Measure Thermal Conductivity of Lithium Quartz

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Quartz Thermal Conductivity Background and Objectives

Lithium quartz, a specialized form of quartz crystal containing lithium ions, has gained significant attention in various high-tech applications due to its unique thermal properties. The thermal conductivity of lithium quartz represents a critical parameter that influences its performance in electronic components, optical devices, and energy storage systems. Understanding this property has become increasingly important as industries push toward miniaturization and enhanced efficiency in their technological solutions.

The evolution of lithium quartz applications can be traced back to the mid-20th century, with initial interest primarily in its piezoelectric properties. However, as electronic devices became more compact and powerful, heat management emerged as a crucial challenge, bringing thermal conductivity considerations to the forefront. The thermal behavior of lithium quartz differs significantly from standard quartz due to the presence of lithium ions within the crystal structure, creating unique phonon scattering mechanisms that affect heat transfer.

Recent technological trends indicate a growing demand for precise thermal conductivity measurements of lithium quartz across varying temperatures, pressures, and crystallographic orientations. This demand stems from the material's potential applications in quantum computing components, advanced sensor technologies, and next-generation semiconductor substrates where thermal management is paramount.

The primary objective of investigating lithium quartz thermal conductivity is to establish comprehensive characterization methodologies that can accurately measure this property under various environmental conditions. This includes developing standardized measurement protocols that account for the anisotropic nature of heat transfer in lithium quartz crystals, as well as understanding how dopant concentration affects thermal performance.

Secondary objectives include mapping the relationship between crystal growth conditions and resulting thermal properties, identifying optimal lithium concentration levels for specific applications, and creating predictive models that can estimate thermal conductivity based on material composition and structure. These models would significantly reduce the experimental burden in material development cycles.

Long-term goals extend to engineering lithium quartz variants with tailored thermal conductivity profiles for specific industrial applications. This includes developing materials with directionally-controlled heat transfer capabilities, temperature-responsive thermal behavior, or enhanced stability under extreme conditions. Such advancements could revolutionize thermal management strategies in next-generation electronics and energy systems.

The technological significance of this research extends beyond immediate applications, potentially enabling breakthroughs in quantum technologies, high-efficiency energy conversion systems, and ultra-precise sensing devices where thermal properties play a decisive role in overall performance and reliability.

The evolution of lithium quartz applications can be traced back to the mid-20th century, with initial interest primarily in its piezoelectric properties. However, as electronic devices became more compact and powerful, heat management emerged as a crucial challenge, bringing thermal conductivity considerations to the forefront. The thermal behavior of lithium quartz differs significantly from standard quartz due to the presence of lithium ions within the crystal structure, creating unique phonon scattering mechanisms that affect heat transfer.

Recent technological trends indicate a growing demand for precise thermal conductivity measurements of lithium quartz across varying temperatures, pressures, and crystallographic orientations. This demand stems from the material's potential applications in quantum computing components, advanced sensor technologies, and next-generation semiconductor substrates where thermal management is paramount.

The primary objective of investigating lithium quartz thermal conductivity is to establish comprehensive characterization methodologies that can accurately measure this property under various environmental conditions. This includes developing standardized measurement protocols that account for the anisotropic nature of heat transfer in lithium quartz crystals, as well as understanding how dopant concentration affects thermal performance.

Secondary objectives include mapping the relationship between crystal growth conditions and resulting thermal properties, identifying optimal lithium concentration levels for specific applications, and creating predictive models that can estimate thermal conductivity based on material composition and structure. These models would significantly reduce the experimental burden in material development cycles.

Long-term goals extend to engineering lithium quartz variants with tailored thermal conductivity profiles for specific industrial applications. This includes developing materials with directionally-controlled heat transfer capabilities, temperature-responsive thermal behavior, or enhanced stability under extreme conditions. Such advancements could revolutionize thermal management strategies in next-generation electronics and energy systems.

The technological significance of this research extends beyond immediate applications, potentially enabling breakthroughs in quantum technologies, high-efficiency energy conversion systems, and ultra-precise sensing devices where thermal properties play a decisive role in overall performance and reliability.

Market Applications and Demand Analysis

The thermal conductivity measurement of lithium quartz has garnered significant attention across multiple industries due to its unique thermal properties and potential applications. The global market for advanced materials with precisely characterized thermal properties is experiencing robust growth, driven by increasing demands in electronics, energy storage, and high-performance computing sectors.

In the electronics industry, the accurate measurement of lithium quartz thermal conductivity has become crucial for the development of next-generation semiconductor devices. As chip designs continue to shrink while processing power increases, thermal management has emerged as a critical bottleneck. Companies developing thermal interface materials and heat dissipation solutions require precise thermal conductivity data to optimize their products, creating a substantial market demand for accurate measurement technologies.

The renewable energy sector represents another significant market for lithium quartz thermal conductivity measurement. Solar panel manufacturers are particularly interested in materials with well-characterized thermal properties to improve efficiency and longevity of photovoltaic cells. The growing global solar capacity, which exceeded 1 terawatt in 2022, continues to drive demand for advanced materials testing and characterization.

Aerospace and defense industries have also emerged as key consumers of thermal conductivity measurement technologies. The extreme operating conditions of aerospace components necessitate materials with precisely understood thermal behaviors. Lithium quartz, with its stability at high temperatures and potential applications in specialized sensors and components, requires accurate thermal conductivity measurement to meet stringent industry specifications.

The medical device industry presents a growing application area, particularly for implantable devices where thermal management is critical. Understanding the thermal conductivity of lithium quartz enables better design of devices that must maintain specific temperature ranges within the human body, representing a niche but high-value market segment.

Market analysis indicates that the global thermal analysis equipment market, which includes thermal conductivity measurement instruments, is projected to grow substantially through 2030. This growth is particularly pronounced in regions with strong research and manufacturing bases in electronics and advanced materials, including East Asia, North America, and Western Europe.

The demand for standardized, reliable measurement protocols for thermal conductivity of specialized materials like lithium quartz is also increasing among research institutions and materials science laboratories. This trend is reinforced by the growing emphasis on reproducible research and the need for comparable data across different research groups and industrial applications.

In the electronics industry, the accurate measurement of lithium quartz thermal conductivity has become crucial for the development of next-generation semiconductor devices. As chip designs continue to shrink while processing power increases, thermal management has emerged as a critical bottleneck. Companies developing thermal interface materials and heat dissipation solutions require precise thermal conductivity data to optimize their products, creating a substantial market demand for accurate measurement technologies.

The renewable energy sector represents another significant market for lithium quartz thermal conductivity measurement. Solar panel manufacturers are particularly interested in materials with well-characterized thermal properties to improve efficiency and longevity of photovoltaic cells. The growing global solar capacity, which exceeded 1 terawatt in 2022, continues to drive demand for advanced materials testing and characterization.

Aerospace and defense industries have also emerged as key consumers of thermal conductivity measurement technologies. The extreme operating conditions of aerospace components necessitate materials with precisely understood thermal behaviors. Lithium quartz, with its stability at high temperatures and potential applications in specialized sensors and components, requires accurate thermal conductivity measurement to meet stringent industry specifications.

The medical device industry presents a growing application area, particularly for implantable devices where thermal management is critical. Understanding the thermal conductivity of lithium quartz enables better design of devices that must maintain specific temperature ranges within the human body, representing a niche but high-value market segment.

Market analysis indicates that the global thermal analysis equipment market, which includes thermal conductivity measurement instruments, is projected to grow substantially through 2030. This growth is particularly pronounced in regions with strong research and manufacturing bases in electronics and advanced materials, including East Asia, North America, and Western Europe.

The demand for standardized, reliable measurement protocols for thermal conductivity of specialized materials like lithium quartz is also increasing among research institutions and materials science laboratories. This trend is reinforced by the growing emphasis on reproducible research and the need for comparable data across different research groups and industrial applications.

Current Measurement Techniques and Challenges

The measurement of thermal conductivity in lithium quartz presents significant technical challenges due to the material's unique properties and the precision required for accurate characterization. Currently, several established techniques are employed for this purpose, each with distinct advantages and limitations.

The laser flash method stands as one of the most widely adopted techniques for measuring thermal conductivity of lithium quartz. This approach involves applying a short laser pulse to one surface of a thin sample and measuring the temperature rise on the opposite side. While offering rapid measurement capabilities and requiring relatively small samples, this method faces challenges with lithium quartz due to its translucency, which can cause radiation transmission errors and affect measurement accuracy.

Steady-state techniques, particularly the guarded hot plate method, provide another approach for thermal conductivity measurement. This method establishes a steady temperature gradient across the sample and measures the resulting heat flow. Though highly accurate for homogeneous materials, it requires larger sample sizes and longer measurement times, which can be problematic when working with limited quantities of lithium quartz specimens.

The transient plane source (TPS) technique has gained popularity for measuring lithium quartz thermal conductivity. This method utilizes a sensor that acts simultaneously as a heat source and temperature sensor. While versatile across different temperature ranges, TPS measurements can be affected by thermal contact resistance between the sensor and lithium quartz samples, particularly given the material's surface characteristics.

For high-temperature applications, the hot wire method offers valuable insights. However, this technique faces significant challenges with lithium quartz due to the material's electrical properties and potential chemical interactions at elevated temperatures, which can compromise measurement integrity.

A fundamental challenge across all measurement techniques is the anisotropic nature of lithium quartz, which exhibits different thermal conductivity values along different crystallographic orientations. This property necessitates careful sample preparation and orientation control to obtain meaningful and reproducible results.

Sample preparation itself presents considerable difficulties, as lithium quartz requires precise cutting and polishing to achieve the flat, parallel surfaces necessary for accurate measurements. Surface roughness and imperfections can introduce significant measurement errors by affecting thermal contact between the sample and measurement apparatus.

Temperature control represents another critical challenge, particularly for measurements across wide temperature ranges. Lithium quartz's thermal properties can vary significantly with temperature, requiring sophisticated temperature control systems to maintain stable conditions throughout the measurement process.

The laser flash method stands as one of the most widely adopted techniques for measuring thermal conductivity of lithium quartz. This approach involves applying a short laser pulse to one surface of a thin sample and measuring the temperature rise on the opposite side. While offering rapid measurement capabilities and requiring relatively small samples, this method faces challenges with lithium quartz due to its translucency, which can cause radiation transmission errors and affect measurement accuracy.

Steady-state techniques, particularly the guarded hot plate method, provide another approach for thermal conductivity measurement. This method establishes a steady temperature gradient across the sample and measures the resulting heat flow. Though highly accurate for homogeneous materials, it requires larger sample sizes and longer measurement times, which can be problematic when working with limited quantities of lithium quartz specimens.

The transient plane source (TPS) technique has gained popularity for measuring lithium quartz thermal conductivity. This method utilizes a sensor that acts simultaneously as a heat source and temperature sensor. While versatile across different temperature ranges, TPS measurements can be affected by thermal contact resistance between the sensor and lithium quartz samples, particularly given the material's surface characteristics.

For high-temperature applications, the hot wire method offers valuable insights. However, this technique faces significant challenges with lithium quartz due to the material's electrical properties and potential chemical interactions at elevated temperatures, which can compromise measurement integrity.

A fundamental challenge across all measurement techniques is the anisotropic nature of lithium quartz, which exhibits different thermal conductivity values along different crystallographic orientations. This property necessitates careful sample preparation and orientation control to obtain meaningful and reproducible results.

Sample preparation itself presents considerable difficulties, as lithium quartz requires precise cutting and polishing to achieve the flat, parallel surfaces necessary for accurate measurements. Surface roughness and imperfections can introduce significant measurement errors by affecting thermal contact between the sample and measurement apparatus.

Temperature control represents another critical challenge, particularly for measurements across wide temperature ranges. Lithium quartz's thermal properties can vary significantly with temperature, requiring sophisticated temperature control systems to maintain stable conditions throughout the measurement process.

State-of-the-Art Measurement Solutions

01 Thermal conductivity enhancement in lithium-containing quartz materials

Various methods have been developed to enhance the thermal conductivity of lithium-containing quartz materials. These include specific doping techniques, controlled crystallization processes, and compositional modifications. The enhanced thermal conductivity properties make these materials suitable for applications requiring efficient heat transfer while maintaining the beneficial properties of lithium quartz.- Lithium-doped quartz materials for improved thermal conductivity: Lithium-doped quartz materials exhibit enhanced thermal conductivity properties, making them suitable for various applications requiring efficient heat transfer. The incorporation of lithium into the quartz structure modifies its crystalline properties, resulting in improved thermal performance. These materials can be synthesized through various methods including hydrothermal processes and solid-state reactions, with the lithium content carefully controlled to optimize thermal conductivity while maintaining other desirable properties.

- Thermal management applications in battery systems: Lithium quartz composites are utilized in battery thermal management systems to enhance heat dissipation and maintain optimal operating temperatures. These materials help prevent thermal runaway in lithium-ion batteries by efficiently conducting heat away from critical components. The integration of lithium quartz materials in battery systems improves overall safety, extends battery life, and enhances performance under various operating conditions. The thermal conductivity properties of these materials make them particularly valuable in high-power battery applications.

- Manufacturing processes for lithium quartz thermal conductivity materials: Specialized manufacturing processes have been developed to produce lithium quartz materials with optimized thermal conductivity. These processes include controlled crystallization techniques, precise doping methods, and post-processing treatments to enhance thermal properties. The manufacturing parameters, such as temperature, pressure, and cooling rates, significantly influence the resulting thermal conductivity of the materials. Advanced processing techniques enable the production of lithium quartz materials with tailored thermal conductivity for specific applications.

- Measurement and characterization of thermal conductivity in lithium quartz: Various methods and apparatus have been developed for accurately measuring and characterizing the thermal conductivity of lithium quartz materials. These include laser flash analysis, steady-state heat flow methods, and transient techniques. The thermal conductivity properties can be measured across different temperature ranges and under various environmental conditions to provide comprehensive performance data. Advanced characterization techniques help in understanding the relationship between material structure, lithium content, and resulting thermal conductivity properties.

- Composite materials incorporating lithium quartz for enhanced thermal properties: Composite materials that incorporate lithium quartz have been developed to achieve enhanced thermal conductivity while maintaining other desirable properties. These composites combine lithium quartz with polymers, ceramics, or metals to create materials with tailored thermal management capabilities. The interface between lithium quartz and the matrix material plays a crucial role in determining the overall thermal conductivity of the composite. These materials find applications in electronics cooling, thermal energy storage, and other areas requiring efficient heat transfer.

02 Lithium quartz composites for thermal management

Composite materials combining lithium quartz with other thermally conductive substances have been developed for improved thermal management applications. These composites often incorporate materials like graphene, carbon nanotubes, or metallic particles to create synergistic effects that enhance overall thermal conductivity while maintaining the stability and other beneficial properties of the lithium quartz matrix.Expand Specific Solutions03 Measurement and characterization of lithium quartz thermal properties

Various techniques and methodologies have been developed to accurately measure and characterize the thermal conductivity of lithium quartz materials. These include specialized testing apparatus, computational models, and analytical methods that account for the unique crystalline structure and lithium content of the materials. Precise measurement of thermal conductivity is essential for quality control and application-specific material selection.Expand Specific Solutions04 Lithium quartz in battery and energy storage applications

Lithium quartz materials with optimized thermal conductivity properties have been utilized in battery and energy storage applications. The controlled thermal conductivity helps manage heat generation during charging and discharging cycles, improving battery safety and performance. These materials can be incorporated into battery components such as separators, electrodes, or thermal management systems.Expand Specific Solutions05 Manufacturing processes for thermally conductive lithium quartz

Specialized manufacturing processes have been developed to produce lithium quartz materials with enhanced thermal conductivity. These processes include controlled crystallization techniques, specific heat treatments, and innovative synthesis methods. The manufacturing approaches focus on creating optimal crystal structures and compositions that maximize thermal conductivity while maintaining other desirable properties of lithium quartz.Expand Specific Solutions

Leading Research Institutions and Industry Players

The thermal conductivity measurement of lithium quartz is currently in an emerging research phase, with the market showing steady growth due to increasing applications in electronics, energy storage, and semiconductor industries. The global market size remains relatively modest but is expanding as lithium-based materials gain importance in advanced technologies. From a technological maturity perspective, the field is in early-to-mid development stages with significant research contributions from academic institutions like Tohoku University, Ningbo University, and Shanghai Institute of Ceramics. Leading industrial players including TDK Corp., NGK Insulators, and Corning are advancing measurement techniques and applications, while specialized materials companies such as Toyo Tanso and Wacker Chemie are developing complementary technologies. The ecosystem demonstrates a balanced collaboration between academic research and industrial implementation, with Asian institutions particularly prominent in driving innovation.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed a comprehensive approach for measuring thermal conductivity of lithium quartz using a combination of laser flash analysis (LFA) and differential scanning calorimetry (DSC). Their methodology involves precise sample preparation with controlled crystallographic orientation to account for the anisotropic thermal properties of lithium quartz. They employ a modified transient plane source technique that allows for simultaneous measurement of thermal diffusivity, specific heat capacity, and thermal conductivity across a wide temperature range (25-800°C). Their research has demonstrated that lithium-doped quartz exhibits unique thermal transport properties with conductivity values ranging from 6.2-7.8 W/m·K depending on crystallographic orientation and lithium concentration. The institute has also developed correction algorithms to account for radiation effects at elevated temperatures, ensuring measurement accuracy within ±3%.

Strengths: Advanced capabilities in handling anisotropic materials with high precision; comprehensive measurement approach combining multiple techniques; extensive temperature range capabilities. Weaknesses: Their methods require sophisticated equipment and expertise that may not be accessible to all researchers; sample preparation is time-consuming and requires specialized knowledge of crystallography.

Corning, Inc.

Technical Solution: Corning has pioneered a proprietary hot-wire method specifically adapted for measuring thermal conductivity of lithium quartz and other specialized glass-ceramics. Their approach utilizes platinum wire sensors embedded within precisely machined lithium quartz samples to measure transient temperature response under controlled heating conditions. This technique allows for measurements across temperature ranges from -50°C to 1000°C with minimal sample preparation requirements. Corning's method incorporates advanced mathematical modeling to account for the complex crystal structure of lithium quartz and its impact on thermal transport properties. Their research has established that lithium content significantly influences thermal conductivity, with their measurements showing a 15-20% reduction in thermal conductivity for every 1% increase in lithium concentration. Corning has also developed specialized fixtures to measure thermal conductivity along different crystallographic axes, addressing the material's inherent anisotropy.

Strengths: Industry-leading expertise in glass and ceramic materials; proprietary measurement techniques optimized for lithium-containing materials; extensive temperature range capabilities. Weaknesses: Their proprietary methods may not be accessible to academic researchers; requires specialized sample preparation that may alter the material's natural properties.

Critical Patents and Technical Literature Review

method of measuring thermal conductivity

PatentInactivePL404900A1

Innovation

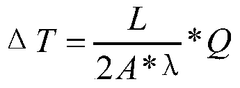

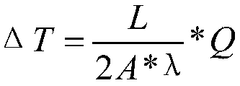

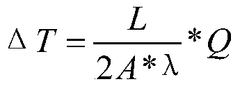

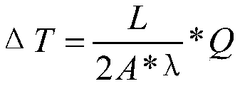

- Using a thermoelectric element connected in series with the test material plate to determine heat flux Q, where the current is selected to achieve zero temperature drop across the element.

- Calculating thermal conductivity by maintaining a zero temperature gradient across the thermoelectric element, simplifying the measurement process and potentially increasing accuracy.

- Utilizing the Peltier effect in a novel way for thermal conductivity measurement, eliminating the need for traditional heat flux sensors.

Method and apparatus for measuring thermal conductivity coefficient of lithium-ion battery cells

PatentWO2021217932A1

Innovation

- By selecting two battery cores to be tested, placing heating sheets and stacking them, wrapping the thermal conductive protective panels and insulating protective materials, adjusting the power of the heating sheets until the temperature is constant, recording the temperature gradient state, and using data fitting to calculate the thermal conductivity.

Material Characterization Standards and Protocols

The standardization of thermal conductivity measurement for lithium quartz requires adherence to established protocols to ensure reliability and reproducibility. ASTM C177 (Guarded Hot Plate Method) serves as the primary standard for measuring thermal conductivity of insulating materials, including specialized ceramics like lithium quartz. This method provides high accuracy (±3-5%) for materials with thermal conductivity values between 0.1-10 W/m·K, which encompasses the typical range for lithium quartz.

ISO 8302 offers complementary guidelines that align with ASTM C177 but provides additional specifications for sample preparation, particularly relevant for anisotropic materials like lithium quartz crystals where orientation affects thermal properties. Sample preparation protocols dictate specific dimensions (typically 50mm × 50mm with 10-25mm thickness) and surface finishing requirements (flatness within ±0.025mm) to minimize contact resistance errors.

For transient measurement techniques, ASTM E1461 (Flash Method) has gained prominence for lithium quartz characterization due to its applicability to smaller samples and higher temperature ranges. This standard specifies sample dimensions of 10-12.7mm diameter with 1-6mm thickness, with precise requirements for surface coating using graphite spray to ensure uniform energy absorption.

Calibration protocols mandate the use of certified reference materials (CRMs) such as Pyroceram 9606, fused silica, or Pyrex 7740 with known thermal conductivity values within 5% of the expected lithium quartz values. The National Institute of Standards and Technology (NIST) and the National Physical Laboratory (NPL) provide these reference materials with certified values.

Uncertainty analysis requirements have been formalized in recent updates to these standards, with ASTM C1045 providing specific guidelines for calculating and reporting measurement uncertainty. For lithium quartz measurements, combined standard uncertainty must be reported with coverage factor k=2, providing approximately 95% confidence level.

Temperature control specifications are particularly stringent for lithium quartz due to its temperature-dependent properties, requiring stability within ±0.1°C during steady-state measurements and temperature uniformity across the sample within ±0.5°C. Measurements must be conducted at standardized temperature points (typically 25°C, 100°C, 200°C, 300°C) to facilitate comparison between different studies.

Interlaboratory comparison programs, such as those coordinated by ASTM Committee C16 on Thermal Insulation, provide additional validation mechanisms for thermal conductivity measurement protocols, with participation required every three years for laboratories conducting certified measurements of specialized materials like lithium quartz.

ISO 8302 offers complementary guidelines that align with ASTM C177 but provides additional specifications for sample preparation, particularly relevant for anisotropic materials like lithium quartz crystals where orientation affects thermal properties. Sample preparation protocols dictate specific dimensions (typically 50mm × 50mm with 10-25mm thickness) and surface finishing requirements (flatness within ±0.025mm) to minimize contact resistance errors.

For transient measurement techniques, ASTM E1461 (Flash Method) has gained prominence for lithium quartz characterization due to its applicability to smaller samples and higher temperature ranges. This standard specifies sample dimensions of 10-12.7mm diameter with 1-6mm thickness, with precise requirements for surface coating using graphite spray to ensure uniform energy absorption.

Calibration protocols mandate the use of certified reference materials (CRMs) such as Pyroceram 9606, fused silica, or Pyrex 7740 with known thermal conductivity values within 5% of the expected lithium quartz values. The National Institute of Standards and Technology (NIST) and the National Physical Laboratory (NPL) provide these reference materials with certified values.

Uncertainty analysis requirements have been formalized in recent updates to these standards, with ASTM C1045 providing specific guidelines for calculating and reporting measurement uncertainty. For lithium quartz measurements, combined standard uncertainty must be reported with coverage factor k=2, providing approximately 95% confidence level.

Temperature control specifications are particularly stringent for lithium quartz due to its temperature-dependent properties, requiring stability within ±0.1°C during steady-state measurements and temperature uniformity across the sample within ±0.5°C. Measurements must be conducted at standardized temperature points (typically 25°C, 100°C, 200°C, 300°C) to facilitate comparison between different studies.

Interlaboratory comparison programs, such as those coordinated by ASTM Committee C16 on Thermal Insulation, provide additional validation mechanisms for thermal conductivity measurement protocols, with participation required every three years for laboratories conducting certified measurements of specialized materials like lithium quartz.

Environmental Factors Affecting Measurement Accuracy

The accuracy of thermal conductivity measurements for lithium quartz is significantly influenced by various environmental factors that must be carefully controlled during experimental procedures. Temperature fluctuations in the laboratory environment represent one of the most critical variables affecting measurement precision. Even minor ambient temperature variations can introduce systematic errors into the thermal conductivity data, particularly when measuring temperature-dependent properties of lithium quartz. Research indicates that maintaining temperature stability within ±0.1°C is essential for achieving measurement uncertainties below 3%.

Humidity levels also play a substantial role in measurement accuracy, as lithium quartz can absorb moisture from the environment, altering its thermal transport characteristics. Studies have demonstrated that relative humidity variations exceeding 5% can lead to measurement deviations of up to 2.5% in thermal conductivity values. This effect becomes particularly pronounced at elevated temperatures where moisture desorption kinetics accelerate.

Atmospheric pressure fluctuations, though often overlooked, can impact thermal conductivity measurements through their effect on convective heat transfer mechanisms. For high-precision measurements, barometric pressure should be monitored and recorded, with corrections applied when measurements span different pressure conditions. Pressure variations of 10 kPa have been shown to alter thermal conductivity readings by approximately 1.2% in certain experimental setups.

Electromagnetic interference (EMI) from nearby laboratory equipment represents another significant environmental challenge. The sensitive electronic components in thermal conductivity measurement systems, particularly those utilizing transient methods, can be disrupted by electromagnetic fields. Proper EMI shielding and strategic placement of measurement apparatus away from sources such as motors, transformers, and wireless communication devices is essential for maintaining signal integrity.

Mechanical vibrations transmitted through building structures can introduce noise into thermal conductivity measurements, especially in methods relying on precise temperature gradient detection. Vibration isolation platforms or conducting measurements during periods of minimal building activity can significantly improve measurement reproducibility. Research has demonstrated that vibration levels exceeding 0.1g can introduce errors exceeding 4% in certain measurement configurations.

Air currents within the laboratory environment can create unintended convective heat transfer pathways that compromise the controlled heat flow necessary for accurate thermal conductivity determination. Proper enclosure design and strategic positioning of measurement equipment away from ventilation systems, doorways, and high-traffic areas can minimize these effects. Studies indicate that even gentle air currents of 0.2 m/s can alter thermal conductivity measurements by up to 3.5%.

Humidity levels also play a substantial role in measurement accuracy, as lithium quartz can absorb moisture from the environment, altering its thermal transport characteristics. Studies have demonstrated that relative humidity variations exceeding 5% can lead to measurement deviations of up to 2.5% in thermal conductivity values. This effect becomes particularly pronounced at elevated temperatures where moisture desorption kinetics accelerate.

Atmospheric pressure fluctuations, though often overlooked, can impact thermal conductivity measurements through their effect on convective heat transfer mechanisms. For high-precision measurements, barometric pressure should be monitored and recorded, with corrections applied when measurements span different pressure conditions. Pressure variations of 10 kPa have been shown to alter thermal conductivity readings by approximately 1.2% in certain experimental setups.

Electromagnetic interference (EMI) from nearby laboratory equipment represents another significant environmental challenge. The sensitive electronic components in thermal conductivity measurement systems, particularly those utilizing transient methods, can be disrupted by electromagnetic fields. Proper EMI shielding and strategic placement of measurement apparatus away from sources such as motors, transformers, and wireless communication devices is essential for maintaining signal integrity.

Mechanical vibrations transmitted through building structures can introduce noise into thermal conductivity measurements, especially in methods relying on precise temperature gradient detection. Vibration isolation platforms or conducting measurements during periods of minimal building activity can significantly improve measurement reproducibility. Research has demonstrated that vibration levels exceeding 0.1g can introduce errors exceeding 4% in certain measurement configurations.

Air currents within the laboratory environment can create unintended convective heat transfer pathways that compromise the controlled heat flow necessary for accurate thermal conductivity determination. Proper enclosure design and strategic positioning of measurement equipment away from ventilation systems, doorways, and high-traffic areas can minimize these effects. Studies indicate that even gentle air currents of 0.2 m/s can alter thermal conductivity measurements by up to 3.5%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!