Optimize OLED Sealing Techniques for Enhanced Water Resistance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Sealing Technology Background and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized display and lighting industries since its commercial introduction in the late 1990s. The evolution of OLED technology has been marked by significant improvements in efficiency, color reproduction, and form factor flexibility. However, one persistent challenge has been the susceptibility of organic materials to degradation when exposed to moisture and oxygen, necessitating effective sealing techniques to ensure device longevity.

The historical development of OLED sealing technologies began with rudimentary glass-to-glass encapsulation methods, which provided adequate protection but limited the potential for flexible applications. As the industry moved toward flexible displays, thin-film encapsulation (TFE) emerged as a promising alternative, allowing for bendable and foldable OLED panels while maintaining barrier properties against environmental contaminants.

Current OLED sealing technologies primarily focus on multi-layer approaches that combine inorganic and organic materials to create effective moisture barriers. These hybrid structures typically achieve water vapor transmission rates (WVTR) in the range of 10^-6 g/m²/day, which has enabled commercial viability but still falls short of ideal performance for extended device lifetimes in challenging environments.

The technical objective of optimizing OLED sealing techniques for enhanced water resistance is multifaceted. First, it aims to achieve ultra-low WVTR values approaching 10^-7 g/m²/day or better, which would significantly extend device lifetimes even in high-humidity conditions. Second, it seeks to maintain or improve this barrier performance while reducing thickness and enhancing flexibility, critical factors for next-generation foldable and rollable displays.

Additionally, the optimization efforts must address manufacturing scalability, as current high-performance sealing techniques often involve complex deposition processes that are difficult to implement in mass production. Cost reduction represents another crucial objective, as premium encapsulation solutions currently contribute significantly to overall OLED device costs.

The technological trajectory suggests that atomic layer deposition (ALD) and advanced nanocomposite materials will play increasingly important roles in future sealing solutions. Recent research has demonstrated promising results with graphene-based barriers and metal-organic frameworks (MOFs) that could potentially revolutionize the field by offering unprecedented combinations of flexibility and barrier properties.

As consumer electronics continue to evolve toward more durable, water-resistant designs, the advancement of OLED sealing technology becomes increasingly critical to maintaining competitive advantage in the display market and enabling new application scenarios previously limited by moisture sensitivity concerns.

The historical development of OLED sealing technologies began with rudimentary glass-to-glass encapsulation methods, which provided adequate protection but limited the potential for flexible applications. As the industry moved toward flexible displays, thin-film encapsulation (TFE) emerged as a promising alternative, allowing for bendable and foldable OLED panels while maintaining barrier properties against environmental contaminants.

Current OLED sealing technologies primarily focus on multi-layer approaches that combine inorganic and organic materials to create effective moisture barriers. These hybrid structures typically achieve water vapor transmission rates (WVTR) in the range of 10^-6 g/m²/day, which has enabled commercial viability but still falls short of ideal performance for extended device lifetimes in challenging environments.

The technical objective of optimizing OLED sealing techniques for enhanced water resistance is multifaceted. First, it aims to achieve ultra-low WVTR values approaching 10^-7 g/m²/day or better, which would significantly extend device lifetimes even in high-humidity conditions. Second, it seeks to maintain or improve this barrier performance while reducing thickness and enhancing flexibility, critical factors for next-generation foldable and rollable displays.

Additionally, the optimization efforts must address manufacturing scalability, as current high-performance sealing techniques often involve complex deposition processes that are difficult to implement in mass production. Cost reduction represents another crucial objective, as premium encapsulation solutions currently contribute significantly to overall OLED device costs.

The technological trajectory suggests that atomic layer deposition (ALD) and advanced nanocomposite materials will play increasingly important roles in future sealing solutions. Recent research has demonstrated promising results with graphene-based barriers and metal-organic frameworks (MOFs) that could potentially revolutionize the field by offering unprecedented combinations of flexibility and barrier properties.

As consumer electronics continue to evolve toward more durable, water-resistant designs, the advancement of OLED sealing technology becomes increasingly critical to maintaining competitive advantage in the display market and enabling new application scenarios previously limited by moisture sensitivity concerns.

Market Demand for Water-Resistant OLED Displays

The global market for water-resistant OLED displays has witnessed substantial growth in recent years, driven primarily by the increasing consumer demand for durable electronic devices. As smartphones, wearables, and other portable electronics become integral to daily life, users expect these devices to withstand various environmental conditions, including water exposure. This shift in consumer expectations has created a significant market opportunity for manufacturers who can deliver enhanced water resistance in OLED displays.

Consumer electronics represent the largest segment demanding water-resistant OLED technology. Smartphone manufacturers have recognized water resistance as a key differentiating feature, with premium models now routinely advertising IP67 or IP68 ratings. Market research indicates that consumers are willing to pay a premium of 15-20% for devices with proven water resistance capabilities, highlighting the commercial value of this feature.

The wearable technology sector presents another rapidly expanding market for water-resistant OLED displays. Smartwatches, fitness trackers, and health monitoring devices require robust water protection as they are frequently exposed to moisture from sweat, rain, and recreational activities. The global wearable market is projected to maintain double-digit growth rates through 2027, with water resistance consistently ranking among the top five features consumers consider when making purchase decisions.

Automotive applications represent an emerging high-value market for water-resistant OLED technology. As vehicle manufacturers increasingly incorporate OLED displays into dashboards, entertainment systems, and control panels, these components must withstand varying humidity levels and potential liquid exposure. The premium automotive segment has shown particular interest in OLED technology for its superior visual performance and design flexibility.

Industrial and medical sectors also demonstrate growing demand for water-resistant OLED displays. In industrial environments, displays must function reliably despite exposure to moisture, chemicals, and varying environmental conditions. Medical devices require displays that can withstand frequent cleaning and disinfection procedures, creating specific requirements for enhanced sealing technologies.

Market analysis reveals regional variations in demand patterns. North American and European consumers place higher value on water resistance as a feature, while Asian markets show the fastest growth rate in adoption. This regional differentiation suggests the need for market-specific approaches to product development and marketing strategies.

The competitive landscape shows increasing investment in water-resistant display technologies, with major display manufacturers allocating significant R&D resources to improving OLED sealing techniques. This trend indicates industry recognition of the market potential and highlights the strategic importance of developing cost-effective solutions for mass production.

Consumer electronics represent the largest segment demanding water-resistant OLED technology. Smartphone manufacturers have recognized water resistance as a key differentiating feature, with premium models now routinely advertising IP67 or IP68 ratings. Market research indicates that consumers are willing to pay a premium of 15-20% for devices with proven water resistance capabilities, highlighting the commercial value of this feature.

The wearable technology sector presents another rapidly expanding market for water-resistant OLED displays. Smartwatches, fitness trackers, and health monitoring devices require robust water protection as they are frequently exposed to moisture from sweat, rain, and recreational activities. The global wearable market is projected to maintain double-digit growth rates through 2027, with water resistance consistently ranking among the top five features consumers consider when making purchase decisions.

Automotive applications represent an emerging high-value market for water-resistant OLED technology. As vehicle manufacturers increasingly incorporate OLED displays into dashboards, entertainment systems, and control panels, these components must withstand varying humidity levels and potential liquid exposure. The premium automotive segment has shown particular interest in OLED technology for its superior visual performance and design flexibility.

Industrial and medical sectors also demonstrate growing demand for water-resistant OLED displays. In industrial environments, displays must function reliably despite exposure to moisture, chemicals, and varying environmental conditions. Medical devices require displays that can withstand frequent cleaning and disinfection procedures, creating specific requirements for enhanced sealing technologies.

Market analysis reveals regional variations in demand patterns. North American and European consumers place higher value on water resistance as a feature, while Asian markets show the fastest growth rate in adoption. This regional differentiation suggests the need for market-specific approaches to product development and marketing strategies.

The competitive landscape shows increasing investment in water-resistant display technologies, with major display manufacturers allocating significant R&D resources to improving OLED sealing techniques. This trend indicates industry recognition of the market potential and highlights the strategic importance of developing cost-effective solutions for mass production.

Current Sealing Techniques and Waterproofing Challenges

The current landscape of OLED sealing techniques presents a complex array of methodologies, each with distinct advantages and limitations in achieving water resistance. Glass-to-glass encapsulation remains the traditional approach, utilizing a glass lid bonded with UV-curable adhesives or frit glass to create a hermetic seal. While this method offers excellent barrier properties with water vapor transmission rates (WVTR) below 10^-6 g/m²/day, it suffers from increased device thickness and weight, limiting applications in flexible displays.

Thin-film encapsulation (TFE) has emerged as the predominant solution for modern OLED devices, especially in flexible applications. This technique alternates inorganic layers (typically SiNx, Al2O3, or SiO2) with organic layers to create a multi-layer barrier. The inorganic layers provide the primary moisture barrier while organic layers decouple defects and accommodate mechanical stress. Current state-of-the-art TFE systems achieve WVTR values of approximately 10^-5 g/m²/day, though industry requirements increasingly demand 10^-6 g/m²/day for extended device lifetimes.

Atomic Layer Deposition (ALD) represents a significant advancement in inorganic barrier layer formation, enabling the creation of ultra-thin, highly conformal Al2O3 layers with superior moisture resistance. However, ALD processes face challenges in manufacturing scalability due to slow deposition rates and equipment costs, limiting widespread industrial adoption despite their technical superiority.

The edge sealing region remains particularly vulnerable in OLED devices, as moisture penetration often occurs laterally rather than through the primary encapsulation layers. Current edge sealing approaches utilize specialized barrier adhesives or extended inorganic layers, but these solutions often compromise flexibility or add manufacturing complexity.

A critical challenge in waterproofing OLEDs stems from the inherent trade-off between barrier performance and mechanical flexibility. As devices become increasingly bendable and foldable, maintaining seal integrity under repeated mechanical stress presents significant technical hurdles. Micro-cracks and delamination at interfaces between different material layers frequently serve as moisture ingress pathways, accelerating device degradation.

Manufacturing scalability presents another substantial challenge, as high-performance sealing techniques often require precise process control and specialized equipment. The industry struggles to balance production throughput with the stringent quality requirements necessary for effective moisture barriers. Techniques that excel in laboratory settings frequently encounter yield issues when transferred to mass production environments.

Temperature sensitivity of OLED materials further constrains available sealing options, as many conventional barrier formation processes involve thermal treatments that could damage the organic layers. This necessitates the development of low-temperature deposition methods that maintain barrier integrity without compromising the underlying OLED structure.

Thin-film encapsulation (TFE) has emerged as the predominant solution for modern OLED devices, especially in flexible applications. This technique alternates inorganic layers (typically SiNx, Al2O3, or SiO2) with organic layers to create a multi-layer barrier. The inorganic layers provide the primary moisture barrier while organic layers decouple defects and accommodate mechanical stress. Current state-of-the-art TFE systems achieve WVTR values of approximately 10^-5 g/m²/day, though industry requirements increasingly demand 10^-6 g/m²/day for extended device lifetimes.

Atomic Layer Deposition (ALD) represents a significant advancement in inorganic barrier layer formation, enabling the creation of ultra-thin, highly conformal Al2O3 layers with superior moisture resistance. However, ALD processes face challenges in manufacturing scalability due to slow deposition rates and equipment costs, limiting widespread industrial adoption despite their technical superiority.

The edge sealing region remains particularly vulnerable in OLED devices, as moisture penetration often occurs laterally rather than through the primary encapsulation layers. Current edge sealing approaches utilize specialized barrier adhesives or extended inorganic layers, but these solutions often compromise flexibility or add manufacturing complexity.

A critical challenge in waterproofing OLEDs stems from the inherent trade-off between barrier performance and mechanical flexibility. As devices become increasingly bendable and foldable, maintaining seal integrity under repeated mechanical stress presents significant technical hurdles. Micro-cracks and delamination at interfaces between different material layers frequently serve as moisture ingress pathways, accelerating device degradation.

Manufacturing scalability presents another substantial challenge, as high-performance sealing techniques often require precise process control and specialized equipment. The industry struggles to balance production throughput with the stringent quality requirements necessary for effective moisture barriers. Techniques that excel in laboratory settings frequently encounter yield issues when transferred to mass production environments.

Temperature sensitivity of OLED materials further constrains available sealing options, as many conventional barrier formation processes involve thermal treatments that could damage the organic layers. This necessitates the development of low-temperature deposition methods that maintain barrier integrity without compromising the underlying OLED structure.

Current Water-Resistant OLED Sealing Solutions

01 Thin film encapsulation techniques for OLED water resistance

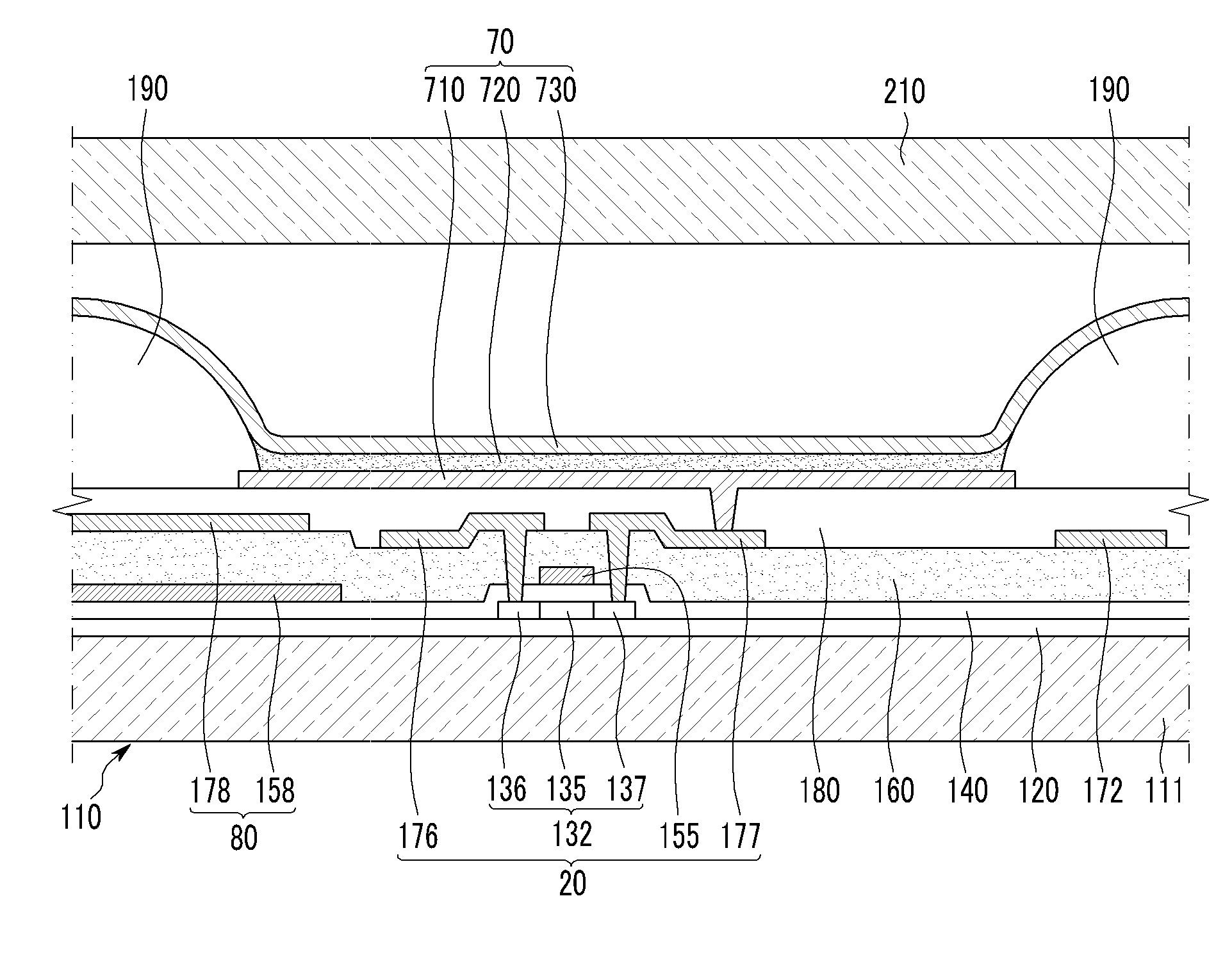

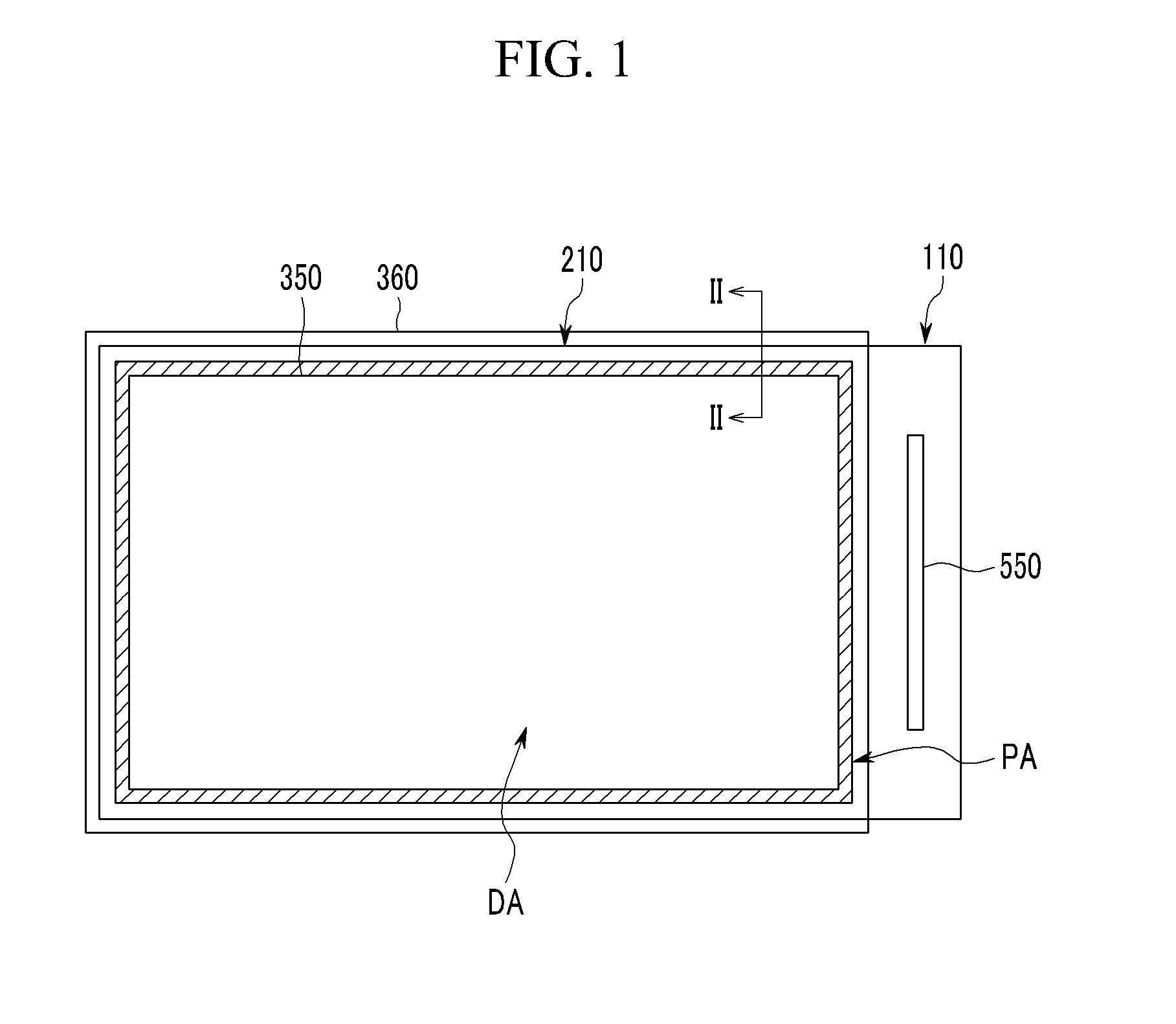

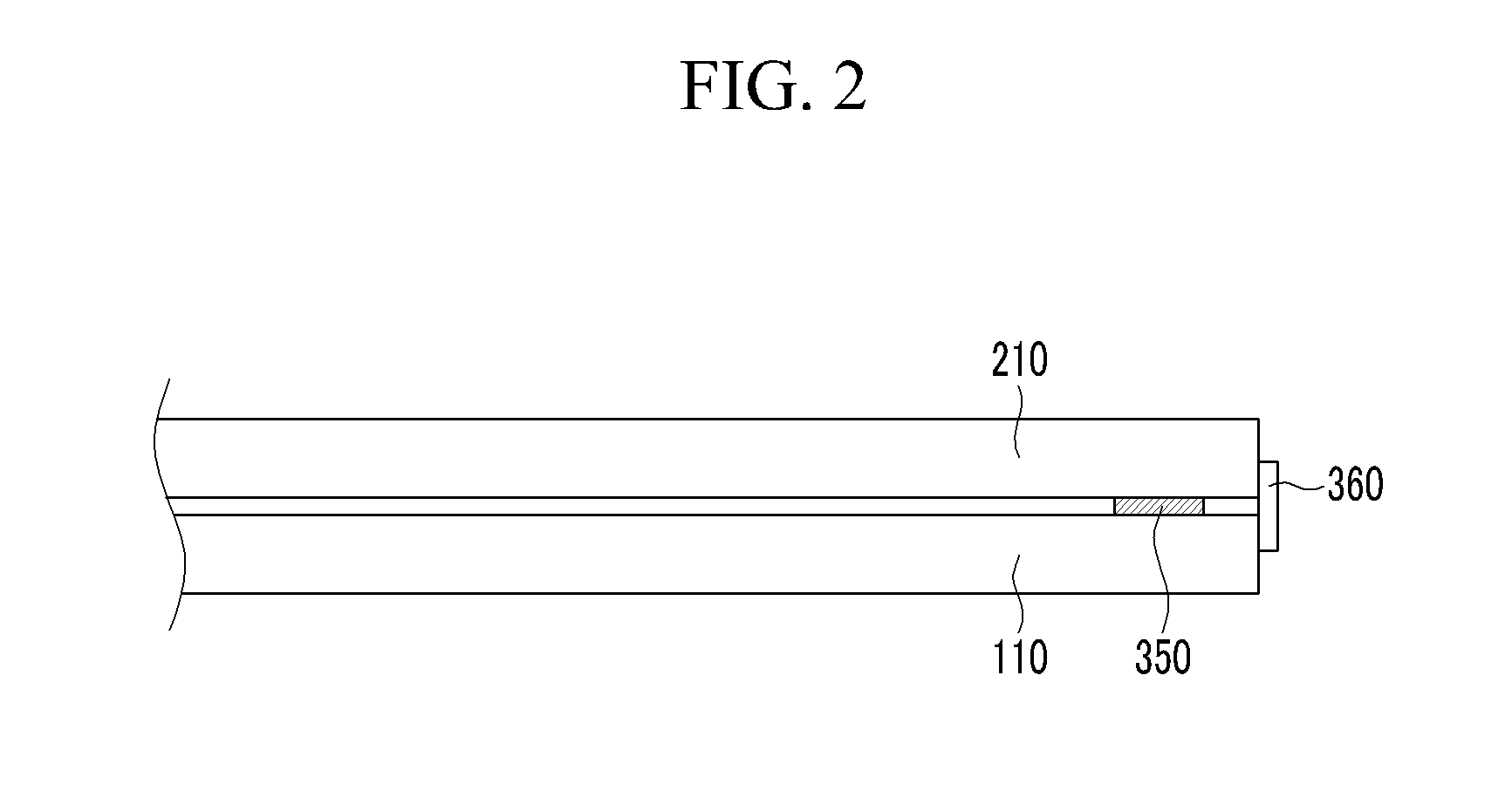

Thin film encapsulation (TFE) is a key technique for protecting OLEDs from moisture and oxygen. This approach involves depositing alternating inorganic and organic layers to create a barrier against water penetration. The inorganic layers (such as silicon nitride, aluminum oxide) provide the primary moisture barrier, while organic layers help relieve stress and prevent crack propagation. This multi-layer structure effectively blocks water molecules while maintaining flexibility in the display.- Thin film encapsulation techniques for OLED water resistance: Thin film encapsulation (TFE) is a key technique for protecting OLEDs from moisture and oxygen. This approach involves depositing alternating inorganic and organic layers to create a barrier against water penetration. The inorganic layers (such as silicon nitride, aluminum oxide) provide the primary moisture barrier, while organic layers help relieve stress and prevent crack propagation. This multi-layer structure effectively blocks water molecules while maintaining flexibility in the display.

- Edge sealing methods for OLED devices: Edge sealing is critical for preventing lateral moisture ingress in OLED displays. These techniques focus on creating robust seals around the perimeter of the device using materials like frit glass, UV-curable adhesives, or metal welding. Advanced edge sealing methods incorporate moisture absorbing materials (desiccants) within the seal structure to capture any moisture that penetrates the initial barrier. Some designs feature double-barrier edge structures with a primary seal and secondary protective layer to enhance water resistance.

- Inorganic barrier layer compositions for moisture protection: Specialized inorganic materials are used to create highly effective moisture barriers for OLEDs. These include metal oxides (aluminum oxide, silicon oxide), nitrides (silicon nitride), and hybrid materials deposited using techniques like atomic layer deposition (ALD) or plasma-enhanced chemical vapor deposition (PECVD). Some approaches use nanolaminate structures with ultra-thin alternating layers to block moisture penetration pathways. The composition and deposition parameters of these inorganic layers are optimized to achieve maximum density and minimal defects.

- Flexible encapsulation solutions for bendable OLEDs: Flexible OLEDs require specialized encapsulation techniques that maintain water resistance while allowing the device to bend. These solutions include ultra-thin glass encapsulation, flexible multi-layer barrier films, and hybrid organic-inorganic structures with stress-relieving properties. Some approaches use specially formulated polymers that can stretch without creating microcracks that would allow water penetration. Advanced flexible encapsulation may incorporate self-healing materials that can repair minor damage to maintain barrier integrity during repeated bending cycles.

- Integration of desiccant materials for enhanced moisture protection: Desiccant materials are incorporated into OLED encapsulation structures to actively absorb any moisture that penetrates the primary barriers. These moisture-absorbing materials can be integrated as discrete components within the device cavity, dispersed within adhesive layers, or incorporated as nanoparticles in polymer matrices. Some advanced designs feature channels or reservoirs filled with desiccants to create a moisture capture system. The selection of desiccant materials is based on absorption capacity, activation temperature, and compatibility with OLED materials.

02 Edge sealing methods for OLED water protection

Edge sealing is critical for preventing lateral moisture ingress in OLED devices. These techniques focus on creating robust seals around the perimeter of the display to block water penetration from the edges. Methods include using frit glass sealing, UV-curable adhesives, and specialized sealant materials that can be applied around the edges of the OLED panel. Some approaches incorporate desiccant materials within the edge seal to absorb any moisture that might penetrate the initial barrier, providing an additional layer of protection.Expand Specific Solutions03 Inorganic barrier layer compositions for moisture resistance

Specialized inorganic materials are used to create highly effective moisture barriers for OLEDs. These include metal oxides (aluminum oxide, silicon oxide), nitrides (silicon nitride), and other inorganic compounds deposited using techniques such as atomic layer deposition (ALD), chemical vapor deposition (CVD), or sputtering. These materials provide excellent water vapor transmission rate (WVTR) properties, with some formulations achieving extremely low permeation rates necessary for long OLED lifetimes. The composition, thickness, and deposition parameters of these layers are optimized to maximize water resistance.Expand Specific Solutions04 Hybrid encapsulation structures combining films and rigid covers

Hybrid encapsulation approaches combine the benefits of thin film barriers with rigid or semi-rigid cover materials to enhance water resistance. These systems typically feature a thin film barrier directly over the OLED, followed by an adhesive layer and a rigid cover (glass, metal, or advanced polymers). Some designs incorporate air gaps or desiccant materials between the layers. This multi-layered approach provides redundant protection against moisture while maintaining device reliability under various environmental conditions and mechanical stresses.Expand Specific Solutions05 Advanced deposition techniques for water-resistant barriers

Innovative deposition methods are employed to create high-quality, defect-free barrier layers for OLED water protection. These include plasma-enhanced chemical vapor deposition (PECVD), atomic layer deposition (ALD), and specialized sputtering techniques that enable precise control over layer thickness and composition. Some approaches use laser-assisted deposition or ion beam techniques to create ultra-dense barrier films. These advanced processes minimize pinhole defects and microcracks that could serve as pathways for moisture ingress, significantly improving the water resistance and lifetime of OLED devices.Expand Specific Solutions

Leading OLED Sealing Technology Manufacturers

The OLED sealing technology market is in a growth phase, driven by increasing demand for water-resistant displays in consumer electronics and automotive applications. The global market size is expanding rapidly, expected to reach significant value as OLED adoption continues across multiple industries. Technologically, the field shows varying maturity levels, with established players like Samsung Display, LG Chem, and BOE Technology leading innovation in advanced encapsulation techniques. Corning has pioneered glass-based sealing solutions, while companies like Visionox and TCL CSOT are advancing thin-film encapsulation methods. Research institutions including Industrial Technology Research Institute and TNO are contributing breakthrough approaches to enhance OLED longevity through improved moisture barriers, positioning this technology for continued evolution and commercial expansion.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive OLED sealing solution centered around their proprietary "BOE-Shield" technology. This approach utilizes a multi-layer barrier structure consisting of alternating inorganic (SiNx, Al2O3) and organic polymer layers deposited through a combination of PECVD and solution processing methods. The inorganic layers provide the primary moisture barrier while the organic layers decouple defects between adjacent inorganic layers and provide stress relief during flexing. BOE has optimized their barrier stack to achieve water vapor transmission rates below 10^-5 g/m²/day while maintaining optical transparency above 90%. Their technology also incorporates specialized edge sealing using UV-curable resins reinforced with nanoparticles to enhance barrier properties at the vulnerable display edges. For rigid OLED applications, BOE employs glass frit sealing with laser-assisted bonding to create hermetic encapsulation with superior moisture resistance.

Strengths: Cost-effective manufacturing process suitable for mass production; excellent optical properties with minimal impact on display brightness; compatible with both rigid and flexible display architectures. Weaknesses: Barrier performance slightly behind industry leaders; edge sealing technology requires further optimization for ultra-flexible displays; process sensitivity to environmental contaminants during manufacturing.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed advanced thin-film encapsulation (TFE) technology for OLED sealing that utilizes alternating layers of inorganic and organic materials. Their proprietary multi-barrier structure combines plasma-enhanced chemical vapor deposition (PECVD) for inorganic layers (typically silicon nitride or aluminum oxide) with inkjet-printed organic layers. This hybrid approach creates a tortuous path for moisture penetration, significantly enhancing water resistance. Samsung has also pioneered the integration of edge sealing techniques using laser-assisted frit glass bonding that creates hermetic seals with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. Their latest innovation includes the implementation of atomic layer deposition (ALD) for ultra-thin barrier films with enhanced density and uniformity, allowing for flexible OLED applications while maintaining excellent moisture barrier properties.

Strengths: Industry-leading barrier performance with extremely low WVTR values; scalable manufacturing process suitable for large-area displays; compatibility with flexible substrates. Weaknesses: Complex multi-step deposition process increases production costs; edge sealing techniques may limit design flexibility for certain form factors; requires specialized equipment for high-precision deposition control.

Key Patents in Advanced OLED Encapsulation

Organic light-emitting diode

PatentWO2004079781A2

Innovation

- The use of amorphous silicon carbide, hydrogenated silicon oxycarbide, and silica-based barrier coatings, either singularly or in multilayer combinations, to create a robust barrier that reduces water and oxygen permeability, combined with transparent or non-transparent electrode layers and substrates, enhances the durability and flexibility of OLEDs.

Organic light emitting diode display and manufacturing method thereof

PatentInactiveUS20110278550A1

Innovation

- The use of a soft sealant with high fracture toughness, such as epoxy, acrylate, or urethaneacrylate, in combination with a brittle frit sealant, separated by a predetermined interval, to adhere and seal the display and encapsulation substrates, preventing cracks and moisture permeation.

Environmental Impact of Sealing Materials

The environmental impact of sealing materials used in OLED technology represents a critical consideration in the ongoing pursuit of enhanced water resistance. Traditional sealing materials, particularly those containing heavy metals and volatile organic compounds (VOCs), pose significant environmental hazards throughout their lifecycle. These materials often require energy-intensive manufacturing processes and release harmful emissions during production, contributing to air and water pollution.

Glass frit sealing, while effective for water resistance, involves high-temperature firing processes that consume substantial energy and produce greenhouse gas emissions. The lead oxide commonly found in these frits presents additional environmental concerns regarding disposal and potential leaching into ecosystems. Recent regulatory frameworks, including RoHS and REACH, have increasingly restricted the use of lead-containing materials, driving the industry toward more sustainable alternatives.

Epoxy-based sealants offer improved environmental profiles compared to traditional options but still contain potentially harmful hardeners and additives. Their limited recyclability presents end-of-life management challenges, as these materials typically end up in landfills where they degrade slowly and may release toxins into surrounding soil and groundwater systems.

Emerging environmentally friendly alternatives include bio-based epoxies derived from renewable resources such as vegetable oils and lignin. These materials demonstrate promising water resistance properties while significantly reducing carbon footprints. Silicon-based organic sealants represent another eco-friendly option, offering excellent moisture barrier properties with minimal environmental impact during production and disposal phases.

Life cycle assessment (LCA) studies indicate that thin-film encapsulation techniques generally demonstrate superior environmental performance compared to traditional sealing methods. These approaches require fewer raw materials and generate less waste, though the specialized equipment needed for deposition processes may offset some environmental benefits through increased energy consumption.

Water-based sealant formulations have emerged as particularly promising solutions, eliminating the need for organic solvents and reducing VOC emissions. However, these formulations currently face performance limitations in achieving the extreme water resistance requirements of OLED applications, highlighting the ongoing challenge of balancing environmental considerations with technical performance.

The electronics industry's shift toward circular economy principles has accelerated research into recyclable and biodegradable sealing materials. These innovations aim to address end-of-life environmental impacts while maintaining the stringent water resistance properties essential for OLED longevity. As regulatory pressures intensify and consumer demand for sustainable electronics grows, environmental considerations will increasingly drive innovation in OLED sealing technology.

Glass frit sealing, while effective for water resistance, involves high-temperature firing processes that consume substantial energy and produce greenhouse gas emissions. The lead oxide commonly found in these frits presents additional environmental concerns regarding disposal and potential leaching into ecosystems. Recent regulatory frameworks, including RoHS and REACH, have increasingly restricted the use of lead-containing materials, driving the industry toward more sustainable alternatives.

Epoxy-based sealants offer improved environmental profiles compared to traditional options but still contain potentially harmful hardeners and additives. Their limited recyclability presents end-of-life management challenges, as these materials typically end up in landfills where they degrade slowly and may release toxins into surrounding soil and groundwater systems.

Emerging environmentally friendly alternatives include bio-based epoxies derived from renewable resources such as vegetable oils and lignin. These materials demonstrate promising water resistance properties while significantly reducing carbon footprints. Silicon-based organic sealants represent another eco-friendly option, offering excellent moisture barrier properties with minimal environmental impact during production and disposal phases.

Life cycle assessment (LCA) studies indicate that thin-film encapsulation techniques generally demonstrate superior environmental performance compared to traditional sealing methods. These approaches require fewer raw materials and generate less waste, though the specialized equipment needed for deposition processes may offset some environmental benefits through increased energy consumption.

Water-based sealant formulations have emerged as particularly promising solutions, eliminating the need for organic solvents and reducing VOC emissions. However, these formulations currently face performance limitations in achieving the extreme water resistance requirements of OLED applications, highlighting the ongoing challenge of balancing environmental considerations with technical performance.

The electronics industry's shift toward circular economy principles has accelerated research into recyclable and biodegradable sealing materials. These innovations aim to address end-of-life environmental impacts while maintaining the stringent water resistance properties essential for OLED longevity. As regulatory pressures intensify and consumer demand for sustainable electronics grows, environmental considerations will increasingly drive innovation in OLED sealing technology.

Reliability Testing Standards for Water-Resistant OLEDs

Reliability testing standards for water-resistant OLEDs have evolved significantly over the past decade, becoming increasingly rigorous to meet the growing demands of consumer electronics applications. The International Electrotechnical Commission (IEC) has established several standards specifically addressing OLED display reliability, with IEC 62341-6-3 focusing on environmental testing methods including water resistance parameters.

The industry has adopted a multi-tiered approach to water resistance testing, categorizing devices from IPX0 (no protection) to IPX8 (continuous immersion beyond 1 meter). For OLED displays with enhanced water-resistant sealing, testing typically begins with IPX7 standards, requiring survival after immersion in 1 meter of water for 30 minutes without performance degradation.

Accelerated aging tests represent another critical component of reliability standards, simulating years of environmental exposure in compressed timeframes. These tests typically subject sealed OLED panels to 85°C temperature and 85% relative humidity (85/85 test) for periods ranging from 500 to 1000 hours. Devices that maintain at least 95% of initial luminance and show no visible defects are considered to meet premium water resistance standards.

Cyclic testing protocols have gained prominence, better reflecting real-world usage conditions. These involve alternating between extreme humidity (95% RH) and dry conditions (30% RH) while cycling temperatures between -10°C and 60°C. Industry standards now recommend 500-1000 cycles for consumer electronics and 2000+ cycles for automotive and outdoor display applications.

Quantitative assessment metrics have become standardized, including Water Vapor Transmission Rate (WVTR) measurements, with current standards requiring rates below 10^-6 g/m²/day for high-performance OLEDs. Calcium tests, which visualize water penetration through oxidation patterns, provide complementary qualitative data on seal integrity.

Advanced testing now incorporates mechanical stress factors alongside humidity exposure. Devices undergo bend testing (1000-5000 cycles at specified radii) while simultaneously exposed to high humidity environments, simulating real-world usage scenarios where mechanical stress may compromise water-resistant seals.

The emergence of quantum dot OLED (QD-OLED) technology has prompted the development of specialized testing protocols addressing the unique degradation mechanisms of quantum dots when exposed to moisture. These standards typically require maintenance of color gamut coverage (>95% DCI-P3) after humidity exposure, alongside traditional luminance retention metrics.

The industry has adopted a multi-tiered approach to water resistance testing, categorizing devices from IPX0 (no protection) to IPX8 (continuous immersion beyond 1 meter). For OLED displays with enhanced water-resistant sealing, testing typically begins with IPX7 standards, requiring survival after immersion in 1 meter of water for 30 minutes without performance degradation.

Accelerated aging tests represent another critical component of reliability standards, simulating years of environmental exposure in compressed timeframes. These tests typically subject sealed OLED panels to 85°C temperature and 85% relative humidity (85/85 test) for periods ranging from 500 to 1000 hours. Devices that maintain at least 95% of initial luminance and show no visible defects are considered to meet premium water resistance standards.

Cyclic testing protocols have gained prominence, better reflecting real-world usage conditions. These involve alternating between extreme humidity (95% RH) and dry conditions (30% RH) while cycling temperatures between -10°C and 60°C. Industry standards now recommend 500-1000 cycles for consumer electronics and 2000+ cycles for automotive and outdoor display applications.

Quantitative assessment metrics have become standardized, including Water Vapor Transmission Rate (WVTR) measurements, with current standards requiring rates below 10^-6 g/m²/day for high-performance OLEDs. Calcium tests, which visualize water penetration through oxidation patterns, provide complementary qualitative data on seal integrity.

Advanced testing now incorporates mechanical stress factors alongside humidity exposure. Devices undergo bend testing (1000-5000 cycles at specified radii) while simultaneously exposed to high humidity environments, simulating real-world usage scenarios where mechanical stress may compromise water-resistant seals.

The emergence of quantum dot OLED (QD-OLED) technology has prompted the development of specialized testing protocols addressing the unique degradation mechanisms of quantum dots when exposed to moisture. These standards typically require maintenance of color gamut coverage (>95% DCI-P3) after humidity exposure, alongside traditional luminance retention metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!