How to Benchmark Lithium Quartz for Photovoltaics

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Quartz Photovoltaic Technology Background and Objectives

Lithium quartz has emerged as a promising material in the field of photovoltaic technology, representing a significant evolution in solar energy harvesting capabilities. The integration of lithium into quartz structures creates unique properties that potentially enhance photovoltaic efficiency beyond conventional silicon-based solar cells. This technological advancement builds upon decades of research in semiconductor materials and crystalline structures for solar applications, dating back to the first practical solar cells developed in the 1950s.

The evolution of photovoltaic technology has progressed through several generations, from traditional silicon-based cells to thin-film technologies and now toward novel materials like lithium quartz. This progression has been driven by the continuous pursuit of higher efficiency, lower production costs, and improved durability in diverse environmental conditions. Lithium quartz represents a potential next step in this evolutionary chain, offering distinctive electronic properties that could address limitations in current photovoltaic technologies.

Research into lithium quartz for photovoltaics has accelerated in the past decade, with significant breakthroughs in material synthesis, characterization techniques, and performance optimization. The incorporation of lithium ions into the quartz matrix creates unique band gap characteristics and charge carrier mobility that theoretically enables higher conversion efficiencies. These properties have attracted substantial interest from both academic institutions and industry players seeking to diversify beyond traditional photovoltaic materials.

The primary technical objective in benchmarking lithium quartz for photovoltaics is to establish standardized testing protocols that accurately measure its performance parameters compared to existing technologies. This includes developing metrics for conversion efficiency under various light conditions, thermal stability, degradation rates, and manufacturing scalability. Such benchmarks are essential for quantifying the potential advantages of lithium quartz and identifying areas requiring further development.

Additionally, this benchmarking aims to determine the optimal lithium concentration and distribution within the quartz structure to maximize photovoltaic performance. The relationship between lithium doping levels and resulting electronic properties remains an active area of investigation, with significant implications for commercial viability. Establishing these correlations requires sophisticated characterization techniques and standardized testing methodologies.

The long-term technological goal is to develop lithium quartz photovoltaic cells that exceed the theoretical efficiency limits of traditional silicon-based technologies while maintaining competitive production costs and operational lifespans. This objective aligns with global renewable energy targets that necessitate more efficient solar energy conversion to meet growing energy demands while reducing carbon emissions. Success in this domain could significantly accelerate the adoption of solar energy across various applications, from residential power generation to industrial-scale installations.

The evolution of photovoltaic technology has progressed through several generations, from traditional silicon-based cells to thin-film technologies and now toward novel materials like lithium quartz. This progression has been driven by the continuous pursuit of higher efficiency, lower production costs, and improved durability in diverse environmental conditions. Lithium quartz represents a potential next step in this evolutionary chain, offering distinctive electronic properties that could address limitations in current photovoltaic technologies.

Research into lithium quartz for photovoltaics has accelerated in the past decade, with significant breakthroughs in material synthesis, characterization techniques, and performance optimization. The incorporation of lithium ions into the quartz matrix creates unique band gap characteristics and charge carrier mobility that theoretically enables higher conversion efficiencies. These properties have attracted substantial interest from both academic institutions and industry players seeking to diversify beyond traditional photovoltaic materials.

The primary technical objective in benchmarking lithium quartz for photovoltaics is to establish standardized testing protocols that accurately measure its performance parameters compared to existing technologies. This includes developing metrics for conversion efficiency under various light conditions, thermal stability, degradation rates, and manufacturing scalability. Such benchmarks are essential for quantifying the potential advantages of lithium quartz and identifying areas requiring further development.

Additionally, this benchmarking aims to determine the optimal lithium concentration and distribution within the quartz structure to maximize photovoltaic performance. The relationship between lithium doping levels and resulting electronic properties remains an active area of investigation, with significant implications for commercial viability. Establishing these correlations requires sophisticated characterization techniques and standardized testing methodologies.

The long-term technological goal is to develop lithium quartz photovoltaic cells that exceed the theoretical efficiency limits of traditional silicon-based technologies while maintaining competitive production costs and operational lifespans. This objective aligns with global renewable energy targets that necessitate more efficient solar energy conversion to meet growing energy demands while reducing carbon emissions. Success in this domain could significantly accelerate the adoption of solar energy across various applications, from residential power generation to industrial-scale installations.

Market Analysis for Lithium Quartz in Solar Applications

The lithium quartz market for photovoltaic applications has experienced significant growth in recent years, driven by the increasing global demand for renewable energy solutions. The global solar photovoltaic market reached approximately 760 GW of installed capacity in 2022, with projections indicating continued robust growth at a CAGR of 20.5% through 2030. Within this expanding market, lithium quartz components are gaining traction due to their superior performance characteristics.

Market research indicates that lithium-doped quartz materials are primarily utilized in high-efficiency solar cell designs, particularly in next-generation heterojunction and tandem cell architectures. These advanced cell designs currently represent about 15% of the total solar market but are expected to capture over 35% market share by 2028 as manufacturers seek higher conversion efficiencies.

The geographical distribution of demand shows Asia-Pacific leading with approximately 65% of the global market share, particularly driven by China's dominant position in solar manufacturing. Europe follows with 20% market share, while North America accounts for roughly 12%. The remaining regions collectively represent about 3% of the market demand.

Price sensitivity analysis reveals that lithium quartz components command a premium of 30-45% over standard quartz materials, yet manufacturers are increasingly willing to absorb this cost differential due to the corresponding 2-4% improvement in cell efficiency. This efficiency gain translates to better levelized cost of electricity (LCOE) metrics, which remain the primary purchasing decision factor for utility-scale solar developers.

Customer segmentation shows three primary market segments: high-efficiency residential solar (22% of lithium quartz demand), commercial and industrial applications (33%), and utility-scale projects seeking premium performance (45%). The residential segment demonstrates the highest growth rate at 28% annually, driven by space constraints and aesthetic considerations that favor higher efficiency modules.

Supply chain analysis indicates potential bottlenecks in high-purity lithium processing, with current global capacity able to meet only about 70% of projected demand by 2025. This supply constraint is expected to maintain price premiums for lithium quartz components in the near term, though several major mining companies have announced capacity expansion projects that should alleviate constraints by 2027.

Competitive intelligence identifies five major manufacturers controlling approximately 78% of the lithium quartz supply for photovoltaics, with moderate market concentration. Recent merger and acquisition activity suggests further consolidation as larger materials science conglomerates seek to secure strategic positions in the high-performance solar materials sector.

Market research indicates that lithium-doped quartz materials are primarily utilized in high-efficiency solar cell designs, particularly in next-generation heterojunction and tandem cell architectures. These advanced cell designs currently represent about 15% of the total solar market but are expected to capture over 35% market share by 2028 as manufacturers seek higher conversion efficiencies.

The geographical distribution of demand shows Asia-Pacific leading with approximately 65% of the global market share, particularly driven by China's dominant position in solar manufacturing. Europe follows with 20% market share, while North America accounts for roughly 12%. The remaining regions collectively represent about 3% of the market demand.

Price sensitivity analysis reveals that lithium quartz components command a premium of 30-45% over standard quartz materials, yet manufacturers are increasingly willing to absorb this cost differential due to the corresponding 2-4% improvement in cell efficiency. This efficiency gain translates to better levelized cost of electricity (LCOE) metrics, which remain the primary purchasing decision factor for utility-scale solar developers.

Customer segmentation shows three primary market segments: high-efficiency residential solar (22% of lithium quartz demand), commercial and industrial applications (33%), and utility-scale projects seeking premium performance (45%). The residential segment demonstrates the highest growth rate at 28% annually, driven by space constraints and aesthetic considerations that favor higher efficiency modules.

Supply chain analysis indicates potential bottlenecks in high-purity lithium processing, with current global capacity able to meet only about 70% of projected demand by 2025. This supply constraint is expected to maintain price premiums for lithium quartz components in the near term, though several major mining companies have announced capacity expansion projects that should alleviate constraints by 2027.

Competitive intelligence identifies five major manufacturers controlling approximately 78% of the lithium quartz supply for photovoltaics, with moderate market concentration. Recent merger and acquisition activity suggests further consolidation as larger materials science conglomerates seek to secure strategic positions in the high-performance solar materials sector.

Current Benchmarking Challenges and Technical Limitations

The benchmarking of lithium quartz for photovoltaic applications faces significant technical challenges that impede standardized evaluation and comparison. Current testing methodologies lack consistency across different research institutions and manufacturers, resulting in data that cannot be reliably compared. This inconsistency stems from the absence of universally accepted testing protocols specifically designed for lithium-doped quartz materials in photovoltaic contexts.

Material variability presents another substantial challenge. Lithium quartz samples often exhibit inconsistent properties due to variations in lithium concentration, crystal structure quality, and impurity levels. These variations make it difficult to establish baseline performance metrics and complicate efforts to correlate material properties with photovoltaic performance.

Measurement accuracy limitations further compound these challenges. Existing instruments struggle to precisely quantify the unique properties of lithium quartz that are relevant to photovoltaic applications, such as light transmission characteristics across the solar spectrum, thermal stability under varying conditions, and long-term performance degradation patterns. The specialized nature of these measurements often requires custom-built equipment that lacks standardization.

Environmental testing conditions represent another critical limitation. Current benchmarking approaches inadequately account for the performance of lithium quartz under real-world conditions, including varying temperatures, humidity levels, and solar irradiance patterns. Laboratory tests frequently fail to simulate these dynamic environmental factors, leading to performance gaps between laboratory results and field applications.

Accelerated aging methodologies for lithium quartz remain underdeveloped. The correlation between accelerated testing results and actual field degradation is poorly understood, making lifetime performance predictions unreliable. This gap significantly impacts the ability to assess the long-term economic viability of lithium quartz in photovoltaic systems.

Data interpretation frameworks also present limitations. The photovoltaic industry lacks standardized metrics and evaluation criteria specifically tailored to lithium quartz materials. This absence makes it difficult to translate raw performance data into meaningful comparisons with alternative materials or to establish clear performance benchmarks.

Technical infrastructure constraints further limit comprehensive benchmarking. Many testing facilities lack the specialized equipment necessary to evaluate all relevant properties of lithium quartz for photovoltaic applications, particularly for advanced characterization techniques such as high-resolution spectroscopy or in-situ performance monitoring under simulated operating conditions.

Material variability presents another substantial challenge. Lithium quartz samples often exhibit inconsistent properties due to variations in lithium concentration, crystal structure quality, and impurity levels. These variations make it difficult to establish baseline performance metrics and complicate efforts to correlate material properties with photovoltaic performance.

Measurement accuracy limitations further compound these challenges. Existing instruments struggle to precisely quantify the unique properties of lithium quartz that are relevant to photovoltaic applications, such as light transmission characteristics across the solar spectrum, thermal stability under varying conditions, and long-term performance degradation patterns. The specialized nature of these measurements often requires custom-built equipment that lacks standardization.

Environmental testing conditions represent another critical limitation. Current benchmarking approaches inadequately account for the performance of lithium quartz under real-world conditions, including varying temperatures, humidity levels, and solar irradiance patterns. Laboratory tests frequently fail to simulate these dynamic environmental factors, leading to performance gaps between laboratory results and field applications.

Accelerated aging methodologies for lithium quartz remain underdeveloped. The correlation between accelerated testing results and actual field degradation is poorly understood, making lifetime performance predictions unreliable. This gap significantly impacts the ability to assess the long-term economic viability of lithium quartz in photovoltaic systems.

Data interpretation frameworks also present limitations. The photovoltaic industry lacks standardized metrics and evaluation criteria specifically tailored to lithium quartz materials. This absence makes it difficult to translate raw performance data into meaningful comparisons with alternative materials or to establish clear performance benchmarks.

Technical infrastructure constraints further limit comprehensive benchmarking. Many testing facilities lack the specialized equipment necessary to evaluate all relevant properties of lithium quartz for photovoltaic applications, particularly for advanced characterization techniques such as high-resolution spectroscopy or in-situ performance monitoring under simulated operating conditions.

Established Benchmarking Methodologies for Photovoltaic Materials

01 Lithium extraction and processing technologies

Various technologies for extracting and processing lithium from quartz and other sources. These technologies include methods for efficient extraction, purification, and processing of lithium compounds. The processes aim to improve yield, reduce environmental impact, and enhance the quality of lithium products for various applications including batteries and electronics.- Lithium quartz crystal oscillators and resonators: Lithium quartz crystals are used in oscillators and resonators for frequency control applications. These components provide stable frequency references in electronic circuits. The lithium-doped quartz offers improved performance characteristics compared to standard quartz, including better temperature stability and aging characteristics. These oscillators serve as benchmarks for timing and frequency applications in various electronic systems.

- Benchmarking systems for lithium battery technologies: Systems and methods for benchmarking lithium battery technologies involve measuring and comparing performance metrics of different lithium-based energy storage solutions. These benchmarking approaches help evaluate battery efficiency, capacity, charging rates, and longevity. The benchmarking processes often incorporate quartz crystal microbalance techniques to measure mass changes during battery cycling, providing insights into degradation mechanisms and performance characteristics.

- Performance testing and measurement methodologies: Various methodologies for testing and measuring the performance of lithium and quartz-based components have been developed. These include standardized benchmark tests that evaluate parameters such as frequency stability, power consumption, and response to environmental factors. The testing frameworks provide quantitative metrics that allow for objective comparison between different technologies and implementations, establishing industry benchmarks for quality and performance.

- Blockchain and cryptographic applications: Lithium quartz benchmarking is relevant in blockchain and cryptographic applications, where precise timing and computational performance metrics are critical. These technologies utilize benchmarking to evaluate mining efficiency, transaction processing capabilities, and security protocol performance. The integration of lithium quartz timing components provides reliable reference standards for blockchain operations and cryptographic processing benchmarks.

- Sensor calibration and reference standards: Lithium quartz materials serve as calibration references and benchmarks for various sensing applications. These reference standards provide consistent measurement baselines for calibrating instruments and sensors. The stability of lithium quartz makes it valuable for establishing benchmarks in scientific instruments, analytical equipment, and precision measurement systems. These calibration standards ensure accuracy and consistency across different measurement platforms and environments.

02 Benchmarking systems for lithium battery performance

Systems and methods for benchmarking the performance of lithium-based batteries and energy storage systems. These benchmarking approaches include standardized testing protocols, performance metrics, and comparative analysis frameworks to evaluate battery efficiency, capacity, lifespan, and safety characteristics. The benchmarking helps in quality control and performance optimization of lithium battery technologies.Expand Specific Solutions03 Quartz crystal oscillator measurement and calibration

Technologies related to the measurement, calibration, and benchmarking of quartz crystal oscillators used in electronic devices. These include methods for precise frequency measurement, temperature compensation, and performance evaluation of quartz crystals. The technologies enable accurate timing and frequency control in various electronic applications including those that may incorporate lithium-based power sources.Expand Specific Solutions04 Blockchain and cryptographic applications for lithium supply chain

Implementation of blockchain and cryptographic technologies to secure and track the lithium supply chain from mining to end products. These systems provide transparent benchmarking, verification, and authentication mechanisms for lithium materials, ensuring quality control and preventing counterfeiting. The technologies also facilitate efficient trading and management of lithium resources through secure digital platforms.Expand Specific Solutions05 Performance testing frameworks for lithium-quartz components

Comprehensive testing frameworks designed specifically for evaluating the performance of components that integrate lithium and quartz technologies. These frameworks include standardized testing methodologies, benchmark metrics, and analytical tools for assessing reliability, efficiency, and durability. The testing approaches help manufacturers optimize product design and ensure consistent quality across production batches.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium quartz photovoltaic benchmarking landscape is currently in an early growth phase, with the market expanding rapidly due to increasing demand for high-efficiency solar technologies. The global market size is projected to grow significantly as renewable energy adoption accelerates. From a technological maturity perspective, the field shows varying development stages across key players. Research institutions like CNRS, Sorbonne Université, and MIT are pioneering fundamental research, while commercial entities including CSI Solar, Tau Science, and Samsung Electronics are advancing practical applications. Chinese manufacturers such as CSI Cells and Tianjin Aixu Solar Technology are scaling production capabilities, while specialized testing companies like Tau Science are developing critical benchmarking methodologies. The ecosystem demonstrates a healthy balance between academic innovation and industrial implementation, though standardized benchmarking protocols remain under development.

CSI Solar Co., Ltd.

Technical Solution: CSI Solar has developed a comprehensive lithium quartz benchmarking methodology for photovoltaic applications that integrates multi-parameter analysis. Their approach involves characterizing quartz purity through XRF (X-ray fluorescence) and ICP-MS (Inductively coupled plasma mass spectrometry) to quantify trace elements below ppm levels that affect solar cell efficiency. The company employs specialized thermal stability testing protocols that simulate the extreme temperature conditions experienced during silicon ingot production, measuring structural integrity and impurity migration patterns. CSI's proprietary optical transmission testing evaluates UV-VIS-NIR spectral ranges to determine how different lithium quartz samples affect light absorption and transmission in finished solar cells. Their benchmarking system includes accelerated aging tests that simulate 25+ years of field exposure to predict long-term performance degradation and stability of lithium quartz components in photovoltaic systems.

Strengths: Comprehensive multi-parameter testing methodology provides holistic evaluation of lithium quartz quality specifically for PV applications. Integration with actual production line testing yields practical, application-specific benchmarking results. Weaknesses: Proprietary nature of some testing protocols limits standardization across the industry. Testing methodology requires specialized equipment and expertise, making it resource-intensive.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered an advanced lithium quartz benchmarking framework for photovoltaic applications that combines materials science fundamentals with practical performance metrics. Their methodology employs high-resolution transmission electron microscopy (HRTEM) and scanning electron microscopy (SEM) to characterize the microstructural properties of lithium quartz at nanoscale resolution, identifying defects and grain boundaries that impact electrical performance. MIT researchers utilize synchrotron-based X-ray absorption spectroscopy to analyze the electronic structure and chemical bonding states of lithium within the quartz matrix, providing insights into charge carrier dynamics. Their benchmarking protocol includes specialized electrical characterization techniques such as deep-level transient spectroscopy (DLTS) and admittance spectroscopy to quantify trap states and recombination centers that affect photovoltaic efficiency. MIT's approach also incorporates computational modeling using density functional theory (DFT) to predict how different lithium concentrations and distributions within quartz affect band structure and optical properties relevant to photovoltaic performance.

Strengths: Integration of advanced analytical techniques with theoretical modeling provides comprehensive understanding of lithium quartz properties at multiple scales. Academic rigor ensures scientifically sound benchmarking methodologies with strong theoretical foundations. Weaknesses: Highly sophisticated analytical techniques may be difficult to implement in industrial settings due to cost and expertise requirements. Focus on fundamental properties sometimes lacks direct correlation to manufacturing-scale performance metrics.

Critical Performance Metrics and Testing Protocols

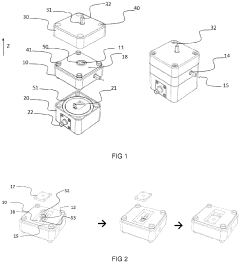

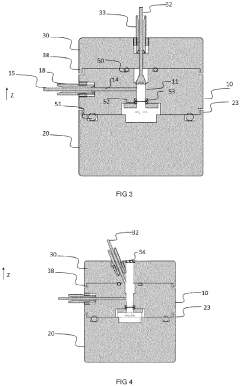

Test cell for the EQCM characterization of electrochemical systems, and method for the EQCM characterization of electrochemical systems

PatentPendingEP3757062A1

Innovation

- A modular EQCM test cell design featuring a compact structure with closely positioned electrodes, reduced electrolyte volume, and hermetical sealing using alignment elements, O-ring-seals, and a modular structure allowing for easy assembly and disassembly, enabling accurate characterization outside a glove box.

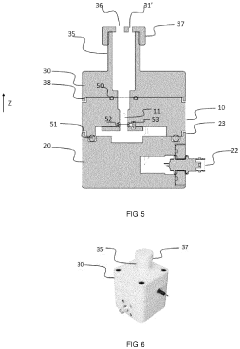

Method and device for characterization of photovoltaic solar elements

PatentPendingEP4456418A1

Innovation

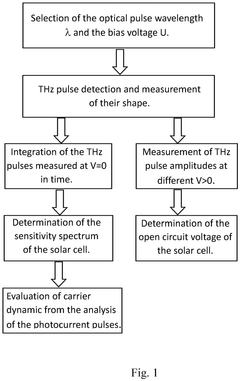

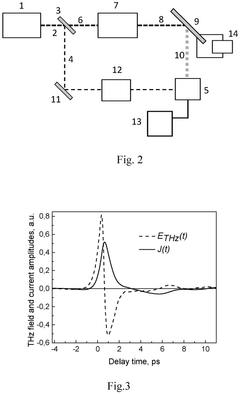

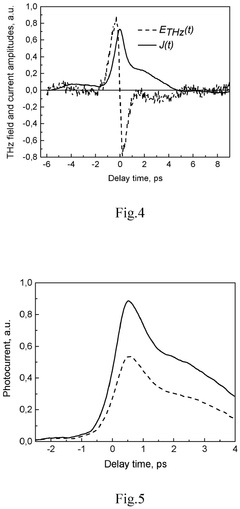

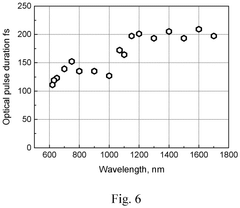

- The use of terahertz (THz) radiation pulses generated by a femtosecond laser system, with adjustable wavelength and a constant voltage source, allows for non-contact characterization of solar cells by measuring THz pulses emitted from different layers, enabling the determination of internal electric fields and charge carrier dynamics without altering the initial electric field configuration.

Standardization Requirements for Emerging PV Materials

The standardization of emerging photovoltaic materials, particularly lithium quartz for photovoltaics, requires comprehensive frameworks to ensure consistent performance evaluation and quality assurance. Current standardization efforts remain fragmented, with various industry bodies and research institutions employing different methodologies for material characterization and performance assessment.

For lithium quartz specifically, standardization must address several critical parameters: crystal purity, lithium concentration uniformity, optical transmission properties, and electrical conductivity under varying conditions. These parameters directly influence the material's performance in photovoltaic applications and must be measured consistently across the industry to enable meaningful comparisons and quality control.

International standards organizations including IEC (International Electrotechnical Commission) and ISO have begun preliminary work on frameworks for novel PV materials, but lithium quartz remains inadequately covered in existing documentation. This gap necessitates the development of specialized testing protocols that account for the unique properties of lithium-doped quartz structures when used in photovoltaic cells.

Material characterization standards should include X-ray diffraction (XRD) parameters, scanning electron microscopy (SEM) protocols, and specific procedures for measuring lithium distribution within the quartz matrix. Performance evaluation standards must address efficiency measurement under standardized light conditions, temperature coefficient determination, and degradation assessment methodologies.

Certification requirements represent another critical aspect of standardization. Third-party verification systems must be established to validate manufacturer claims regarding lithium quartz performance in photovoltaic applications. These certification processes should include batch testing procedures, statistical sampling methodologies, and clear pass/fail criteria based on established performance thresholds.

Interoperability standards are equally important, ensuring that lithium quartz-based components can function effectively within existing photovoltaic systems. This includes standardized dimensions, electrical connection specifications, and compatibility with common encapsulation materials used in PV module manufacturing.

The development of these standards requires collaborative efforts between material scientists, photovoltaic engineers, manufacturing specialists, and standards organizations. Industry consortia focused on emerging PV materials could serve as effective vehicles for driving standardization initiatives forward, potentially accelerating the commercial adoption of lithium quartz technology in photovoltaic applications.

For lithium quartz specifically, standardization must address several critical parameters: crystal purity, lithium concentration uniformity, optical transmission properties, and electrical conductivity under varying conditions. These parameters directly influence the material's performance in photovoltaic applications and must be measured consistently across the industry to enable meaningful comparisons and quality control.

International standards organizations including IEC (International Electrotechnical Commission) and ISO have begun preliminary work on frameworks for novel PV materials, but lithium quartz remains inadequately covered in existing documentation. This gap necessitates the development of specialized testing protocols that account for the unique properties of lithium-doped quartz structures when used in photovoltaic cells.

Material characterization standards should include X-ray diffraction (XRD) parameters, scanning electron microscopy (SEM) protocols, and specific procedures for measuring lithium distribution within the quartz matrix. Performance evaluation standards must address efficiency measurement under standardized light conditions, temperature coefficient determination, and degradation assessment methodologies.

Certification requirements represent another critical aspect of standardization. Third-party verification systems must be established to validate manufacturer claims regarding lithium quartz performance in photovoltaic applications. These certification processes should include batch testing procedures, statistical sampling methodologies, and clear pass/fail criteria based on established performance thresholds.

Interoperability standards are equally important, ensuring that lithium quartz-based components can function effectively within existing photovoltaic systems. This includes standardized dimensions, electrical connection specifications, and compatibility with common encapsulation materials used in PV module manufacturing.

The development of these standards requires collaborative efforts between material scientists, photovoltaic engineers, manufacturing specialists, and standards organizations. Industry consortia focused on emerging PV materials could serve as effective vehicles for driving standardization initiatives forward, potentially accelerating the commercial adoption of lithium quartz technology in photovoltaic applications.

Environmental Impact Assessment of Lithium Quartz PV Systems

The environmental impact assessment of lithium quartz photovoltaic systems requires a comprehensive analysis of their lifecycle effects on ecosystems, resource consumption, and climate change factors. These systems, while promising for renewable energy generation, present unique environmental considerations that must be carefully evaluated.

The extraction and processing of lithium quartz for photovoltaic applications involves significant land disturbance, water usage, and energy consumption. Mining operations typically require extensive land clearing, which can lead to habitat destruction and biodiversity loss in affected areas. Water consumption is particularly concerning, as lithium extraction often occurs in water-scarce regions, potentially exacerbating local water stress and affecting surrounding communities.

Energy requirements for processing lithium quartz into photovoltaic-grade materials contribute to the carbon footprint of these systems. However, this initial environmental investment must be balanced against the long-term carbon offset achieved during the operational phase of the photovoltaic systems. Life cycle assessment (LCA) studies indicate that lithium quartz PV systems typically achieve energy payback within 1-3 years, depending on geographical location and system efficiency.

Waste management presents another significant environmental challenge. The manufacturing process generates various byproducts and chemical wastes that require proper handling and disposal. Additionally, end-of-life considerations for lithium quartz PV panels must address recycling capabilities and potential leaching of materials into soil and groundwater if improperly disposed of.

Air quality impacts occur primarily during the manufacturing phase, with emissions of particulate matter, volatile organic compounds, and other pollutants. These emissions vary significantly based on manufacturing location and regulatory standards, highlighting the importance of regional environmental governance in determining overall impact.

When benchmarking lithium quartz for photovoltaics, environmental performance metrics should include greenhouse gas emissions per kWh generated, water consumption per unit of production, land use efficiency, toxicity potential, and recyclability rates. These metrics allow for meaningful comparisons with alternative PV technologies and conventional energy sources.

Mitigation strategies to reduce environmental impacts include developing closed-loop water systems for manufacturing, implementing energy-efficient processing techniques, establishing robust recycling programs, and sourcing materials from environmentally responsible suppliers. Continuous monitoring and reporting of environmental performance indicators are essential for transparency and ongoing improvement in the sector.

The extraction and processing of lithium quartz for photovoltaic applications involves significant land disturbance, water usage, and energy consumption. Mining operations typically require extensive land clearing, which can lead to habitat destruction and biodiversity loss in affected areas. Water consumption is particularly concerning, as lithium extraction often occurs in water-scarce regions, potentially exacerbating local water stress and affecting surrounding communities.

Energy requirements for processing lithium quartz into photovoltaic-grade materials contribute to the carbon footprint of these systems. However, this initial environmental investment must be balanced against the long-term carbon offset achieved during the operational phase of the photovoltaic systems. Life cycle assessment (LCA) studies indicate that lithium quartz PV systems typically achieve energy payback within 1-3 years, depending on geographical location and system efficiency.

Waste management presents another significant environmental challenge. The manufacturing process generates various byproducts and chemical wastes that require proper handling and disposal. Additionally, end-of-life considerations for lithium quartz PV panels must address recycling capabilities and potential leaching of materials into soil and groundwater if improperly disposed of.

Air quality impacts occur primarily during the manufacturing phase, with emissions of particulate matter, volatile organic compounds, and other pollutants. These emissions vary significantly based on manufacturing location and regulatory standards, highlighting the importance of regional environmental governance in determining overall impact.

When benchmarking lithium quartz for photovoltaics, environmental performance metrics should include greenhouse gas emissions per kWh generated, water consumption per unit of production, land use efficiency, toxicity potential, and recyclability rates. These metrics allow for meaningful comparisons with alternative PV technologies and conventional energy sources.

Mitigation strategies to reduce environmental impacts include developing closed-loop water systems for manufacturing, implementing energy-efficient processing techniques, establishing robust recycling programs, and sourcing materials from environmentally responsible suppliers. Continuous monitoring and reporting of environmental performance indicators are essential for transparency and ongoing improvement in the sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!