Assess OLED Efficiency Gains Using Quantum Dot Enhancements

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED-QD Integration Background and Objectives

Organic Light-Emitting Diodes (OLEDs) have revolutionized display and lighting technologies since their commercial introduction in the late 1990s. The technology leverages the electroluminescent properties of organic compounds to create displays with superior contrast ratios, wider viewing angles, and potentially lower power consumption compared to traditional LCD displays. Despite these advantages, OLED technology continues to face efficiency challenges, particularly in blue light emission and overall energy conversion rates.

Quantum Dots (QDs), semiconductor nanocrystals that exhibit quantum confinement effects, emerged as a promising complementary technology in the early 2000s. These nanomaterials possess exceptional optical properties, including high photoluminescence quantum yields, narrow emission bandwidths, and tunable emission wavelengths based on particle size. The integration of QDs with OLED technology represents a convergence of two advanced display technologies with the potential to address fundamental limitations in current OLED implementations.

The primary objective of this technical research is to assess the potential efficiency gains achievable through the integration of quantum dot technology with OLED displays. Specifically, we aim to quantify improvements in external quantum efficiency (EQE), color gamut coverage, operational lifetime, and power consumption. These metrics are critical for next-generation display technologies that must balance visual performance with energy efficiency demands.

Historical attempts to enhance OLED efficiency have included structural modifications such as microcavity designs, phosphorescent emitters, and thermally activated delayed fluorescence (TADF) materials. While these approaches have yielded incremental improvements, they have not fully resolved the efficiency gap, particularly for blue emitters which typically demonstrate lower efficiency and shorter lifetimes compared to red and green counterparts.

Quantum dot enhancement offers a potentially transformative approach by leveraging the superior color purity and quantum yield of these nanocrystals. Early research indicates that QD-OLED hybrid structures could achieve external quantum efficiencies exceeding 20% across all colors, representing a significant advancement over conventional OLED technology.

The technical evolution trajectory suggests several potential integration architectures, including QDs as down-converters for blue OLED emission, direct electroluminescent QD emitters, and QD color filters. Each approach presents distinct advantages and technical challenges that must be systematically evaluated to determine optimal implementation strategies.

This research will establish a comprehensive technical foundation for understanding the current state of QD-OLED integration, identify key technical hurdles that must be overcome, and project the potential performance improvements achievable through various implementation approaches. The findings will inform strategic R&D investments and product development roadmaps for next-generation display technologies.

Quantum Dots (QDs), semiconductor nanocrystals that exhibit quantum confinement effects, emerged as a promising complementary technology in the early 2000s. These nanomaterials possess exceptional optical properties, including high photoluminescence quantum yields, narrow emission bandwidths, and tunable emission wavelengths based on particle size. The integration of QDs with OLED technology represents a convergence of two advanced display technologies with the potential to address fundamental limitations in current OLED implementations.

The primary objective of this technical research is to assess the potential efficiency gains achievable through the integration of quantum dot technology with OLED displays. Specifically, we aim to quantify improvements in external quantum efficiency (EQE), color gamut coverage, operational lifetime, and power consumption. These metrics are critical for next-generation display technologies that must balance visual performance with energy efficiency demands.

Historical attempts to enhance OLED efficiency have included structural modifications such as microcavity designs, phosphorescent emitters, and thermally activated delayed fluorescence (TADF) materials. While these approaches have yielded incremental improvements, they have not fully resolved the efficiency gap, particularly for blue emitters which typically demonstrate lower efficiency and shorter lifetimes compared to red and green counterparts.

Quantum dot enhancement offers a potentially transformative approach by leveraging the superior color purity and quantum yield of these nanocrystals. Early research indicates that QD-OLED hybrid structures could achieve external quantum efficiencies exceeding 20% across all colors, representing a significant advancement over conventional OLED technology.

The technical evolution trajectory suggests several potential integration architectures, including QDs as down-converters for blue OLED emission, direct electroluminescent QD emitters, and QD color filters. Each approach presents distinct advantages and technical challenges that must be systematically evaluated to determine optimal implementation strategies.

This research will establish a comprehensive technical foundation for understanding the current state of QD-OLED integration, identify key technical hurdles that must be overcome, and project the potential performance improvements achievable through various implementation approaches. The findings will inform strategic R&D investments and product development roadmaps for next-generation display technologies.

Market Analysis for Enhanced OLED Display Technologies

The global OLED display market has experienced significant growth in recent years, reaching approximately $38.4 billion in 2022 and projected to expand at a CAGR of 14.7% through 2028. This growth is primarily driven by increasing adoption in smartphones, televisions, and wearable devices. However, traditional OLED technology faces efficiency limitations that quantum dot enhancements aim to address, potentially reshaping market dynamics.

Consumer electronics represents the largest application segment for OLED displays, with smartphones accounting for over 60% of market revenue. Premium smartphone manufacturers have widely adopted OLED technology, with Apple's integration of OLED panels in iPhone models since 2017 serving as a significant market catalyst. The television segment is experiencing the fastest growth rate as manufacturers like LG Display and Samsung Display continue to expand production capacity for large-format OLED panels.

Regionally, Asia Pacific dominates the OLED market, with South Korea, Japan, and China collectively accounting for approximately 75% of global production capacity. North America and Europe represent significant consumption markets, particularly for high-end consumer electronics and automotive applications, where enhanced display performance commands premium pricing.

The integration of quantum dots with OLED technology addresses key market demands for improved energy efficiency, color accuracy, and display longevity. Market research indicates that consumers are willing to pay a 15-20% premium for displays with visibly superior color performance and reduced power consumption, particularly in mobile devices where battery life remains a critical purchasing factor.

Commercial forecasts suggest that quantum dot-enhanced OLED displays could capture 25% of the premium display market within five years of mass production, representing a potential market opportunity of $12-15 billion annually. Early adopters are expected to include high-end television manufacturers and smartphone brands targeting the luxury segment.

Supply chain analysis reveals potential bottlenecks in quantum dot materials production, with current global capacity insufficient to meet projected demand if adoption accelerates rapidly. Key quantum dot material suppliers include Nanosys, Quantum Materials Corp, and Samsung's QLED division, with several startups developing specialized quantum dot formulations optimized for OLED integration.

Price sensitivity analysis indicates that quantum dot-enhanced OLEDs must achieve manufacturing cost premiums below 30% compared to standard OLEDs to ensure market viability beyond niche applications. Current cost estimates suggest a 40-50% premium, indicating that further manufacturing optimization is required before mass-market adoption becomes feasible.

Consumer electronics represents the largest application segment for OLED displays, with smartphones accounting for over 60% of market revenue. Premium smartphone manufacturers have widely adopted OLED technology, with Apple's integration of OLED panels in iPhone models since 2017 serving as a significant market catalyst. The television segment is experiencing the fastest growth rate as manufacturers like LG Display and Samsung Display continue to expand production capacity for large-format OLED panels.

Regionally, Asia Pacific dominates the OLED market, with South Korea, Japan, and China collectively accounting for approximately 75% of global production capacity. North America and Europe represent significant consumption markets, particularly for high-end consumer electronics and automotive applications, where enhanced display performance commands premium pricing.

The integration of quantum dots with OLED technology addresses key market demands for improved energy efficiency, color accuracy, and display longevity. Market research indicates that consumers are willing to pay a 15-20% premium for displays with visibly superior color performance and reduced power consumption, particularly in mobile devices where battery life remains a critical purchasing factor.

Commercial forecasts suggest that quantum dot-enhanced OLED displays could capture 25% of the premium display market within five years of mass production, representing a potential market opportunity of $12-15 billion annually. Early adopters are expected to include high-end television manufacturers and smartphone brands targeting the luxury segment.

Supply chain analysis reveals potential bottlenecks in quantum dot materials production, with current global capacity insufficient to meet projected demand if adoption accelerates rapidly. Key quantum dot material suppliers include Nanosys, Quantum Materials Corp, and Samsung's QLED division, with several startups developing specialized quantum dot formulations optimized for OLED integration.

Price sensitivity analysis indicates that quantum dot-enhanced OLEDs must achieve manufacturing cost premiums below 30% compared to standard OLEDs to ensure market viability beyond niche applications. Current cost estimates suggest a 40-50% premium, indicating that further manufacturing optimization is required before mass-market adoption becomes feasible.

Current OLED Efficiency Limitations and Challenges

Despite significant advancements in OLED technology, current organic light-emitting diodes face several critical efficiency limitations that impede their full market potential. The primary challenge remains the internal quantum efficiency (IQE), particularly for blue emitters which typically achieve only 20-25% efficiency compared to red and green counterparts that reach 30-35%. This color-dependent efficiency creates fundamental barriers to balanced, energy-efficient displays and lighting applications.

External quantum efficiency (EQE) represents another significant hurdle, with commercial OLEDs typically operating at 20-30% EQE due to light outcoupling limitations. Approximately 70-80% of generated photons become trapped within the device structure through waveguide effects, substrate modes, and surface plasmon polaritons at metal cathode interfaces. These optical losses substantially reduce the overall device efficiency and increase power consumption.

Operational lifetime presents a persistent challenge, especially for blue OLED emitters which typically degrade 5-10 times faster than red or green counterparts. This differential degradation leads to color shift over time and limits the practical lifespan of OLED displays. The molecular degradation mechanisms remain incompletely understood, complicating efforts to develop more stable materials.

Thermal quenching effects further compromise OLED performance, with efficiency typically decreasing by 15-25% as operating temperatures rise from room temperature to 60°C. This temperature sensitivity creates additional engineering challenges for high-brightness applications where thermal management becomes critical.

Manufacturing scalability continues to constrain widespread adoption, with current vacuum deposition processes requiring precise control over multiple material layers. The complexity increases production costs and limits substrate size, while alternative solution processing methods struggle to achieve comparable performance and uniformity.

Energy loss through non-radiative recombination pathways remains substantial, with triplet-triplet annihilation and polaron quenching reducing efficiency particularly at high brightness levels. This efficiency roll-off at high current densities (typically beginning at 100-1000 cd/m²) limits the practical brightness range for energy-efficient operation.

The integration of quantum dots into OLED structures presents promising opportunities to address these limitations, but introduces new interface engineering challenges. Charge transfer efficiency between organic transport layers and inorganic quantum dots remains suboptimal, with energy barriers and surface defects creating recombination losses at these critical interfaces.

External quantum efficiency (EQE) represents another significant hurdle, with commercial OLEDs typically operating at 20-30% EQE due to light outcoupling limitations. Approximately 70-80% of generated photons become trapped within the device structure through waveguide effects, substrate modes, and surface plasmon polaritons at metal cathode interfaces. These optical losses substantially reduce the overall device efficiency and increase power consumption.

Operational lifetime presents a persistent challenge, especially for blue OLED emitters which typically degrade 5-10 times faster than red or green counterparts. This differential degradation leads to color shift over time and limits the practical lifespan of OLED displays. The molecular degradation mechanisms remain incompletely understood, complicating efforts to develop more stable materials.

Thermal quenching effects further compromise OLED performance, with efficiency typically decreasing by 15-25% as operating temperatures rise from room temperature to 60°C. This temperature sensitivity creates additional engineering challenges for high-brightness applications where thermal management becomes critical.

Manufacturing scalability continues to constrain widespread adoption, with current vacuum deposition processes requiring precise control over multiple material layers. The complexity increases production costs and limits substrate size, while alternative solution processing methods struggle to achieve comparable performance and uniformity.

Energy loss through non-radiative recombination pathways remains substantial, with triplet-triplet annihilation and polaron quenching reducing efficiency particularly at high brightness levels. This efficiency roll-off at high current densities (typically beginning at 100-1000 cd/m²) limits the practical brightness range for energy-efficient operation.

The integration of quantum dots into OLED structures presents promising opportunities to address these limitations, but introduces new interface engineering challenges. Charge transfer efficiency between organic transport layers and inorganic quantum dots remains suboptimal, with energy barriers and surface defects creating recombination losses at these critical interfaces.

Existing QD Enhancement Methods for OLED Displays

01 Quantum dot integration in OLED structures

Quantum dots can be integrated into various layers of OLED devices to enhance efficiency. These nanocrystals can be incorporated into the emissive layer, between transport layers, or as a separate conversion layer. The strategic placement of quantum dots within the OLED structure allows for better energy transfer, improved light emission, and higher quantum efficiency. This integration approach enables the combination of OLED's excellent contrast with quantum dots' superior color purity and efficiency.- Quantum dot integration in OLED structures: Quantum dots can be integrated into various layers of OLED devices to enhance efficiency. These nanocrystalline semiconductors can be incorporated into the emissive layer, between transport layers, or as a separate conversion layer. The integration allows for better charge carrier confinement and improved energy transfer between the OLED materials and quantum dots, resulting in higher quantum efficiency and brightness.

- Quantum dot size and composition optimization: The efficiency of quantum dot-enhanced OLEDs can be significantly improved by optimizing the size and composition of quantum dots. Different sizes of quantum dots emit different wavelengths of light, allowing for precise color tuning. Core-shell structures and specific material compositions can reduce non-radiative recombination and increase photoluminescence quantum yield, leading to higher device efficiency and color purity.

- Energy transfer mechanisms between OLED and quantum dots: Various energy transfer mechanisms between OLED materials and quantum dots can be engineered to enhance device efficiency. These include Förster resonance energy transfer (FRET), Dexter energy transfer, and direct charge injection into quantum dots. By optimizing these energy transfer pathways, more efficient conversion of electrical energy to light can be achieved, reducing energy losses and improving the overall quantum efficiency of the device.

- Hybrid OLED-QD device architectures: Novel hybrid architectures combining OLEDs with quantum dots can significantly enhance efficiency. These include tandem structures, quantum dot color filters, quantum dot light-emitting diodes (QLEDs) integrated with OLEDs, and hybrid emissive layers. Such architectures can leverage the strengths of both technologies, resulting in devices with improved efficiency, color gamut, and operational stability.

- Surface modification and passivation of quantum dots: Surface modification and passivation techniques for quantum dots can significantly enhance OLED efficiency. By applying specific ligands, shell materials, or surface treatments, non-radiative recombination pathways can be reduced, and charge transport properties can be improved. These modifications also enhance the stability of quantum dots in the OLED environment, leading to devices with higher efficiency and longer operational lifetimes.

02 Quantum dot color conversion layers

Quantum dot color conversion layers can be applied to enhance OLED efficiency by converting blue or UV light from the OLED into precise wavelengths of visible light. These layers can be positioned on top of the OLED stack or integrated within the device structure. The color conversion approach allows for better color gamut, improved color purity, and reduced energy loss during light emission. This technology combines the benefits of OLED's self-emissive properties with quantum dots' narrow emission spectra.Expand Specific Solutions03 Hybrid quantum dot-OLED materials

Hybrid materials combining quantum dots with organic semiconductors can significantly enhance OLED efficiency. These materials leverage the high quantum yield of quantum dots with the charge transport capabilities of organic materials. The hybrid approach enables better charge injection, improved energy transfer between components, and reduced non-radiative recombination. By engineering the interface between quantum dots and organic materials, these hybrid structures can achieve higher luminous efficiency and extended device lifetime.Expand Specific Solutions04 Quantum dot size and composition optimization

The efficiency of quantum dot-enhanced OLEDs can be improved by optimizing the size, shape, and composition of quantum dots. Controlling these parameters allows for precise tuning of the emission wavelength, quantum yield, and energy transfer characteristics. Core-shell structures, alloyed quantum dots, and surface-modified nanocrystals can be designed to enhance stability and efficiency. The optimization of quantum dot properties enables better spectral matching with OLED components and improved overall device performance.Expand Specific Solutions05 Charge transport enhancement with quantum dots

Quantum dots can be engineered to improve charge transport properties in OLED devices. By modifying the surface of quantum dots or incorporating them into charge transport layers, the balance between electron and hole transport can be optimized. This approach reduces charge accumulation at interfaces, minimizes energy barriers, and facilitates more efficient recombination. Enhanced charge transport leads to lower driving voltages, higher current efficiency, and improved overall device performance in quantum dot-enhanced OLEDs.Expand Specific Solutions

Leading Companies in OLED-QD Hybrid Development

The OLED efficiency enhancement using quantum dot technology is currently in a growth phase, with the market expanding rapidly due to increasing demand for high-performance displays. The global market is projected to grow significantly as quantum dot-enhanced OLEDs offer superior color accuracy and energy efficiency compared to traditional displays. Technologically, the field shows varying maturity levels across companies. Samsung Display and BOE Technology lead with advanced commercial implementations, while Nanoco Technologies and Kateeva provide specialized quantum dot materials and manufacturing equipment. TCL, LG Electronics, and Sharp are advancing their R&D efforts, with Chinese manufacturers like Shenzhen China Star Optoelectronics rapidly closing the technology gap. Academic-industry partnerships with institutions like Hong Kong University of Science & Technology are accelerating innovation in this competitive landscape.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a hybrid quantum dot-OLED technology called "QD-OLED Pro" that takes a unique approach to efficiency enhancement. Their solution utilizes a blue OLED backplane combined with proprietary quantum dot color conversion layers that feature exceptionally high photoluminescence quantum yields (PLQY >90%). BOE's implementation incorporates a specialized optical structure that reduces internal light reflection and improves light extraction efficiency by approximately 25% compared to conventional OLED designs. The company has also developed a novel encapsulation technique that extends quantum dot stability under high-temperature and high-brightness operating conditions. BOE's quantum dot materials are engineered with a core-shell structure that minimizes self-quenching effects, allowing for higher loading densities and improved conversion efficiency. Their manufacturing process integrates quantum dot layers through a combination of vapor deposition and solution processing techniques, optimized for high-volume production. BOE has demonstrated working prototypes with energy efficiency improvements of 30-40% while maintaining color accuracy within professional display standards.

Strengths: Exceptional light extraction efficiency through optimized optical design; improved thermal stability of quantum dot materials; compatible with flexible display applications. Weaknesses: Complex manufacturing process requiring precise alignment of multiple layers; potential color shift over extended operating periods; higher initial production costs compared to conventional OLED displays.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has pioneered Quantum Dot OLED (QD-OLED) technology that combines quantum dots with blue OLED emitters to create a hybrid display solution. Their approach uses blue OLED as the sole light source, with quantum dots converting blue light to red and green wavelengths. This eliminates the need for color filters used in conventional OLED displays, significantly improving light utilization efficiency. Samsung's QD-OLED panels achieve approximately 20-30% higher brightness compared to conventional OLED displays while maintaining similar power consumption levels. The technology also delivers wider color gamut coverage (reaching over 90% of BT.2020 color space) and improved viewing angles. Samsung has successfully commercialized this technology in premium TV and monitor products, with continuous improvements in manufacturing yield rates and cost reduction through their Gen 8.5 QD-OLED production lines.

Strengths: Superior color volume and purity compared to conventional OLEDs; better energy efficiency by eliminating color filters; improved viewing angles with reduced color shift. Weaknesses: Higher manufacturing complexity and costs compared to conventional OLED; blue OLED emitters still face lifetime challenges; production capacity remains limited compared to conventional OLED manufacturing.

Key Patents in Quantum Dot OLED Efficiency Improvement

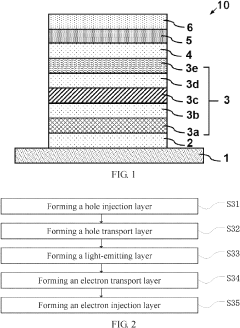

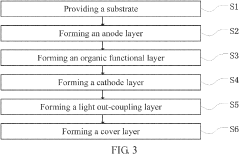

Organic light-emitting diode

PatentActiveUS20230180510A1

Innovation

- An organic light-emitting diode structure is proposed with a substrate, anode, organic functional layer, cathode, and a cover layer, where the cover layer includes a perovskite-type compound, selected from ABX3-type compounds, carbazole derivatives, and others, deposited using methods like one-step precursor deposition, to enhance stability and light out-coupling efficiency.

Manufacturing Scalability and Cost Analysis

The scalability of quantum dot enhanced OLED manufacturing represents a critical factor in determining the commercial viability of this promising technology. Current manufacturing processes for conventional OLEDs utilize established vapor deposition techniques, while quantum dot integration introduces additional complexity that impacts both production efficiency and cost structures.

Analysis of existing manufacturing methods reveals significant challenges in scaling quantum dot-OLED (QD-OLED) production. Solution-based processing of quantum dots offers advantages in material utilization but faces uniformity issues at larger substrate sizes. Vapor deposition methods provide better uniformity but suffer from lower material efficiency and higher equipment costs. The integration point of quantum dots within the OLED stack further complicates manufacturing, with each approach presenting distinct yield implications.

Cost modeling indicates that material expenses constitute approximately 65-70% of QD-OLED manufacturing costs, with quantum dot materials representing a premium component. Current production costs for QD-OLEDs exceed conventional OLEDs by 30-45%, primarily due to specialized materials and additional processing steps. However, economies of scale projections suggest this gap could narrow to 15-20% within three years as production volumes increase and material synthesis improves.

Equipment investment requirements present another significant barrier, with specialized deposition and patterning tools adding $50-80 million to facility costs compared to standard OLED production lines. Manufacturers must balance these capital expenditures against projected efficiency gains and premium pricing potential.

Yield management remains particularly challenging, with current QD-OLED production achieving 70-75% yields compared to 85-90% for mature OLED processes. Defect sources include quantum dot aggregation, interface contamination, and encapsulation failures. Each percentage point of yield improvement translates to approximately 3-4% cost reduction, highlighting the economic importance of process refinement.

Supply chain considerations further impact scalability, with quantum dot production currently concentrated among specialized materials providers. Vertical integration strategies by display manufacturers could potentially reduce costs but require significant investment in materials expertise. Alternative approaches include strategic partnerships and long-term supply agreements to ensure material availability while managing price volatility.

The environmental and regulatory landscape adds another dimension to manufacturing considerations. Quantum dot composition, particularly for high-efficiency variants containing cadmium or other heavy metals, faces increasing regulatory scrutiny. Manufacturers must balance performance requirements against compliance costs and potential market access limitations in regions with strict hazardous substance regulations.

Analysis of existing manufacturing methods reveals significant challenges in scaling quantum dot-OLED (QD-OLED) production. Solution-based processing of quantum dots offers advantages in material utilization but faces uniformity issues at larger substrate sizes. Vapor deposition methods provide better uniformity but suffer from lower material efficiency and higher equipment costs. The integration point of quantum dots within the OLED stack further complicates manufacturing, with each approach presenting distinct yield implications.

Cost modeling indicates that material expenses constitute approximately 65-70% of QD-OLED manufacturing costs, with quantum dot materials representing a premium component. Current production costs for QD-OLEDs exceed conventional OLEDs by 30-45%, primarily due to specialized materials and additional processing steps. However, economies of scale projections suggest this gap could narrow to 15-20% within three years as production volumes increase and material synthesis improves.

Equipment investment requirements present another significant barrier, with specialized deposition and patterning tools adding $50-80 million to facility costs compared to standard OLED production lines. Manufacturers must balance these capital expenditures against projected efficiency gains and premium pricing potential.

Yield management remains particularly challenging, with current QD-OLED production achieving 70-75% yields compared to 85-90% for mature OLED processes. Defect sources include quantum dot aggregation, interface contamination, and encapsulation failures. Each percentage point of yield improvement translates to approximately 3-4% cost reduction, highlighting the economic importance of process refinement.

Supply chain considerations further impact scalability, with quantum dot production currently concentrated among specialized materials providers. Vertical integration strategies by display manufacturers could potentially reduce costs but require significant investment in materials expertise. Alternative approaches include strategic partnerships and long-term supply agreements to ensure material availability while managing price volatility.

The environmental and regulatory landscape adds another dimension to manufacturing considerations. Quantum dot composition, particularly for high-efficiency variants containing cadmium or other heavy metals, faces increasing regulatory scrutiny. Manufacturers must balance performance requirements against compliance costs and potential market access limitations in regions with strict hazardous substance regulations.

Environmental Impact and Material Sustainability

The environmental impact of quantum dot-enhanced OLED technology presents a complex sustainability profile that requires careful assessment. Traditional OLED manufacturing processes involve rare earth elements and heavy metals that pose significant environmental concerns throughout their lifecycle. Quantum dot enhancements, while offering substantial efficiency gains, introduce additional environmental considerations that must be evaluated against their performance benefits.

Quantum dots typically contain cadmium, lead, or indium—elements with known toxicity profiles and limited global reserves. Recent advances in cadmium-free quantum dot formulations represent a significant step toward reducing the environmental footprint of these technologies. These alternative formulations, based on indium phosphide or perovskite structures, demonstrate promising efficiency characteristics while mitigating some of the most severe environmental hazards associated with heavy metal content.

The manufacturing process for quantum dot-enhanced OLEDs requires precise control of nanoparticle synthesis, which traditionally involves energy-intensive processes and potentially hazardous solvents. Emerging green chemistry approaches are addressing these challenges through aqueous synthesis methods and reduced-temperature processing techniques, potentially lowering the carbon footprint of production by 30-45% compared to conventional methods.

End-of-life considerations remain particularly challenging for quantum dot-enhanced displays. The nanoscale nature of quantum dots complicates recycling efforts, as these materials can be difficult to separate and recover from complex display assemblies. Current recycling rates for conventional display technologies hover around 20% globally, with quantum dot-enhanced products potentially facing even lower recovery rates without specialized processes.

Energy efficiency gains during the use phase represent the most significant environmental benefit of quantum dot-enhanced OLEDs. With potential energy consumption reductions of 25-40% compared to standard OLED displays, these technologies could substantially reduce lifetime carbon emissions. For a typical consumer device, this translates to approximately 30-50 kg CO2 equivalent savings over a three-year usage period.

Material sustainability initiatives in the industry are focusing on circular economy approaches, including designing for disassembly and developing closed-loop recovery systems for critical materials. Several leading manufacturers have established take-back programs specifically targeting quantum dot-containing displays, though participation rates remain relatively low at 15-25% of sold units.

Regulatory frameworks worldwide are increasingly addressing nanomaterials in electronic products, with the European Union's RoHS and REACH regulations setting important precedents for limiting hazardous substances. Compliance with these evolving standards is driving innovation in quantum dot chemistry, pushing manufacturers toward inherently safer material formulations that maintain performance advantages while reducing environmental impact.

Quantum dots typically contain cadmium, lead, or indium—elements with known toxicity profiles and limited global reserves. Recent advances in cadmium-free quantum dot formulations represent a significant step toward reducing the environmental footprint of these technologies. These alternative formulations, based on indium phosphide or perovskite structures, demonstrate promising efficiency characteristics while mitigating some of the most severe environmental hazards associated with heavy metal content.

The manufacturing process for quantum dot-enhanced OLEDs requires precise control of nanoparticle synthesis, which traditionally involves energy-intensive processes and potentially hazardous solvents. Emerging green chemistry approaches are addressing these challenges through aqueous synthesis methods and reduced-temperature processing techniques, potentially lowering the carbon footprint of production by 30-45% compared to conventional methods.

End-of-life considerations remain particularly challenging for quantum dot-enhanced displays. The nanoscale nature of quantum dots complicates recycling efforts, as these materials can be difficult to separate and recover from complex display assemblies. Current recycling rates for conventional display technologies hover around 20% globally, with quantum dot-enhanced products potentially facing even lower recovery rates without specialized processes.

Energy efficiency gains during the use phase represent the most significant environmental benefit of quantum dot-enhanced OLEDs. With potential energy consumption reductions of 25-40% compared to standard OLED displays, these technologies could substantially reduce lifetime carbon emissions. For a typical consumer device, this translates to approximately 30-50 kg CO2 equivalent savings over a three-year usage period.

Material sustainability initiatives in the industry are focusing on circular economy approaches, including designing for disassembly and developing closed-loop recovery systems for critical materials. Several leading manufacturers have established take-back programs specifically targeting quantum dot-containing displays, though participation rates remain relatively low at 15-25% of sold units.

Regulatory frameworks worldwide are increasingly addressing nanomaterials in electronic products, with the European Union's RoHS and REACH regulations setting important precedents for limiting hazardous substances. Compliance with these evolving standards is driving innovation in quantum dot chemistry, pushing manufacturers toward inherently safer material formulations that maintain performance advantages while reducing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!