OLED Photovoltage vs Fluorescent: Efficiency in Lighting Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Photovoltage Technology Evolution and Objectives

OLED technology has evolved significantly since its inception in the 1950s when electroluminescence in organic materials was first observed. The journey from laboratory curiosity to commercial application began in earnest during the 1980s when Ching W. Tang and Steven Van Slyke at Eastman Kodak developed the first practical OLED device. This breakthrough demonstrated the potential of organic materials for efficient light emission through electrical stimulation, establishing the foundation for modern OLED technology.

The evolution of OLED photovoltage technology has been characterized by continuous improvements in efficiency, stability, and manufacturing processes. Early OLED devices suffered from short operational lifetimes and low luminous efficiency, limiting their practical applications. However, the introduction of phosphorescent materials in the late 1990s marked a significant advancement, substantially improving quantum efficiency by harvesting both singlet and triplet excitons for light emission.

In the 2000s, the development of solution-processable OLEDs opened new manufacturing possibilities, reducing production costs and enabling larger display formats. Concurrently, researchers focused on enhancing charge carrier mobility and optimizing device architectures to improve power efficiency, a critical factor when comparing OLEDs with traditional fluorescent lighting systems.

The past decade has witnessed remarkable progress in OLED photovoltage technology, particularly in addressing the efficiency gap between laboratory prototypes and commercial products. Innovations in electrode materials, charge transport layers, and emissive compounds have collectively pushed OLED efficiency beyond 200 lm/W in laboratory settings, surpassing many fluorescent lighting solutions.

Current technological objectives center on several key areas. First, improving operational stability remains crucial, as blue OLED emitters still lag behind their red and green counterparts in longevity. Second, reducing manufacturing costs through simplified device structures and improved production yields is essential for broader market adoption. Third, enhancing light extraction efficiency represents a significant opportunity, as internal quantum efficiency has approached theoretical limits while external quantum efficiency still has considerable room for improvement.

Looking forward, the integration of OLED technology with emerging materials such as quantum dots and perovskites presents promising avenues for efficiency enhancement. Additionally, the development of flexible and transparent OLED lighting systems aims to create new application scenarios beyond the capabilities of conventional fluorescent lighting. The ultimate objective is to establish OLED technology as the dominant lighting solution across residential, commercial, and industrial sectors by achieving superior efficiency, environmental performance, and versatility compared to fluorescent alternatives.

The evolution of OLED photovoltage technology has been characterized by continuous improvements in efficiency, stability, and manufacturing processes. Early OLED devices suffered from short operational lifetimes and low luminous efficiency, limiting their practical applications. However, the introduction of phosphorescent materials in the late 1990s marked a significant advancement, substantially improving quantum efficiency by harvesting both singlet and triplet excitons for light emission.

In the 2000s, the development of solution-processable OLEDs opened new manufacturing possibilities, reducing production costs and enabling larger display formats. Concurrently, researchers focused on enhancing charge carrier mobility and optimizing device architectures to improve power efficiency, a critical factor when comparing OLEDs with traditional fluorescent lighting systems.

The past decade has witnessed remarkable progress in OLED photovoltage technology, particularly in addressing the efficiency gap between laboratory prototypes and commercial products. Innovations in electrode materials, charge transport layers, and emissive compounds have collectively pushed OLED efficiency beyond 200 lm/W in laboratory settings, surpassing many fluorescent lighting solutions.

Current technological objectives center on several key areas. First, improving operational stability remains crucial, as blue OLED emitters still lag behind their red and green counterparts in longevity. Second, reducing manufacturing costs through simplified device structures and improved production yields is essential for broader market adoption. Third, enhancing light extraction efficiency represents a significant opportunity, as internal quantum efficiency has approached theoretical limits while external quantum efficiency still has considerable room for improvement.

Looking forward, the integration of OLED technology with emerging materials such as quantum dots and perovskites presents promising avenues for efficiency enhancement. Additionally, the development of flexible and transparent OLED lighting systems aims to create new application scenarios beyond the capabilities of conventional fluorescent lighting. The ultimate objective is to establish OLED technology as the dominant lighting solution across residential, commercial, and industrial sectors by achieving superior efficiency, environmental performance, and versatility compared to fluorescent alternatives.

Market Analysis for Energy-Efficient Lighting Solutions

The global market for energy-efficient lighting solutions has experienced significant growth over the past decade, driven by increasing environmental awareness, government regulations, and the rising cost of energy. The transition from traditional incandescent bulbs to more efficient alternatives has created a dynamic marketplace where OLED (Organic Light Emitting Diode) and fluorescent technologies compete for market share alongside other solutions like LED lighting.

Current market valuations indicate that the energy-efficient lighting sector represents approximately $80 billion globally, with projections suggesting growth to $112 billion by 2025. This represents a compound annual growth rate of 7.3%, significantly outpacing the general lighting market's growth rate of 4.5%. Within this expanding market, fluorescent lighting currently holds about 31% market share, while OLED technology, though newer, has captured roughly 5% and is growing at a faster rate of 22% annually.

Consumer demand patterns reveal an increasing preference for lighting solutions that offer both energy efficiency and enhanced lighting quality. Market surveys indicate that 67% of commercial customers and 54% of residential consumers now prioritize energy efficiency when making lighting purchase decisions, compared to just 38% and 22% respectively five years ago. This shift represents a fundamental change in market dynamics that favors technologies offering superior efficiency metrics.

Regional market analysis shows varying adoption rates, with North America and Europe leading in OLED adoption due to stronger environmental regulations and higher disposable income. The Asia-Pacific region dominates in fluorescent lighting production and consumption, though this is gradually shifting as manufacturing capabilities for advanced lighting technologies expand in countries like China and South Korea.

Price sensitivity remains a critical factor influencing market penetration. While fluorescent lighting maintains a competitive edge in terms of initial purchase cost (averaging $8-15 per equivalent unit compared to $25-40 for comparable OLED solutions), the total cost of ownership calculations increasingly favor OLED technology when factoring in energy consumption and replacement frequency. Market data suggests a price elasticity of demand of -1.8 for energy-efficient lighting, indicating that continued price reductions in OLED technology could trigger accelerated market adoption.

Industry forecasts predict that as manufacturing scales and technology improves, the price gap between OLED and fluorescent solutions will narrow to less than 20% by 2026, potentially creating a tipping point for mass market adoption of OLED technology. This transition is further supported by the gradual phase-out of certain fluorescent technologies under environmental regulations in major markets including the European Union, California, and Canada.

Current market valuations indicate that the energy-efficient lighting sector represents approximately $80 billion globally, with projections suggesting growth to $112 billion by 2025. This represents a compound annual growth rate of 7.3%, significantly outpacing the general lighting market's growth rate of 4.5%. Within this expanding market, fluorescent lighting currently holds about 31% market share, while OLED technology, though newer, has captured roughly 5% and is growing at a faster rate of 22% annually.

Consumer demand patterns reveal an increasing preference for lighting solutions that offer both energy efficiency and enhanced lighting quality. Market surveys indicate that 67% of commercial customers and 54% of residential consumers now prioritize energy efficiency when making lighting purchase decisions, compared to just 38% and 22% respectively five years ago. This shift represents a fundamental change in market dynamics that favors technologies offering superior efficiency metrics.

Regional market analysis shows varying adoption rates, with North America and Europe leading in OLED adoption due to stronger environmental regulations and higher disposable income. The Asia-Pacific region dominates in fluorescent lighting production and consumption, though this is gradually shifting as manufacturing capabilities for advanced lighting technologies expand in countries like China and South Korea.

Price sensitivity remains a critical factor influencing market penetration. While fluorescent lighting maintains a competitive edge in terms of initial purchase cost (averaging $8-15 per equivalent unit compared to $25-40 for comparable OLED solutions), the total cost of ownership calculations increasingly favor OLED technology when factoring in energy consumption and replacement frequency. Market data suggests a price elasticity of demand of -1.8 for energy-efficient lighting, indicating that continued price reductions in OLED technology could trigger accelerated market adoption.

Industry forecasts predict that as manufacturing scales and technology improves, the price gap between OLED and fluorescent solutions will narrow to less than 20% by 2026, potentially creating a tipping point for mass market adoption of OLED technology. This transition is further supported by the gradual phase-out of certain fluorescent technologies under environmental regulations in major markets including the European Union, California, and Canada.

Current OLED vs Fluorescent Technology Assessment

The current landscape of lighting technology presents a significant contrast between OLED (Organic Light Emitting Diode) and fluorescent lighting systems, particularly in terms of efficiency metrics. Fluorescent lighting, having dominated commercial and industrial applications for decades, operates on the principle of electrical discharge through mercury vapor, producing ultraviolet light that is converted to visible light by a phosphor coating. This technology typically achieves efficacy ratings of 60-100 lumens per watt, with operational lifespans ranging from 7,000 to 24,000 hours depending on quality and usage patterns.

OLED technology, by contrast, utilizes organic compounds that emit light when an electric current passes through them. The fundamental architecture consists of organic semiconductor materials placed between two electrodes, at least one of which is transparent. Current OLED lighting panels demonstrate efficacy ratings of 40-80 lumens per watt, with continuous improvement trajectories observed in laboratory settings reaching up to 130 lumens per watt in controlled environments.

Energy consumption analysis reveals that while fluorescent systems have historically maintained an efficiency advantage in large-scale applications, OLEDs demonstrate superior performance in specific metrics including start-up time, color rendering index (CRI), and absence of mercury content. Fluorescent systems typically require warm-up periods of 30-180 seconds to reach full brightness, whereas OLEDs provide instant illumination without delay, offering immediate full spectrum light output.

The photovoltage characteristics between these technologies differ substantially. Fluorescent lighting operates at higher voltages (typically 100-277V), while OLEDs function effectively at lower voltages (3-5V DC), enabling more flexible integration with low-voltage systems and renewable energy sources. This voltage differential impacts both safety considerations and installation requirements across various application environments.

Heat dissipation represents another critical differentiator. Fluorescent systems convert approximately 80% of input energy to heat, necessitating thermal management strategies in confined installations. OLED panels operate at significantly lower temperatures, with surface temperatures rarely exceeding 35°C during standard operation, eliminating many thermal management requirements and enabling novel form factors previously unattainable.

Spectral output analysis demonstrates that current OLED technology provides superior color rendering (CRI >90) compared to standard fluorescent systems (CRI 70-85), with particular advantages in red spectrum reproduction. This spectral advantage translates to reduced eye strain and more accurate color perception in critical visual environments such as medical facilities, design studios, and precision manufacturing settings.

Manufacturing scalability currently favors fluorescent technology due to established production infrastructure, though OLED manufacturing processes have demonstrated significant cost reductions of approximately 36% over the past five years, suggesting an accelerating convergence in production economics as manufacturing volumes increase and novel deposition techniques mature.

OLED technology, by contrast, utilizes organic compounds that emit light when an electric current passes through them. The fundamental architecture consists of organic semiconductor materials placed between two electrodes, at least one of which is transparent. Current OLED lighting panels demonstrate efficacy ratings of 40-80 lumens per watt, with continuous improvement trajectories observed in laboratory settings reaching up to 130 lumens per watt in controlled environments.

Energy consumption analysis reveals that while fluorescent systems have historically maintained an efficiency advantage in large-scale applications, OLEDs demonstrate superior performance in specific metrics including start-up time, color rendering index (CRI), and absence of mercury content. Fluorescent systems typically require warm-up periods of 30-180 seconds to reach full brightness, whereas OLEDs provide instant illumination without delay, offering immediate full spectrum light output.

The photovoltage characteristics between these technologies differ substantially. Fluorescent lighting operates at higher voltages (typically 100-277V), while OLEDs function effectively at lower voltages (3-5V DC), enabling more flexible integration with low-voltage systems and renewable energy sources. This voltage differential impacts both safety considerations and installation requirements across various application environments.

Heat dissipation represents another critical differentiator. Fluorescent systems convert approximately 80% of input energy to heat, necessitating thermal management strategies in confined installations. OLED panels operate at significantly lower temperatures, with surface temperatures rarely exceeding 35°C during standard operation, eliminating many thermal management requirements and enabling novel form factors previously unattainable.

Spectral output analysis demonstrates that current OLED technology provides superior color rendering (CRI >90) compared to standard fluorescent systems (CRI 70-85), with particular advantages in red spectrum reproduction. This spectral advantage translates to reduced eye strain and more accurate color perception in critical visual environments such as medical facilities, design studios, and precision manufacturing settings.

Manufacturing scalability currently favors fluorescent technology due to established production infrastructure, though OLED manufacturing processes have demonstrated significant cost reductions of approximately 36% over the past five years, suggesting an accelerating convergence in production economics as manufacturing volumes increase and novel deposition techniques mature.

Technical Comparison of OLED and Fluorescent Solutions

01 OLED efficiency improvements through material selection

Organic Light Emitting Diode (OLED) efficiency can be significantly improved through careful selection of materials. This includes using phosphorescent materials that achieve higher internal quantum efficiency compared to fluorescent materials. Advanced emitter materials, host materials with appropriate energy levels, and charge transport layers can optimize electron-hole recombination and light emission. These material innovations help reduce energy loss and increase luminous efficacy of OLED lighting systems.- OLED efficiency enhancement techniques: Various techniques are employed to enhance the efficiency of OLED lighting technologies. These include optimizing the organic materials used in the emissive layer, improving electron and hole transport layers, and implementing advanced device architectures. Enhanced phosphorescent and fluorescent materials can significantly increase quantum efficiency, while specialized electrode designs help reduce energy loss during operation. These improvements collectively contribute to higher luminous efficacy and extended operational lifetimes.

- Fluorescent lighting efficiency improvements: Efficiency improvements in fluorescent lighting technologies focus on enhanced phosphor formulations, optimized electrode designs, and advanced ballast systems. Modern fluorescent systems incorporate rare earth phosphors that convert ultraviolet radiation to visible light more efficiently. Electronic ballasts reduce energy losses compared to traditional magnetic ballasts, while specialized reflector designs help maximize light output. These advancements have significantly improved the luminous efficacy of fluorescent lighting systems.

- Comparative efficiency between OLED and fluorescent technologies: OLED and fluorescent lighting technologies exhibit different efficiency characteristics. While fluorescent lighting has historically offered higher luminous efficacy, OLEDs provide advantages in form factor, instant-on capability, and color quality. OLEDs have shown rapid improvement in efficiency metrics, with newer generations approaching or exceeding fluorescent efficiency in certain applications. The efficiency comparison also considers factors such as directional light output, dimming capabilities, and operational lifetime under various conditions.

- Hybrid lighting systems combining OLED and fluorescent technologies: Hybrid lighting systems leverage the complementary strengths of both OLED and fluorescent technologies. These systems typically use fluorescent components for ambient or general lighting requirements where high luminous output is needed, while incorporating OLEDs for task lighting, decorative elements, or areas benefiting from diffuse, glare-free illumination. The integration of both technologies in a single lighting system allows for optimized energy efficiency while meeting diverse lighting requirements.

- Energy management and control systems for lighting efficiency: Advanced energy management and control systems significantly enhance the operational efficiency of both OLED and fluorescent lighting technologies. These systems incorporate sensors for occupancy detection, daylight harvesting, and automated dimming capabilities. Smart controllers can optimize power delivery based on usage patterns and integrate with building management systems. For OLEDs specifically, specialized drivers manage power delivery to maximize efficiency and extend operational lifetime, while fluorescent systems benefit from optimized ballast control strategies.

02 Fluorescent lighting efficiency enhancements

Fluorescent lighting technology efficiency has been improved through various innovations including enhanced phosphor coatings, optimized electrode designs, and advanced ballast systems. Electronic ballasts significantly reduce energy consumption compared to magnetic ballasts by operating at higher frequencies. Improved phosphor formulations provide better color rendering while maintaining high efficiency. These advancements collectively increase the luminous efficacy of fluorescent lighting systems while reducing power consumption.Expand Specific Solutions03 OLED device structure optimization for efficiency

The efficiency of OLED lighting can be enhanced through structural optimization of the device layers. This includes implementing multi-layer structures with precisely controlled thicknesses, utilizing light extraction technologies such as microlens arrays or scattering layers, and incorporating optical outcoupling structures. Tandem OLED structures with multiple emission units connected in series can also significantly improve efficiency. These structural optimizations help extract more light from the device and reduce internal losses.Expand Specific Solutions04 Hybrid lighting systems combining OLED and fluorescent technologies

Hybrid lighting systems that integrate both OLED and fluorescent technologies can leverage the advantages of each to achieve higher overall efficiency. These systems may use fluorescent lighting for ambient illumination while employing OLEDs for task lighting or decorative elements. Smart control systems can optimize the operation of each component based on usage patterns and ambient conditions. This approach allows for energy savings while maintaining desired lighting quality and aesthetic appeal.Expand Specific Solutions05 Driving circuits and power management for lighting efficiency

Advanced driving circuits and power management systems play a crucial role in maximizing the efficiency of both OLED and fluorescent lighting technologies. For OLEDs, constant current drivers with precise control capabilities help maintain optimal operating conditions. For fluorescent lighting, high-frequency electronic ballasts with power factor correction reduce energy losses. Dimming capabilities, thermal management systems, and intelligent power distribution further enhance overall system efficiency by ensuring components operate under optimal conditions.Expand Specific Solutions

Key Industry Players in Advanced Lighting Systems

The OLED vs Fluorescent lighting technology market is currently in a growth phase, with OLED technology gradually maturing but still evolving. The global market size for advanced lighting systems is expanding rapidly, projected to reach significant scale as energy efficiency demands increase. In terms of technical maturity, key players like LG Display, Samsung Display, and Universal Display Corporation lead OLED development with established manufacturing capabilities, while BOE Technology and Visionox are rapidly advancing. Traditional fluorescent lighting companies such as Signify (formerly Philips Lighting) maintain strong market positions. Research institutions including Industrial Technology Research Institute and University of Southern California contribute to innovation, while materials specialists like Merck Patent GmbH and Idemitsu Kosan provide critical components for next-generation lighting solutions.

LG Display Co., Ltd.

Technical Solution: LG Display has developed proprietary WOLED (White OLED) technology for lighting applications that offers significant efficiency advantages over fluorescent lighting systems. Their approach utilizes a multi-emitter stack structure that combines complementary colored phosphorescent emitters to produce high-quality white light with excellent color rendering properties (CRI>90). LG's OLED lighting panels achieve energy efficiency ratings of 60-100 lm/W, substantially outperforming fluorescent systems (typically 50-70 lm/W) while eliminating mercury content and associated environmental concerns. Their panels feature ultra-thin profiles (less than 1mm) and can be manufactured on flexible substrates, enabling novel form factors impossible with traditional lighting technologies. LG has also pioneered advanced light extraction techniques using micro-lens arrays that boost external quantum efficiency by 30-40%. Their manufacturing process incorporates roll-to-roll techniques for certain components, improving production efficiency and reducing costs. LG's OLED lighting technology demonstrates exceptional uniformity with less than 3% variation across the panel surface, eliminating the flickering issues common in fluorescent lighting.

Strengths: Established mass production capabilities; expertise in large-area OLED manufacturing; strong vertical integration from materials to finished products; advanced flexible OLED technology. Weaknesses: Higher manufacturing costs compared to conventional lighting; challenges in achieving very high brightness levels needed for some applications; thermal management requirements at high brightness.

Universal Display Corp.

Technical Solution: Universal Display Corporation has pioneered phosphorescent OLED (PHOLED) technology that significantly improves energy efficiency in lighting systems compared to traditional fluorescent solutions. Their PHOLED technology harvests both singlet and triplet excitons, achieving nearly 100% internal quantum efficiency compared to fluorescent OLEDs that only utilize singlet excitons (25% efficiency). This fundamental advantage allows their lighting systems to convert more electrical energy into light with less heat generation. Universal Display's proprietary emitter materials and device architectures enable higher luminous efficacy (reaching over 100 lm/W in some configurations) while maintaining excellent color rendering properties. Their technology also demonstrates superior operational lifetimes, with some PHOLED devices maintaining 70% of initial brightness after 30,000+ hours of operation. The company continues to advance their technology through innovations in blue PHOLED emitters and flexible/transparent OLED lighting panels that can be integrated into various form factors and applications.

Strengths: Industry-leading phosphorescent technology with nearly 4x the theoretical efficiency of fluorescent OLEDs; extensive patent portfolio; partnerships with major manufacturers. Weaknesses: Higher production costs compared to conventional lighting; blue emitter lifetime challenges; requires specialized manufacturing equipment and expertise.

Critical Patents in Photovoltage OLED Technology

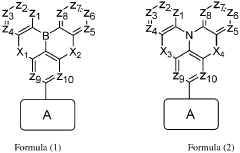

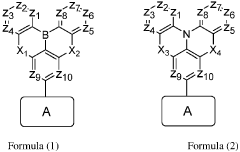

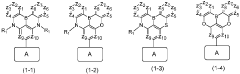

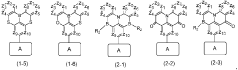

Organic electroluminescent device and display apparatus

PatentPendingEP4291000A1

Innovation

- An organic electroluminescent device with a light-emitting layer comprising a triplet-triplet annihilation type host and a fluorescent dye with specific structures represented by Formulas (1) or (2), which effectively utilizes excitons, reduces triplet exciton concentration, and inhibits intermolecular interactions to enhance luminescence efficiency and stability.

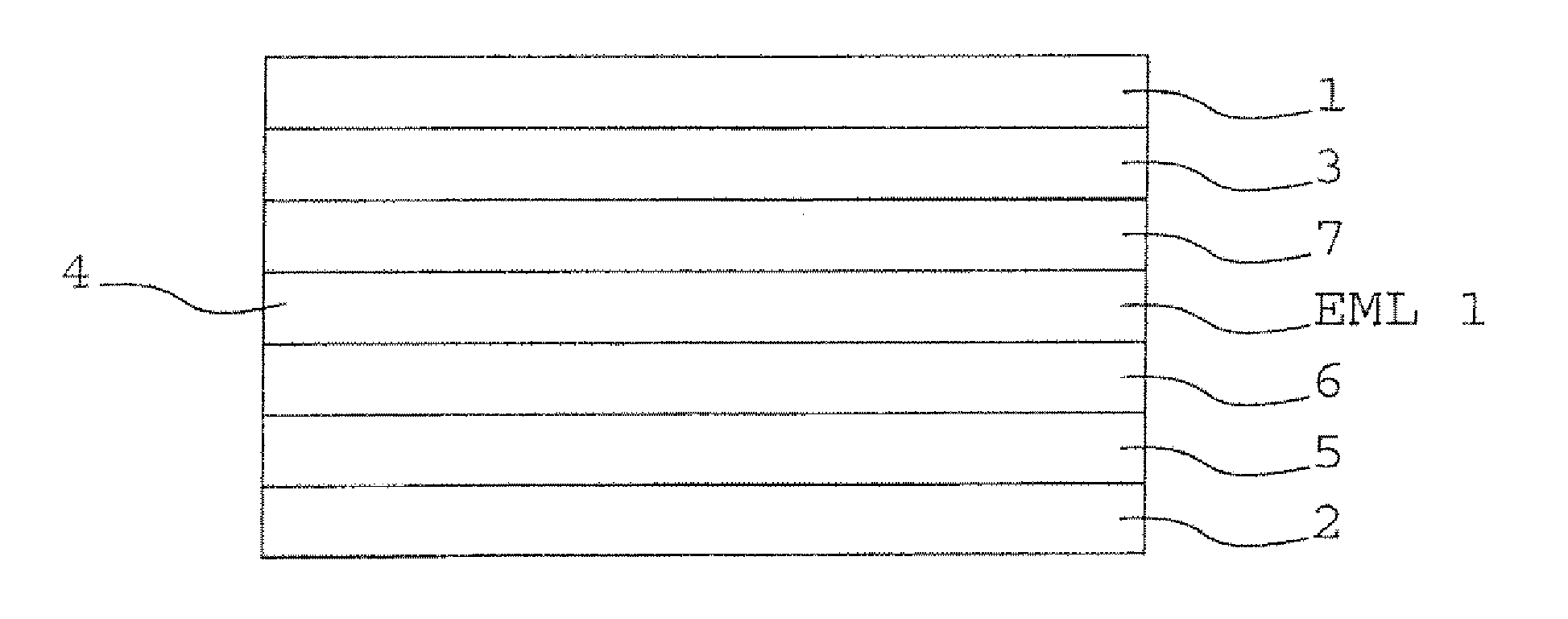

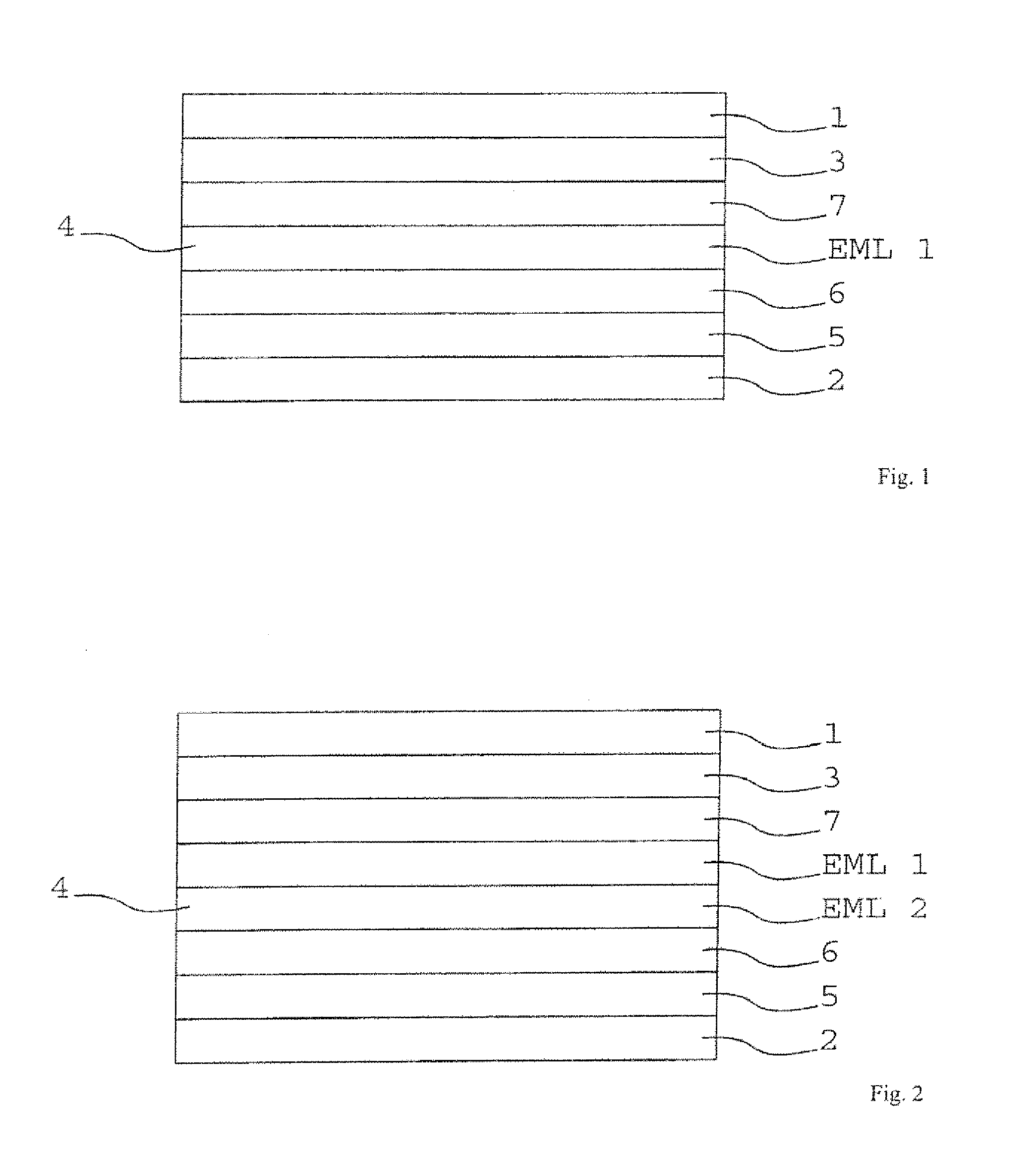

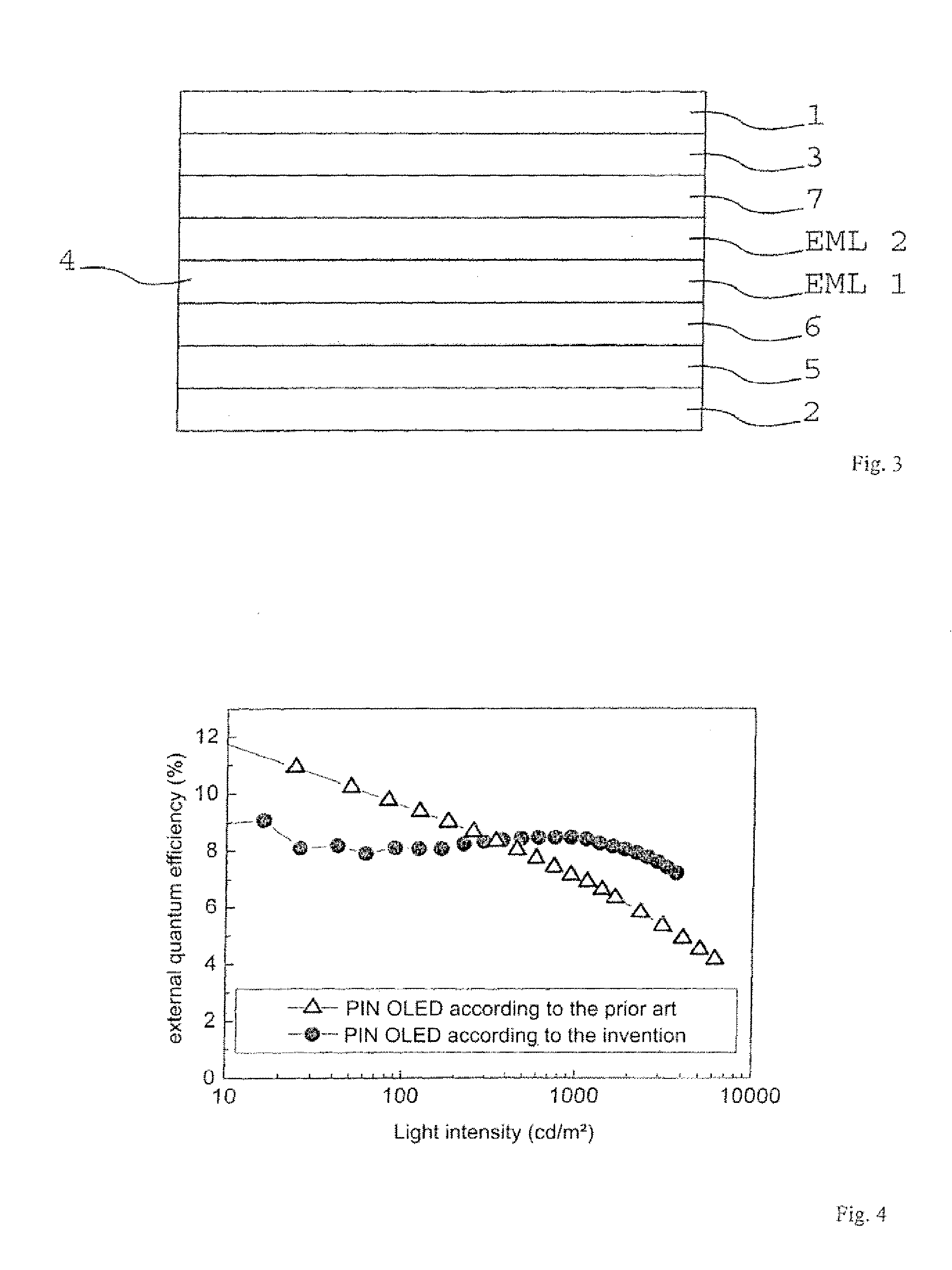

Light-Emitting Component and Method for The Production Thereof

PatentActiveUS20110156059A1

Innovation

- A light-emitting component with an emission layer containing both fluorescent and phosphorescent emitters, where the triplet energy of the fluorescent emitter is higher than or equal to that of the phosphorescent emitter, allowing direct transfer of triplet excitons and minimizing accumulation, thereby maintaining high efficiency at high light densities.

Energy Consumption and Environmental Impact Analysis

The energy consumption patterns of OLED and fluorescent lighting systems reveal significant differences in efficiency and environmental impact. OLED technology demonstrates superior energy efficiency, converting approximately 80% of electrical energy into light compared to fluorescent systems which typically achieve only 60-65% efficiency. This efficiency gap translates to measurable reductions in electricity consumption, with studies indicating that OLED lighting can reduce energy usage by 30-40% in comparable illumination scenarios.

When examining the full lifecycle energy requirements, OLEDs maintain their advantage despite energy-intensive manufacturing processes. The production phase of OLEDs currently requires 1.5-2 times more energy than fluorescent manufacturing, primarily due to specialized clean room environments and precision deposition techniques. However, this initial energy investment is offset by operational savings within 1.5-2 years of typical usage patterns.

Environmental impact assessments reveal that fluorescent lighting systems contain hazardous materials including mercury (3-5mg per bulb), requiring specialized disposal protocols. In contrast, OLED systems are mercury-free and contain significantly lower levels of toxic substances, though they do incorporate trace amounts of heavy metals in certain semiconductor compounds. The absence of mercury eliminates the risk of environmental contamination from improper disposal, which affects approximately 30% of fluorescent bulbs globally.

Carbon footprint analysis demonstrates that OLED lighting systems produce 25-35% less CO2 equivalent emissions over their lifecycle when powered by standard grid electricity. This advantage increases to 40-50% in regions with higher renewable energy penetration in the electricity mix. The reduced thermal output of OLEDs also decreases HVAC energy requirements in commercial and residential settings by an estimated 5-10% compared to fluorescent alternatives.

Waste generation metrics favor OLED technology as well, with longer operational lifespans (15,000-20,000 hours versus 8,000-10,000 for fluorescents) reducing replacement frequency and associated waste. The physical construction of OLEDs also produces less landfill volume per unit, with approximately 60% less material mass than comparable fluorescent systems including ballasts and fixtures.

Resource consumption analysis indicates that while OLEDs require certain rare earth elements and specialized materials, their overall resource intensity per lumen-hour is approximately 20% lower than fluorescent systems when accounting for replacement frequency and energy inputs throughout the product lifecycle.

When examining the full lifecycle energy requirements, OLEDs maintain their advantage despite energy-intensive manufacturing processes. The production phase of OLEDs currently requires 1.5-2 times more energy than fluorescent manufacturing, primarily due to specialized clean room environments and precision deposition techniques. However, this initial energy investment is offset by operational savings within 1.5-2 years of typical usage patterns.

Environmental impact assessments reveal that fluorescent lighting systems contain hazardous materials including mercury (3-5mg per bulb), requiring specialized disposal protocols. In contrast, OLED systems are mercury-free and contain significantly lower levels of toxic substances, though they do incorporate trace amounts of heavy metals in certain semiconductor compounds. The absence of mercury eliminates the risk of environmental contamination from improper disposal, which affects approximately 30% of fluorescent bulbs globally.

Carbon footprint analysis demonstrates that OLED lighting systems produce 25-35% less CO2 equivalent emissions over their lifecycle when powered by standard grid electricity. This advantage increases to 40-50% in regions with higher renewable energy penetration in the electricity mix. The reduced thermal output of OLEDs also decreases HVAC energy requirements in commercial and residential settings by an estimated 5-10% compared to fluorescent alternatives.

Waste generation metrics favor OLED technology as well, with longer operational lifespans (15,000-20,000 hours versus 8,000-10,000 for fluorescents) reducing replacement frequency and associated waste. The physical construction of OLEDs also produces less landfill volume per unit, with approximately 60% less material mass than comparable fluorescent systems including ballasts and fixtures.

Resource consumption analysis indicates that while OLEDs require certain rare earth elements and specialized materials, their overall resource intensity per lumen-hour is approximately 20% lower than fluorescent systems when accounting for replacement frequency and energy inputs throughout the product lifecycle.

Manufacturing Scalability and Cost Considerations

The manufacturing scalability of OLED and fluorescent lighting technologies represents a critical factor in their commercial viability and market adoption. OLED manufacturing currently faces significant challenges that impact cost-effectiveness at scale. The complex multi-layer structure of OLEDs requires precise deposition processes, typically involving vacuum thermal evaporation or solution processing methods. These processes demand stringent clean room environments and sophisticated equipment, substantially increasing capital expenditure requirements for production facilities.

Fluorescent lighting technology, by contrast, benefits from decades of manufacturing optimization. The established infrastructure for fluorescent tube production allows for high-volume manufacturing with relatively lower capital investment. This mature supply chain contributes to the significantly lower unit costs that fluorescent lighting maintains over OLED alternatives, with fluorescent fixtures typically costing 60-80% less than comparable OLED installations.

Material costs present another substantial differential between these technologies. OLED production relies on specialized organic compounds and rare materials like indium tin oxide (ITO) for transparent electrodes. These materials often face supply constraints and price volatility. Recent market analyses indicate that material costs alone account for approximately 40-50% of total OLED lighting production expenses, compared to just 15-25% for fluorescent technology.

Yield rates further compound the manufacturing challenges for OLEDs. Current industry data suggests OLED lighting panel production yields range from 60-85%, depending on size and specifications, whereas fluorescent manufacturing consistently achieves yields exceeding 95%. Each percentage point of yield improvement translates directly to cost reduction, giving fluorescent technology a significant advantage in production economics.

Energy consumption during manufacturing presents another consideration. OLED production processes are typically more energy-intensive, requiring an estimated 1.5-2.5 times more energy per equivalent light output capacity than fluorescent manufacturing. This energy differential contributes to both higher production costs and greater environmental impact during the manufacturing phase.

Recent technological advancements are gradually improving OLED manufacturing economics. Roll-to-roll processing techniques show promise for dramatically increasing throughput while reducing substrate costs. Similarly, developments in solution-processed OLEDs may eventually eliminate the need for costly vacuum deposition equipment. Industry projections suggest these innovations could reduce OLED manufacturing costs by 30-40% within the next five years, potentially narrowing the cost gap with fluorescent technology.

Fluorescent lighting technology, by contrast, benefits from decades of manufacturing optimization. The established infrastructure for fluorescent tube production allows for high-volume manufacturing with relatively lower capital investment. This mature supply chain contributes to the significantly lower unit costs that fluorescent lighting maintains over OLED alternatives, with fluorescent fixtures typically costing 60-80% less than comparable OLED installations.

Material costs present another substantial differential between these technologies. OLED production relies on specialized organic compounds and rare materials like indium tin oxide (ITO) for transparent electrodes. These materials often face supply constraints and price volatility. Recent market analyses indicate that material costs alone account for approximately 40-50% of total OLED lighting production expenses, compared to just 15-25% for fluorescent technology.

Yield rates further compound the manufacturing challenges for OLEDs. Current industry data suggests OLED lighting panel production yields range from 60-85%, depending on size and specifications, whereas fluorescent manufacturing consistently achieves yields exceeding 95%. Each percentage point of yield improvement translates directly to cost reduction, giving fluorescent technology a significant advantage in production economics.

Energy consumption during manufacturing presents another consideration. OLED production processes are typically more energy-intensive, requiring an estimated 1.5-2.5 times more energy per equivalent light output capacity than fluorescent manufacturing. This energy differential contributes to both higher production costs and greater environmental impact during the manufacturing phase.

Recent technological advancements are gradually improving OLED manufacturing economics. Roll-to-roll processing techniques show promise for dramatically increasing throughput while reducing substrate costs. Similarly, developments in solution-processed OLEDs may eventually eliminate the need for costly vacuum deposition equipment. Industry projections suggest these innovations could reduce OLED manufacturing costs by 30-40% within the next five years, potentially narrowing the cost gap with fluorescent technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!