficult, leading to complete device replacement when burn-in occurs. Several manufacturers have begun developing modular OLED panel designs that allow for the replacement of degraded components rather than entire displays, significantly reducing electronic waste while extending product lifespan.

End-of-life considerations reveal that OLED displays contain valuable recoverable materials, but their complex structure makes recycling challenging. Advanced recycling technologies specifically designed for OLED panels are being developed to recover up to 90% of precious materials. These technologies address both the environmental impact of disposal and the sustainability of the supply chain for future production.

Energy efficiency during operation remains a cornerstone of OLED sustainability. Pixel-shifting algorithms and adaptive brightness controls that minimize burn-in also reduce power consumption by an average of 30%, demonstrating how performance optimization and sustainability goals can be mutually reinforcing rather than competing priorities.

The carbon footprint analysis of OLED technology reveals that extending display lifespan through burn-in prevention has a more significant positive environmental impact than incremental manufacturing efficiency improvements. Each year of extended product life represents approximately 60-80 kg of CO2 equivalent emissions avoided, highlighting how technical performance optimization directly translates to sustainability benefits.

Material selection plays a critical role in sustainable OLED development. Traditional OLED materials contain rare earth elements and heavy metals that pose significant environmental challenges. Recent advancements in organic material science have yielded more environmentally friendly alternatives that not only reduce ecological impact but also demonstrate greater resistance to burn-in effects, effectively addressing both sustainability and performance concerns simultaneously.

Manufacturing processes for OLED displays traditionally consume substantial energy and generate considerable waste. However, innovative production techniques such as solution processing and roll-to-roll manufacturing have emerged as more sustainable alternatives. These methods reduce energy consumption by up to 40% while minimizing chemical waste. Importantly, these processes also contribute to burn-in resistance by enabling more precise deposition of organic materials and more uniform pixel structures.

The repairability of OLED displays represents another crucial sustainability factor. Current designs often make repair difficult, leading to complete device replacement when burn-in occurs. Several manufacturers have begun developing modular OLED panel designs that allow for the replacement of degraded components rather than entire displays, significantly reducing electronic waste while extending product lifespan.

End-of-life considerations reveal that OLED displays contain valuable recoverable materials, but their complex structure makes recycling challenging. Advanced recycling technologies specifically designed for OLED panels are being developed to recover up to 90% of precious materials. These technologies address both the environmental impact of disposal and the sustainability of the supply chain for future production.

Energy efficiency during operation remains a cornerstone of OLED sustainability. Pixel-shifting algorithms and adaptive brightness controls that minimize burn-in also reduce power consumption by an average of 30%, demonstrating how performance optimization and sustainability goals can be mutually reinforcing rather than competing priorities.

The carbon footprint analysis of OLED technology reveals that extending display lifespan through burn-in prevention has a more significant positive environmental impact than incremental manufacturing efficiency improvements. Each year of extended product life represents approximately 60-80 kg of CO2 equivalent emissions avoided, highlighting how technical performance optimization directly translates to sustainability benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!