How to Conduct Solar Inverter Failure Analysis?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Failure Analysis Background and Objectives

Solar inverter failure analysis has become increasingly crucial as the global adoption of solar energy continues to surge. This field of study focuses on identifying, understanding, and mitigating the various factors that lead to solar inverter malfunctions, which are critical components in photovoltaic systems. The background of this analysis stems from the rapid growth of the solar energy sector and the consequent need for improved reliability and efficiency in solar power generation.

The evolution of solar inverter technology has been marked by significant advancements in efficiency, durability, and functionality. From early central inverters to modern string and microinverters, the industry has witnessed a continuous drive towards more reliable and high-performing solutions. However, as solar installations become more widespread and diverse in their applications, the challenges associated with inverter failures have also grown in complexity.

The primary objective of conducting solar inverter failure analysis is to enhance the overall performance and longevity of photovoltaic systems. By systematically examining the root causes of inverter failures, researchers and engineers aim to develop more robust designs, improve manufacturing processes, and implement effective maintenance strategies. This analysis not only serves to reduce downtime and repair costs but also contributes to the broader goal of increasing the competitiveness of solar energy in the global energy market.

Another key objective is to establish standardized methodologies for failure analysis across the industry. As solar installations vary greatly in size, location, and environmental conditions, creating a unified approach to failure analysis can significantly improve the accuracy and efficiency of troubleshooting efforts. This standardization also facilitates better communication and knowledge sharing among manufacturers, installers, and maintenance teams.

Furthermore, solar inverter failure analysis aims to predict and prevent potential issues before they occur. By leveraging data analytics and machine learning techniques, researchers seek to develop predictive maintenance models that can identify early warning signs of impending failures. This proactive approach not only minimizes unexpected downtime but also optimizes the allocation of maintenance resources, leading to substantial cost savings for solar plant operators.

The analysis also extends to understanding the impact of external factors on inverter performance. This includes studying the effects of environmental conditions such as temperature fluctuations, humidity, and dust accumulation, as well as grid-related issues like voltage variations and harmonic distortions. By comprehensively examining these factors, analysts can provide valuable insights for improving inverter designs and developing more effective protection mechanisms.

Ultimately, the background and objectives of solar inverter failure analysis align with the broader goals of the renewable energy sector: to increase reliability, reduce costs, and accelerate the global transition to clean energy sources. As solar technology continues to evolve, the importance of robust failure analysis methodologies will only grow, driving innovation and ensuring the long-term sustainability of solar power systems worldwide.

The evolution of solar inverter technology has been marked by significant advancements in efficiency, durability, and functionality. From early central inverters to modern string and microinverters, the industry has witnessed a continuous drive towards more reliable and high-performing solutions. However, as solar installations become more widespread and diverse in their applications, the challenges associated with inverter failures have also grown in complexity.

The primary objective of conducting solar inverter failure analysis is to enhance the overall performance and longevity of photovoltaic systems. By systematically examining the root causes of inverter failures, researchers and engineers aim to develop more robust designs, improve manufacturing processes, and implement effective maintenance strategies. This analysis not only serves to reduce downtime and repair costs but also contributes to the broader goal of increasing the competitiveness of solar energy in the global energy market.

Another key objective is to establish standardized methodologies for failure analysis across the industry. As solar installations vary greatly in size, location, and environmental conditions, creating a unified approach to failure analysis can significantly improve the accuracy and efficiency of troubleshooting efforts. This standardization also facilitates better communication and knowledge sharing among manufacturers, installers, and maintenance teams.

Furthermore, solar inverter failure analysis aims to predict and prevent potential issues before they occur. By leveraging data analytics and machine learning techniques, researchers seek to develop predictive maintenance models that can identify early warning signs of impending failures. This proactive approach not only minimizes unexpected downtime but also optimizes the allocation of maintenance resources, leading to substantial cost savings for solar plant operators.

The analysis also extends to understanding the impact of external factors on inverter performance. This includes studying the effects of environmental conditions such as temperature fluctuations, humidity, and dust accumulation, as well as grid-related issues like voltage variations and harmonic distortions. By comprehensively examining these factors, analysts can provide valuable insights for improving inverter designs and developing more effective protection mechanisms.

Ultimately, the background and objectives of solar inverter failure analysis align with the broader goals of the renewable energy sector: to increase reliability, reduce costs, and accelerate the global transition to clean energy sources. As solar technology continues to evolve, the importance of robust failure analysis methodologies will only grow, driving innovation and ensuring the long-term sustainability of solar power systems worldwide.

Market Demand for Reliable Solar Inverters

The global solar energy market has witnessed substantial growth in recent years, driven by increasing environmental concerns and the push for sustainable energy sources. As solar installations continue to expand, the demand for reliable solar inverters has become paramount. Solar inverters play a crucial role in converting direct current (DC) generated by solar panels into alternating current (AC) for use in homes, businesses, and the power grid. The reliability of these inverters directly impacts the overall performance and efficiency of solar power systems.

Market research indicates a significant increase in the adoption of solar energy solutions across residential, commercial, and utility-scale sectors. This growth has led to a corresponding rise in the demand for high-quality, dependable solar inverters. Consumers and businesses investing in solar technology expect long-term performance and minimal downtime, making inverter reliability a key factor in purchasing decisions.

The market for solar inverters is projected to experience steady growth, with a particular emphasis on advanced, smart inverters that offer improved efficiency and grid integration capabilities. These next-generation inverters are designed to address the challenges of grid stability and power quality as the penetration of solar energy increases in power systems worldwide.

Reliability concerns have become a focal point for both manufacturers and end-users. Inverter failures can result in significant energy production losses, increased maintenance costs, and reduced return on investment for solar projects. As a result, there is a growing demand for inverters with enhanced durability, longer lifespans, and improved fault tolerance.

The push for reliable solar inverters is also driven by regulatory requirements and industry standards. Many countries have implemented strict guidelines for grid-connected solar systems, necessitating inverters that can maintain stable operation under various grid conditions and contribute to overall power system reliability.

Furthermore, as solar energy projects scale up in size and complexity, the need for sophisticated monitoring and diagnostics capabilities in inverters has intensified. Customers are seeking inverters with advanced features such as real-time performance tracking, predictive maintenance, and remote troubleshooting to minimize downtime and optimize system performance.

The market demand for reliable solar inverters extends beyond traditional grid-tied systems. Off-grid and hybrid solar solutions, particularly in developing regions and remote areas, require inverters that can operate consistently in challenging environments. This has led to the development of ruggedized inverters designed to withstand harsh conditions and maintain reliability in diverse settings.

Market research indicates a significant increase in the adoption of solar energy solutions across residential, commercial, and utility-scale sectors. This growth has led to a corresponding rise in the demand for high-quality, dependable solar inverters. Consumers and businesses investing in solar technology expect long-term performance and minimal downtime, making inverter reliability a key factor in purchasing decisions.

The market for solar inverters is projected to experience steady growth, with a particular emphasis on advanced, smart inverters that offer improved efficiency and grid integration capabilities. These next-generation inverters are designed to address the challenges of grid stability and power quality as the penetration of solar energy increases in power systems worldwide.

Reliability concerns have become a focal point for both manufacturers and end-users. Inverter failures can result in significant energy production losses, increased maintenance costs, and reduced return on investment for solar projects. As a result, there is a growing demand for inverters with enhanced durability, longer lifespans, and improved fault tolerance.

The push for reliable solar inverters is also driven by regulatory requirements and industry standards. Many countries have implemented strict guidelines for grid-connected solar systems, necessitating inverters that can maintain stable operation under various grid conditions and contribute to overall power system reliability.

Furthermore, as solar energy projects scale up in size and complexity, the need for sophisticated monitoring and diagnostics capabilities in inverters has intensified. Customers are seeking inverters with advanced features such as real-time performance tracking, predictive maintenance, and remote troubleshooting to minimize downtime and optimize system performance.

The market demand for reliable solar inverters extends beyond traditional grid-tied systems. Off-grid and hybrid solar solutions, particularly in developing regions and remote areas, require inverters that can operate consistently in challenging environments. This has led to the development of ruggedized inverters designed to withstand harsh conditions and maintain reliability in diverse settings.

Current Challenges in Solar Inverter Reliability

Solar inverter reliability remains a critical challenge in the photovoltaic industry, impacting system performance, maintenance costs, and overall energy production efficiency. As solar installations continue to grow globally, the demand for more reliable and durable inverters has intensified. One of the primary challenges is the complex interplay between environmental factors and inverter components, leading to premature failures and reduced lifespans.

Thermal management stands out as a significant hurdle in solar inverter reliability. Inverters are often exposed to harsh outdoor conditions, including extreme temperatures and humidity. The internal heat generated during operation, combined with external thermal stresses, can lead to component degradation and eventual failure. Developing more effective cooling systems and thermally resilient materials is crucial for addressing this challenge.

Another pressing issue is the susceptibility of inverters to power quality problems and grid instabilities. Voltage fluctuations, frequency variations, and harmonic distortions can stress inverter components, particularly capacitors and switching devices. Enhancing the robustness of inverters against these grid anomalies while maintaining high efficiency remains a complex engineering challenge.

The reliability of power electronic components, especially semiconductor devices like IGBTs and MOSFETs, is also a major concern. These components are subject to thermal cycling, voltage spikes, and current surges, which can lead to degradation over time. Improving the design and manufacturing processes of these critical components is essential for enhancing overall inverter reliability.

Software and firmware issues present another layer of complexity. As inverters become more sophisticated, incorporating advanced grid support functions and communication capabilities, the potential for software-related failures increases. Ensuring robust software design, thorough testing, and secure update mechanisms is crucial for maintaining long-term reliability.

The variability in installation quality and maintenance practices across different regions and installers also impacts inverter reliability. Improper installation, inadequate grounding, or insufficient maintenance can lead to premature failures. Standardizing installation procedures and developing more user-friendly maintenance protocols are important steps in addressing this challenge.

Lastly, the accelerated pace of technology evolution in the solar industry poses a challenge for long-term reliability assessment. New inverter designs and technologies are introduced rapidly, making it difficult to accumulate long-term performance data. Developing accelerated testing methods that accurately predict long-term reliability remains an ongoing challenge for manufacturers and researchers in the field.

Thermal management stands out as a significant hurdle in solar inverter reliability. Inverters are often exposed to harsh outdoor conditions, including extreme temperatures and humidity. The internal heat generated during operation, combined with external thermal stresses, can lead to component degradation and eventual failure. Developing more effective cooling systems and thermally resilient materials is crucial for addressing this challenge.

Another pressing issue is the susceptibility of inverters to power quality problems and grid instabilities. Voltage fluctuations, frequency variations, and harmonic distortions can stress inverter components, particularly capacitors and switching devices. Enhancing the robustness of inverters against these grid anomalies while maintaining high efficiency remains a complex engineering challenge.

The reliability of power electronic components, especially semiconductor devices like IGBTs and MOSFETs, is also a major concern. These components are subject to thermal cycling, voltage spikes, and current surges, which can lead to degradation over time. Improving the design and manufacturing processes of these critical components is essential for enhancing overall inverter reliability.

Software and firmware issues present another layer of complexity. As inverters become more sophisticated, incorporating advanced grid support functions and communication capabilities, the potential for software-related failures increases. Ensuring robust software design, thorough testing, and secure update mechanisms is crucial for maintaining long-term reliability.

The variability in installation quality and maintenance practices across different regions and installers also impacts inverter reliability. Improper installation, inadequate grounding, or insufficient maintenance can lead to premature failures. Standardizing installation procedures and developing more user-friendly maintenance protocols are important steps in addressing this challenge.

Lastly, the accelerated pace of technology evolution in the solar industry poses a challenge for long-term reliability assessment. New inverter designs and technologies are introduced rapidly, making it difficult to accumulate long-term performance data. Developing accelerated testing methods that accurately predict long-term reliability remains an ongoing challenge for manufacturers and researchers in the field.

Existing Failure Analysis Methodologies for Solar Inverters

01 Fault detection and diagnosis systems

Advanced fault detection and diagnosis systems are implemented in solar inverters to identify and analyze potential failures. These systems use various sensors and algorithms to monitor key parameters, detect anomalies, and predict potential issues before they lead to complete failure. This proactive approach helps in maintaining the efficiency and reliability of solar power systems.- Fault detection and diagnosis systems: Advanced fault detection and diagnosis systems are implemented in solar inverters to identify and analyze failures. These systems use various sensors and algorithms to monitor key parameters, detect anomalies, and provide early warnings of potential issues. This approach helps in preventing catastrophic failures and minimizing downtime.

- Thermal management solutions: Effective thermal management is crucial for preventing solar inverter failures. This includes the use of advanced cooling systems, heat sinks, and temperature monitoring devices. Proper thermal management helps to maintain optimal operating temperatures, extend component lifespan, and prevent thermal-related failures.

- Grid integration and protection mechanisms: Solar inverters are equipped with sophisticated grid integration and protection mechanisms to handle grid-related issues. These include anti-islanding protection, voltage and frequency ride-through capabilities, and grid synchronization features. Such mechanisms help prevent inverter failures due to grid disturbances and ensure compliance with grid codes.

- Modular and redundant designs: Modular and redundant designs are implemented in solar inverters to enhance reliability and minimize the impact of component failures. This approach allows for easier maintenance, quick replacement of faulty modules, and continued operation even if one module fails, thereby reducing overall system downtime.

- Remote monitoring and predictive maintenance: Advanced remote monitoring systems and predictive maintenance techniques are employed to prevent solar inverter failures. These systems use data analytics, machine learning algorithms, and IoT technologies to continuously monitor inverter performance, predict potential failures, and schedule maintenance activities proactively.

02 Thermal management and cooling solutions

Effective thermal management and cooling solutions are crucial for preventing solar inverter failures caused by overheating. These solutions may include advanced heat sink designs, liquid cooling systems, or intelligent temperature control mechanisms. Proper thermal management extends the lifespan of inverter components and ensures optimal performance under various environmental conditions.Expand Specific Solutions03 Grid integration and protection mechanisms

Solar inverters incorporate sophisticated grid integration and protection mechanisms to prevent failures caused by grid instabilities or abnormalities. These mechanisms include anti-islanding protection, voltage and frequency ride-through capabilities, and intelligent grid synchronization algorithms. Such features ensure the inverter's safe operation and compliance with grid codes.Expand Specific Solutions04 Remote monitoring and predictive maintenance

Remote monitoring systems and predictive maintenance algorithms are implemented to track solar inverter performance and identify potential issues before they escalate. These systems collect and analyze data in real-time, allowing for timely interventions and reducing downtime. Advanced analytics and machine learning techniques are often employed to improve the accuracy of failure predictions.Expand Specific Solutions05 Modular and redundant design approaches

Modular and redundant design approaches are adopted in solar inverter manufacturing to enhance reliability and minimize the impact of component failures. These designs allow for easier maintenance, quicker replacements, and continued operation even if one module fails. Redundant critical components ensure that the inverter can continue functioning at reduced capacity in case of partial failures.Expand Specific Solutions

Key Players in Solar Inverter Manufacturing and Testing

The solar inverter failure analysis market is in a growth phase, driven by increasing solar energy adoption worldwide. The market size is expanding rapidly, with a growing demand for reliable and efficient solar power systems. Technologically, the field is advancing, with companies like SMA Solar Technology AG, OMRON Corp., and Sineng Electric Co., Ltd. leading innovation in inverter design and diagnostics. These firms are developing sophisticated monitoring systems and predictive maintenance tools to enhance inverter reliability and performance. However, the technology is still evolving, with ongoing research by institutions like the Korea Institute of Energy Research and Huaneng Clean Energy Research Institute focusing on improving failure prediction algorithms and diagnostic techniques to further optimize solar inverter performance and longevity.

Solar Analytics Pty Ltd.

Technical Solution: Solar Analytics Pty Ltd. has developed a sophisticated solar inverter failure analysis system that leverages big data analytics and machine learning. Their approach focuses on continuous monitoring of inverter performance metrics, including voltage, current, and power output. The company's software platform analyzes this data in real-time, comparing it against expected performance models and historical data to identify deviations that may indicate potential failures[4]. Solar Analytics also incorporates weather data and satellite imagery to account for environmental factors that could affect inverter performance. Their system can detect subtle changes in inverter efficiency, which may be early indicators of impending failures. Additionally, they provide detailed reporting and visualization tools that allow technicians to quickly diagnose issues and plan maintenance activities[5].

Strengths: Advanced data analytics capabilities, integration of environmental factors, and user-friendly reporting tools. Weaknesses: May require significant data collection infrastructure and could be less effective for smaller solar installations.

Power Electronics ESPAÑA SL

Technical Solution: Power Electronics ESPAÑA SL has developed a comprehensive approach to solar inverter failure analysis that combines hardware and software solutions. Their method includes the use of advanced sensors integrated into their inverters to monitor key parameters such as temperature, voltage fluctuations, and current flow. These sensors feed data into a centralized monitoring system that uses proprietary algorithms to detect anomalies and predict potential failures[6]. The company has also implemented a remote diagnostics platform that allows technicians to perform in-depth analysis and troubleshooting without the need for on-site visits in many cases. Power Electronics' failure analysis process includes automated fault classification, which helps to quickly identify the root cause of issues and recommend appropriate corrective actions[7]. They have also developed a modular inverter design that allows for easier replacement of faulty components, reducing downtime and maintenance costs.

Strengths: Integrated hardware and software approach, remote diagnostics capabilities, and modular design for easy maintenance. Weaknesses: May be limited to their own inverter models, potentially reducing applicability to other brands.

Advanced Diagnostic Tools for Solar Inverter Failure Analysis

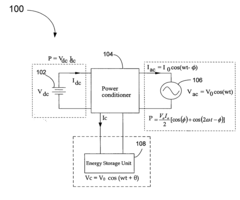

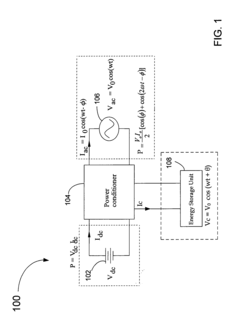

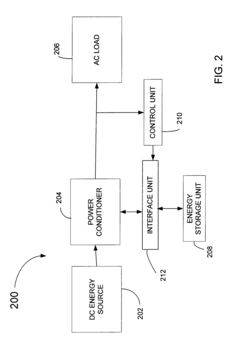

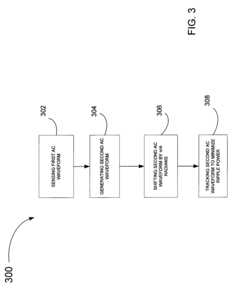

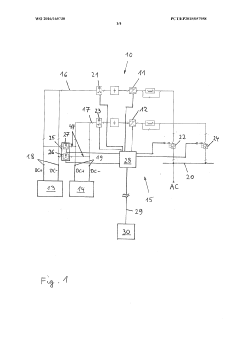

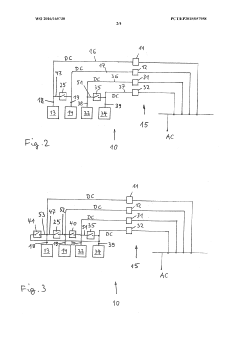

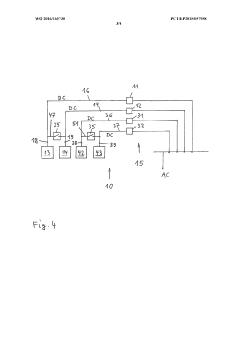

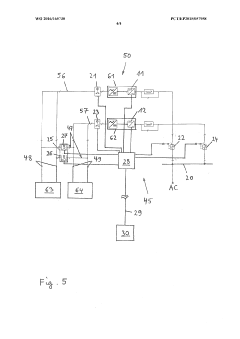

Methods for minimizing double-frequency ripple power in single-phase power conditioners

PatentActiveUS20110305050A1

Innovation

- A method that senses the AC waveform at the output of the power conditioner and generates a second AC waveform with the same frequency but shifted by n/4 radians, minimizing double-frequency ripple power by controlling the flow of electrical power through an energy storage device, allowing for the use of smaller, more reliable film capacitors or inductors.

Method for error handling and partial redundancy in parallel inverters by means of input switches

PatentWO2016165730A1

Innovation

- Automatically reroute the direct current input of a faulty inverter to a functioning one, allowing partial power takeover until a technician arrives, with remote monitoring and controlled switch management to ensure safe operation and minimize accidental reconnections.

Environmental Factors Affecting Solar Inverter Performance

Environmental factors play a crucial role in the performance and longevity of solar inverters. These devices, essential for converting DC power from solar panels to AC power for grid use, are often exposed to various environmental challenges that can significantly impact their efficiency and reliability.

Temperature is one of the most critical environmental factors affecting solar inverter performance. Extreme heat can lead to reduced efficiency and increased wear on components, while cold temperatures may cause condensation and potential electrical issues. Inverters typically have an optimal operating temperature range, and deviations from this range can result in decreased output or even system shutdowns.

Humidity is another significant factor that can impact solar inverter functionality. High humidity levels can lead to condensation within the inverter, potentially causing short circuits or corrosion of internal components. In coastal areas, salt-laden air can accelerate corrosion, further compromising the inverter's performance and lifespan.

Dust and particulate matter pose additional challenges to solar inverter operation. Accumulation of dust on cooling systems can impair heat dissipation, leading to overheating and reduced efficiency. In some cases, fine particles may infiltrate the inverter housing, potentially causing short circuits or component damage.

Solar radiation, while essential for photovoltaic energy production, can also negatively affect inverter performance. Prolonged exposure to intense sunlight can cause degradation of external components and contribute to overheating issues. UV radiation, in particular, can lead to the breakdown of plastic components and insulation materials over time.

Altitude is an often-overlooked environmental factor that can impact inverter performance. At higher altitudes, the reduced air density can affect cooling efficiency, potentially leading to overheating and decreased performance. Some inverters may require derating or specialized cooling solutions when installed at high elevations.

Weather events such as lightning strikes, heavy rain, and strong winds can also pose significant risks to solar inverters. Lightning protection systems are crucial to prevent damage from electrical surges, while proper sealing and mounting are necessary to protect against water ingress and wind-related stresses.

Understanding these environmental factors is essential for conducting thorough solar inverter failure analysis. By considering the specific environmental conditions at the installation site, analysts can better identify potential causes of failure and develop more effective mitigation strategies. This knowledge also informs the design and selection of inverters for different geographical locations, ensuring optimal performance and longevity across diverse environmental conditions.

Temperature is one of the most critical environmental factors affecting solar inverter performance. Extreme heat can lead to reduced efficiency and increased wear on components, while cold temperatures may cause condensation and potential electrical issues. Inverters typically have an optimal operating temperature range, and deviations from this range can result in decreased output or even system shutdowns.

Humidity is another significant factor that can impact solar inverter functionality. High humidity levels can lead to condensation within the inverter, potentially causing short circuits or corrosion of internal components. In coastal areas, salt-laden air can accelerate corrosion, further compromising the inverter's performance and lifespan.

Dust and particulate matter pose additional challenges to solar inverter operation. Accumulation of dust on cooling systems can impair heat dissipation, leading to overheating and reduced efficiency. In some cases, fine particles may infiltrate the inverter housing, potentially causing short circuits or component damage.

Solar radiation, while essential for photovoltaic energy production, can also negatively affect inverter performance. Prolonged exposure to intense sunlight can cause degradation of external components and contribute to overheating issues. UV radiation, in particular, can lead to the breakdown of plastic components and insulation materials over time.

Altitude is an often-overlooked environmental factor that can impact inverter performance. At higher altitudes, the reduced air density can affect cooling efficiency, potentially leading to overheating and decreased performance. Some inverters may require derating or specialized cooling solutions when installed at high elevations.

Weather events such as lightning strikes, heavy rain, and strong winds can also pose significant risks to solar inverters. Lightning protection systems are crucial to prevent damage from electrical surges, while proper sealing and mounting are necessary to protect against water ingress and wind-related stresses.

Understanding these environmental factors is essential for conducting thorough solar inverter failure analysis. By considering the specific environmental conditions at the installation site, analysts can better identify potential causes of failure and develop more effective mitigation strategies. This knowledge also informs the design and selection of inverters for different geographical locations, ensuring optimal performance and longevity across diverse environmental conditions.

Regulatory Standards for Solar Inverter Reliability Testing

Regulatory standards for solar inverter reliability testing play a crucial role in ensuring the safety, performance, and longevity of these essential components in photovoltaic systems. These standards are developed and maintained by various international and regional organizations, such as the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and the Institute of Electrical and Electronics Engineers (IEEE).

The IEC 62109 series, particularly IEC 62109-1 and IEC 62109-2, form the cornerstone of safety requirements for power converters used in photovoltaic systems. These standards outline the general safety requirements and specific requirements for inverters, respectively. They cover aspects such as protection against electric shock, fire hazards, mechanical hazards, and environmental factors.

For reliability testing, the IEC 61215 series provides comprehensive guidelines for the design qualification and type approval of photovoltaic modules. While primarily focused on modules, many of its principles are applicable to inverters. The IEC 62093 standard specifically addresses the balance of system components for photovoltaic systems, including inverters, and outlines design qualification testing procedures.

The UL 1741 standard, widely recognized in North America, sets forth the requirements for inverters, converters, controllers, and interconnection system equipment used with distributed energy resources. This standard ensures compliance with IEEE 1547, which governs the interconnection and interoperability of distributed energy resources with electric power systems.

Environmental testing is a critical aspect of inverter reliability. The IEC 60068 series provides a comprehensive framework for environmental testing of electronic equipment. It includes tests for temperature extremes, humidity, vibration, and shock, all of which are relevant to solar inverter reliability.

Electromagnetic compatibility (EMC) is another crucial consideration in inverter testing. The IEC 61000 series addresses various aspects of EMC, including emission and immunity requirements. Solar inverters must comply with these standards to ensure they do not interfere with other electronic devices and can operate reliably in the presence of electromagnetic disturbances.

Grid connection standards, such as VDE-AR-N 4105 in Germany and G99 in the UK, impose additional requirements on inverters to ensure grid stability and power quality. These standards typically include specifications for frequency and voltage ride-through capabilities, reactive power control, and anti-islanding protection.

As the solar industry evolves, regulatory standards continue to adapt. Recent trends include increased focus on cybersecurity (addressed in IEC 62351) and smart grid integration (covered by standards like IEC 61850). These emerging areas reflect the growing complexity of modern solar inverters and their role in the broader energy ecosystem.

The IEC 62109 series, particularly IEC 62109-1 and IEC 62109-2, form the cornerstone of safety requirements for power converters used in photovoltaic systems. These standards outline the general safety requirements and specific requirements for inverters, respectively. They cover aspects such as protection against electric shock, fire hazards, mechanical hazards, and environmental factors.

For reliability testing, the IEC 61215 series provides comprehensive guidelines for the design qualification and type approval of photovoltaic modules. While primarily focused on modules, many of its principles are applicable to inverters. The IEC 62093 standard specifically addresses the balance of system components for photovoltaic systems, including inverters, and outlines design qualification testing procedures.

The UL 1741 standard, widely recognized in North America, sets forth the requirements for inverters, converters, controllers, and interconnection system equipment used with distributed energy resources. This standard ensures compliance with IEEE 1547, which governs the interconnection and interoperability of distributed energy resources with electric power systems.

Environmental testing is a critical aspect of inverter reliability. The IEC 60068 series provides a comprehensive framework for environmental testing of electronic equipment. It includes tests for temperature extremes, humidity, vibration, and shock, all of which are relevant to solar inverter reliability.

Electromagnetic compatibility (EMC) is another crucial consideration in inverter testing. The IEC 61000 series addresses various aspects of EMC, including emission and immunity requirements. Solar inverters must comply with these standards to ensure they do not interfere with other electronic devices and can operate reliably in the presence of electromagnetic disturbances.

Grid connection standards, such as VDE-AR-N 4105 in Germany and G99 in the UK, impose additional requirements on inverters to ensure grid stability and power quality. These standards typically include specifications for frequency and voltage ride-through capabilities, reactive power control, and anti-islanding protection.

As the solar industry evolves, regulatory standards continue to adapt. Recent trends include increased focus on cybersecurity (addressed in IEC 62351) and smart grid integration (covered by standards like IEC 61850). These emerging areas reflect the growing complexity of modern solar inverters and their role in the broader energy ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!