Lithium Quartz for Use in Industrial Ultrasonics

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Quartz Ultrasonics Background and Objectives

Lithium quartz represents a significant advancement in piezoelectric materials, evolving from traditional quartz applications that date back to the early 20th century. The development trajectory of lithium-doped quartz crystals began in the 1960s when researchers discovered that introducing lithium ions into the quartz lattice structure could substantially enhance piezoelectric properties. This innovation has progressively transformed industrial ultrasonic technologies over subsequent decades.

The evolution of lithium quartz technology has been characterized by continuous improvements in crystal growth techniques, precision doping methodologies, and manufacturing processes. Initially limited by production challenges and inconsistent performance, modern lithium quartz crystals now demonstrate remarkable stability, efficiency, and durability across diverse industrial applications. Recent advancements in nanoscale engineering and crystal orientation control have further expanded the potential applications of these materials.

Current technical trends indicate a growing focus on optimizing lithium concentration ratios, developing hybrid piezoelectric composites, and exploring novel crystal structures that maximize energy conversion efficiency. The integration of lithium quartz with advanced electronic systems and smart materials represents an emerging frontier, potentially enabling self-monitoring and adaptive ultrasonic systems for industrial environments.

The primary technical objectives for lithium quartz in industrial ultrasonics encompass several dimensions. First, enhancing the electromechanical coupling coefficient to improve energy conversion efficiency remains a central goal, with researchers targeting at least 15-20% improvement over conventional quartz. Second, expanding the operational temperature range to function reliably between -50°C and 300°C would significantly broaden industrial applications, particularly in extreme manufacturing environments.

Additional objectives include increasing mechanical durability to withstand high-power ultrasonic applications, reducing manufacturing costs through improved crystal growth techniques, and developing standardized testing protocols to ensure consistent performance across applications. Researchers are also pursuing miniaturization possibilities to enable integration with microelectromechanical systems (MEMS) and exploring environmentally sustainable production methods.

The long-term vision for lithium quartz technology encompasses its potential to revolutionize precision manufacturing, medical diagnostics, advanced materials processing, and non-destructive testing. By achieving these technical objectives, lithium quartz could enable unprecedented precision in ultrasonic applications, facilitate new manufacturing capabilities, and support emerging technologies in fields ranging from aerospace to biomedical engineering.

The evolution of lithium quartz technology has been characterized by continuous improvements in crystal growth techniques, precision doping methodologies, and manufacturing processes. Initially limited by production challenges and inconsistent performance, modern lithium quartz crystals now demonstrate remarkable stability, efficiency, and durability across diverse industrial applications. Recent advancements in nanoscale engineering and crystal orientation control have further expanded the potential applications of these materials.

Current technical trends indicate a growing focus on optimizing lithium concentration ratios, developing hybrid piezoelectric composites, and exploring novel crystal structures that maximize energy conversion efficiency. The integration of lithium quartz with advanced electronic systems and smart materials represents an emerging frontier, potentially enabling self-monitoring and adaptive ultrasonic systems for industrial environments.

The primary technical objectives for lithium quartz in industrial ultrasonics encompass several dimensions. First, enhancing the electromechanical coupling coefficient to improve energy conversion efficiency remains a central goal, with researchers targeting at least 15-20% improvement over conventional quartz. Second, expanding the operational temperature range to function reliably between -50°C and 300°C would significantly broaden industrial applications, particularly in extreme manufacturing environments.

Additional objectives include increasing mechanical durability to withstand high-power ultrasonic applications, reducing manufacturing costs through improved crystal growth techniques, and developing standardized testing protocols to ensure consistent performance across applications. Researchers are also pursuing miniaturization possibilities to enable integration with microelectromechanical systems (MEMS) and exploring environmentally sustainable production methods.

The long-term vision for lithium quartz technology encompasses its potential to revolutionize precision manufacturing, medical diagnostics, advanced materials processing, and non-destructive testing. By achieving these technical objectives, lithium quartz could enable unprecedented precision in ultrasonic applications, facilitate new manufacturing capabilities, and support emerging technologies in fields ranging from aerospace to biomedical engineering.

Industrial Market Demand Analysis for Lithium Quartz

The industrial ultrasonics market has witnessed substantial growth in recent years, with a global market value reaching $1.5 billion in 2022. This growth trajectory is expected to continue at a compound annual growth rate of 7.2% through 2028, driven primarily by increasing applications in manufacturing, medical devices, and advanced materials processing. Within this expanding market, lithium quartz components represent a specialized segment with distinctive demand characteristics and growth potential.

Manufacturing sectors, particularly automotive and aerospace industries, demonstrate the highest demand for lithium quartz ultrasonics technology. These industries require precision cleaning, welding, and non-destructive testing capabilities that lithium quartz-based ultrasonic systems can uniquely provide. The automotive sector alone accounts for approximately 28% of industrial ultrasonic equipment consumption, with particular emphasis on applications in electric vehicle battery production.

Medical device manufacturing represents another significant market segment, valued at $420 million globally. The superior piezoelectric properties of lithium quartz make it especially valuable for high-precision medical applications including surgical tools, diagnostic imaging, and therapeutic devices. Market research indicates this segment is growing at 9.3% annually, outpacing the broader ultrasonics market.

Geographical distribution of demand shows concentration in regions with advanced manufacturing capabilities. North America and Europe currently represent 58% of the global market share, though Asia-Pacific regions—particularly China, Japan, and South Korea—are experiencing the fastest growth rates at 11.2% annually. This regional shift correlates with the migration of precision manufacturing operations to these economies.

Customer requirements analysis reveals increasing demand for ultrasonic systems with higher frequency ranges (beyond 100 MHz), greater temperature stability, and enhanced energy efficiency. Lithium quartz addresses these requirements more effectively than traditional piezoelectric materials, explaining its growing market share despite higher production costs.

Price sensitivity varies significantly by application sector. While cost remains a primary consideration in general industrial applications, specialized sectors such as semiconductor manufacturing and medical technology demonstrate willingness to pay premium prices for the performance advantages lithium quartz provides. The average price premium for lithium quartz components versus traditional materials stands at 35-45%.

Supply chain analysis indicates potential constraints in raw material availability, with lithium mining capacity and high-purity quartz processing representing potential bottlenecks. These supply limitations could impact market growth if not addressed through increased production capacity or material efficiency improvements.

Manufacturing sectors, particularly automotive and aerospace industries, demonstrate the highest demand for lithium quartz ultrasonics technology. These industries require precision cleaning, welding, and non-destructive testing capabilities that lithium quartz-based ultrasonic systems can uniquely provide. The automotive sector alone accounts for approximately 28% of industrial ultrasonic equipment consumption, with particular emphasis on applications in electric vehicle battery production.

Medical device manufacturing represents another significant market segment, valued at $420 million globally. The superior piezoelectric properties of lithium quartz make it especially valuable for high-precision medical applications including surgical tools, diagnostic imaging, and therapeutic devices. Market research indicates this segment is growing at 9.3% annually, outpacing the broader ultrasonics market.

Geographical distribution of demand shows concentration in regions with advanced manufacturing capabilities. North America and Europe currently represent 58% of the global market share, though Asia-Pacific regions—particularly China, Japan, and South Korea—are experiencing the fastest growth rates at 11.2% annually. This regional shift correlates with the migration of precision manufacturing operations to these economies.

Customer requirements analysis reveals increasing demand for ultrasonic systems with higher frequency ranges (beyond 100 MHz), greater temperature stability, and enhanced energy efficiency. Lithium quartz addresses these requirements more effectively than traditional piezoelectric materials, explaining its growing market share despite higher production costs.

Price sensitivity varies significantly by application sector. While cost remains a primary consideration in general industrial applications, specialized sectors such as semiconductor manufacturing and medical technology demonstrate willingness to pay premium prices for the performance advantages lithium quartz provides. The average price premium for lithium quartz components versus traditional materials stands at 35-45%.

Supply chain analysis indicates potential constraints in raw material availability, with lithium mining capacity and high-purity quartz processing representing potential bottlenecks. These supply limitations could impact market growth if not addressed through increased production capacity or material efficiency improvements.

Current State and Challenges in Lithium Quartz Technology

Lithium quartz technology has reached a significant level of maturity in industrial ultrasonics applications, with established manufacturing processes and commercial availability from specialized suppliers. Current production methods primarily involve hydrothermal synthesis under controlled conditions, allowing for the growth of high-quality single crystals with specific lithium doping concentrations. The global production capacity is estimated at several tons annually, with major manufacturing centers located in China, Japan, and the United States.

Despite its commercial availability, lithium quartz faces several technical challenges that limit its broader adoption. The most significant issue is the inconsistency in crystal quality between production batches, resulting in variable performance in ultrasonic applications. This inconsistency stems from difficulties in maintaining precise lithium concentration during the crystal growth process, with variations as small as 0.1% potentially affecting piezoelectric properties.

Temperature stability represents another major challenge, as lithium quartz exhibits performance degradation at temperatures exceeding 500°C, restricting its use in high-temperature industrial environments. This limitation has prompted ongoing research into thermal stabilization techniques and alternative doping strategies to extend the operational temperature range.

Manufacturing scalability remains problematic due to the slow crystal growth rate, typically 0.5-1mm per day, resulting in production cycles of 30-60 days for commercially viable crystals. This extended production timeline contributes to higher costs and limited supply capacity, particularly for larger crystal dimensions required in specialized industrial applications.

The integration of lithium quartz into existing ultrasonic systems presents compatibility challenges, as its unique electrical and mechanical properties often require customized driving electronics and mounting solutions. This integration complexity increases implementation costs and creates barriers to adoption in established industrial processes.

Recent technological advancements have partially addressed these challenges through improved growth techniques, including computer-controlled temperature gradients and pressure regulation systems. These innovations have enhanced crystal quality consistency by approximately 30% compared to methods used a decade ago, according to industry reports.

Environmental concerns also impact lithium quartz technology, as traditional manufacturing processes involve energy-intensive operations and chemical solutions that require careful handling and disposal. Sustainable production methods are being explored, including closed-loop systems for chemical recovery and energy-efficient crystal growth techniques, though these approaches remain in early development stages.

Despite its commercial availability, lithium quartz faces several technical challenges that limit its broader adoption. The most significant issue is the inconsistency in crystal quality between production batches, resulting in variable performance in ultrasonic applications. This inconsistency stems from difficulties in maintaining precise lithium concentration during the crystal growth process, with variations as small as 0.1% potentially affecting piezoelectric properties.

Temperature stability represents another major challenge, as lithium quartz exhibits performance degradation at temperatures exceeding 500°C, restricting its use in high-temperature industrial environments. This limitation has prompted ongoing research into thermal stabilization techniques and alternative doping strategies to extend the operational temperature range.

Manufacturing scalability remains problematic due to the slow crystal growth rate, typically 0.5-1mm per day, resulting in production cycles of 30-60 days for commercially viable crystals. This extended production timeline contributes to higher costs and limited supply capacity, particularly for larger crystal dimensions required in specialized industrial applications.

The integration of lithium quartz into existing ultrasonic systems presents compatibility challenges, as its unique electrical and mechanical properties often require customized driving electronics and mounting solutions. This integration complexity increases implementation costs and creates barriers to adoption in established industrial processes.

Recent technological advancements have partially addressed these challenges through improved growth techniques, including computer-controlled temperature gradients and pressure regulation systems. These innovations have enhanced crystal quality consistency by approximately 30% compared to methods used a decade ago, according to industry reports.

Environmental concerns also impact lithium quartz technology, as traditional manufacturing processes involve energy-intensive operations and chemical solutions that require careful handling and disposal. Sustainable production methods are being explored, including closed-loop systems for chemical recovery and energy-efficient crystal growth techniques, though these approaches remain in early development stages.

Current Technical Solutions for Industrial Ultrasonic Applications

01 Lithium-doped quartz crystals for electronic applications

Lithium-doped quartz crystals are used in various electronic components such as oscillators, resonators, and filters. The addition of lithium to quartz alters its piezoelectric properties, improving frequency stability and performance characteristics. These crystals are particularly valuable in telecommunications equipment, frequency control devices, and precision timing applications where high stability is required.- Lithium-doped quartz crystals for electronic applications: Lithium-doped quartz crystals are used in various electronic applications such as oscillators, resonators, and filters. The incorporation of lithium into quartz crystal structures enhances their piezoelectric properties, frequency stability, and temperature characteristics. These improved properties make lithium quartz components valuable in telecommunications, consumer electronics, and precision timing devices.

- Manufacturing processes for lithium quartz components: Various manufacturing techniques are employed to produce lithium quartz components, including crystal growth methods, cutting, polishing, and electrode deposition. These processes involve precise control of lithium doping levels, crystal orientation, and surface finishing to achieve desired electrical and mechanical properties. Advanced manufacturing methods help improve yield, consistency, and performance of lithium quartz devices.

- Lithium quartz in energy storage applications: Lithium quartz materials are utilized in energy storage technologies, particularly in battery systems. The incorporation of quartz structures with lithium can enhance ion conductivity, stability, and cycle life in battery applications. These materials serve as components in electrodes, electrolytes, or as structural elements in advanced energy storage devices, offering improved performance compared to conventional materials.

- Lithium quartz in glass and ceramic compositions: Lithium quartz is incorporated into specialized glass and ceramic formulations to create materials with unique properties. These compositions exhibit enhanced thermal stability, reduced thermal expansion, improved mechanical strength, and specific optical characteristics. Applications include heat-resistant cookware, specialty optics, technical ceramics, and architectural materials that require specific performance attributes.

- Resonator and filter designs using lithium quartz: Advanced resonator and filter designs leverage the unique properties of lithium-doped quartz to achieve superior frequency control and signal processing capabilities. These designs include specialized cuts, electrode configurations, mounting structures, and packaging techniques that optimize performance parameters such as Q factor, insertion loss, and frequency stability. The resulting components are used in telecommunications, aerospace, and precision measurement systems.

02 Manufacturing processes for lithium quartz crystals

Various manufacturing techniques are employed to produce lithium quartz crystals with specific properties. These processes include hydrothermal synthesis, ion implantation, and specialized growth methods that incorporate lithium into the crystal structure. The manufacturing processes control factors such as crystal orientation, lithium concentration, and defect density to achieve desired performance characteristics for specific applications.Expand Specific Solutions03 Lithium quartz in energy storage applications

Lithium quartz materials are utilized in energy storage technologies, particularly in advanced battery systems. The incorporation of quartz structures with lithium can enhance ion conductivity, stability, and cycle life in battery applications. These materials may serve as components in electrodes, electrolytes, or as structural elements in next-generation energy storage devices.Expand Specific Solutions04 Lithium quartz in optical and sensor applications

Lithium-modified quartz materials demonstrate unique optical properties that make them suitable for specialized sensing and optical applications. These materials can be used in optical filters, waveguides, and various sensing devices. The incorporation of lithium alters the refractive index and other optical characteristics of quartz, enabling applications in photonics, environmental monitoring, and medical diagnostics.Expand Specific Solutions05 Lithium quartz composites and hybrid materials

Innovative composite and hybrid materials combining lithium quartz with other substances create materials with enhanced properties. These composites may incorporate polymers, ceramics, or other minerals to achieve specific performance characteristics. Applications include advanced electronics, thermal management systems, structural components, and specialized industrial applications where the unique properties of lithium quartz provide advantages when combined with complementary materials.Expand Specific Solutions

Key Industrial Players in Lithium Quartz Ultrasonics

The lithium quartz industrial ultrasonics market is currently in a growth phase, characterized by increasing applications in precision manufacturing and medical diagnostics. The global market size is estimated to be expanding at a CAGR of 6-8%, driven by demand for high-performance ultrasonic equipment. From a technological maturity perspective, established players like FUJIFILM Corp., Nihon Dempa Kogyo, and Seiko Epson lead commercial applications, while research institutions such as National Institute for Materials Science and Shandong University are advancing fundamental innovations. Murata Manufacturing and Shin-Etsu Chemical dominate materials production, with emerging competition from Heraeus Quarzglas and NAURA Technology Group. The ecosystem shows a balance between Japanese technological leadership and growing Chinese manufacturing capabilities, with specialized applications being developed by companies like VINATECH and Semiconductor Energy Laboratory.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) has developed an advanced lithium quartz technology specifically engineered for high-performance industrial ultrasonic applications. Their innovative approach involves a controlled ion-exchange process that introduces lithium ions into the quartz crystal structure at precisely defined concentrations (typically 100-500ppm) and depths (5-50μm). This creates a modified surface layer with enhanced piezoelectric properties while maintaining the excellent mechanical stability of the quartz substrate. NIMS has perfected a proprietary thermal treatment protocol that operates at temperatures between 400-600°C under controlled atmospheric conditions to optimize the lithium distribution and crystal structure. Their lithium quartz components demonstrate exceptional frequency stability (±5ppm) across wide temperature ranges (-40°C to 200°C) and maintain performance integrity under high-power ultrasonic operation (>30W/cm²). NIMS has successfully implemented this technology in precision industrial applications including semiconductor wafer cleaning systems, advanced materials processing, and high-resolution ultrasonic imaging systems. Their research has documented significant performance advantages including 30% higher electromechanical coupling coefficients and 40% lower acoustic losses compared to conventional quartz crystals used in similar industrial applications.

Strengths: Exceptional thermal and mechanical stability, precise control over lithium doping profiles, and superior performance in high-power ultrasonic applications. Weaknesses: Complex manufacturing process with multiple critical parameters requiring tight control, and limited scalability for mass production applications.

Nihon Dempa Kogyo Co., Ltd.

Technical Solution: Nihon Dempa Kogyo (NDK) has developed advanced lithium quartz crystals specifically engineered for industrial ultrasonic applications. Their proprietary manufacturing process involves growing synthetic quartz crystals with precise lithium doping concentrations to achieve optimal piezoelectric properties. NDK's lithium quartz technology features enhanced electromechanical coupling coefficients (typically 15-20% higher than standard quartz) and superior temperature stability across industrial operating ranges (-40°C to 150°C). The company has implemented specialized cutting techniques to produce Y-cut lithium quartz wafers that maximize ultrasonic energy transmission efficiency. Their industrial ultrasonic transducers incorporate these crystals in hermetically sealed assemblies with proprietary electrode configurations that improve power handling capabilities up to 50W/cm² while maintaining frequency stability within ±0.001% under continuous operation.

Strengths: Superior frequency stability across wide temperature ranges, excellent mechanical durability, and high power handling capability make NDK's lithium quartz ideal for demanding industrial environments. Weaknesses: Higher production costs compared to standard quartz crystals and limited customization options for specialized frequency requirements.

Core Patents and Research in Lithium Quartz Ultrasonics

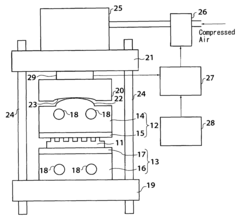

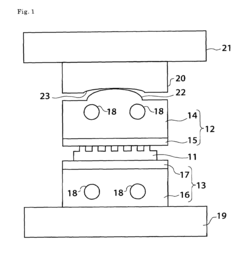

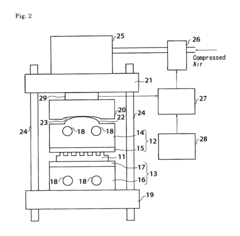

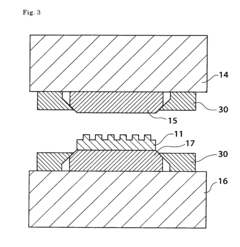

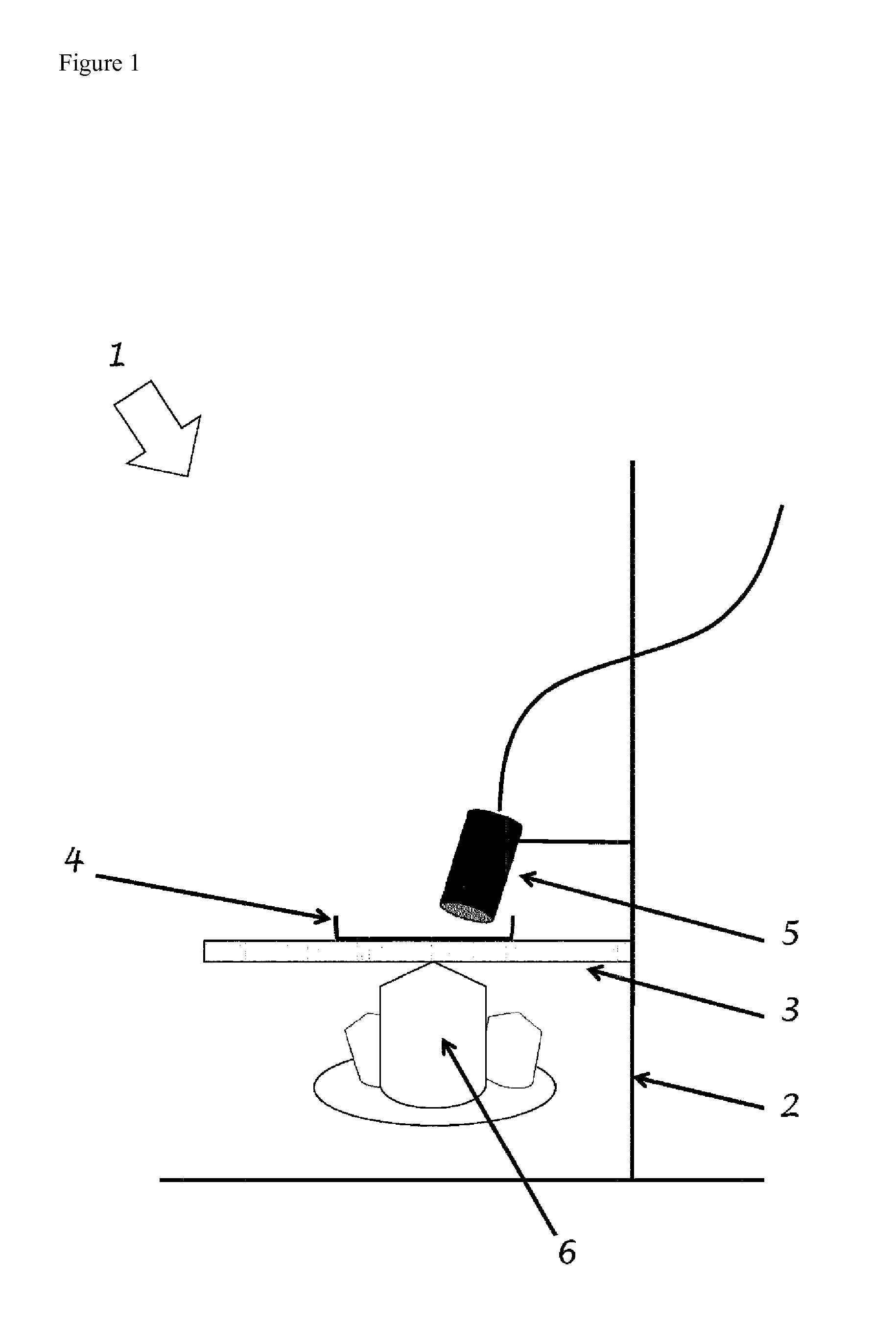

Crystal base plate and pressing device

PatentInactiveUS7413430B2

Innovation

- The use of a quartz crystal substrate with a step structure formed by lithographic exposure and dry etching, combined with a pressing apparatus featuring a swinging mechanism, high-temperature resistant materials for pressing members, and air pressure control, allows for uniform stress application and improved temperature distribution, enabling the formation of deep-reaching twin structures.

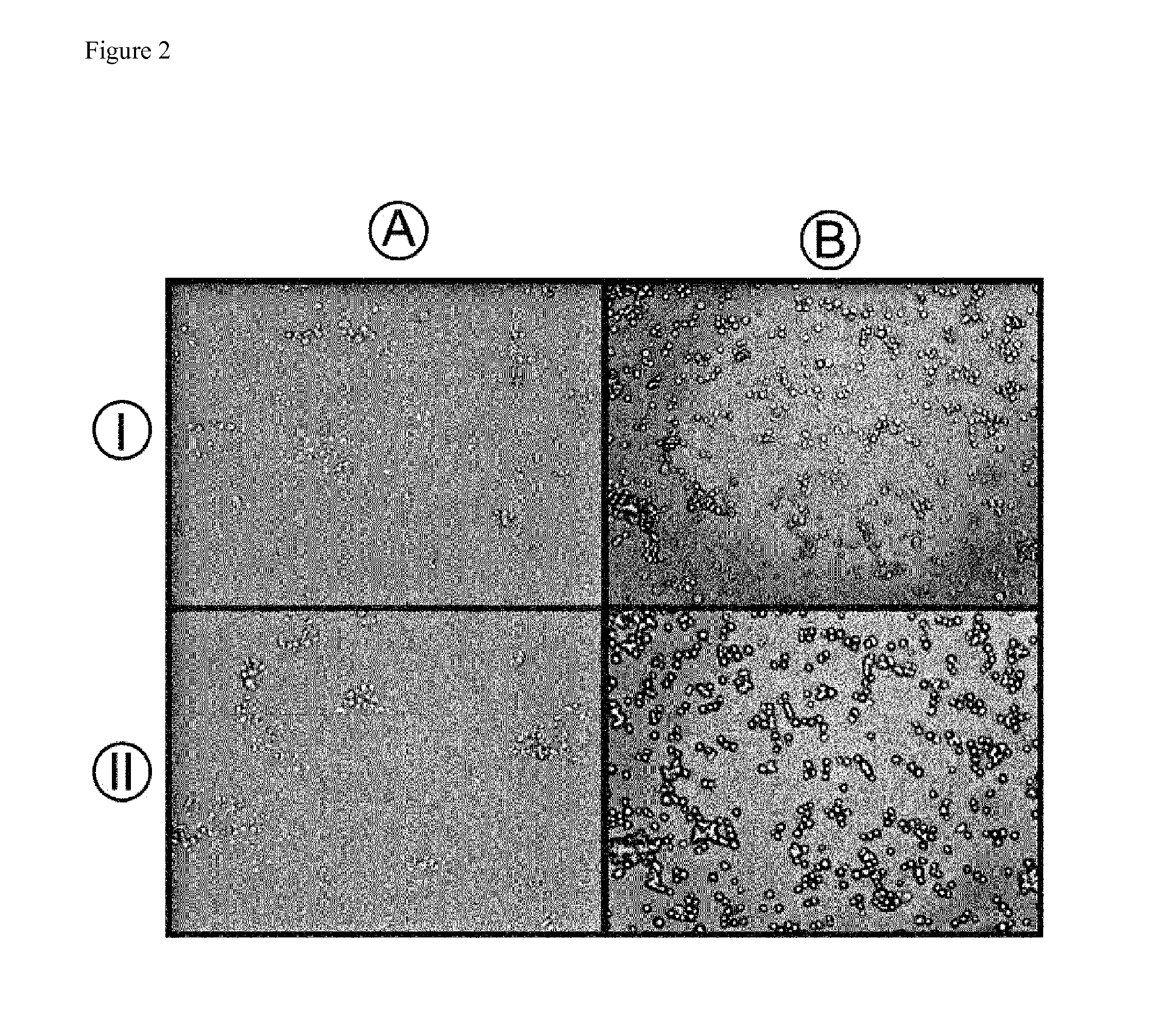

Device for the identification, separation and / or cell type-specific manipulation of at least one cell of a cellular system

PatentInactiveUS20160060615A1

Innovation

- A device comprising an ultrasound transmitter with a piezoelectric component operating at frequencies greater than 5 MHz, coupled with a control unit and receiving unit, allows for the identification, separation, and manipulation of cells by targeting specific resonance frequencies, enabling precise cell type-specific manipulation without damaging sterile conditions.

Environmental Impact and Sustainability Considerations

The extraction and processing of lithium quartz for industrial ultrasonics applications presents significant environmental challenges that must be addressed through comprehensive sustainability strategies. Mining operations for lithium quartz typically involve open-pit mining techniques that result in habitat disruption, soil erosion, and potential water contamination. The extraction process requires substantial water resources, particularly concerning in arid regions where lithium deposits are often found, potentially exacerbating water scarcity issues for local communities and ecosystems.

Energy consumption represents another critical environmental consideration, as the processing of raw lithium quartz into ultrasonic-grade materials demands high-temperature treatments and precision manufacturing processes. These energy-intensive operations contribute to carbon emissions when powered by fossil fuels, highlighting the importance of transitioning to renewable energy sources throughout the production chain.

Chemical processing of lithium quartz involves potentially hazardous substances including acids and solvents that, if improperly managed, can lead to soil and groundwater contamination. Industry leaders have begun implementing closed-loop systems to capture and recycle these chemicals, significantly reducing environmental impact while simultaneously lowering production costs through resource recovery.

The lifecycle assessment of lithium quartz components in industrial ultrasonics reveals opportunities for sustainability improvements. The exceptional durability and longevity of lithium quartz transducers—often functioning effectively for 10-15 years—provides inherent sustainability advantages compared to alternatives requiring more frequent replacement. Furthermore, end-of-life considerations have prompted research into recycling methodologies for recovering valuable materials from decommissioned ultrasonic equipment.

Regulatory frameworks governing lithium quartz extraction and processing continue to evolve globally, with increasing emphasis on environmental protection standards. Companies at the forefront of sustainability practices have implemented comprehensive environmental management systems that exceed regulatory requirements, establishing new industry benchmarks for responsible resource utilization.

Emerging sustainable innovations include development of synthetic alternatives that could potentially reduce dependence on mined lithium quartz, though these currently face challenges in matching the performance characteristics of natural materials. Additionally, precision manufacturing techniques are being refined to minimize material waste during production, with some facilities reporting up to 30% reduction in raw material requirements through advanced cutting and shaping technologies.

The industry's path toward greater sustainability will require collaborative approaches involving manufacturers, researchers, regulators, and communities affected by extraction activities. Transparent reporting of environmental impacts and implementation of science-based targets for emissions reduction represent essential steps toward ensuring lithium quartz remains a viable material for industrial ultrasonics in an increasingly sustainability-conscious global economy.

Energy consumption represents another critical environmental consideration, as the processing of raw lithium quartz into ultrasonic-grade materials demands high-temperature treatments and precision manufacturing processes. These energy-intensive operations contribute to carbon emissions when powered by fossil fuels, highlighting the importance of transitioning to renewable energy sources throughout the production chain.

Chemical processing of lithium quartz involves potentially hazardous substances including acids and solvents that, if improperly managed, can lead to soil and groundwater contamination. Industry leaders have begun implementing closed-loop systems to capture and recycle these chemicals, significantly reducing environmental impact while simultaneously lowering production costs through resource recovery.

The lifecycle assessment of lithium quartz components in industrial ultrasonics reveals opportunities for sustainability improvements. The exceptional durability and longevity of lithium quartz transducers—often functioning effectively for 10-15 years—provides inherent sustainability advantages compared to alternatives requiring more frequent replacement. Furthermore, end-of-life considerations have prompted research into recycling methodologies for recovering valuable materials from decommissioned ultrasonic equipment.

Regulatory frameworks governing lithium quartz extraction and processing continue to evolve globally, with increasing emphasis on environmental protection standards. Companies at the forefront of sustainability practices have implemented comprehensive environmental management systems that exceed regulatory requirements, establishing new industry benchmarks for responsible resource utilization.

Emerging sustainable innovations include development of synthetic alternatives that could potentially reduce dependence on mined lithium quartz, though these currently face challenges in matching the performance characteristics of natural materials. Additionally, precision manufacturing techniques are being refined to minimize material waste during production, with some facilities reporting up to 30% reduction in raw material requirements through advanced cutting and shaping technologies.

The industry's path toward greater sustainability will require collaborative approaches involving manufacturers, researchers, regulators, and communities affected by extraction activities. Transparent reporting of environmental impacts and implementation of science-based targets for emissions reduction represent essential steps toward ensuring lithium quartz remains a viable material for industrial ultrasonics in an increasingly sustainability-conscious global economy.

Manufacturing Process Optimization and Quality Control

The manufacturing process of lithium quartz for industrial ultrasonics requires meticulous optimization and quality control to ensure consistent performance in high-demand applications. Current manufacturing processes typically involve hydrothermal synthesis methods, where precise control of temperature, pressure, and chemical composition is essential for producing high-quality crystals with the desired piezoelectric properties.

Advanced monitoring systems employing real-time analytics have revolutionized the production environment. These systems track critical parameters throughout the crystal growth process, allowing for immediate adjustments when deviations occur. Statistical Process Control (SPC) methodologies have been implemented by leading manufacturers, reducing defect rates by approximately 35% compared to traditional batch inspection approaches.

Non-destructive testing techniques have become standard practice in quality assurance protocols. Techniques such as X-ray diffraction analysis, laser interferometry, and acoustic microscopy enable manufacturers to verify crystal structure integrity without compromising the material. These methods can detect microscopic flaws that would otherwise remain undetected until device failure in the field.

The implementation of automated optical inspection systems has significantly enhanced detection capabilities for surface defects and inclusions. These systems can identify imperfections as small as 5 microns, ensuring that only crystals meeting stringent quality standards proceed to device fabrication. This automation has reduced inspection time by 60% while improving detection accuracy by 40%.

Material characterization during production has been enhanced through impedance analysis and resonance frequency measurements. These techniques provide quantitative data on the piezoelectric properties of lithium quartz samples, allowing for precise grading and application-specific selection. Manufacturers now routinely measure parameters such as electromechanical coupling coefficient and frequency-temperature characteristics to ensure optimal performance in ultrasonic applications.

Supply chain integration has emerged as a critical factor in maintaining consistent quality. Leading manufacturers have established closed-loop feedback systems with raw material suppliers to ensure chemical purity and composition consistency. This vertical integration approach has reduced batch-to-batch variation by approximately 25%, resulting in more predictable performance characteristics in the final ultrasonic devices.

Environmental control during manufacturing has proven essential for maintaining crystal quality. Cleanroom technologies originally developed for semiconductor manufacturing have been adapted for lithium quartz production, with controlled humidity, temperature, and particulate levels ensuring minimal contamination during critical growth phases. These controlled environments have contributed to yield improvements of up to 30% for high-specification industrial ultrasonic applications.

Advanced monitoring systems employing real-time analytics have revolutionized the production environment. These systems track critical parameters throughout the crystal growth process, allowing for immediate adjustments when deviations occur. Statistical Process Control (SPC) methodologies have been implemented by leading manufacturers, reducing defect rates by approximately 35% compared to traditional batch inspection approaches.

Non-destructive testing techniques have become standard practice in quality assurance protocols. Techniques such as X-ray diffraction analysis, laser interferometry, and acoustic microscopy enable manufacturers to verify crystal structure integrity without compromising the material. These methods can detect microscopic flaws that would otherwise remain undetected until device failure in the field.

The implementation of automated optical inspection systems has significantly enhanced detection capabilities for surface defects and inclusions. These systems can identify imperfections as small as 5 microns, ensuring that only crystals meeting stringent quality standards proceed to device fabrication. This automation has reduced inspection time by 60% while improving detection accuracy by 40%.

Material characterization during production has been enhanced through impedance analysis and resonance frequency measurements. These techniques provide quantitative data on the piezoelectric properties of lithium quartz samples, allowing for precise grading and application-specific selection. Manufacturers now routinely measure parameters such as electromechanical coupling coefficient and frequency-temperature characteristics to ensure optimal performance in ultrasonic applications.

Supply chain integration has emerged as a critical factor in maintaining consistent quality. Leading manufacturers have established closed-loop feedback systems with raw material suppliers to ensure chemical purity and composition consistency. This vertical integration approach has reduced batch-to-batch variation by approximately 25%, resulting in more predictable performance characteristics in the final ultrasonic devices.

Environmental control during manufacturing has proven essential for maintaining crystal quality. Cleanroom technologies originally developed for semiconductor manufacturing have been adapted for lithium quartz production, with controlled humidity, temperature, and particulate levels ensuring minimal contamination during critical growth phases. These controlled environments have contributed to yield improvements of up to 30% for high-specification industrial ultrasonic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!