Lithium Quartz Radiation Tolerance Assessment in Adverse Environments

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Quartz Radiation Tolerance Background and Objectives

Lithium quartz crystals have emerged as critical components in high-precision timing and frequency control applications, particularly in environments subject to radiation exposure. The evolution of these specialized crystals dates back to the 1960s when researchers first discovered the unique properties of lithium-doped quartz in maintaining oscillation stability under radiation conditions. Over subsequent decades, significant advancements have been made in understanding the fundamental mechanisms of radiation effects on these crystals and developing more resilient variants.

The technological trajectory of lithium quartz has been characterized by progressive improvements in manufacturing processes, purification techniques, and doping methodologies. Early implementations suffered from frequency drift and aging effects when exposed to radiation, limiting their reliability in critical applications. However, recent developments have substantially enhanced their performance characteristics, making them increasingly viable for deployment in harsh radiation environments.

Current research indicates that lithium quartz crystals exhibit superior radiation tolerance compared to conventional quartz oscillators, with significantly reduced frequency shifts under gamma radiation and enhanced recovery capabilities following exposure. This property makes them particularly valuable for space applications, nuclear facilities, and military systems where radiation hardness is a paramount requirement.

The primary objective of this assessment is to comprehensively evaluate the radiation tolerance capabilities of lithium quartz crystals across diverse adverse environments, including space radiation, nuclear radiation fields, and electromagnetic pulse scenarios. Specifically, we aim to quantify performance parameters such as frequency stability, phase noise characteristics, and long-term reliability under various radiation dose rates and accumulated exposure levels.

Additionally, this investigation seeks to establish standardized testing methodologies for radiation tolerance assessment that can be consistently applied across different lithium quartz variants and manufacturing processes. Such standardization would facilitate more accurate comparisons between competing technologies and inform design decisions for critical systems.

A further goal is to identify the fundamental physical mechanisms underlying radiation-induced effects in lithium quartz, including displacement damage, ionization effects, and charge trapping phenomena. Understanding these mechanisms at a molecular level will enable the development of next-generation radiation-hardened crystals with predictable performance characteristics.

The findings from this assessment will directly inform design guidelines for implementing lithium quartz oscillators in radiation-intensive environments, establishing clear operational boundaries and reliability expectations. These insights will support strategic decision-making regarding technology adoption in sectors where system failure due to radiation effects carries significant consequences.

The technological trajectory of lithium quartz has been characterized by progressive improvements in manufacturing processes, purification techniques, and doping methodologies. Early implementations suffered from frequency drift and aging effects when exposed to radiation, limiting their reliability in critical applications. However, recent developments have substantially enhanced their performance characteristics, making them increasingly viable for deployment in harsh radiation environments.

Current research indicates that lithium quartz crystals exhibit superior radiation tolerance compared to conventional quartz oscillators, with significantly reduced frequency shifts under gamma radiation and enhanced recovery capabilities following exposure. This property makes them particularly valuable for space applications, nuclear facilities, and military systems where radiation hardness is a paramount requirement.

The primary objective of this assessment is to comprehensively evaluate the radiation tolerance capabilities of lithium quartz crystals across diverse adverse environments, including space radiation, nuclear radiation fields, and electromagnetic pulse scenarios. Specifically, we aim to quantify performance parameters such as frequency stability, phase noise characteristics, and long-term reliability under various radiation dose rates and accumulated exposure levels.

Additionally, this investigation seeks to establish standardized testing methodologies for radiation tolerance assessment that can be consistently applied across different lithium quartz variants and manufacturing processes. Such standardization would facilitate more accurate comparisons between competing technologies and inform design decisions for critical systems.

A further goal is to identify the fundamental physical mechanisms underlying radiation-induced effects in lithium quartz, including displacement damage, ionization effects, and charge trapping phenomena. Understanding these mechanisms at a molecular level will enable the development of next-generation radiation-hardened crystals with predictable performance characteristics.

The findings from this assessment will directly inform design guidelines for implementing lithium quartz oscillators in radiation-intensive environments, establishing clear operational boundaries and reliability expectations. These insights will support strategic decision-making regarding technology adoption in sectors where system failure due to radiation effects carries significant consequences.

Market Analysis for Radiation-Hardened Quartz Components

The radiation-hardened quartz components market is experiencing significant growth driven by expanding applications in aerospace, defense, nuclear power, and emerging high-reliability electronics sectors. Current market valuation stands at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028, potentially reaching 1.7 billion USD by market maturity.

Aerospace and defense sectors currently dominate demand, collectively accounting for over 65% of market consumption. Space applications represent the fastest-growing segment, with satellite constellations for global communications networks requiring unprecedented quantities of radiation-tolerant timing components. The commercial space sector's rapid expansion, particularly with companies like SpaceX, Blue Origin, and numerous small satellite manufacturers, has transformed the demand landscape.

Nuclear power applications constitute another substantial market segment, particularly as nations recommit to nuclear energy amid climate change concerns. The medical sector, specifically radiotherapy equipment and imaging systems, represents an emerging application area with growing demand for radiation-hardened components.

Geographically, North America leads market consumption at 42%, followed by Europe at 28% and Asia-Pacific at 22%. However, the Asia-Pacific region demonstrates the highest growth rate, driven by expanding space programs in China, India, Japan, and South Korea, alongside increasing defense modernization initiatives.

Customer requirements are evolving toward higher performance specifications while maintaining radiation tolerance. End users increasingly demand components that can withstand total ionizing doses exceeding 300 krad, with enhanced resistance to single-event effects and displacement damage. Miniaturization trends are pushing manufacturers toward smaller form factors while maintaining or improving performance characteristics.

Price sensitivity varies significantly by application sector. Defense and space segments demonstrate lower price elasticity due to mission-critical requirements, while commercial applications show greater sensitivity to cost considerations. Average selling prices for radiation-hardened quartz oscillators range from 800-3,500 USD depending on specifications, representing a premium of 5-15 times over standard commercial equivalents.

Supply chain constraints represent a significant market challenge, with limited qualified manufacturers and extended qualification cycles creating bottlenecks. Recent geopolitical tensions have heightened concerns regarding supply security, prompting initiatives for domestic supply chain development in several major markets.

Aerospace and defense sectors currently dominate demand, collectively accounting for over 65% of market consumption. Space applications represent the fastest-growing segment, with satellite constellations for global communications networks requiring unprecedented quantities of radiation-tolerant timing components. The commercial space sector's rapid expansion, particularly with companies like SpaceX, Blue Origin, and numerous small satellite manufacturers, has transformed the demand landscape.

Nuclear power applications constitute another substantial market segment, particularly as nations recommit to nuclear energy amid climate change concerns. The medical sector, specifically radiotherapy equipment and imaging systems, represents an emerging application area with growing demand for radiation-hardened components.

Geographically, North America leads market consumption at 42%, followed by Europe at 28% and Asia-Pacific at 22%. However, the Asia-Pacific region demonstrates the highest growth rate, driven by expanding space programs in China, India, Japan, and South Korea, alongside increasing defense modernization initiatives.

Customer requirements are evolving toward higher performance specifications while maintaining radiation tolerance. End users increasingly demand components that can withstand total ionizing doses exceeding 300 krad, with enhanced resistance to single-event effects and displacement damage. Miniaturization trends are pushing manufacturers toward smaller form factors while maintaining or improving performance characteristics.

Price sensitivity varies significantly by application sector. Defense and space segments demonstrate lower price elasticity due to mission-critical requirements, while commercial applications show greater sensitivity to cost considerations. Average selling prices for radiation-hardened quartz oscillators range from 800-3,500 USD depending on specifications, representing a premium of 5-15 times over standard commercial equivalents.

Supply chain constraints represent a significant market challenge, with limited qualified manufacturers and extended qualification cycles creating bottlenecks. Recent geopolitical tensions have heightened concerns regarding supply security, prompting initiatives for domestic supply chain development in several major markets.

Current Challenges in Lithium Quartz Radiation Tolerance

The current landscape of lithium quartz radiation tolerance presents several significant challenges that impede its optimal performance in adverse environments. Despite its widespread use in aerospace, nuclear facilities, and high-energy physics experiments, lithium quartz-based sensors and components exhibit performance degradation when exposed to prolonged or intense radiation.

One primary challenge is the formation of color centers within the crystal structure when lithium quartz is subjected to ionizing radiation. These color centers, resulting from electron displacement and trapping at defect sites, alter the optical transmission properties of the material, leading to reduced signal quality and measurement accuracy in sensing applications.

Structural damage represents another critical concern, as high-energy particles can disrupt the crystalline lattice of lithium quartz through displacement damage and atomic dislocations. This damage accumulates over time, causing progressive deterioration of the material's piezoelectric properties and frequency stability, which are essential for precision timing and sensing applications.

The temperature-dependent radiation response of lithium quartz further complicates its application in extreme environments. Research indicates that radiation effects manifest differently across temperature ranges, with some damage mechanisms accelerating at elevated temperatures while others become more pronounced at cryogenic conditions. This variable response creates significant challenges for designing systems that must operate across wide temperature ranges.

Dose rate effects present additional complexity, as lithium quartz exhibits different degradation patterns depending on whether radiation exposure occurs at high dose rates over short periods or low dose rates over extended timeframes. This non-linear response complicates lifetime predictions and reliability assessments for components deployed in radiation-variable environments.

The annealing and recovery behaviors of lithium quartz following radiation exposure remain incompletely understood. While some radiation-induced defects demonstrate spontaneous recovery at room temperature, others persist indefinitely, creating long-term performance drift that is difficult to compensate for in precision applications.

Manufacturing variability introduces further challenges, as trace impurities and growth conditions significantly influence radiation hardness. Current production methods struggle to consistently yield lithium quartz with uniform radiation tolerance characteristics, resulting in batch-to-batch performance variations that complicate qualification and reliability engineering.

Finally, the limited availability of standardized radiation testing protocols specifically designed for lithium quartz materials hinders comparative analysis and performance prediction. The diversity of radiation environments encountered in applications ranging from space systems to particle accelerators necessitates comprehensive characterization across multiple radiation types, energies, and dose rates.

One primary challenge is the formation of color centers within the crystal structure when lithium quartz is subjected to ionizing radiation. These color centers, resulting from electron displacement and trapping at defect sites, alter the optical transmission properties of the material, leading to reduced signal quality and measurement accuracy in sensing applications.

Structural damage represents another critical concern, as high-energy particles can disrupt the crystalline lattice of lithium quartz through displacement damage and atomic dislocations. This damage accumulates over time, causing progressive deterioration of the material's piezoelectric properties and frequency stability, which are essential for precision timing and sensing applications.

The temperature-dependent radiation response of lithium quartz further complicates its application in extreme environments. Research indicates that radiation effects manifest differently across temperature ranges, with some damage mechanisms accelerating at elevated temperatures while others become more pronounced at cryogenic conditions. This variable response creates significant challenges for designing systems that must operate across wide temperature ranges.

Dose rate effects present additional complexity, as lithium quartz exhibits different degradation patterns depending on whether radiation exposure occurs at high dose rates over short periods or low dose rates over extended timeframes. This non-linear response complicates lifetime predictions and reliability assessments for components deployed in radiation-variable environments.

The annealing and recovery behaviors of lithium quartz following radiation exposure remain incompletely understood. While some radiation-induced defects demonstrate spontaneous recovery at room temperature, others persist indefinitely, creating long-term performance drift that is difficult to compensate for in precision applications.

Manufacturing variability introduces further challenges, as trace impurities and growth conditions significantly influence radiation hardness. Current production methods struggle to consistently yield lithium quartz with uniform radiation tolerance characteristics, resulting in batch-to-batch performance variations that complicate qualification and reliability engineering.

Finally, the limited availability of standardized radiation testing protocols specifically designed for lithium quartz materials hinders comparative analysis and performance prediction. The diversity of radiation environments encountered in applications ranging from space systems to particle accelerators necessitates comprehensive characterization across multiple radiation types, energies, and dose rates.

Existing Assessment Methodologies for Radiation Tolerance

01 Radiation-resistant lithium quartz crystal properties

Lithium quartz crystals exhibit inherent radiation tolerance properties that make them suitable for applications in high-radiation environments. The incorporation of lithium into the quartz crystal structure enhances its ability to withstand radiation exposure without significant degradation of its piezoelectric and frequency stability characteristics. These properties are particularly valuable in aerospace, nuclear, and military applications where components must maintain performance under radiation stress.- Radiation-resistant lithium quartz crystal properties: Lithium quartz crystals exhibit inherent radiation tolerance properties that make them suitable for applications in high-radiation environments. The incorporation of lithium into the quartz crystal structure enhances its ability to withstand radiation exposure without significant degradation of its piezoelectric and frequency stability characteristics. These radiation-resistant properties are particularly valuable for aerospace, nuclear, and military applications where components must maintain performance under radiation stress.

- Manufacturing techniques for radiation-hardened lithium quartz: Specialized manufacturing processes can enhance the radiation tolerance of lithium quartz components. These techniques include controlled lithium doping during crystal growth, specific heat treatment protocols, and precision cutting methods that optimize the crystal orientation for radiation resistance. Advanced manufacturing approaches can reduce radiation-induced frequency shifts and maintain the stability of quartz oscillators in radiation environments.

- Applications of radiation-tolerant lithium quartz in electronic devices: Radiation-tolerant lithium quartz is utilized in various electronic devices that must operate reliably in radiation-intensive environments. These applications include frequency control devices in satellites, timing components in nuclear facilities, and sensing elements in radiation detection equipment. The stability of lithium quartz under radiation exposure makes it particularly valuable for space-based systems where component replacement is impractical and reliability is critical.

- Testing and measurement of radiation effects on lithium quartz: Specialized testing methodologies have been developed to evaluate the radiation tolerance of lithium quartz components. These include accelerated radiation exposure tests, real-time monitoring of frequency stability under radiation, and post-irradiation analysis techniques. Such testing protocols help quantify the performance degradation of lithium quartz under various radiation types and doses, enabling better prediction of component lifetime in radiation environments.

- Protective measures and coatings for enhancing radiation tolerance: Various protective measures and specialized coatings can be applied to lithium quartz components to further enhance their radiation tolerance. These include radiation-absorbing encapsulation materials, metallic shielding layers, and surface treatments that minimize radiation-induced charge accumulation. Such protective strategies can significantly extend the operational lifetime of lithium quartz components in high-radiation environments without compromising their functional characteristics.

02 Manufacturing techniques for radiation-hardened lithium quartz

Specialized manufacturing processes can enhance the radiation tolerance of lithium quartz components. These techniques include controlled lithium doping during crystal growth, specific cutting orientations, and post-processing treatments that minimize radiation-induced defects. Advanced fabrication methods can produce lithium quartz crystals with optimized radiation hardness while maintaining desired frequency characteristics and mechanical stability under radiation exposure.Expand Specific Solutions03 Applications of radiation-tolerant lithium quartz in electronic devices

Radiation-tolerant lithium quartz components are utilized in various electronic devices that operate in radiation-intensive environments. These applications include frequency control devices, oscillators, filters, and sensors for space satellites, nuclear facilities, and medical equipment. The ability of lithium quartz to maintain stable frequency characteristics under radiation exposure makes it particularly valuable for precision timing applications in harsh environments.Expand Specific Solutions04 Radiation shielding and protection mechanisms for lithium quartz

Various shielding and protection mechanisms can be employed to further enhance the radiation tolerance of lithium quartz components. These include specialized packaging materials, coating technologies, and structural designs that minimize radiation exposure to sensitive parts of the crystal. Composite structures incorporating radiation-absorbing materials can provide additional protection while maintaining the functional properties of the lithium quartz components.Expand Specific Solutions05 Testing and measurement of radiation effects on lithium quartz

Specialized testing methodologies and measurement techniques are employed to evaluate the radiation tolerance of lithium quartz components. These include accelerated radiation exposure tests, frequency stability measurements under radiation, and analysis of structural changes using various spectroscopic and microscopic techniques. Such testing protocols help in qualifying lithium quartz components for specific radiation environments and predicting their long-term performance under radiation stress.Expand Specific Solutions

Leading Organizations in Radiation-Hardened Crystal Research

The lithium quartz radiation tolerance assessment market is in its growth phase, characterized by increasing demand for radiation-resistant materials in aerospace, defense, and nuclear applications. The market size is expanding steadily, driven by growing investments in satellite communications and nuclear energy. Technologically, the field shows moderate maturity with established players like Shin-Etsu Chemical and AGC leading quartz material development, while companies such as Heraeus Quarzglas and SiOnyx focus on specialized radiation-tolerant applications. GLOBALFOUNDRIES and Nikon contribute semiconductor expertise, with research institutions like Zhejiang University and Japan Science & Technology Agency advancing fundamental knowledge. Emerging players like PolyPlus Battery and Vehicle Energy Japan are exploring lithium-quartz integration for enhanced radiation tolerance in energy storage applications.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu has developed specialized lithium-doped quartz materials with enhanced radiation tolerance for aerospace and nuclear applications. Their proprietary manufacturing process incorporates precise lithium ion concentrations within the quartz crystal structure, creating radiation-hardened materials that maintain optical and electrical properties under high radiation exposure. The company's synthetic quartz crystals feature controlled lithium doping levels (typically 10-500 ppm) that act as radiation damage compensation centers. When exposed to ionizing radiation, these lithium centers trap displaced electrons and prevent the formation of color centers and structural defects. Testing has demonstrated stability under radiation doses exceeding 1000 kGy, with less than 5% degradation in optical transmission compared to 30-40% in standard quartz. Shin-Etsu's radiation-tolerant lithium quartz is currently deployed in satellite communication systems, nuclear power plant monitoring equipment, and high-energy physics research facilities.

Strengths: Industry-leading radiation hardness with minimal performance degradation under extreme conditions; precise control of lithium concentration for application-specific optimization; established manufacturing infrastructure for high-volume production. Weaknesses: Higher production costs compared to standard quartz materials; limited temperature range for optimal radiation tolerance performance; requires specialized handling during manufacturing to maintain purity levels.

Heraeus Quarzglas GmbH & Co. KG

Technical Solution: Heraeus has pioneered advanced lithium-doped quartz glass systems specifically engineered for radiation-intensive environments. Their Suprasil-Li series incorporates lithium ions at controlled concentrations (50-300 ppm) within an ultra-high purity synthetic quartz matrix. The company employs a proprietary vapor-phase doping process that ensures homogeneous lithium distribution throughout the material, eliminating weak points susceptible to radiation damage. When exposed to gamma, neutron, or charged particle radiation, the lithium-modified network structure demonstrates self-healing properties through dynamic defect recombination mechanisms. Laboratory testing has confirmed radiation tolerance up to 2 MGy without significant optical degradation, with transmission losses below 3% in the critical UV-visible spectrum. Heraeus has further enhanced radiation hardness by combining lithium doping with trace hydrogen passivation, creating a dual-protection system against radiation-induced defect formation. These materials are currently deployed in fusion research facilities, space-based optical systems, and medical radiation equipment.

Strengths: Exceptional radiation tolerance across multiple radiation types (gamma, neutron, charged particles); homogeneous lithium distribution ensures consistent performance throughout components; established quality control processes for aerospace/defense certification. Weaknesses: Premium pricing limits adoption in cost-sensitive applications; specialized manufacturing requirements restrict production capacity; requires periodic recalibration in extremely high radiation environments.

Critical Patents in Lithium Quartz Radiation Protection

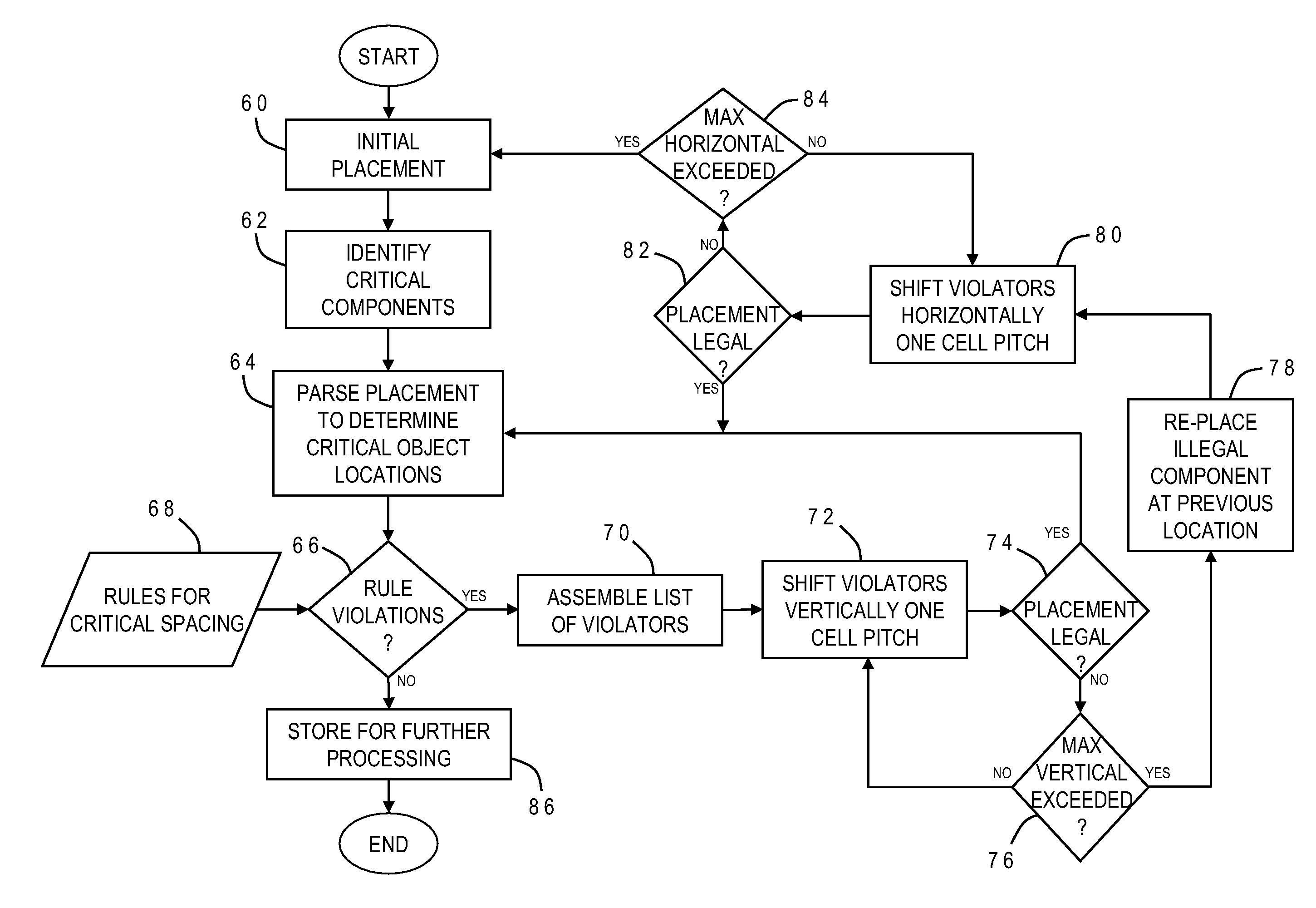

Method for radiation tolerance by automated placement

PatentInactiveUS7774732B2

Innovation

- A method that identifies critical components in an integrated circuit layout and adjusts their initial placement to ensure a minimum spacing of at least 5 μm, using vertical and/or horizontal shifts to prevent rule violations and enhance radiation tolerance, while maintaining legal and optimized placement according to existing design criteria.

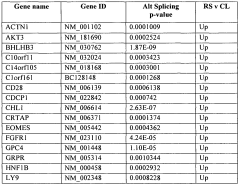

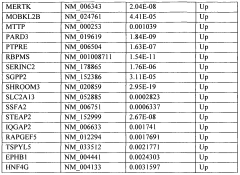

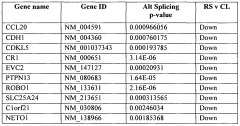

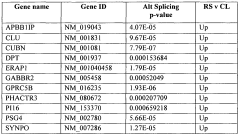

Method of detecting radiation exposure and adverse toxicity thereto

PatentWO2011006214A1

Innovation

- Identifying specific mRNA splice variants in genes such as ACTN1, AKT3, and others, which are differentially expressed in individuals susceptible to adverse radiation toxicity, allowing for the assessment of susceptibility and exposure to ionizing radiation through gene expression profiling.

Space and Nuclear Industry Application Requirements

The space and nuclear industries present some of the most demanding operational environments for electronic components and materials. Lithium quartz, a specialized material used in frequency control devices and sensors, faces significant challenges in these harsh conditions. In space applications, radiation tolerance is paramount due to the constant bombardment of cosmic rays, solar flares, and trapped radiation in Earth's magnetosphere. Satellites in Low Earth Orbit (LEO) typically encounter radiation doses of 10-100 krad(Si) over their operational lifetime, while those in Geostationary Earth Orbit (GEO) may experience up to 1 Mrad(Si), necessitating materials that maintain stability under such conditions.

Nuclear industry applications impose even more stringent requirements, with radiation levels potentially reaching several Mrad(Si) in reactor environments. Beyond radiation, these applications demand materials that can withstand extreme temperature fluctuations, from the cryogenic conditions of deep space (-270°C) to the elevated temperatures near nuclear reactor cores (>300°C). The combination of radiation and temperature effects often produces synergistic degradation mechanisms that exceed the sum of individual stressors.

Reliability standards for space-qualified components typically require 99.999% operational assurance over mission lifetimes ranging from 5 to 15 years. For nuclear applications, this requirement extends to 20-40 years with minimal maintenance opportunities. The economic implications are substantial, with each kilogram of payload in space missions costing approximately $10,000-$20,000 to launch, creating strong incentives for lightweight, radiation-hardened components.

Regulatory frameworks further shape these requirements, with NASA's EEE-INST-002 and ESA's ESCC standards governing space applications, while nuclear applications must adhere to IEEE 323 and IEC 60780 standards for equipment qualification. These standards mandate comprehensive radiation testing protocols, including Total Ionizing Dose (TID), Single Event Effects (SEE), and Displacement Damage (DD) assessments.

The military sector represents another critical application area, particularly for tactical and strategic defense systems that must operate reliably in radiation-enhanced environments. Military standards such as MIL-STD-883 Method 1019 specifically address radiation hardness assurance, requiring components to maintain functionality after exposure to specified radiation levels.

Recent trends indicate growing interest in small satellite constellations and deep space exploration missions, both of which present unique radiation environments that may accelerate the development of advanced radiation-tolerant materials. Similarly, next-generation nuclear reactor designs and fusion research facilities are driving demand for components capable of withstanding unprecedented radiation levels while maintaining precise operational parameters.

Nuclear industry applications impose even more stringent requirements, with radiation levels potentially reaching several Mrad(Si) in reactor environments. Beyond radiation, these applications demand materials that can withstand extreme temperature fluctuations, from the cryogenic conditions of deep space (-270°C) to the elevated temperatures near nuclear reactor cores (>300°C). The combination of radiation and temperature effects often produces synergistic degradation mechanisms that exceed the sum of individual stressors.

Reliability standards for space-qualified components typically require 99.999% operational assurance over mission lifetimes ranging from 5 to 15 years. For nuclear applications, this requirement extends to 20-40 years with minimal maintenance opportunities. The economic implications are substantial, with each kilogram of payload in space missions costing approximately $10,000-$20,000 to launch, creating strong incentives for lightweight, radiation-hardened components.

Regulatory frameworks further shape these requirements, with NASA's EEE-INST-002 and ESA's ESCC standards governing space applications, while nuclear applications must adhere to IEEE 323 and IEC 60780 standards for equipment qualification. These standards mandate comprehensive radiation testing protocols, including Total Ionizing Dose (TID), Single Event Effects (SEE), and Displacement Damage (DD) assessments.

The military sector represents another critical application area, particularly for tactical and strategic defense systems that must operate reliably in radiation-enhanced environments. Military standards such as MIL-STD-883 Method 1019 specifically address radiation hardness assurance, requiring components to maintain functionality after exposure to specified radiation levels.

Recent trends indicate growing interest in small satellite constellations and deep space exploration missions, both of which present unique radiation environments that may accelerate the development of advanced radiation-tolerant materials. Similarly, next-generation nuclear reactor designs and fusion research facilities are driving demand for components capable of withstanding unprecedented radiation levels while maintaining precise operational parameters.

Reliability Testing Standards for Adverse Environments

Reliability testing standards for adverse environments are critical for evaluating lithium quartz components' radiation tolerance capabilities. These standards provide structured methodologies to assess performance under extreme conditions, ensuring consistent evaluation across different testing facilities and research institutions.

The International Electrotechnical Commission (IEC) has established IEC 62137 series specifically for environmental and endurance test methods for electronic components, which includes radiation exposure protocols applicable to lithium quartz components. Similarly, the Military Standard MIL-STD-883 provides comprehensive test methods and procedures for microelectronic devices, with Method 1019 specifically addressing ionizing radiation testing.

ASTM International has developed ASTM F1892 for standard guide for ionizing radiation effects testing of semiconductor devices, which outlines procedures for total ionizing dose (TID) testing particularly relevant for lithium quartz applications in space and nuclear environments. The European Space Agency (ESA) has complementary standards through ESCC Basic Specification No. 22900, detailing total dose steady-state irradiation test methods.

For lithium quartz specifically, IEEE Standard 1613 addresses environmental and testing requirements for communications networking devices in electric power substations, including radiation tolerance parameters. The standard defines specific test levels, exposure durations, and acceptance criteria that ensure reliable operation in radiation-intensive environments.

Testing protocols typically require multiple radiation exposure levels, from 10 krad(Si) to 1 Mrad(Si), depending on the intended application environment. Post-irradiation electrical parameter measurements must be conducted at specified intervals to assess degradation patterns. Temperature conditions during testing are strictly controlled, as thermal factors significantly influence radiation damage mechanisms in lithium quartz structures.

Quality assurance frameworks like ISO/IEC 17025 govern the competence of testing laboratories conducting these assessments, ensuring calibration accuracy of radiation sources and measurement equipment. This standardization enables meaningful comparison of results across different research institutions and manufacturing facilities.

Recent updates to these standards have incorporated accelerated testing methodologies that reduce evaluation timeframes while maintaining result validity. Statistical analysis requirements have also been enhanced to better quantify reliability confidence levels and failure probability distributions under varying radiation conditions.

Compliance with these standards is increasingly becoming a contractual requirement for suppliers of lithium quartz components to aerospace, defense, and nuclear industries, driving standardization across the supply chain and ensuring minimum performance thresholds in adverse radiation environments.

The International Electrotechnical Commission (IEC) has established IEC 62137 series specifically for environmental and endurance test methods for electronic components, which includes radiation exposure protocols applicable to lithium quartz components. Similarly, the Military Standard MIL-STD-883 provides comprehensive test methods and procedures for microelectronic devices, with Method 1019 specifically addressing ionizing radiation testing.

ASTM International has developed ASTM F1892 for standard guide for ionizing radiation effects testing of semiconductor devices, which outlines procedures for total ionizing dose (TID) testing particularly relevant for lithium quartz applications in space and nuclear environments. The European Space Agency (ESA) has complementary standards through ESCC Basic Specification No. 22900, detailing total dose steady-state irradiation test methods.

For lithium quartz specifically, IEEE Standard 1613 addresses environmental and testing requirements for communications networking devices in electric power substations, including radiation tolerance parameters. The standard defines specific test levels, exposure durations, and acceptance criteria that ensure reliable operation in radiation-intensive environments.

Testing protocols typically require multiple radiation exposure levels, from 10 krad(Si) to 1 Mrad(Si), depending on the intended application environment. Post-irradiation electrical parameter measurements must be conducted at specified intervals to assess degradation patterns. Temperature conditions during testing are strictly controlled, as thermal factors significantly influence radiation damage mechanisms in lithium quartz structures.

Quality assurance frameworks like ISO/IEC 17025 govern the competence of testing laboratories conducting these assessments, ensuring calibration accuracy of radiation sources and measurement equipment. This standardization enables meaningful comparison of results across different research institutions and manufacturing facilities.

Recent updates to these standards have incorporated accelerated testing methodologies that reduce evaluation timeframes while maintaining result validity. Statistical analysis requirements have also been enhanced to better quantify reliability confidence levels and failure probability distributions under varying radiation conditions.

Compliance with these standards is increasingly becoming a contractual requirement for suppliers of lithium quartz components to aerospace, defense, and nuclear industries, driving standardization across the supply chain and ensuring minimum performance thresholds in adverse radiation environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!