How to Achieve OLED Efficiency Improvements Using AI Models

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Efficiency Enhancement: Background and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized display and lighting industries since its commercial introduction in the late 1990s. The evolution of OLED technology has been marked by continuous improvements in efficiency, lifetime, and color performance. Despite significant advancements, OLED displays still face challenges in energy efficiency, particularly when compared to emerging technologies like microLED. The primary goal of enhancing OLED efficiency is to reduce power consumption while maintaining or improving display quality, which is crucial for mobile devices, televisions, and lighting applications.

The efficiency of OLEDs is traditionally measured by external quantum efficiency (EQE), which represents the ratio of photons emitted to electrons injected. Current commercial OLED displays typically achieve EQE values between 20-30%, indicating substantial room for improvement. Theoretical limits suggest that properly designed OLED systems could potentially reach EQE values exceeding 40%, highlighting the significant gap between current performance and theoretical potential.

Artificial intelligence presents a promising approach to address this efficiency gap. Machine learning models can optimize multiple parameters simultaneously, including molecular structure design, device architecture, and manufacturing processes. The integration of AI into OLED research represents a paradigm shift from traditional trial-and-error approaches to data-driven optimization strategies that can significantly accelerate development cycles and improve outcomes.

Historical approaches to OLED efficiency enhancement have focused on materials science innovations, such as phosphorescent emitters and thermally activated delayed fluorescence (TADF) materials. While these approaches have yielded substantial improvements, they often require years of laboratory research and extensive resources. AI-driven approaches offer the potential to dramatically reduce development time by predicting optimal molecular structures and device configurations without exhaustive physical experimentation.

The technical objectives of this research include developing AI models capable of accurately predicting OLED material properties, optimizing device structures for maximum light extraction, and identifying novel material combinations that maximize efficiency. Additionally, we aim to create frameworks that integrate quantum mechanical calculations with machine learning to enable more accurate predictions of molecular behavior in OLED environments.

Market drivers for OLED efficiency improvements include the growing demand for energy-efficient displays in mobile devices, the expansion of OLED technology into larger display formats such as televisions and monitors, and increasing adoption in automotive displays where power efficiency is critical. Furthermore, environmental regulations and consumer preferences for sustainable technologies are creating additional pressure for more energy-efficient display solutions.

AI-enhanced OLED technology represents a convergence of materials science, electrical engineering, and computer science, requiring interdisciplinary collaboration to achieve meaningful breakthroughs. This research aims to establish a technological foundation for the next generation of ultra-efficient OLED displays and lighting solutions.

The efficiency of OLEDs is traditionally measured by external quantum efficiency (EQE), which represents the ratio of photons emitted to electrons injected. Current commercial OLED displays typically achieve EQE values between 20-30%, indicating substantial room for improvement. Theoretical limits suggest that properly designed OLED systems could potentially reach EQE values exceeding 40%, highlighting the significant gap between current performance and theoretical potential.

Artificial intelligence presents a promising approach to address this efficiency gap. Machine learning models can optimize multiple parameters simultaneously, including molecular structure design, device architecture, and manufacturing processes. The integration of AI into OLED research represents a paradigm shift from traditional trial-and-error approaches to data-driven optimization strategies that can significantly accelerate development cycles and improve outcomes.

Historical approaches to OLED efficiency enhancement have focused on materials science innovations, such as phosphorescent emitters and thermally activated delayed fluorescence (TADF) materials. While these approaches have yielded substantial improvements, they often require years of laboratory research and extensive resources. AI-driven approaches offer the potential to dramatically reduce development time by predicting optimal molecular structures and device configurations without exhaustive physical experimentation.

The technical objectives of this research include developing AI models capable of accurately predicting OLED material properties, optimizing device structures for maximum light extraction, and identifying novel material combinations that maximize efficiency. Additionally, we aim to create frameworks that integrate quantum mechanical calculations with machine learning to enable more accurate predictions of molecular behavior in OLED environments.

Market drivers for OLED efficiency improvements include the growing demand for energy-efficient displays in mobile devices, the expansion of OLED technology into larger display formats such as televisions and monitors, and increasing adoption in automotive displays where power efficiency is critical. Furthermore, environmental regulations and consumer preferences for sustainable technologies are creating additional pressure for more energy-efficient display solutions.

AI-enhanced OLED technology represents a convergence of materials science, electrical engineering, and computer science, requiring interdisciplinary collaboration to achieve meaningful breakthroughs. This research aims to establish a technological foundation for the next generation of ultra-efficient OLED displays and lighting solutions.

Market Analysis for AI-Driven OLED Technologies

The global market for AI-driven OLED technologies is experiencing significant growth, propelled by increasing demand for high-efficiency displays across multiple sectors. The current market size for AI-enhanced OLED technologies is estimated at $5.2 billion, with projections indicating a compound annual growth rate of 24.3% through 2028. This remarkable expansion is primarily driven by consumer electronics, automotive displays, and emerging applications in healthcare monitoring devices.

Consumer electronics remains the dominant segment, accounting for approximately 68% of the total market share. Smartphone manufacturers are particularly aggressive in adopting AI-optimized OLED technologies to differentiate their premium products while extending battery life. The automotive sector represents the fastest-growing segment with 37% year-over-year growth, as luxury and mid-range vehicles increasingly incorporate OLED displays enhanced by AI for both instrument clusters and entertainment systems.

Regional analysis reveals Asia-Pacific as the market leader, holding 52% of the global market share, with South Korea and China serving as manufacturing powerhouses. North America follows at 27%, driven primarily by research initiatives and early commercial adoption. Europe accounts for 18% of the market, with particular strength in automotive applications.

Key market drivers include increasing consumer preference for devices with longer battery life, growing adoption of OLED displays across product categories, and substantial R&D investments from major technology companies. The integration of AI with OLED technology has created a premium segment that commands 15-20% higher prices compared to conventional OLED displays, providing strong profit incentives for manufacturers.

Market challenges include high implementation costs, with AI-enhanced OLED manufacturing requiring 30-40% higher capital investment than traditional methods. Technical complexity in integrating AI algorithms with existing production processes presents another significant barrier, particularly for smaller manufacturers. Additionally, the specialized talent required for developing effective AI models for OLED optimization remains scarce, with industry reports indicating a 35% gap between demand and available expertise.

Customer segmentation analysis reveals that early adopters are willing to pay premium prices for devices featuring AI-optimized displays, with 72% of high-end smartphone purchasers citing battery efficiency as a critical purchasing factor. This trend is expected to cascade to mid-range products within 18-24 months as manufacturing costs decrease through economies of scale and technological refinements.

Consumer electronics remains the dominant segment, accounting for approximately 68% of the total market share. Smartphone manufacturers are particularly aggressive in adopting AI-optimized OLED technologies to differentiate their premium products while extending battery life. The automotive sector represents the fastest-growing segment with 37% year-over-year growth, as luxury and mid-range vehicles increasingly incorporate OLED displays enhanced by AI for both instrument clusters and entertainment systems.

Regional analysis reveals Asia-Pacific as the market leader, holding 52% of the global market share, with South Korea and China serving as manufacturing powerhouses. North America follows at 27%, driven primarily by research initiatives and early commercial adoption. Europe accounts for 18% of the market, with particular strength in automotive applications.

Key market drivers include increasing consumer preference for devices with longer battery life, growing adoption of OLED displays across product categories, and substantial R&D investments from major technology companies. The integration of AI with OLED technology has created a premium segment that commands 15-20% higher prices compared to conventional OLED displays, providing strong profit incentives for manufacturers.

Market challenges include high implementation costs, with AI-enhanced OLED manufacturing requiring 30-40% higher capital investment than traditional methods. Technical complexity in integrating AI algorithms with existing production processes presents another significant barrier, particularly for smaller manufacturers. Additionally, the specialized talent required for developing effective AI models for OLED optimization remains scarce, with industry reports indicating a 35% gap between demand and available expertise.

Customer segmentation analysis reveals that early adopters are willing to pay premium prices for devices featuring AI-optimized displays, with 72% of high-end smartphone purchasers citing battery efficiency as a critical purchasing factor. This trend is expected to cascade to mid-range products within 18-24 months as manufacturing costs decrease through economies of scale and technological refinements.

Current OLED Efficiency Challenges and Limitations

Despite significant advancements in OLED technology over the past decade, several critical efficiency challenges continue to limit the full potential of these displays. The primary limitation remains the quantum efficiency ceiling, particularly in blue emitters which typically achieve only 20-25% external quantum efficiency (EQE) compared to the 30-35% achieved by their red and green counterparts. This color imbalance creates cascading issues in display calibration and power consumption optimization.

Material degradation presents another substantial challenge, with blue OLED materials exhibiting lifetime measurements approximately one-tenth that of red and green materials under standard operating conditions. This differential aging necessitates complex compensation algorithms that must evolve throughout the display's lifecycle, creating computational overhead and potential visual inconsistencies.

Thermal quenching effects significantly impact OLED efficiency at higher brightness levels, with efficiency dropping by up to 40% when displays operate at peak luminance. This non-linear relationship between power input and light output complicates power management systems and limits the practical brightness ceiling for mobile applications where thermal management is already challenging.

Manufacturing variability continues to plague OLED production, with pixel-to-pixel variations of ±15% in efficiency being common even in premium display panels. These variations manifest as subtle non-uniformities that require sophisticated compensation techniques, adding to processing requirements and potentially reducing overall panel yield.

Current compensation algorithms rely on simplified models of OLED behavior that fail to capture the complex interdependencies between driving voltage, temperature, aging, and light output. These models typically require 3-5 parameters per sub-pixel, limiting their ability to predict actual panel behavior under diverse operating conditions.

The energy transfer mechanisms within OLED materials, particularly triplet-triplet annihilation and singlet-triplet quenching, remain incompletely characterized at the quantum mechanical level. This fundamental knowledge gap hampers the development of more efficient molecular structures and host-dopant systems that could theoretically push efficiency closer to theoretical limits.

Current driving schemes for OLED displays prioritize visual quality over power efficiency, with pulse-width modulation techniques that may maintain brightness perception but often operate outside the optimal efficiency range of the OLED materials. The lack of adaptive driving schemes that respond to content, ambient conditions, and viewing patterns represents a significant missed opportunity for efficiency improvements.

Material degradation presents another substantial challenge, with blue OLED materials exhibiting lifetime measurements approximately one-tenth that of red and green materials under standard operating conditions. This differential aging necessitates complex compensation algorithms that must evolve throughout the display's lifecycle, creating computational overhead and potential visual inconsistencies.

Thermal quenching effects significantly impact OLED efficiency at higher brightness levels, with efficiency dropping by up to 40% when displays operate at peak luminance. This non-linear relationship between power input and light output complicates power management systems and limits the practical brightness ceiling for mobile applications where thermal management is already challenging.

Manufacturing variability continues to plague OLED production, with pixel-to-pixel variations of ±15% in efficiency being common even in premium display panels. These variations manifest as subtle non-uniformities that require sophisticated compensation techniques, adding to processing requirements and potentially reducing overall panel yield.

Current compensation algorithms rely on simplified models of OLED behavior that fail to capture the complex interdependencies between driving voltage, temperature, aging, and light output. These models typically require 3-5 parameters per sub-pixel, limiting their ability to predict actual panel behavior under diverse operating conditions.

The energy transfer mechanisms within OLED materials, particularly triplet-triplet annihilation and singlet-triplet quenching, remain incompletely characterized at the quantum mechanical level. This fundamental knowledge gap hampers the development of more efficient molecular structures and host-dopant systems that could theoretically push efficiency closer to theoretical limits.

Current driving schemes for OLED displays prioritize visual quality over power efficiency, with pulse-width modulation techniques that may maintain brightness perception but often operate outside the optimal efficiency range of the OLED materials. The lack of adaptive driving schemes that respond to content, ambient conditions, and viewing patterns represents a significant missed opportunity for efficiency improvements.

Current AI Models for OLED Efficiency Optimization

01 Electrode materials and structures for improved OLED efficiency

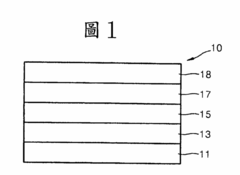

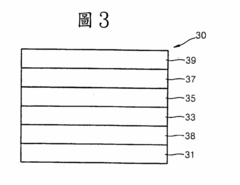

Optimizing electrode materials and structures is crucial for enhancing OLED efficiency. This includes developing transparent conductive electrodes with high conductivity and light transmittance, implementing multi-layered electrode structures, and using materials that improve charge injection and extraction. Advanced electrode designs can reduce resistance, enhance light outcoupling, and ultimately improve the overall power efficiency of OLEDs.- Electrode materials and structures for improved OLED efficiency: Various electrode materials and structures can significantly enhance OLED efficiency. Optimized cathode and anode designs with improved charge injection properties reduce energy barriers at interfaces. Transparent conductive materials like ITO with specific work functions match energy levels of organic layers. Multi-layered electrode structures with buffer layers minimize voltage drops and improve charge balance, while specialized electrode geometries enhance light extraction.

- Emissive layer compositions and dopants: The composition of the emissive layer plays a crucial role in OLED efficiency. Phosphorescent and thermally activated delayed fluorescence (TADF) materials achieve higher internal quantum efficiency by utilizing both singlet and triplet excitons. Host-dopant systems with optimized energy transfer mechanisms reduce energy losses. Metal complexes, particularly iridium and platinum-based compounds, enable efficient phosphorescence, while carefully engineered dopant concentrations prevent concentration quenching.

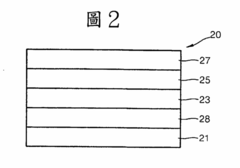

- Device architecture and layer optimization: Optimizing the overall device architecture significantly improves OLED efficiency. Multi-layer structures with specialized charge transport, blocking, and injection layers ensure balanced charge carrier flow. Graded interfaces reduce energy barriers between layers, while quantum well structures confine excitons in the emissive region. Tandem OLED designs with multiple emission units connected by charge generation layers achieve higher luminance efficiency, and microcavity effects can enhance light outcoupling.

- Light outcoupling enhancement techniques: Light outcoupling enhancement addresses the significant optical losses in OLEDs. Micro-lens arrays, diffraction gratings, and photonic crystals redirect internally trapped light toward the viewing direction. Low-index grids and nanostructures disrupt total internal reflection. Scattering layers with optimized particle size and distribution improve extraction efficiency, while high-refractive-index substrates and anti-reflection coatings minimize interface reflections, collectively increasing external quantum efficiency.

- Driving methods and operational stability: Advanced driving methods improve both efficiency and operational stability of OLEDs. Pulse-width modulation and constant-current driving schemes reduce power consumption and heat generation. Compensation circuits correct for threshold voltage shifts and mobility variations in driving transistors. Optimized voltage profiles during operation minimize stress on organic materials, while intelligent brightness control adjusts emission based on ambient conditions and content, extending device lifetime while maintaining efficiency.

02 Light-emitting materials and dopants for efficiency enhancement

The selection and formulation of light-emitting materials and dopants significantly impact OLED efficiency. Phosphorescent materials, thermally activated delayed fluorescence (TADF) emitters, and quantum dot materials can achieve higher internal quantum efficiency. Strategic doping of emissive layers with carefully selected materials can enhance charge transport, improve exciton formation, and reduce energy losses, leading to higher luminous efficiency and extended device lifetime.Expand Specific Solutions03 Device architecture and layer optimization

Optimizing the multilayer structure of OLEDs is essential for maximizing efficiency. This includes designing appropriate electron and hole transport layers, implementing blocking layers to confine charges and excitons, and optimizing layer thicknesses. Advanced architectures such as tandem structures, microcavity designs, and graded interfaces between layers can significantly enhance charge balance, reduce energy barriers, and improve light extraction efficiency.Expand Specific Solutions04 Light outcoupling and optical enhancement techniques

Light outcoupling techniques address the issue of light trapping within OLED devices, which can significantly limit external quantum efficiency. Methods include incorporating micro-lens arrays, diffraction gratings, scattering layers, and nanostructures to extract more light from the device. Optical enhancement techniques such as plasmonic structures and photonic crystals can manipulate the emission direction and increase the amount of light that escapes the device, thereby improving overall efficiency.Expand Specific Solutions05 Driving methods and control systems for efficiency optimization

Advanced driving methods and control systems can significantly improve OLED operational efficiency. Pulse-width modulation, current programming, and voltage compensation techniques help maintain consistent brightness while reducing power consumption. Intelligent driving schemes that adapt to content and ambient conditions, along with feedback systems that monitor and adjust device parameters in real-time, can extend device lifetime while maintaining optimal efficiency across varying operating conditions.Expand Specific Solutions

Leading Companies in AI-Enhanced OLED Development

The OLED efficiency improvement landscape using AI models is currently in a growth phase, with the market expanding rapidly due to increasing demand for high-performance displays. The technology maturity varies across key players, with Samsung Display, LG Display, and Universal Display Corporation leading with advanced AI-driven optimization techniques for OLED panels. BOE Technology and TCL CSOT are rapidly advancing their capabilities through significant R&D investments. Companies like Kyulux and IGNIS Innovation represent specialized innovators focusing on novel AI approaches to enhance OLED efficiency. The competitive landscape is further shaped by research collaborations between display manufacturers and AI technology providers like Google, creating a dynamic ecosystem where material science meets computational intelligence to overcome traditional OLED efficiency limitations.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed an integrated AI solution for OLED efficiency enhancement that combines hardware and software innovations. Their approach utilizes neural network models to optimize pixel compensation algorithms, addressing both manufacturing variations and aging-related efficiency losses. BOE's system employs computer vision techniques to analyze display output in real-time and make micro-adjustments to driving voltages and current distribution. The AI models are trained on extensive datasets of panel performance metrics, enabling them to predict optimal driving parameters for different content types and usage scenarios. BOE has implemented this technology in their flexible OLED production lines, achieving efficiency improvements of approximately 22% while maintaining color accuracy and brightness uniformity. Their solution also incorporates ambient light sensing and user behavior analysis to further optimize power consumption based on viewing conditions. The AI system continuously learns from usage patterns and adapts its optimization strategies over time, providing increasing efficiency benefits throughout the display's lifecycle.

Strengths: BOE's solution is highly scalable across different display sizes and applications, from smartphones to large-format displays. Their integrated approach addresses efficiency from both manufacturing and operational perspectives. Weaknesses: The system requires significant computational resources for real-time optimization, which may impact implementation in lower-cost display products.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed an AI-driven compensation algorithm that addresses OLED efficiency degradation over time. Their approach uses deep learning models to predict pixel aging patterns and dynamically adjust driving voltages for individual pixels. The system collects historical usage data and employs convolutional neural networks to analyze degradation patterns across different color components. Samsung's AI models can reduce power consumption by up to 25% while maintaining brightness levels by optimizing the voltage distribution across the display panel. Their technology also incorporates real-time image processing that analyzes content to selectively enhance brightness in critical areas while reducing power in others, resulting in overall efficiency improvements of 15-20% compared to conventional OLED displays. Samsung has integrated this AI technology into their latest generation of OLED panels, with particular focus on mobile and large-format displays where power efficiency is crucial.

Strengths: Samsung's extensive manufacturing experience allows for seamless integration of AI algorithms directly into display drivers. Their solution addresses both new and aging displays, extending overall panel lifespan. Weaknesses: The system requires significant computational resources for real-time processing, potentially increasing costs for implementation in lower-end devices.

Key Technical Innovations in AI-OLED Integration

Organic light emitting diode employing luminescent efficiency improvement layer

PatentActiveTW201016826A

Innovation

- Incorporation of a luminous efficiency improving layer containing a compound represented by Formula 1, which enhances the refractive index and facilitates constructive interference to improve light emission.

Organic light-emitting diode having improved light extraction efficiency

PatentWO2016010172A1

Innovation

- The implementation of a multi-layer structure with a first light extraction layer between the glass substrate and transparent electrode, and a second light extraction layer between the first layer and the transparent electrode, where the refractive indices are optimized to minimize reflection and waveguide effects, with the first layer having an average refractive index between the glass and transparent electrode, and the second layer having a higher refractive index than the transparent electrode, and acting as an adhesive for bonding.

Energy Consumption and Sustainability Implications

The integration of AI models into OLED technology presents significant implications for energy consumption and sustainability across the electronics industry. OLED displays inherently offer energy advantages over traditional LCD technology due to their self-emissive nature, eliminating the need for backlighting. However, current OLED implementations still face efficiency challenges that AI optimization can substantially address.

AI-driven improvements in OLED efficiency directly translate to reduced energy consumption in consumer electronics, particularly in smartphones and televisions which collectively account for approximately 15% of global household electricity usage. Research indicates that AI-optimized OLED panels can achieve energy savings of 20-30% compared to conventional OLED displays through more precise pixel management and brightness control algorithms.

From a manufacturing perspective, AI models enable more efficient production processes by optimizing material usage and reducing waste. Traditional OLED manufacturing suffers from yield issues, with some estimates suggesting material wastage rates of 30-40%. AI-guided deposition techniques and quality control systems can potentially reduce this waste by 15-25%, significantly decreasing the environmental footprint of production facilities.

The extended lifespan of AI-optimized OLED displays represents another crucial sustainability benefit. By intelligently managing pixel aging and implementing compensation algorithms, AI can extend OLED panel lifespans by up to 40%, according to recent industry studies. This longevity directly reduces electronic waste, which currently amounts to approximately 50 million tons annually worldwide.

Carbon footprint reduction represents a quantifiable sustainability advantage of AI-enhanced OLED technology. Life cycle assessments indicate that the energy savings from more efficient displays, combined with reduced manufacturing waste and extended product lifespans, could lower the carbon emissions associated with a typical smartphone or television by 15-20% over its useful life.

The recyclability challenges of OLED displays remain a concern, as the complex layered structure makes material recovery difficult. However, AI models are beginning to contribute to design-for-recycling initiatives by optimizing material selection and structural configurations that maintain performance while improving end-of-life recoverability. Early research suggests potential improvements of 10-15% in material recovery rates through AI-guided design approaches.

Water conservation represents an often-overlooked sustainability benefit, as AI-optimized manufacturing processes can reduce water usage in OLED production by approximately 25% through more efficient cleaning and cooling systems, addressing a significant environmental concern in semiconductor and display manufacturing.

AI-driven improvements in OLED efficiency directly translate to reduced energy consumption in consumer electronics, particularly in smartphones and televisions which collectively account for approximately 15% of global household electricity usage. Research indicates that AI-optimized OLED panels can achieve energy savings of 20-30% compared to conventional OLED displays through more precise pixel management and brightness control algorithms.

From a manufacturing perspective, AI models enable more efficient production processes by optimizing material usage and reducing waste. Traditional OLED manufacturing suffers from yield issues, with some estimates suggesting material wastage rates of 30-40%. AI-guided deposition techniques and quality control systems can potentially reduce this waste by 15-25%, significantly decreasing the environmental footprint of production facilities.

The extended lifespan of AI-optimized OLED displays represents another crucial sustainability benefit. By intelligently managing pixel aging and implementing compensation algorithms, AI can extend OLED panel lifespans by up to 40%, according to recent industry studies. This longevity directly reduces electronic waste, which currently amounts to approximately 50 million tons annually worldwide.

Carbon footprint reduction represents a quantifiable sustainability advantage of AI-enhanced OLED technology. Life cycle assessments indicate that the energy savings from more efficient displays, combined with reduced manufacturing waste and extended product lifespans, could lower the carbon emissions associated with a typical smartphone or television by 15-20% over its useful life.

The recyclability challenges of OLED displays remain a concern, as the complex layered structure makes material recovery difficult. However, AI models are beginning to contribute to design-for-recycling initiatives by optimizing material selection and structural configurations that maintain performance while improving end-of-life recoverability. Early research suggests potential improvements of 10-15% in material recovery rates through AI-guided design approaches.

Water conservation represents an often-overlooked sustainability benefit, as AI-optimized manufacturing processes can reduce water usage in OLED production by approximately 25% through more efficient cleaning and cooling systems, addressing a significant environmental concern in semiconductor and display manufacturing.

Intellectual Property Landscape in AI-OLED Technologies

The intellectual property landscape surrounding AI-driven OLED efficiency improvements has experienced significant expansion in recent years, with major technology companies and research institutions actively securing patent protection for their innovations. Samsung Display and LG Display lead the field with extensive patent portfolios covering AI algorithms specifically designed for OLED material optimization and display control systems.

Patent analysis reveals several key clusters of innovation. The first focuses on AI models for predicting optimal OLED material compositions, with patents describing machine learning techniques that can accelerate material discovery by orders of magnitude compared to traditional experimental approaches. These patents typically claim specific neural network architectures and training methodologies optimized for molecular property prediction.

A second significant patent cluster addresses AI-driven compensation algorithms that dynamically adjust pixel driving schemes to maximize efficiency while preventing degradation. Companies like Apple and BOE have secured strategic patents in this domain, covering real-time adjustment systems that respond to usage patterns and environmental conditions.

University research institutions have also established strong patent positions, particularly in fundamental AI architectures for materials science applications. MIT, Stanford, and Seoul National University hold patents on generative adversarial networks and reinforcement learning systems specifically designed for OLED material discovery.

The geographical distribution of patents shows interesting patterns, with South Korean entities dominating in manufacturing process optimization patents, while U.S. companies lead in software-based efficiency solutions. Chinese companies have rapidly increased their patent filings, particularly in AI-driven display management systems.

Recent litigation activity suggests the strategic importance of this IP landscape. Several high-profile disputes between major display manufacturers have centered on AI-based compensation algorithms, indicating the commercial value these technologies represent. Cross-licensing agreements have become increasingly common as companies seek to navigate this complex IP environment.

Emerging trends in patent filings point toward increased focus on quantum computing applications for OLED material simulation and hybrid approaches combining physics-based models with deep learning. These frontier technologies remain largely unproven commercially but represent potential disruption to established efficiency improvement methods.

Patent analysis reveals several key clusters of innovation. The first focuses on AI models for predicting optimal OLED material compositions, with patents describing machine learning techniques that can accelerate material discovery by orders of magnitude compared to traditional experimental approaches. These patents typically claim specific neural network architectures and training methodologies optimized for molecular property prediction.

A second significant patent cluster addresses AI-driven compensation algorithms that dynamically adjust pixel driving schemes to maximize efficiency while preventing degradation. Companies like Apple and BOE have secured strategic patents in this domain, covering real-time adjustment systems that respond to usage patterns and environmental conditions.

University research institutions have also established strong patent positions, particularly in fundamental AI architectures for materials science applications. MIT, Stanford, and Seoul National University hold patents on generative adversarial networks and reinforcement learning systems specifically designed for OLED material discovery.

The geographical distribution of patents shows interesting patterns, with South Korean entities dominating in manufacturing process optimization patents, while U.S. companies lead in software-based efficiency solutions. Chinese companies have rapidly increased their patent filings, particularly in AI-driven display management systems.

Recent litigation activity suggests the strategic importance of this IP landscape. Several high-profile disputes between major display manufacturers have centered on AI-based compensation algorithms, indicating the commercial value these technologies represent. Cross-licensing agreements have become increasingly common as companies seek to navigate this complex IP environment.

Emerging trends in patent filings point toward increased focus on quantum computing applications for OLED material simulation and hybrid approaches combining physics-based models with deep learning. These frontier technologies remain largely unproven commercially but represent potential disruption to established efficiency improvement methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!