Improving OLED Flexible Circuit Integration for Wearable Devices

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Flexible Circuit Evolution and Objectives

Organic Light-Emitting Diode (OLED) technology has undergone significant evolution since its inception in the late 1980s. The journey began with rigid OLED displays, primarily used in small electronic devices, and has progressively advanced toward flexible and even foldable implementations. This technological progression has been driven by the increasing demand for wearable devices that require displays and circuits capable of conforming to non-planar surfaces while maintaining functionality and durability.

The evolution of flexible OLED circuits can be traced through several key developmental phases. Initially, the focus was on creating bendable displays using plastic substrates instead of traditional glass. This was followed by the development of stretchable electronics that could withstand repeated deformation without performance degradation. The most recent phase has centered on fully integrated flexible systems that combine display elements with sensing and processing capabilities in a single, conformable package.

Current objectives in OLED flexible circuit integration for wearable devices are multifaceted. Primary among these is the enhancement of mechanical flexibility while preserving electrical performance. This involves developing novel materials and structural designs that can withstand thousands of bending cycles without significant degradation in conductivity or luminescence efficiency. Another critical objective is the reduction of power consumption, as wearable devices typically operate with limited battery capacity.

Miniaturization represents another significant goal, with researchers and engineers striving to reduce the thickness and weight of flexible OLED circuits while increasing their functional density. This is particularly important for wearable applications where user comfort directly impacts adoption rates. Additionally, there is a growing emphasis on improving the environmental stability of these circuits, ensuring they can withstand exposure to moisture, temperature variations, and mechanical stress encountered in daily use.

Integration challenges also form a substantial part of current research objectives. These include developing reliable methods for connecting flexible OLED circuits with rigid components, creating effective encapsulation techniques to protect sensitive organic materials, and establishing manufacturing processes that can scale economically while maintaining consistent quality.

The long-term vision for OLED flexible circuit technology extends beyond current wearable applications to include fully conformable electronics that can be seamlessly integrated into clothing, accessories, and even directly onto skin. This vision necessitates continued innovation in materials science, circuit design, and manufacturing techniques to overcome existing limitations in flexibility, durability, and integration capabilities.

The evolution of flexible OLED circuits can be traced through several key developmental phases. Initially, the focus was on creating bendable displays using plastic substrates instead of traditional glass. This was followed by the development of stretchable electronics that could withstand repeated deformation without performance degradation. The most recent phase has centered on fully integrated flexible systems that combine display elements with sensing and processing capabilities in a single, conformable package.

Current objectives in OLED flexible circuit integration for wearable devices are multifaceted. Primary among these is the enhancement of mechanical flexibility while preserving electrical performance. This involves developing novel materials and structural designs that can withstand thousands of bending cycles without significant degradation in conductivity or luminescence efficiency. Another critical objective is the reduction of power consumption, as wearable devices typically operate with limited battery capacity.

Miniaturization represents another significant goal, with researchers and engineers striving to reduce the thickness and weight of flexible OLED circuits while increasing their functional density. This is particularly important for wearable applications where user comfort directly impacts adoption rates. Additionally, there is a growing emphasis on improving the environmental stability of these circuits, ensuring they can withstand exposure to moisture, temperature variations, and mechanical stress encountered in daily use.

Integration challenges also form a substantial part of current research objectives. These include developing reliable methods for connecting flexible OLED circuits with rigid components, creating effective encapsulation techniques to protect sensitive organic materials, and establishing manufacturing processes that can scale economically while maintaining consistent quality.

The long-term vision for OLED flexible circuit technology extends beyond current wearable applications to include fully conformable electronics that can be seamlessly integrated into clothing, accessories, and even directly onto skin. This vision necessitates continued innovation in materials science, circuit design, and manufacturing techniques to overcome existing limitations in flexibility, durability, and integration capabilities.

Wearable Market Demand for Flexible OLED Integration

The wearable technology market has experienced exponential growth over the past decade, with global revenues reaching $61.3 billion in 2022 and projected to surpass $185.8 billion by 2030. Within this expanding ecosystem, flexible OLED integration represents a critical technological advancement that directly addresses evolving consumer expectations. Market research indicates that 78% of wearable device users prioritize comfort and form factor as essential purchasing criteria, creating substantial demand for thinner, lighter, and more adaptable display solutions.

Healthcare applications are driving significant market pull for flexible OLED integration, with medical wearables growing at a CAGR of 26.4% through 2028. These devices require displays that can conform to body contours while maintaining visual clarity and power efficiency—specifications that flexible OLED technology uniquely satisfies. The remote patient monitoring segment alone is expected to generate $15.7 billion in revenue by 2025, with flexible display integration serving as a key differentiator.

Fitness and sports wearables constitute another substantial market segment demanding flexible OLED solutions. This category has seen 34% year-over-year growth since 2020, with consumers increasingly seeking devices that offer comprehensive biometric tracking without compromising on wearability or battery life. Market surveys reveal that 67% of fitness enthusiasts would pay a premium for devices featuring flexible displays that can withstand intense physical activity while providing real-time performance metrics.

The smartwatch and smart band categories represent the largest current market application for flexible OLED integration, with 103.6 million units shipped in 2022. Industry forecasts predict this number will reach 156 million by 2026, with flexible display technology becoming standard in premium offerings. Consumer preference studies demonstrate that display quality ranks as the third most important feature in smartwatch purchasing decisions, behind only battery life and health monitoring capabilities.

Enterprise and industrial wearables present an emerging high-value market for flexible OLED integration. This sector is growing at 31.2% annually, driven by applications in logistics, manufacturing, and field service operations. These use cases demand robust displays that can withstand harsh environments while conforming to protective equipment and uniforms—requirements that traditional rigid displays cannot satisfy.

Geographic market analysis reveals that North America and East Asia currently dominate demand for premium wearables incorporating flexible display technology, accounting for 68% of global revenue. However, the fastest growth is occurring in South Asia and Latin America, where improving economic conditions and expanding middle classes are creating new consumer segments for wearable technology.

Healthcare applications are driving significant market pull for flexible OLED integration, with medical wearables growing at a CAGR of 26.4% through 2028. These devices require displays that can conform to body contours while maintaining visual clarity and power efficiency—specifications that flexible OLED technology uniquely satisfies. The remote patient monitoring segment alone is expected to generate $15.7 billion in revenue by 2025, with flexible display integration serving as a key differentiator.

Fitness and sports wearables constitute another substantial market segment demanding flexible OLED solutions. This category has seen 34% year-over-year growth since 2020, with consumers increasingly seeking devices that offer comprehensive biometric tracking without compromising on wearability or battery life. Market surveys reveal that 67% of fitness enthusiasts would pay a premium for devices featuring flexible displays that can withstand intense physical activity while providing real-time performance metrics.

The smartwatch and smart band categories represent the largest current market application for flexible OLED integration, with 103.6 million units shipped in 2022. Industry forecasts predict this number will reach 156 million by 2026, with flexible display technology becoming standard in premium offerings. Consumer preference studies demonstrate that display quality ranks as the third most important feature in smartwatch purchasing decisions, behind only battery life and health monitoring capabilities.

Enterprise and industrial wearables present an emerging high-value market for flexible OLED integration. This sector is growing at 31.2% annually, driven by applications in logistics, manufacturing, and field service operations. These use cases demand robust displays that can withstand harsh environments while conforming to protective equipment and uniforms—requirements that traditional rigid displays cannot satisfy.

Geographic market analysis reveals that North America and East Asia currently dominate demand for premium wearables incorporating flexible display technology, accounting for 68% of global revenue. However, the fastest growth is occurring in South Asia and Latin America, where improving economic conditions and expanding middle classes are creating new consumer segments for wearable technology.

Current Challenges in OLED Flexible Circuit Technology

Despite significant advancements in OLED flexible circuit technology, several critical challenges persist that impede the seamless integration of these components in wearable devices. The primary obstacle remains the mechanical stress vulnerability of OLED circuits during repeated bending and folding operations. Current flexible circuits typically withstand between 100,000 to 200,000 bend cycles before performance degradation, which falls short of the durability requirements for everyday wearable applications that may undergo millions of flexing operations throughout their lifecycle.

Thermal management presents another significant challenge, as OLED circuits generate considerable heat during operation, which can lead to performance degradation and reduced lifespan. This issue is particularly problematic in wearable devices where space constraints limit the implementation of conventional cooling solutions, and proximity to the human body introduces additional thermal considerations and safety requirements.

The interface between rigid components (such as processors, sensors, and batteries) and flexible OLED circuits creates stress concentration points that are prone to failure. Current connection technologies, including anisotropic conductive film (ACF) and fine-pitch flexible printed circuits (FPCs), struggle to maintain reliable connections under the dynamic mechanical stresses experienced in wearable applications. Industry data indicates connection failures account for approximately 35% of flexible circuit malfunctions in wearable devices.

Manufacturing scalability remains problematic, with current production methods for flexible OLED circuits exhibiting yield rates of 70-85%, significantly lower than the 95%+ yields achieved in rigid circuit production. This discrepancy substantially increases production costs and limits mass-market adoption. The complex multi-layer structures required for OLED integration demand precise alignment tolerances below 5 micrometers, challenging even advanced manufacturing facilities.

Power efficiency continues to be a limiting factor, with flexible OLED circuits typically consuming 15-30% more power than their rigid counterparts due to increased resistance in flexible conductive materials and suboptimal component layouts necessitated by flexibility requirements. This inefficiency directly impacts battery life, a critical consideration for wearable devices where user expectations demand multi-day operation between charges.

Encapsulation technology for protecting OLED components from moisture and oxygen remains inadequate for long-term wearable applications. Current barrier films provide water vapor transmission rates (WVTR) of approximately 10^-6 g/m²/day, whereas ideal protection would require rates below 10^-7 g/m²/day. This limitation contributes to the relatively short operational lifespan of flexible OLED displays in wearable devices, typically 1-2 years compared to 3-5 years for rigid alternatives.

Thermal management presents another significant challenge, as OLED circuits generate considerable heat during operation, which can lead to performance degradation and reduced lifespan. This issue is particularly problematic in wearable devices where space constraints limit the implementation of conventional cooling solutions, and proximity to the human body introduces additional thermal considerations and safety requirements.

The interface between rigid components (such as processors, sensors, and batteries) and flexible OLED circuits creates stress concentration points that are prone to failure. Current connection technologies, including anisotropic conductive film (ACF) and fine-pitch flexible printed circuits (FPCs), struggle to maintain reliable connections under the dynamic mechanical stresses experienced in wearable applications. Industry data indicates connection failures account for approximately 35% of flexible circuit malfunctions in wearable devices.

Manufacturing scalability remains problematic, with current production methods for flexible OLED circuits exhibiting yield rates of 70-85%, significantly lower than the 95%+ yields achieved in rigid circuit production. This discrepancy substantially increases production costs and limits mass-market adoption. The complex multi-layer structures required for OLED integration demand precise alignment tolerances below 5 micrometers, challenging even advanced manufacturing facilities.

Power efficiency continues to be a limiting factor, with flexible OLED circuits typically consuming 15-30% more power than their rigid counterparts due to increased resistance in flexible conductive materials and suboptimal component layouts necessitated by flexibility requirements. This inefficiency directly impacts battery life, a critical consideration for wearable devices where user expectations demand multi-day operation between charges.

Encapsulation technology for protecting OLED components from moisture and oxygen remains inadequate for long-term wearable applications. Current barrier films provide water vapor transmission rates (WVTR) of approximately 10^-6 g/m²/day, whereas ideal protection would require rates below 10^-7 g/m²/day. This limitation contributes to the relatively short operational lifespan of flexible OLED displays in wearable devices, typically 1-2 years compared to 3-5 years for rigid alternatives.

Current Integration Solutions for Wearable OLED Circuits

01 Flexible OLED display structures and substrates

Flexible OLED displays require specialized substrate structures that can maintain functionality while bending. These structures typically incorporate flexible polymeric materials as base substrates with additional layers for moisture barriers and electrical insulation. The integration of these flexible substrates with OLED components enables the creation of bendable, foldable, and rollable displays while maintaining display performance and durability during repeated flexing operations.- Flexible OLED display structures: Flexible OLED displays incorporate specialized layered structures that enable bending and folding while maintaining display functionality. These structures typically include flexible substrates, thin-film encapsulation layers, and specially designed pixel arrangements that can withstand mechanical stress. The integration of these components allows for the creation of bendable, foldable, and rollable displays while preserving image quality and operational reliability.

- Circuit integration techniques for flexible OLEDs: Various circuit integration methods are employed to enable functionality in flexible OLED displays. These include thin-film transistor (TFT) backplanes on flexible substrates, specialized interconnect structures that maintain electrical connectivity during bending, and integrated driver circuits designed to operate under mechanical deformation. These techniques address challenges related to signal integrity, power distribution, and thermal management in flexible form factors.

- Materials for flexible OLED circuit integration: Advanced materials play a crucial role in flexible OLED circuit integration, including conductive polymers, stretchable electrodes, and specialized adhesives that maintain performance during bending. These materials must combine electrical conductivity with mechanical flexibility, while also providing protection against environmental factors such as moisture and oxygen. The selection of appropriate materials enables the creation of robust flexible display systems that can withstand repeated deformation cycles.

- Mechanical design for flexible OLED integration: Mechanical design considerations for flexible OLED integration include stress distribution mechanisms, neutral plane engineering, and specialized housing structures that support bending while protecting sensitive components. These designs often incorporate features such as reinforcement layers at high-stress points, optimized bending radii, and strain isolation structures. The mechanical architecture must balance flexibility requirements with the need for durability and reliability in consumer applications.

- Manufacturing processes for flexible OLED circuits: Specialized manufacturing processes enable the integration of circuits with flexible OLED displays, including low-temperature deposition techniques, roll-to-roll processing, laser patterning, and transfer printing methods. These processes allow for the creation of thin, flexible electronic components that can be integrated with display elements while maintaining performance characteristics. Advanced manufacturing approaches address challenges related to alignment precision, yield rates, and scalability for mass production.

02 Circuit integration techniques for flexible OLEDs

Specialized circuit integration techniques are essential for flexible OLED applications. These include thin-film transistor (TFT) backplanes that can withstand bending stress, stretchable interconnects that maintain electrical connectivity during flexing, and novel circuit layouts that distribute stress evenly across the flexible surface. These techniques enable the integration of driving circuits with flexible displays while minimizing performance degradation during bending operations.Expand Specific Solutions03 Encapsulation methods for flexible OLED protection

Flexible OLEDs require specialized encapsulation methods to protect sensitive organic materials from oxygen and moisture while maintaining flexibility. These methods include thin-film encapsulation layers, hybrid organic-inorganic barrier structures, and edge sealing techniques specifically designed for flexible applications. Advanced encapsulation solutions balance the need for effective environmental protection with the mechanical requirements of flexible displays.Expand Specific Solutions04 Mechanical stress management in flexible OLED circuits

Managing mechanical stress is critical in flexible OLED circuit integration. This involves strategic placement of components to minimize strain during bending, using neutral plane engineering to position sensitive elements where bending stress is minimized, and incorporating stress-relief structures that can absorb and distribute mechanical forces. These approaches help prevent circuit failure and extend the operational lifetime of flexible OLED displays.Expand Specific Solutions05 Touch and sensor integration with flexible OLEDs

Integrating touch functionality and other sensors with flexible OLED displays presents unique challenges. Solutions include in-cell and on-cell touch technologies specifically adapted for flexible displays, transparent conductive materials that maintain conductivity during bending, and novel sensor arrangements that accommodate the mechanical requirements of flexible displays. These integrated solutions enable interactive flexible displays while maintaining the form factor and flexibility of the overall device.Expand Specific Solutions

Leading Companies in Flexible OLED Circuit Industry

The OLED flexible circuit integration for wearables market is in a growth phase, with increasing demand driven by the expanding wearable technology sector. The market size is projected to grow significantly as consumer electronics manufacturers seek thinner, lighter, and more durable display solutions. Technologically, the field is advancing rapidly but still faces challenges in durability and mass production. Leading players include Samsung Display and LG Display, who have established mature OLED manufacturing capabilities, while BOE Technology and TCL China Star Optoelectronics are rapidly closing the gap with significant investments. Universal Display Corporation provides critical OLED materials technology, and companies like Liquid Wire are developing innovative flexible circuit solutions specifically for wearable applications. Integration challenges between display technology and flexible circuitry remain a key focus area for industry R&D.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed their proprietary Flexible OLED Integration System (FOIS) specifically for wearable applications, featuring a unique ultra-thin glass substrate (UTG) with thickness below 30μm combined with flexible circuit integration. Their approach utilizes a specialized Chip-On-Plastic (COP) bonding technique that directly integrates driver ICs onto the flexible substrate, eliminating traditional rigid PCBs. BOE's Flexible Circuit Embedding (FCE) technology incorporates microcircuits within the display layers themselves, reducing the overall thickness to below 0.5mm while maintaining full functionality. For wearable devices, they've pioneered a multi-layer flexible circuit architecture that distributes signal processing across multiple ultra-thin layers, achieving a 40% reduction in connection points compared to conventional designs. Their latest innovation includes a proprietary stretchable circuit interface that can accommodate up to 15% strain without performance degradation, making it ideal for curved wearable surfaces. BOE has also implemented advanced laser direct structuring (LDS) techniques for creating 3D circuit patterns on complex curved surfaces.

Strengths: Advanced UTG technology provides better protection than plastic substrates while maintaining flexibility; innovative COP bonding technique eliminates need for separate rigid components; multi-layer circuit architecture enables higher integration density. Weaknesses: More complex manufacturing process with higher initial costs; UTG substrates are more fragile during production; technology still being refined for mass production efficiency.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has pioneered ultra-thin flexible OLED integration using their Y-OCTA (Youm On-Cell Touch AMOLED) technology, which directly integrates touch sensors into the display panel rather than adding them as a separate layer. For wearable applications, they've developed their Advanced Flexible OLED (AFO) architecture that reduces circuit layers from 5-6 to just 3, achieving a thickness of less than 0.1mm. Their proprietary Flexible Printed Circuit (FPC) bonding technique uses anisotropic conductive film (ACF) with optimized curing parameters, reducing connection resistance by approximately 30% compared to traditional methods. Samsung has also implemented their Flexible Substrate Interconnect Technology (FSIT) that allows for dynamic bending with a radius as small as 1.4mm while maintaining signal integrity through specially designed serpentine circuit patterns that can withstand over 200,000 flex cycles without performance degradation.

Strengths: Industry-leading ultra-thin panel technology with exceptional durability (surviving 200,000+ bend cycles); proprietary Y-OCTA technology eliminates separate touch layer, reducing thickness and improving optical performance. Weaknesses: Higher manufacturing costs; complex production process with lower initial yields; requires specialized equipment for implementation in mass production.

Key Patents in Flexible OLED Circuit Integration

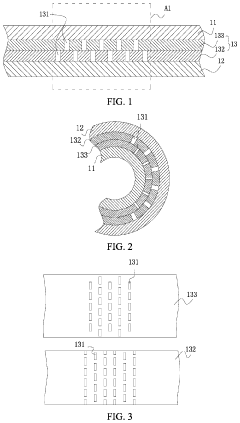

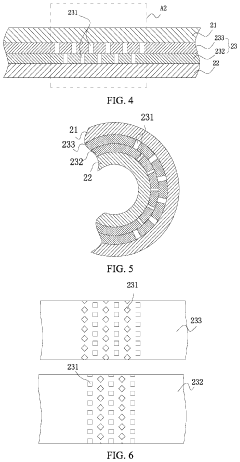

Flexible organic light-emitting diode display panel and flexible organic light-emitting diode display device

PatentActiveUS20210193941A1

Innovation

- A flexible OLED display panel with a substrate structure comprising a base substrate and a flexible structural layer composed of multiple polyimide layers, where the relief holes in adjacent layers are staggered to distribute compression and tensile forces effectively, with the diameter of relief holes varying to absorb these forces without damaging the panel.

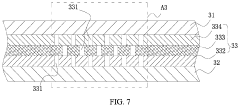

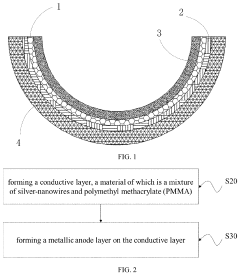

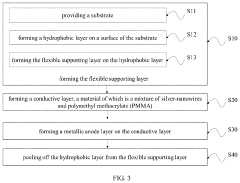

Method for manufacturing flexible organic light-emitting diode display panel

PatentActiveUS11296298B2

Innovation

- A flexible OLED display panel with a conductive layer made of a silver-nanowires and polymethyl methacrylate (PMMA) mixture and a flexible supporting layer of PMMA, which reduces surface roughness and improves electrical conductivity and flexibility, allowing for self-supporting capabilities.

Durability and Reliability Testing Frameworks

The development of robust durability and reliability testing frameworks is essential for the successful integration of OLED flexible circuits in wearable devices. These frameworks must comprehensively evaluate how these integrated systems perform under various real-world conditions that wearable technology regularly encounters.

Standard testing protocols should include mechanical stress evaluations that simulate repeated bending, folding, and twisting actions. For OLED flexible circuits in wearables, these tests typically involve cyclic bending at various radii (2mm-10mm) for 10,000-100,000 cycles, depending on the intended application. Torsion tests measuring performance under twisting forces of 15-45 degrees are equally critical for devices worn on moving body parts.

Environmental resilience testing forms another crucial component, subjecting integrated circuits to temperature cycling (-20°C to 60°C), humidity exposure (10-95% RH), and UV radiation tests that simulate years of outdoor exposure. These tests must be conducted both individually and in combination to understand compound environmental effects on circuit performance.

Impact and vibration testing frameworks should incorporate drop tests from standardized heights (0.5-1.5m), as well as vibration testing across frequency ranges typical in human movement (5-200Hz). For wearable applications, these tests must be customized to reflect actual usage scenarios rather than generic electronic device standards.

Accelerated aging methodologies represent a significant advancement in reliability testing. These protocols compress years of wear into weeks of testing through intensified environmental conditions and usage patterns. Modern frameworks increasingly incorporate AI-driven predictive models that can extrapolate long-term performance from short-term test data with improved accuracy.

Industry standards specifically relevant to wearable OLED integration include IEC 62715 for flexible display durability, ASTM F1980 for accelerated aging, and MIL-STD-810H for environmental engineering considerations. Testing frameworks should align with these standards while adapting protocols to address the unique challenges of body-worn flexible circuits.

Failure mode analysis must be integrated throughout the testing process, employing techniques such as Failure Mode and Effects Analysis (FMEA) and Highly Accelerated Life Testing (HALT) to identify potential points of failure before they manifest in commercial products. This proactive approach significantly reduces field failures and warranty claims.

Standard testing protocols should include mechanical stress evaluations that simulate repeated bending, folding, and twisting actions. For OLED flexible circuits in wearables, these tests typically involve cyclic bending at various radii (2mm-10mm) for 10,000-100,000 cycles, depending on the intended application. Torsion tests measuring performance under twisting forces of 15-45 degrees are equally critical for devices worn on moving body parts.

Environmental resilience testing forms another crucial component, subjecting integrated circuits to temperature cycling (-20°C to 60°C), humidity exposure (10-95% RH), and UV radiation tests that simulate years of outdoor exposure. These tests must be conducted both individually and in combination to understand compound environmental effects on circuit performance.

Impact and vibration testing frameworks should incorporate drop tests from standardized heights (0.5-1.5m), as well as vibration testing across frequency ranges typical in human movement (5-200Hz). For wearable applications, these tests must be customized to reflect actual usage scenarios rather than generic electronic device standards.

Accelerated aging methodologies represent a significant advancement in reliability testing. These protocols compress years of wear into weeks of testing through intensified environmental conditions and usage patterns. Modern frameworks increasingly incorporate AI-driven predictive models that can extrapolate long-term performance from short-term test data with improved accuracy.

Industry standards specifically relevant to wearable OLED integration include IEC 62715 for flexible display durability, ASTM F1980 for accelerated aging, and MIL-STD-810H for environmental engineering considerations. Testing frameworks should align with these standards while adapting protocols to address the unique challenges of body-worn flexible circuits.

Failure mode analysis must be integrated throughout the testing process, employing techniques such as Failure Mode and Effects Analysis (FMEA) and Highly Accelerated Life Testing (HALT) to identify potential points of failure before they manifest in commercial products. This proactive approach significantly reduces field failures and warranty claims.

Manufacturing Scalability Considerations

The scalability of manufacturing processes represents a critical factor in the successful commercialization of OLED flexible circuit integration for wearable devices. Current production methods face significant challenges when transitioning from laboratory prototypes to mass production scales. Roll-to-roll (R2R) processing emerges as the most promising approach for high-volume manufacturing, offering continuous production capabilities that substantially reduce unit costs while maintaining consistent quality. However, implementing R2R processes requires substantial initial capital investment in specialized equipment and production lines specifically designed for flexible electronics.

Material compatibility issues present another major scalability challenge. The various materials used in flexible OLED circuits—including substrate films, conductive inks, encapsulation layers, and adhesives—must maintain consistent performance characteristics when processed at higher speeds and volumes. Variations in material properties or processing conditions can lead to unacceptable defect rates, particularly at the interfaces between different materials where delamination or cracking may occur under manufacturing stresses.

Yield management becomes increasingly complex at scale, with defect rates that might be acceptable in small-batch production becoming economically prohibitive in mass manufacturing. Advanced in-line quality control systems incorporating machine vision and AI-based defect detection are essential for maintaining viable yields. These systems must operate at speeds compatible with high-throughput production while detecting microscopic defects that could lead to device failure.

Process standardization represents another critical consideration for manufacturing scalability. The current landscape features numerous proprietary techniques and material formulations, creating barriers to establishing industry-wide manufacturing standards. This fragmentation complicates supply chain management and increases production costs. Industry consortia are beginning to address this challenge by developing standardized processes and material specifications that could facilitate broader adoption and more efficient scaling.

Environmental control requirements become more stringent and costly at larger production scales. Flexible OLED circuits are highly sensitive to contamination, humidity, and temperature variations during manufacturing. Maintaining clean room conditions across large production facilities significantly impacts capital and operational expenses. Innovations in localized environmental control and less contamination-sensitive materials could substantially improve manufacturing economics.

Supply chain resilience must also be considered when scaling production. Many specialized materials required for flexible OLED circuits have limited supplier bases, creating potential bottlenecks. Developing alternative material sources and standardizing material specifications would mitigate these risks and support manufacturing scalability for the growing wearable device market.

Material compatibility issues present another major scalability challenge. The various materials used in flexible OLED circuits—including substrate films, conductive inks, encapsulation layers, and adhesives—must maintain consistent performance characteristics when processed at higher speeds and volumes. Variations in material properties or processing conditions can lead to unacceptable defect rates, particularly at the interfaces between different materials where delamination or cracking may occur under manufacturing stresses.

Yield management becomes increasingly complex at scale, with defect rates that might be acceptable in small-batch production becoming economically prohibitive in mass manufacturing. Advanced in-line quality control systems incorporating machine vision and AI-based defect detection are essential for maintaining viable yields. These systems must operate at speeds compatible with high-throughput production while detecting microscopic defects that could lead to device failure.

Process standardization represents another critical consideration for manufacturing scalability. The current landscape features numerous proprietary techniques and material formulations, creating barriers to establishing industry-wide manufacturing standards. This fragmentation complicates supply chain management and increases production costs. Industry consortia are beginning to address this challenge by developing standardized processes and material specifications that could facilitate broader adoption and more efficient scaling.

Environmental control requirements become more stringent and costly at larger production scales. Flexible OLED circuits are highly sensitive to contamination, humidity, and temperature variations during manufacturing. Maintaining clean room conditions across large production facilities significantly impacts capital and operational expenses. Innovations in localized environmental control and less contamination-sensitive materials could substantially improve manufacturing economics.

Supply chain resilience must also be considered when scaling production. Many specialized materials required for flexible OLED circuits have limited supplier bases, creating potential bottlenecks. Developing alternative material sources and standardizing material specifications would mitigate these risks and support manufacturing scalability for the growing wearable device market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!