How to Advance Cellophane's Compostability Standards?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Compostability Background and Objectives

Cellophane, a transparent sheet made from regenerated cellulose, has been a staple in packaging for over a century. Its popularity stems from its clarity, strength, and barrier properties. However, as environmental concerns grow, the focus has shifted towards improving its compostability standards to align with sustainable practices.

The evolution of cellophane technology has been marked by continuous efforts to enhance its environmental profile. Initially developed as a non-biodegradable material, recent advancements have aimed at making cellophane more eco-friendly. The current objective is to further advance cellophane's compostability standards, ensuring it meets or exceeds international regulations for compostable materials.

Compostability refers to a material's ability to break down into natural elements in a compost environment, leaving no toxic residue. For cellophane, this involves optimizing its molecular structure and additives to facilitate faster decomposition while maintaining its desirable packaging properties.

The drive to improve cellophane's compostability is fueled by increasing consumer demand for sustainable packaging solutions and stricter environmental regulations worldwide. Governments and environmental organizations are setting higher standards for compostable materials, pushing the industry to innovate.

Current compostability standards for cellophane vary globally, with certifications such as EN 13432 in Europe and ASTM D6400 in the United States setting benchmarks. These standards typically require materials to disintegrate within 12 weeks and biodegrade at least 90% within 180 days in industrial composting conditions.

Advancing cellophane's compostability standards involves multifaceted research and development efforts. Scientists are exploring modifications to cellophane's chemical structure, investigating new bio-based additives, and optimizing production processes to enhance biodegradability without compromising performance.

The ultimate goal is to develop cellophane that not only meets current compostability standards but also biodegrades efficiently in various environments, including home composting systems. This would significantly broaden its appeal as a truly sustainable packaging option.

Achieving this objective requires a delicate balance between improving compostability and maintaining cellophane's functional properties. The challenge lies in enhancing biodegradation rates while preserving the material's strength, barrier properties, and clarity – qualities that have made cellophane a preferred choice in packaging for decades.

The evolution of cellophane technology has been marked by continuous efforts to enhance its environmental profile. Initially developed as a non-biodegradable material, recent advancements have aimed at making cellophane more eco-friendly. The current objective is to further advance cellophane's compostability standards, ensuring it meets or exceeds international regulations for compostable materials.

Compostability refers to a material's ability to break down into natural elements in a compost environment, leaving no toxic residue. For cellophane, this involves optimizing its molecular structure and additives to facilitate faster decomposition while maintaining its desirable packaging properties.

The drive to improve cellophane's compostability is fueled by increasing consumer demand for sustainable packaging solutions and stricter environmental regulations worldwide. Governments and environmental organizations are setting higher standards for compostable materials, pushing the industry to innovate.

Current compostability standards for cellophane vary globally, with certifications such as EN 13432 in Europe and ASTM D6400 in the United States setting benchmarks. These standards typically require materials to disintegrate within 12 weeks and biodegrade at least 90% within 180 days in industrial composting conditions.

Advancing cellophane's compostability standards involves multifaceted research and development efforts. Scientists are exploring modifications to cellophane's chemical structure, investigating new bio-based additives, and optimizing production processes to enhance biodegradability without compromising performance.

The ultimate goal is to develop cellophane that not only meets current compostability standards but also biodegrades efficiently in various environments, including home composting systems. This would significantly broaden its appeal as a truly sustainable packaging option.

Achieving this objective requires a delicate balance between improving compostability and maintaining cellophane's functional properties. The challenge lies in enhancing biodegradation rates while preserving the material's strength, barrier properties, and clarity – qualities that have made cellophane a preferred choice in packaging for decades.

Market Demand for Sustainable Packaging Solutions

The global market for sustainable packaging solutions has experienced significant growth in recent years, driven by increasing consumer awareness, stringent environmental regulations, and corporate sustainability initiatives. This trend has created a substantial demand for eco-friendly alternatives to traditional plastic packaging, with cellophane emerging as a promising candidate due to its biodegradable properties.

Consumer preferences have shifted dramatically towards environmentally responsible products, with a growing number of shoppers actively seeking out packaging that aligns with their values. This shift has prompted major retailers and brands to commit to sustainable packaging goals, further fueling the demand for compostable materials like cellophane. The food and beverage industry, in particular, has shown keen interest in adopting compostable packaging solutions to reduce their environmental footprint and appeal to eco-conscious consumers.

Market research indicates that the sustainable packaging market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain in the double digits over the next five years. This growth is particularly pronounced in developed economies such as North America and Europe, where environmental concerns are at the forefront of consumer decision-making processes.

The demand for cellophane as a sustainable packaging material is closely tied to its compostability standards. As consumers and regulatory bodies become more discerning about environmental claims, there is an increasing need for packaging solutions that can meet rigorous compostability certifications. This has created a market pull for advanced cellophane products that can decompose more efficiently in industrial composting facilities and, ideally, in home composting environments.

Retailers and brand owners are actively seeking packaging materials that can help them meet their sustainability targets without compromising on functionality or aesthetics. Cellophane's transparency, flexibility, and barrier properties make it an attractive option for a wide range of applications, from food packaging to personal care products. However, the market demand is not just for any compostable cellophane, but for products that can demonstrate superior compostability performance and faster decomposition rates.

The push for improved compostability standards in cellophane is also driven by the circular economy concept, which is gaining traction globally. Governments and organizations are implementing policies and initiatives to promote closed-loop systems, where packaging materials can be fully reintegrated into the environment or recycling streams. This has created a market opportunity for cellophane manufacturers to develop products that not only meet current compostability standards but exceed them, positioning themselves as leaders in the sustainable packaging space.

Consumer preferences have shifted dramatically towards environmentally responsible products, with a growing number of shoppers actively seeking out packaging that aligns with their values. This shift has prompted major retailers and brands to commit to sustainable packaging goals, further fueling the demand for compostable materials like cellophane. The food and beverage industry, in particular, has shown keen interest in adopting compostable packaging solutions to reduce their environmental footprint and appeal to eco-conscious consumers.

Market research indicates that the sustainable packaging market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain in the double digits over the next five years. This growth is particularly pronounced in developed economies such as North America and Europe, where environmental concerns are at the forefront of consumer decision-making processes.

The demand for cellophane as a sustainable packaging material is closely tied to its compostability standards. As consumers and regulatory bodies become more discerning about environmental claims, there is an increasing need for packaging solutions that can meet rigorous compostability certifications. This has created a market pull for advanced cellophane products that can decompose more efficiently in industrial composting facilities and, ideally, in home composting environments.

Retailers and brand owners are actively seeking packaging materials that can help them meet their sustainability targets without compromising on functionality or aesthetics. Cellophane's transparency, flexibility, and barrier properties make it an attractive option for a wide range of applications, from food packaging to personal care products. However, the market demand is not just for any compostable cellophane, but for products that can demonstrate superior compostability performance and faster decomposition rates.

The push for improved compostability standards in cellophane is also driven by the circular economy concept, which is gaining traction globally. Governments and organizations are implementing policies and initiatives to promote closed-loop systems, where packaging materials can be fully reintegrated into the environment or recycling streams. This has created a market opportunity for cellophane manufacturers to develop products that not only meet current compostability standards but exceed them, positioning themselves as leaders in the sustainable packaging space.

Current Compostability Standards and Challenges

The current compostability standards for cellophane present significant challenges in advancing its environmental sustainability. Existing standards, such as ASTM D6400 and EN 13432, provide guidelines for biodegradable plastics but may not fully address the unique properties of cellophane. These standards typically require materials to disintegrate within 12 weeks and biodegrade 90% within 180 days under industrial composting conditions. However, cellophane's composition and structure often result in slower decomposition rates, making it difficult to meet these stringent timelines.

One of the primary challenges lies in cellophane's moisture resistance properties, which are essential for its functionality in packaging applications but can hinder its compostability. The coating materials used to enhance cellophane's barrier properties, such as nitrocellulose or polyvinylidene chloride (PVDC), often slow down the biodegradation process. This creates a tension between maintaining cellophane's desirable packaging characteristics and improving its compostability.

Another significant hurdle is the variability in composting conditions across different facilities and regions. Industrial composting facilities may have varying temperature, moisture, and microbial activity levels, which can affect cellophane's decomposition rate. This inconsistency makes it challenging to develop universally applicable compostability standards for cellophane that can be reliably met across diverse composting environments.

The lack of specific standards tailored to cellophane's unique properties also poses a challenge. Current standards are often designed with a broad range of materials in mind, potentially overlooking the specific characteristics of cellophane that could be leveraged to enhance its compostability. This gap in standardization makes it difficult for manufacturers to optimize their cellophane products for improved environmental performance while still meeting regulatory requirements.

Furthermore, the testing methodologies used to assess compostability may not accurately reflect real-world conditions for cellophane disposal. Laboratory tests often simulate ideal composting environments, which may not align with the actual conditions in industrial or home composting systems. This discrepancy can lead to overestimation of cellophane's compostability performance in practical applications.

Advancing cellophane's compostability standards also faces economic challenges. Developing new formulations or manufacturing processes to enhance compostability while maintaining product performance can be costly. This economic barrier may slow down industry-wide adoption of improved compostable cellophane products, particularly in competitive markets where price sensitivity is high.

Lastly, the lack of consumer awareness and proper disposal infrastructure presents a challenge in realizing the full potential of compostable cellophane. Even if improved standards are developed and met, the environmental benefits can only be fully realized if consumers correctly dispose of cellophane products in appropriate composting facilities. This highlights the need for comprehensive approaches that address not only technical standards but also education and infrastructure development.

One of the primary challenges lies in cellophane's moisture resistance properties, which are essential for its functionality in packaging applications but can hinder its compostability. The coating materials used to enhance cellophane's barrier properties, such as nitrocellulose or polyvinylidene chloride (PVDC), often slow down the biodegradation process. This creates a tension between maintaining cellophane's desirable packaging characteristics and improving its compostability.

Another significant hurdle is the variability in composting conditions across different facilities and regions. Industrial composting facilities may have varying temperature, moisture, and microbial activity levels, which can affect cellophane's decomposition rate. This inconsistency makes it challenging to develop universally applicable compostability standards for cellophane that can be reliably met across diverse composting environments.

The lack of specific standards tailored to cellophane's unique properties also poses a challenge. Current standards are often designed with a broad range of materials in mind, potentially overlooking the specific characteristics of cellophane that could be leveraged to enhance its compostability. This gap in standardization makes it difficult for manufacturers to optimize their cellophane products for improved environmental performance while still meeting regulatory requirements.

Furthermore, the testing methodologies used to assess compostability may not accurately reflect real-world conditions for cellophane disposal. Laboratory tests often simulate ideal composting environments, which may not align with the actual conditions in industrial or home composting systems. This discrepancy can lead to overestimation of cellophane's compostability performance in practical applications.

Advancing cellophane's compostability standards also faces economic challenges. Developing new formulations or manufacturing processes to enhance compostability while maintaining product performance can be costly. This economic barrier may slow down industry-wide adoption of improved compostable cellophane products, particularly in competitive markets where price sensitivity is high.

Lastly, the lack of consumer awareness and proper disposal infrastructure presents a challenge in realizing the full potential of compostable cellophane. Even if improved standards are developed and met, the environmental benefits can only be fully realized if consumers correctly dispose of cellophane products in appropriate composting facilities. This highlights the need for comprehensive approaches that address not only technical standards but also education and infrastructure development.

Existing Cellophane Compostability Enhancement Methods

01 Biodegradable cellophane compositions

Development of biodegradable cellophane compositions that can be composted. These compositions may include additives or modifications to the cellulose structure to enhance compostability while maintaining desired physical properties.- Biodegradable cellophane compositions: Development of biodegradable cellophane compositions that can be composted. These compositions may include additives or modifications to the cellulose structure to enhance compostability while maintaining desired physical properties.

- Compostable packaging materials: Creation of compostable packaging materials that incorporate cellophane or cellulose-based films. These materials are designed to break down in composting environments, reducing environmental impact.

- Enzymatic degradation of cellophane: Utilization of enzymes to enhance the degradation of cellophane in composting conditions. This approach involves the use of specific enzymes that can break down cellulose structures more efficiently.

- Compostable multi-layer films: Development of multi-layer films that include cellophane or cellulose-based layers combined with other compostable materials. These films are designed to maintain functionality while ensuring complete compostability.

- Compostability testing methods: Establishment of testing methods and standards to evaluate the compostability of cellophane and cellulose-based materials. These methods help determine the rate and extent of decomposition in various composting conditions.

02 Compostable packaging materials

Creation of compostable packaging materials that incorporate cellophane or cellulose-based films. These materials are designed to break down in composting environments, reducing environmental impact.Expand Specific Solutions03 Enzymatic degradation of cellophane

Utilization of enzymes to enhance the degradation of cellophane in composting conditions. This approach involves the development of enzyme formulations or treatments that can accelerate the breakdown of cellulose-based materials.Expand Specific Solutions04 Compostable multi-layer films

Development of multi-layer films that incorporate cellophane and other compostable materials. These films are designed to provide desired functional properties while ensuring complete biodegradation in composting environments.Expand Specific Solutions05 Compostability testing methods

Establishment of testing methods and standards to evaluate the compostability of cellophane-based materials. These methods aim to assess the biodegradation rate, ecotoxicity, and overall environmental impact of cellophane products in composting conditions.Expand Specific Solutions

Key Players in Compostable Packaging Industry

The cellophane compostability standards market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding as more industries adopt sustainable packaging solutions. Technological maturity varies among key players, with companies like DuPont de Nemours, Inc. and Corning, Inc. leading in innovation. Novozymes A/S and BASF Corp. are advancing enzymatic solutions for biodegradation, while Henkel AG & Co. KGaA and Kansai Paint Co., Ltd. focus on eco-friendly coatings. Emerging players like Bio-On SpA and Xyleco, Inc. are introducing novel bioplastic technologies, intensifying competition in this evolving sector.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a bio-based, compostable cellophane alternative called NatureFlex™. This material is derived from wood pulp and is certified compostable according to EN13432 standards[1]. The company has enhanced the material's barrier properties against moisture and gases, making it suitable for food packaging applications. DuPont's approach involves modifying the cellulose structure at the molecular level to improve its compostability while maintaining necessary packaging performance[2]. The material breaks down in industrial composting facilities within 10-12 weeks[3], addressing the growing demand for sustainable packaging solutions.

Strengths: Derived from renewable resources, certified compostable, improved barrier properties. Weaknesses: May require industrial composting facilities, potentially higher production costs compared to traditional cellophane.

BASF Corp.

Technical Solution: BASF has developed ecovio®, a certified compostable bioplastic that can be used as a coating for cellophane to enhance its compostability. The material is based on the biodegradable polymer PBAT (polybutylene adipate terephthalate) and PLA (polylactic acid) derived from renewable resources[4]. BASF's technology focuses on creating a balance between biodegradability and functional properties. The company has also invested in developing additives that can accelerate the decomposition process of cellophane-based materials in industrial composting conditions[5]. BASF's approach includes collaboration with composting facilities to ensure that their materials meet real-world composting standards.

Strengths: Certified compostable, versatile application as coating, accelerates decomposition. Weaknesses: May alter some physical properties of cellophane, requires specific composting conditions.

Innovative Approaches to Improve Cellophane Decomposition

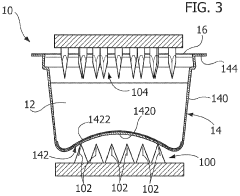

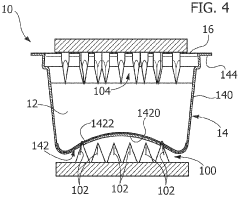

Cartridge for preparing a liquid product

PatentWO2012080908A1

Innovation

- The cartridges use compostable materials for both the foils and the connecting material, ensuring that the entire package can be recovered through composting and biodegradation, adhering to standards like UNI EN 13432, by employing porous materials like cellulose paper and connecting materials like polylactic acid or polyhydroxyalkanoates.

Cartridge for preparing a liquid product

PatentWO2012077066A1

Innovation

- A cartridge with a layered bottom wall structure, comprising a first compostable material that softens at high temperatures and a second compostable material that remains stable, ensuring proper perforation and fluid-tightness, preventing excessive elongation and rupture, and allowing for efficient outflow of the beverage.

Environmental Impact Assessment of Compostable Cellophane

The environmental impact assessment of compostable cellophane is a critical component in advancing its compostability standards. This evaluation encompasses various aspects of the material's lifecycle, from production to disposal, and its effects on ecosystems and biodiversity.

Compostable cellophane, derived from renewable resources such as wood pulp or cotton linters, offers a promising alternative to traditional plastic packaging. Its biodegradability in composting environments is a key advantage, potentially reducing the accumulation of plastic waste in landfills and natural habitats. However, a comprehensive assessment is necessary to ensure that the benefits outweigh any potential drawbacks.

The production process of compostable cellophane requires careful scrutiny. While it utilizes renewable resources, the energy consumption and emissions associated with manufacturing must be quantified and compared to conventional plastics. Additionally, the use of chemicals in the production process, such as carbon disulfide and sodium hydroxide, necessitates an evaluation of their environmental impact and potential for safe disposal or recycling.

Water usage is another crucial factor to consider. The production of cellophane typically involves significant water consumption, which may strain local water resources. Implementing water recycling systems and optimizing production processes can help mitigate this impact.

The end-of-life phase of compostable cellophane is particularly important in assessing its environmental footprint. While it is designed to break down in composting facilities, the actual decomposition rate and conditions required for complete biodegradation must be thoroughly examined. Factors such as temperature, moisture, and microbial activity play crucial roles in the composting process.

It is essential to evaluate the quality of the resulting compost and its potential effects on soil health. The breakdown of cellophane should not introduce harmful substances into the soil or negatively impact plant growth. Long-term studies on soil composition and microbial communities are necessary to ensure the safety and efficacy of compostable cellophane as a soil amendment.

The assessment should also consider the potential for improper disposal of compostable cellophane. If mistakenly sent to landfills or recycling facilities, it may not decompose as intended, potentially causing contamination or disruption to existing waste management systems. Public education and clear labeling are crucial to ensure proper disposal and maximize the environmental benefits of compostable cellophane.

Furthermore, the impact on marine ecosystems must be evaluated, as improper disposal could lead to cellophane entering waterways. While it may biodegrade more readily than conventional plastics, the timeframe and potential effects on marine life during the degradation process require thorough investigation.

By conducting a comprehensive environmental impact assessment, researchers and industry professionals can identify areas for improvement in compostable cellophane production and disposal. This information will be instrumental in advancing compostability standards, ensuring that the material truly delivers on its promise of environmental sustainability.

Compostable cellophane, derived from renewable resources such as wood pulp or cotton linters, offers a promising alternative to traditional plastic packaging. Its biodegradability in composting environments is a key advantage, potentially reducing the accumulation of plastic waste in landfills and natural habitats. However, a comprehensive assessment is necessary to ensure that the benefits outweigh any potential drawbacks.

The production process of compostable cellophane requires careful scrutiny. While it utilizes renewable resources, the energy consumption and emissions associated with manufacturing must be quantified and compared to conventional plastics. Additionally, the use of chemicals in the production process, such as carbon disulfide and sodium hydroxide, necessitates an evaluation of their environmental impact and potential for safe disposal or recycling.

Water usage is another crucial factor to consider. The production of cellophane typically involves significant water consumption, which may strain local water resources. Implementing water recycling systems and optimizing production processes can help mitigate this impact.

The end-of-life phase of compostable cellophane is particularly important in assessing its environmental footprint. While it is designed to break down in composting facilities, the actual decomposition rate and conditions required for complete biodegradation must be thoroughly examined. Factors such as temperature, moisture, and microbial activity play crucial roles in the composting process.

It is essential to evaluate the quality of the resulting compost and its potential effects on soil health. The breakdown of cellophane should not introduce harmful substances into the soil or negatively impact plant growth. Long-term studies on soil composition and microbial communities are necessary to ensure the safety and efficacy of compostable cellophane as a soil amendment.

The assessment should also consider the potential for improper disposal of compostable cellophane. If mistakenly sent to landfills or recycling facilities, it may not decompose as intended, potentially causing contamination or disruption to existing waste management systems. Public education and clear labeling are crucial to ensure proper disposal and maximize the environmental benefits of compostable cellophane.

Furthermore, the impact on marine ecosystems must be evaluated, as improper disposal could lead to cellophane entering waterways. While it may biodegrade more readily than conventional plastics, the timeframe and potential effects on marine life during the degradation process require thorough investigation.

By conducting a comprehensive environmental impact assessment, researchers and industry professionals can identify areas for improvement in compostable cellophane production and disposal. This information will be instrumental in advancing compostability standards, ensuring that the material truly delivers on its promise of environmental sustainability.

Regulatory Framework for Compostable Packaging Materials

The regulatory framework for compostable packaging materials plays a crucial role in advancing cellophane's compostability standards. As the global focus on sustainable packaging solutions intensifies, governments and international organizations are developing and refining regulations to ensure the proper management of compostable materials.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard specifies the characteristics that a material must have to be considered compostable, including biodegradation rate, disintegration during biological treatment, and effect on the biological treatment process. The EU has also introduced the Single-Use Plastics Directive, which encourages the use of sustainable alternatives like compostable cellophane.

In the United States, the ASTM D6400 standard provides specifications for plastics designed to be composted in municipal and industrial aerobic composting facilities. The Federal Trade Commission's Green Guides offer guidelines for environmental marketing claims, including those related to compostability. Additionally, several states have implemented their own regulations, such as California's SB 1335, which requires food service packaging at state facilities to be reusable, recyclable, or compostable.

Internationally, the ISO 17088 standard specifies requirements for plastics that are suitable for recovery through aerobic composting. This standard is widely recognized and often serves as a basis for national and regional regulations. The Biodegradable Products Institute (BPI) in North America and the Australasian Bioplastics Association (ABA) in Australia and New Zealand offer certification programs based on these international standards.

To advance cellophane's compostability standards, manufacturers must navigate this complex regulatory landscape. They need to ensure their products meet or exceed the requirements set by these standards and regulations. This may involve reformulating cellophane compositions, improving manufacturing processes, and conducting extensive testing to demonstrate compliance.

Furthermore, as regulations continue to evolve, industry stakeholders must actively participate in the development of new standards. This includes engaging with policymakers, contributing to research initiatives, and sharing best practices within the industry. By doing so, they can help shape regulations that are both environmentally effective and commercially viable for cellophane producers.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard specifies the characteristics that a material must have to be considered compostable, including biodegradation rate, disintegration during biological treatment, and effect on the biological treatment process. The EU has also introduced the Single-Use Plastics Directive, which encourages the use of sustainable alternatives like compostable cellophane.

In the United States, the ASTM D6400 standard provides specifications for plastics designed to be composted in municipal and industrial aerobic composting facilities. The Federal Trade Commission's Green Guides offer guidelines for environmental marketing claims, including those related to compostability. Additionally, several states have implemented their own regulations, such as California's SB 1335, which requires food service packaging at state facilities to be reusable, recyclable, or compostable.

Internationally, the ISO 17088 standard specifies requirements for plastics that are suitable for recovery through aerobic composting. This standard is widely recognized and often serves as a basis for national and regional regulations. The Biodegradable Products Institute (BPI) in North America and the Australasian Bioplastics Association (ABA) in Australia and New Zealand offer certification programs based on these international standards.

To advance cellophane's compostability standards, manufacturers must navigate this complex regulatory landscape. They need to ensure their products meet or exceed the requirements set by these standards and regulations. This may involve reformulating cellophane compositions, improving manufacturing processes, and conducting extensive testing to demonstrate compliance.

Furthermore, as regulations continue to evolve, industry stakeholders must actively participate in the development of new standards. This includes engaging with policymakers, contributing to research initiatives, and sharing best practices within the industry. By doing so, they can help shape regulations that are both environmentally effective and commercially viable for cellophane producers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!