Comparing OLED vs LCD: Which Is More Energy Efficient?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED vs LCD Technology Background and Objectives

Display technologies have evolved significantly over the past few decades, with Liquid Crystal Display (LCD) and Organic Light Emitting Diode (OLED) emerging as the two dominant technologies in the consumer electronics market. LCD technology, first developed in the 1960s and commercialized in the 1970s, has been the mainstream display solution for televisions, monitors, and mobile devices for several decades. OLED technology, while conceptualized in the 1950s, only began to see commercial applications in the early 2000s.

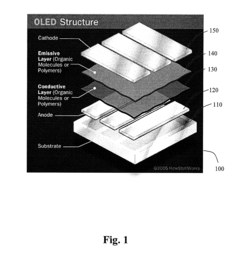

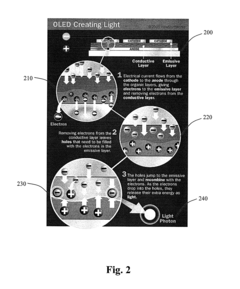

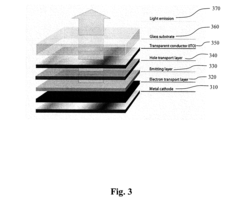

The fundamental difference between these technologies lies in their light emission mechanisms. LCD panels require a backlight (typically LED-based in modern displays) to illuminate the liquid crystal layer, which then filters this light to create images. In contrast, OLED displays consist of organic compounds that emit light directly when an electric current passes through them, eliminating the need for a separate backlight component.

Energy efficiency has become a critical consideration in display technology development due to increasing consumer demand for longer battery life in portable devices and growing environmental concerns regarding power consumption in electronic products. The global push toward sustainability and energy conservation has placed significant emphasis on developing more efficient display technologies.

The evolution of both LCD and OLED technologies has been marked by continuous improvements in energy efficiency. LCD technology has progressed from CCFL (Cold Cathode Fluorescent Lamp) backlighting to more efficient LED backlighting, and further refinements such as local dimming have been implemented to reduce power consumption. OLED technology has seen advancements in materials science and pixel architecture that have enhanced its energy efficiency profile.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of the energy efficiency characteristics of OLED and LCD technologies across various usage scenarios and device categories. This analysis aims to provide clear insights into which technology offers superior energy efficiency under different operating conditions and how these efficiency profiles may impact future technology adoption trends.

Additionally, this report seeks to examine the technological factors that influence energy consumption in both display types, including pixel structure, driving methods, color reproduction mechanisms, and brightness capabilities. Understanding these factors is crucial for predicting future developments in display technology and identifying potential areas for further efficiency improvements.

The findings of this research will serve as a valuable reference for product development strategies, helping to inform decisions regarding display technology selection for various applications where energy efficiency is a priority consideration.

The fundamental difference between these technologies lies in their light emission mechanisms. LCD panels require a backlight (typically LED-based in modern displays) to illuminate the liquid crystal layer, which then filters this light to create images. In contrast, OLED displays consist of organic compounds that emit light directly when an electric current passes through them, eliminating the need for a separate backlight component.

Energy efficiency has become a critical consideration in display technology development due to increasing consumer demand for longer battery life in portable devices and growing environmental concerns regarding power consumption in electronic products. The global push toward sustainability and energy conservation has placed significant emphasis on developing more efficient display technologies.

The evolution of both LCD and OLED technologies has been marked by continuous improvements in energy efficiency. LCD technology has progressed from CCFL (Cold Cathode Fluorescent Lamp) backlighting to more efficient LED backlighting, and further refinements such as local dimming have been implemented to reduce power consumption. OLED technology has seen advancements in materials science and pixel architecture that have enhanced its energy efficiency profile.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of the energy efficiency characteristics of OLED and LCD technologies across various usage scenarios and device categories. This analysis aims to provide clear insights into which technology offers superior energy efficiency under different operating conditions and how these efficiency profiles may impact future technology adoption trends.

Additionally, this report seeks to examine the technological factors that influence energy consumption in both display types, including pixel structure, driving methods, color reproduction mechanisms, and brightness capabilities. Understanding these factors is crucial for predicting future developments in display technology and identifying potential areas for further efficiency improvements.

The findings of this research will serve as a valuable reference for product development strategies, helping to inform decisions regarding display technology selection for various applications where energy efficiency is a priority consideration.

Market Demand Analysis for Energy-Efficient Displays

The display technology market has witnessed a significant shift towards energy-efficient solutions, driven primarily by consumer demand for longer battery life in portable devices and environmental sustainability concerns. Current market research indicates that the global energy-efficient display market is projected to reach $167 billion by 2026, growing at a CAGR of approximately 6.2% from 2021. This growth is substantially influenced by the ongoing competition between OLED and LCD technologies.

Consumer electronics represent the largest application segment for energy-efficient displays, with smartphones accounting for nearly 40% of the total market share. The increasing adoption of smartphones globally, particularly in emerging economies, continues to fuel demand for displays that maximize battery performance. Tablet computers and laptops follow closely, collectively representing about 35% of market demand for energy-efficient display technologies.

Market surveys reveal that battery life has become the third most important purchasing consideration for consumers buying new mobile devices, following only price and processing performance. This consumer preference has created strong market pressure for manufacturers to optimize display energy efficiency, as displays typically account for 40-60% of total power consumption in mobile devices.

Regional analysis shows that Asia-Pacific dominates the energy-efficient display market, accounting for approximately 52% of global demand. This dominance is attributed to the concentration of display manufacturing facilities in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow with 24% and 18% market shares respectively, with both regions showing increased consumer willingness to pay premium prices for devices with superior battery performance.

Industry forecasts suggest that the market demand for energy-efficient displays will continue to grow as new application areas emerge. The automotive sector, for instance, is expected to become a significant consumer of energy-efficient displays, with the electric vehicle market driving demand for displays that minimize power drain on battery systems. The market for wearable devices is also expanding rapidly, with projected annual growth rates exceeding 15% through 2026.

Corporate sustainability initiatives and governmental regulations regarding energy consumption are creating additional market pressures favoring more efficient display technologies. The European Union's Ecodesign Directive and similar regulations in other regions are establishing increasingly stringent energy efficiency requirements for electronic devices, indirectly boosting demand for advanced display technologies that can meet these standards while maintaining performance expectations.

Consumer electronics represent the largest application segment for energy-efficient displays, with smartphones accounting for nearly 40% of the total market share. The increasing adoption of smartphones globally, particularly in emerging economies, continues to fuel demand for displays that maximize battery performance. Tablet computers and laptops follow closely, collectively representing about 35% of market demand for energy-efficient display technologies.

Market surveys reveal that battery life has become the third most important purchasing consideration for consumers buying new mobile devices, following only price and processing performance. This consumer preference has created strong market pressure for manufacturers to optimize display energy efficiency, as displays typically account for 40-60% of total power consumption in mobile devices.

Regional analysis shows that Asia-Pacific dominates the energy-efficient display market, accounting for approximately 52% of global demand. This dominance is attributed to the concentration of display manufacturing facilities in countries like South Korea, Japan, China, and Taiwan. North America and Europe follow with 24% and 18% market shares respectively, with both regions showing increased consumer willingness to pay premium prices for devices with superior battery performance.

Industry forecasts suggest that the market demand for energy-efficient displays will continue to grow as new application areas emerge. The automotive sector, for instance, is expected to become a significant consumer of energy-efficient displays, with the electric vehicle market driving demand for displays that minimize power drain on battery systems. The market for wearable devices is also expanding rapidly, with projected annual growth rates exceeding 15% through 2026.

Corporate sustainability initiatives and governmental regulations regarding energy consumption are creating additional market pressures favoring more efficient display technologies. The European Union's Ecodesign Directive and similar regulations in other regions are establishing increasingly stringent energy efficiency requirements for electronic devices, indirectly boosting demand for advanced display technologies that can meet these standards while maintaining performance expectations.

Current State and Technical Challenges in Display Efficiency

The display technology landscape has witnessed significant evolution over the past decade, with LCD (Liquid Crystal Display) and OLED (Organic Light Emitting Diode) emerging as the dominant technologies in consumer electronics. Currently, LCD technology holds approximately 60% of the global display market share, while OLED has been rapidly gaining ground with about 30% market penetration, particularly in premium smartphones and high-end televisions.

From an energy efficiency perspective, the fundamental operating principles of these technologies create distinct power consumption profiles. LCD displays require a constant backlight regardless of the content being displayed, which inherently limits their energy efficiency. Even when displaying black pixels, the backlight remains active and must be blocked by the liquid crystal layer, resulting in energy wastage. Modern LCD implementations have attempted to address this through local dimming zones, but perfect black levels remain unachievable.

OLED technology, conversely, demonstrates superior efficiency when displaying darker content as each pixel emits its own light and can be completely turned off to display true black. This pixel-level control translates to significant power savings of up to 40% compared to LCDs when displaying typical mixed content. However, OLED efficiency decreases dramatically when displaying bright or white content, sometimes consuming up to 30% more power than comparable LCD panels in these scenarios.

A major technical challenge facing both technologies is the trade-off between brightness and power consumption. LCD displays can achieve higher peak brightness levels (up to 2,000 nits in premium models) but at the cost of increased power draw from the backlight. OLEDs struggle to match this brightness without significantly reducing panel lifespan and increasing power consumption exponentially at higher brightness settings.

Heat management represents another critical challenge, particularly for OLED displays. As brightness increases, so does heat generation, which can accelerate pixel degradation and color shift over time. This creates a technical ceiling for maximum sustainable brightness in OLED panels without advanced cooling solutions.

Manufacturing scalability continues to favor LCD technology, with production costs approximately 30-40% lower than comparable OLED panels. This cost differential has slowed OLED adoption in mid-range and budget devices where energy efficiency must be balanced against production economics.

Emerging hybrid technologies like Mini-LED and Micro-LED aim to combine the best aspects of both display types but face significant manufacturing challenges. These technologies promise LCD-like brightness with OLED-like contrast ratios and potentially superior energy efficiency, but remain in early commercialization stages with limited market presence.

From an energy efficiency perspective, the fundamental operating principles of these technologies create distinct power consumption profiles. LCD displays require a constant backlight regardless of the content being displayed, which inherently limits their energy efficiency. Even when displaying black pixels, the backlight remains active and must be blocked by the liquid crystal layer, resulting in energy wastage. Modern LCD implementations have attempted to address this through local dimming zones, but perfect black levels remain unachievable.

OLED technology, conversely, demonstrates superior efficiency when displaying darker content as each pixel emits its own light and can be completely turned off to display true black. This pixel-level control translates to significant power savings of up to 40% compared to LCDs when displaying typical mixed content. However, OLED efficiency decreases dramatically when displaying bright or white content, sometimes consuming up to 30% more power than comparable LCD panels in these scenarios.

A major technical challenge facing both technologies is the trade-off between brightness and power consumption. LCD displays can achieve higher peak brightness levels (up to 2,000 nits in premium models) but at the cost of increased power draw from the backlight. OLEDs struggle to match this brightness without significantly reducing panel lifespan and increasing power consumption exponentially at higher brightness settings.

Heat management represents another critical challenge, particularly for OLED displays. As brightness increases, so does heat generation, which can accelerate pixel degradation and color shift over time. This creates a technical ceiling for maximum sustainable brightness in OLED panels without advanced cooling solutions.

Manufacturing scalability continues to favor LCD technology, with production costs approximately 30-40% lower than comparable OLED panels. This cost differential has slowed OLED adoption in mid-range and budget devices where energy efficiency must be balanced against production economics.

Emerging hybrid technologies like Mini-LED and Micro-LED aim to combine the best aspects of both display types but face significant manufacturing challenges. These technologies promise LCD-like brightness with OLED-like contrast ratios and potentially superior energy efficiency, but remain in early commercialization stages with limited market presence.

Current Energy Efficiency Solutions in Display Technologies

01 OLED display energy efficiency improvements

OLED displays offer improved energy efficiency through various technological advancements. These include optimized pixel structures, power management systems, and materials that reduce power consumption. OLED displays can selectively illuminate only the necessary pixels, which significantly reduces energy consumption compared to traditional backlit displays. Advanced OLED technologies also incorporate power-saving modes and adaptive brightness features that adjust based on ambient lighting conditions.- Energy efficiency comparison between OLED and LCD technologies: OLED displays generally offer superior energy efficiency compared to LCD displays, particularly when displaying dark content. This is because OLED pixels emit light individually and can be completely turned off when displaying black, consuming no power for those pixels. In contrast, LCD displays require constant backlighting regardless of the content being displayed, making them less energy-efficient especially for dark content. The power consumption difference between these technologies is significant in mobile devices where battery life is critical.

- Power-saving techniques for display technologies: Various power-saving techniques have been developed for both OLED and LCD displays. These include adaptive brightness control, which adjusts display brightness based on ambient light conditions; pixel dimming technologies that selectively reduce power to certain pixels; and power management algorithms that optimize display operation based on content. Advanced power management systems can analyze displayed content in real-time and adjust power distribution accordingly, significantly extending battery life in portable devices.

- Display panel structure innovations for improved efficiency: Structural innovations in display panels have led to significant improvements in energy efficiency. These include the development of more efficient backlight systems for LCDs, such as edge-lit and local dimming technologies; thinner and more transparent substrates that improve light transmission; and advanced pixel architectures that reduce power leakage. For OLEDs, innovations include more efficient organic materials, improved electrode designs, and better encapsulation methods that extend the lifespan while maintaining energy efficiency.

- Driving circuit and control methods for energy optimization: Advanced driving circuits and control methods play a crucial role in optimizing the energy efficiency of display technologies. These include voltage optimization techniques that reduce power consumption without compromising image quality; frame rate control systems that adjust refresh rates based on content requirements; and intelligent power distribution circuits that minimize energy loss. Additionally, specialized integrated circuits have been developed that manage power more efficiently across the entire display system.

- Hybrid and emerging display technologies for energy efficiency: Hybrid and emerging display technologies combine the advantages of multiple display types to achieve optimal energy efficiency. These include Micro-LED displays that offer OLED-like pixel-level control with higher brightness efficiency; dual-mode displays that can switch between reflective and emissive modes depending on ambient conditions; and quantum dot-enhanced displays that improve color accuracy while reducing power requirements. Research is also focused on developing entirely new display technologies that fundamentally reduce power consumption while maintaining or improving visual performance.

02 LCD power optimization techniques

LCD displays have evolved to incorporate various power optimization techniques to improve energy efficiency. These include enhanced backlight control systems, local dimming technologies, and improved light transmission designs. Advanced LCD panels utilize power-saving algorithms that adjust backlight intensity based on content being displayed. Some LCD technologies also implement ambient light sensors to automatically adjust brightness levels, further reducing power consumption while maintaining optimal viewing experience.Expand Specific Solutions03 Comparative energy efficiency between OLED and LCD

The energy efficiency comparison between OLED and LCD technologies reveals distinct advantages in different use cases. OLED displays generally consume less power when displaying darker content since black pixels are completely turned off, while LCD displays maintain consistent power usage regardless of content. However, LCD displays may be more energy-efficient when displaying predominantly bright content. The overall energy efficiency also depends on factors such as display size, resolution, and specific implementation of power management features.Expand Specific Solutions04 Advanced materials and components for energy-efficient displays

The development of advanced materials and components has significantly contributed to improving the energy efficiency of both OLED and LCD displays. These include high-efficiency organic compounds for OLED panels, enhanced transistor technologies, and improved optical films for LCDs. Novel electrode materials and structures help reduce resistance and power loss. Additionally, specialized driver ICs and power management circuits optimize voltage distribution and minimize energy waste during display operation.Expand Specific Solutions05 Adaptive power management systems for displays

Adaptive power management systems represent a significant advancement in display energy efficiency. These systems dynamically adjust power consumption based on various factors including content being displayed, ambient lighting conditions, and user interaction patterns. Technologies such as variable refresh rates, content-adaptive brightness control, and selective pixel activation help optimize energy usage. Some advanced displays also incorporate AI-driven power management that learns user habits to further enhance energy efficiency without compromising visual quality.Expand Specific Solutions

Key Industry Players in OLED and LCD Manufacturing

The OLED vs LCD energy efficiency landscape is currently in a mature development phase, with OLED technology gaining momentum due to its superior power efficiency in dark content scenarios. The global display market exceeds $150 billion annually, with energy-efficient displays becoming increasingly important for mobile devices and sustainability initiatives. Samsung Display and LG Display lead OLED innovation, while BOE Technology and TCL China Star are rapidly advancing in both technologies. Samsung Electronics dominates the commercial application of OLED in consumer electronics, while traditional LCD manufacturers like AUO Corp and Hannstar Display continue optimizing LCD power efficiency through advanced backlighting systems. The competition is intensifying as companies like Novaled and PixelDisplay develop specialized technologies to address the respective weaknesses of both display types.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed cutting-edge OLED panel technology that fundamentally changes the energy consumption equation compared to LCD. Their latest generation OLED panels utilize phosphorescent blue emitters alongside fluorescent red and green materials, achieving up to 25% improved energy efficiency over previous generations[1]. The company's M-series OLED displays incorporate pixel circuit optimizations that reduce driving voltage requirements while maintaining brightness levels, resulting in power savings of approximately 30-35% compared to equivalent LCD panels when displaying mixed content[5]. Samsung Display has also pioneered adaptive pixel technology that can adjust individual sub-pixel power based on content requirements, rather than maintaining constant backlight as required in LCD. Their panels feature ultra-thin encapsulation technology (under 1μm) that improves light extraction efficiency, allowing for lower power operation while maintaining brightness standards. For mobile applications, Samsung Display's latest E6 OLED material set demonstrates 15-20% better power efficiency than previous generations while extending panel lifespan[9].

Strengths: Superior power efficiency for dark/mixed content; perfect blacks with zero power consumption for black pixels; thinner profile enabling more space-efficient designs; excellent response times without additional power draw. Weaknesses: Higher manufacturing complexity and cost; less energy efficient than LCD when displaying predominantly white content; potential for differential aging of organic materials; more complex driving circuitry.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive approach to display energy efficiency that spans both OLED and LCD technologies. Their OLED solutions utilize advanced LTPO (Low-Temperature Polycrystalline Oxide) backplane technology that reduces power consumption by up to 20% compared to conventional LTPS backplanes[3]. BOE's flexible OLED panels incorporate pixel compensation circuits that maintain consistent power efficiency throughout the panel's lifetime, addressing one of OLED's historical weaknesses. For LCD technology, BOE has pioneered advanced Mini-LED backlighting systems with thousands of dimming zones, achieving OLED-like contrast while improving energy efficiency by up to 15% compared to conventional edge-lit LCDs[6]. Their Quantum Dot LCD technology enhances color gamut without the power penalties of traditional color filter approaches. BOE has also implemented sophisticated local dimming algorithms that analyze content frame-by-frame to optimize backlight usage, resulting in power savings of 25-30% in typical mixed-content scenarios compared to standard LCD displays[8]. Additionally, BOE's latest oxide semiconductor technology improves electron mobility while reducing leakage current, further enhancing energy efficiency across both display technologies.

Strengths: Competitive pricing for advanced display technologies; strong performance in both OLED and LCD segments; good energy efficiency across diverse content types; advanced manufacturing scale. Weaknesses: Slightly behind Samsung and LG in cutting-edge OLED efficiency metrics; higher power consumption in OLED panels compared to industry leaders; less optimized power management algorithms; lower peak brightness in energy-efficient modes.

Core Patents and Innovations in Display Power Management

Method and system for an organic light emitting diode structure

PatentInactiveUS20150303396A1

Innovation

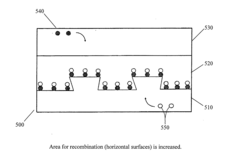

- Incorporating a plurality of spaced inverted non-cylindrical nano-pillars in the structure of OLEDs, specifically between the emissive and conductive layers, to broaden the carrier recombination space and reduce carrier accumulation, thereby enhancing light extraction and efficiency.

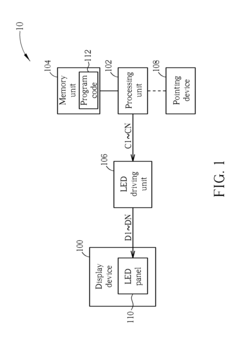

Display power saving method and electronic system

PatentActiveUS20110304536A1

Innovation

- A display power saving method that detects the presence of a pointing device and adjusts the screen brightness by determining the display area based on the pointer's location and the power management mode, reducing the brightness of non-active screen sections when in power saving mode.

Environmental Impact Assessment of Display Technologies

The environmental footprint of display technologies extends far beyond energy consumption, encompassing the entire lifecycle from raw material extraction to end-of-life disposal. When comparing OLED and LCD technologies, several critical environmental factors must be considered.

Manufacturing processes for both technologies involve significant environmental impacts. LCD production requires substantial quantities of water and chemicals for panel fabrication, while also utilizing rare earth elements in backlighting components. OLED manufacturing, though more streamlined in some aspects, involves energy-intensive vacuum deposition processes and relies on precious metals like iridium for certain color emissions.

Resource consumption patterns differ markedly between these technologies. LCDs typically contain more components, including the backlight unit, liquid crystal layer, and color filters, resulting in greater material diversity. OLEDs feature simpler structures but often utilize scarcer materials. The extraction of these resources, particularly rare earth elements for LCDs and precious metals for OLEDs, contributes to habitat destruction, water pollution, and carbon emissions in mining regions.

Carbon footprint assessments reveal interesting contrasts. While OLEDs generally consume less energy during operation, their manufacturing carbon footprint can be 20-30% higher than comparable LCD panels due to energy-intensive production processes. However, this initial carbon debt may be offset over the product lifetime through operational efficiency.

End-of-life considerations present significant challenges for both technologies. LCD recycling faces complications from mercury content in older models and the complex separation of multiple layers. OLED recycling remains underdeveloped, with limited infrastructure to recover valuable materials from these panels. E-waste from both technologies contributes to environmental contamination when improperly disposed of, particularly in developing regions.

Water usage metrics show LCD manufacturing typically consumes 20-40% more water than OLED production, primarily due to extensive cleaning processes required between manufacturing stages. Chemical usage also differs, with LCD production utilizing more diverse chemical compounds, while OLED manufacturing employs fewer but often more specialized and potentially hazardous substances.

Regulatory compliance frameworks increasingly influence manufacturing practices, with restrictions on hazardous substances driving innovations in both technologies. The EU's RoHS and REACH regulations have accelerated the transition away from certain heavy metals and flame retardants previously common in display manufacturing.

Overall lifecycle assessment indicates that neither technology holds a decisive environmental advantage across all metrics. The environmental superiority depends heavily on specific implementation, usage patterns, and end-of-life management practices. Future environmental improvements will likely come from manufacturing efficiency gains, material substitutions, and enhanced recycling technologies rather than wholesale technology shifts.

Manufacturing processes for both technologies involve significant environmental impacts. LCD production requires substantial quantities of water and chemicals for panel fabrication, while also utilizing rare earth elements in backlighting components. OLED manufacturing, though more streamlined in some aspects, involves energy-intensive vacuum deposition processes and relies on precious metals like iridium for certain color emissions.

Resource consumption patterns differ markedly between these technologies. LCDs typically contain more components, including the backlight unit, liquid crystal layer, and color filters, resulting in greater material diversity. OLEDs feature simpler structures but often utilize scarcer materials. The extraction of these resources, particularly rare earth elements for LCDs and precious metals for OLEDs, contributes to habitat destruction, water pollution, and carbon emissions in mining regions.

Carbon footprint assessments reveal interesting contrasts. While OLEDs generally consume less energy during operation, their manufacturing carbon footprint can be 20-30% higher than comparable LCD panels due to energy-intensive production processes. However, this initial carbon debt may be offset over the product lifetime through operational efficiency.

End-of-life considerations present significant challenges for both technologies. LCD recycling faces complications from mercury content in older models and the complex separation of multiple layers. OLED recycling remains underdeveloped, with limited infrastructure to recover valuable materials from these panels. E-waste from both technologies contributes to environmental contamination when improperly disposed of, particularly in developing regions.

Water usage metrics show LCD manufacturing typically consumes 20-40% more water than OLED production, primarily due to extensive cleaning processes required between manufacturing stages. Chemical usage also differs, with LCD production utilizing more diverse chemical compounds, while OLED manufacturing employs fewer but often more specialized and potentially hazardous substances.

Regulatory compliance frameworks increasingly influence manufacturing practices, with restrictions on hazardous substances driving innovations in both technologies. The EU's RoHS and REACH regulations have accelerated the transition away from certain heavy metals and flame retardants previously common in display manufacturing.

Overall lifecycle assessment indicates that neither technology holds a decisive environmental advantage across all metrics. The environmental superiority depends heavily on specific implementation, usage patterns, and end-of-life management practices. Future environmental improvements will likely come from manufacturing efficiency gains, material substitutions, and enhanced recycling technologies rather than wholesale technology shifts.

Manufacturing Cost Analysis and Economic Viability

The manufacturing cost structure of OLED and LCD technologies reveals significant differences that impact their economic viability in various market segments. OLED manufacturing processes require specialized equipment for organic material deposition and encapsulation, resulting in higher initial capital investment compared to LCD production lines. Current industry estimates indicate that OLED panel production costs remain approximately 20-30% higher than equivalent LCD panels, primarily due to lower manufacturing yields and more complex fabrication processes.

Material costs represent another critical factor in the economic equation. OLED displays utilize expensive organic compounds and require precise deposition techniques, while LCD manufacturing benefits from mature supply chains and economies of scale for liquid crystal materials and backlighting components. However, OLED manufacturing has fewer process steps overall, potentially offering long-term cost advantages as production volumes increase and manufacturing techniques mature.

Yield rates significantly impact economic viability, with OLED manufacturing historically suffering from lower yields than LCD production. Recent technological advancements have improved OLED yields to approximately 70-80% for mobile displays, though still trailing behind LCD's 90%+ yields for similar applications. This yield gap narrows for smaller displays but widens considerably for larger panel sizes, explaining OLED's stronger market position in smartphones compared to television segments.

Energy consumption during manufacturing presents another economic consideration. LCD fabrication typically consumes less energy per unit area than OLED production, contributing to lower operational costs for manufacturers. However, when considering product lifecycle energy efficiency, OLED's potential for lower power consumption during use may offset higher manufacturing energy inputs over time.

Market positioning also influences economic viability. OLED technology commands premium pricing in high-end consumer electronics, providing manufacturers with higher margins despite increased production costs. This premium positioning has enabled companies like Samsung Display and LG Display to invest heavily in OLED manufacturing capacity despite initial economic challenges.

Looking forward, economies of scale will play a decisive role in the economic competition between these technologies. As OLED production volumes increase and manufacturing processes mature, the cost differential with LCD is expected to narrow. Industry analysts project that OLED manufacturing costs could achieve parity with LCD for certain display sizes by 2025, potentially accelerating market adoption across broader product categories.

Material costs represent another critical factor in the economic equation. OLED displays utilize expensive organic compounds and require precise deposition techniques, while LCD manufacturing benefits from mature supply chains and economies of scale for liquid crystal materials and backlighting components. However, OLED manufacturing has fewer process steps overall, potentially offering long-term cost advantages as production volumes increase and manufacturing techniques mature.

Yield rates significantly impact economic viability, with OLED manufacturing historically suffering from lower yields than LCD production. Recent technological advancements have improved OLED yields to approximately 70-80% for mobile displays, though still trailing behind LCD's 90%+ yields for similar applications. This yield gap narrows for smaller displays but widens considerably for larger panel sizes, explaining OLED's stronger market position in smartphones compared to television segments.

Energy consumption during manufacturing presents another economic consideration. LCD fabrication typically consumes less energy per unit area than OLED production, contributing to lower operational costs for manufacturers. However, when considering product lifecycle energy efficiency, OLED's potential for lower power consumption during use may offset higher manufacturing energy inputs over time.

Market positioning also influences economic viability. OLED technology commands premium pricing in high-end consumer electronics, providing manufacturers with higher margins despite increased production costs. This premium positioning has enabled companies like Samsung Display and LG Display to invest heavily in OLED manufacturing capacity despite initial economic challenges.

Looking forward, economies of scale will play a decisive role in the economic competition between these technologies. As OLED production volumes increase and manufacturing processes mature, the cost differential with LCD is expected to narrow. Industry analysts project that OLED manufacturing costs could achieve parity with LCD for certain display sizes by 2025, potentially accelerating market adoption across broader product categories.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!