How to Create Eco-Friendly Cellophane as a Plastic Alternative?

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Eco-Cellophane Development Background and Objectives

The development of eco-friendly cellophane as a plastic alternative is rooted in the urgent need to address the global plastic pollution crisis. Traditional plastic materials, derived from fossil fuels, have become a significant environmental concern due to their non-biodegradable nature and long-lasting impact on ecosystems. The concept of eco-cellophane emerges as a potential solution to mitigate these issues while maintaining the functionality and versatility of conventional plastics.

Cellophane, originally invented in the early 20th century, is a thin, transparent sheet made from regenerated cellulose. While traditional cellophane production involves chemical processes that are not entirely environmentally friendly, the renewed interest in this material stems from its biodegradable properties and the potential for more sustainable manufacturing methods.

The primary objective of eco-cellophane development is to create a material that closely mimics the properties of plastic film while significantly reducing environmental impact. This involves improving the production process to minimize chemical usage, exploring renewable sources of cellulose, and enhancing the material's performance characteristics to match or exceed those of conventional plastics.

Key goals in the development of eco-friendly cellophane include achieving complete biodegradability under various environmental conditions, ensuring compatibility with existing packaging and manufacturing infrastructure, and maintaining cost-effectiveness to enable widespread adoption. Additionally, researchers aim to develop eco-cellophane with improved barrier properties against moisture and gases, crucial for food packaging applications.

The evolution of eco-cellophane technology is closely tied to advancements in biotechnology and materials science. Recent progress in enzyme engineering and biomass processing has opened new avenues for more efficient and environmentally benign cellulose extraction and modification. These developments are pivotal in realizing the full potential of eco-cellophane as a viable plastic alternative.

As the demand for sustainable packaging solutions continues to grow, driven by consumer awareness and regulatory pressures, the eco-cellophane sector is poised for significant expansion. The technology's development trajectory aligns with broader sustainability goals, including reducing carbon footprint, promoting circular economy principles, and minimizing microplastic pollution in oceans and terrestrial environments.

In conclusion, the background and objectives of eco-cellophane development represent a convergence of environmental necessity, technological innovation, and market demand. The successful realization of this technology holds the promise of transforming the packaging industry and contributing significantly to global sustainability efforts.

Cellophane, originally invented in the early 20th century, is a thin, transparent sheet made from regenerated cellulose. While traditional cellophane production involves chemical processes that are not entirely environmentally friendly, the renewed interest in this material stems from its biodegradable properties and the potential for more sustainable manufacturing methods.

The primary objective of eco-cellophane development is to create a material that closely mimics the properties of plastic film while significantly reducing environmental impact. This involves improving the production process to minimize chemical usage, exploring renewable sources of cellulose, and enhancing the material's performance characteristics to match or exceed those of conventional plastics.

Key goals in the development of eco-friendly cellophane include achieving complete biodegradability under various environmental conditions, ensuring compatibility with existing packaging and manufacturing infrastructure, and maintaining cost-effectiveness to enable widespread adoption. Additionally, researchers aim to develop eco-cellophane with improved barrier properties against moisture and gases, crucial for food packaging applications.

The evolution of eco-cellophane technology is closely tied to advancements in biotechnology and materials science. Recent progress in enzyme engineering and biomass processing has opened new avenues for more efficient and environmentally benign cellulose extraction and modification. These developments are pivotal in realizing the full potential of eco-cellophane as a viable plastic alternative.

As the demand for sustainable packaging solutions continues to grow, driven by consumer awareness and regulatory pressures, the eco-cellophane sector is poised for significant expansion. The technology's development trajectory aligns with broader sustainability goals, including reducing carbon footprint, promoting circular economy principles, and minimizing microplastic pollution in oceans and terrestrial environments.

In conclusion, the background and objectives of eco-cellophane development represent a convergence of environmental necessity, technological innovation, and market demand. The successful realization of this technology holds the promise of transforming the packaging industry and contributing significantly to global sustainability efforts.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and regulatory pressures. The global market for eco-friendly packaging solutions is projected to reach $258 billion by 2025, with a compound annual growth rate of 5.7% from 2020 to 2025. This growth is primarily fueled by consumer demand for more sustainable products and packaging options, as well as corporate commitments to reduce environmental impact.

Within this market, cellophane as a plastic alternative represents a promising segment. Traditional cellophane, derived from wood pulp, has been used for decades but fell out of favor due to the rise of petroleum-based plastics. However, the renewed focus on sustainability has sparked interest in developing eco-friendly cellophane alternatives that maintain the material's desirable properties while addressing environmental concerns.

The demand for sustainable cellophane is particularly strong in the food and beverage industry, which accounts for approximately 40% of the global packaging market. Consumers are increasingly seeking products with minimal environmental impact, driving brands to explore alternatives to traditional plastic packaging. Eco-friendly cellophane offers potential advantages such as biodegradability, compostability, and renewability, making it an attractive option for food packaging applications.

In addition to food and beverage, other industries showing interest in sustainable cellophane alternatives include personal care, cosmetics, and household products. These sectors are responding to consumer preferences for plastic-free or reduced-plastic packaging options, creating opportunities for innovative cellophane-based solutions.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the sustainable packaging market, including eco-friendly cellophane alternatives. This is attributed to rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India. North America and Europe also represent significant markets, driven by stringent environmental policies and consumer awareness.

Key market drivers for eco-friendly cellophane include government regulations on single-use plastics, corporate sustainability initiatives, and growing consumer awareness of environmental issues. However, challenges such as higher production costs compared to conventional plastics and the need for improved performance characteristics must be addressed to accelerate market adoption.

The competitive landscape for sustainable packaging solutions, including eco-friendly cellophane, is characterized by a mix of established packaging companies and innovative startups. Major players are investing in research and development to create novel bio-based materials that can compete with traditional plastics in terms of performance and cost-effectiveness.

In conclusion, the market for eco-friendly cellophane as a plastic alternative shows significant potential within the broader sustainable packaging industry. As technology advances and production scales up, eco-friendly cellophane is poised to capture a growing share of the packaging market, particularly in applications where biodegradability and renewability are prioritized.

Within this market, cellophane as a plastic alternative represents a promising segment. Traditional cellophane, derived from wood pulp, has been used for decades but fell out of favor due to the rise of petroleum-based plastics. However, the renewed focus on sustainability has sparked interest in developing eco-friendly cellophane alternatives that maintain the material's desirable properties while addressing environmental concerns.

The demand for sustainable cellophane is particularly strong in the food and beverage industry, which accounts for approximately 40% of the global packaging market. Consumers are increasingly seeking products with minimal environmental impact, driving brands to explore alternatives to traditional plastic packaging. Eco-friendly cellophane offers potential advantages such as biodegradability, compostability, and renewability, making it an attractive option for food packaging applications.

In addition to food and beverage, other industries showing interest in sustainable cellophane alternatives include personal care, cosmetics, and household products. These sectors are responding to consumer preferences for plastic-free or reduced-plastic packaging options, creating opportunities for innovative cellophane-based solutions.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the sustainable packaging market, including eco-friendly cellophane alternatives. This is attributed to rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India. North America and Europe also represent significant markets, driven by stringent environmental policies and consumer awareness.

Key market drivers for eco-friendly cellophane include government regulations on single-use plastics, corporate sustainability initiatives, and growing consumer awareness of environmental issues. However, challenges such as higher production costs compared to conventional plastics and the need for improved performance characteristics must be addressed to accelerate market adoption.

The competitive landscape for sustainable packaging solutions, including eco-friendly cellophane, is characterized by a mix of established packaging companies and innovative startups. Major players are investing in research and development to create novel bio-based materials that can compete with traditional plastics in terms of performance and cost-effectiveness.

In conclusion, the market for eco-friendly cellophane as a plastic alternative shows significant potential within the broader sustainable packaging industry. As technology advances and production scales up, eco-friendly cellophane is poised to capture a growing share of the packaging market, particularly in applications where biodegradability and renewability are prioritized.

Current Challenges in Biodegradable Cellophane Production

The production of biodegradable cellophane as an eco-friendly alternative to plastic faces several significant challenges. One of the primary obstacles is the complexity of the manufacturing process. Traditional cellophane production involves the use of toxic chemicals and energy-intensive procedures, which contradict the goal of creating an environmentally friendly product. Developing a more sustainable production method that maintains the desirable properties of cellophane while reducing environmental impact remains a major hurdle.

Material sourcing presents another challenge. Biodegradable cellophane requires renewable raw materials, typically derived from plant sources such as wood pulp or cotton linters. Ensuring a consistent and sustainable supply of these materials without contributing to deforestation or competing with food crops is crucial. Additionally, the quality and uniformity of these natural raw materials can vary, affecting the final product's properties and performance.

The cost-effectiveness of biodegradable cellophane production is a significant barrier to widespread adoption. Current production methods for eco-friendly alternatives are often more expensive than conventional plastic manufacturing, making it difficult to compete in price-sensitive markets. Scaling up production while maintaining quality and reducing costs is a key challenge that requires substantial investment in research and development.

Achieving the desired physical properties in biodegradable cellophane is another technical hurdle. While traditional cellophane offers excellent barrier properties against moisture and gases, replicating these characteristics in a fully biodegradable version without compromising on sustainability is challenging. Balancing biodegradability with durability and functionality remains a complex task for researchers and manufacturers.

The degradation process of biodegradable cellophane also presents challenges. Ensuring that the material breaks down completely in various environmental conditions without leaving harmful residues or microplastics is crucial. Developing standardized testing methods to verify biodegradability claims and establishing appropriate disposal infrastructure are ongoing challenges in the industry.

Regulatory compliance and certification pose additional hurdles. As environmental regulations become more stringent, manufacturers must navigate complex approval processes and meet evolving standards for biodegradable materials. This includes demonstrating the material's safety for food contact applications and its environmental impact throughout its lifecycle.

Lastly, consumer perception and education represent significant challenges. While there is growing demand for sustainable packaging solutions, many consumers are unfamiliar with biodegradable cellophane and its proper disposal methods. Overcoming misconceptions and educating the public about the benefits and limitations of this material is essential for its successful adoption in the marketplace.

Material sourcing presents another challenge. Biodegradable cellophane requires renewable raw materials, typically derived from plant sources such as wood pulp or cotton linters. Ensuring a consistent and sustainable supply of these materials without contributing to deforestation or competing with food crops is crucial. Additionally, the quality and uniformity of these natural raw materials can vary, affecting the final product's properties and performance.

The cost-effectiveness of biodegradable cellophane production is a significant barrier to widespread adoption. Current production methods for eco-friendly alternatives are often more expensive than conventional plastic manufacturing, making it difficult to compete in price-sensitive markets. Scaling up production while maintaining quality and reducing costs is a key challenge that requires substantial investment in research and development.

Achieving the desired physical properties in biodegradable cellophane is another technical hurdle. While traditional cellophane offers excellent barrier properties against moisture and gases, replicating these characteristics in a fully biodegradable version without compromising on sustainability is challenging. Balancing biodegradability with durability and functionality remains a complex task for researchers and manufacturers.

The degradation process of biodegradable cellophane also presents challenges. Ensuring that the material breaks down completely in various environmental conditions without leaving harmful residues or microplastics is crucial. Developing standardized testing methods to verify biodegradability claims and establishing appropriate disposal infrastructure are ongoing challenges in the industry.

Regulatory compliance and certification pose additional hurdles. As environmental regulations become more stringent, manufacturers must navigate complex approval processes and meet evolving standards for biodegradable materials. This includes demonstrating the material's safety for food contact applications and its environmental impact throughout its lifecycle.

Lastly, consumer perception and education represent significant challenges. While there is growing demand for sustainable packaging solutions, many consumers are unfamiliar with biodegradable cellophane and its proper disposal methods. Overcoming misconceptions and educating the public about the benefits and limitations of this material is essential for its successful adoption in the marketplace.

Existing Eco-Cellophane Manufacturing Techniques

01 Biodegradable cellophane materials

Development of eco-friendly cellophane using biodegradable materials such as plant-based polymers or modified cellulose. These materials break down naturally in the environment, reducing plastic waste and environmental impact.- Biodegradable cellophane materials: Development of eco-friendly cellophane using biodegradable materials such as plant-based polymers or modified cellulose. These materials break down naturally in the environment, reducing plastic waste and environmental impact.

- Recyclable cellophane compositions: Creation of cellophane formulations that are easily recyclable, allowing for the material to be reprocessed and reused multiple times. This approach reduces the need for new raw materials and minimizes waste in the packaging industry.

- Reduced environmental impact manufacturing processes: Implementation of eco-friendly manufacturing processes for cellophane production, including the use of renewable energy sources, water conservation techniques, and reduction of harmful chemical emissions. These methods aim to minimize the carbon footprint of cellophane production.

- Compostable cellophane alternatives: Development of compostable alternatives to traditional cellophane that can break down in industrial or home composting systems. These materials offer a sustainable end-of-life solution for packaging waste.

- Bio-based additives for improved eco-friendliness: Incorporation of bio-based additives into cellophane formulations to enhance biodegradability, improve barrier properties, or reduce the overall environmental impact of the material. These additives may include natural plasticizers, antioxidants, or antimicrobial agents derived from renewable sources.

02 Recyclable cellophane compositions

Creation of cellophane formulations that are easily recyclable, allowing for the material to be reprocessed and reused multiple times. This approach reduces the need for new raw materials and minimizes waste in the packaging industry.Expand Specific Solutions03 Eco-friendly production processes

Implementation of environmentally friendly manufacturing processes for cellophane production, including the use of renewable energy sources, water conservation techniques, and reduction of harmful chemical emissions during production.Expand Specific Solutions04 Compostable cellophane alternatives

Development of compostable alternatives to traditional cellophane that can break down in industrial or home composting systems. These materials offer a sustainable end-of-life solution for packaging waste.Expand Specific Solutions05 Bio-based additives for cellophane

Incorporation of bio-based additives and fillers in cellophane production to enhance its eco-friendliness. These additives can improve the material's biodegradability, reduce its carbon footprint, or add functional properties without compromising environmental sustainability.Expand Specific Solutions

Key Players in Sustainable Packaging Industry

The eco-friendly cellophane market is in its early growth stage, with increasing demand for sustainable packaging solutions driving innovation. The global market size for biodegradable plastics is projected to reach $6.12 billion by 2023, with cellophane alternatives poised for significant growth. While the technology is still evolving, several companies are making strides in developing eco-friendly cellophane alternatives. Futamura Chemical Co., Ltd. and Papershell AB are leading innovators in this space, with Futamura's NatureFlex™ cellulose-based films gaining traction. Research institutions like South China University of Technology and Nanyang Technological University are also contributing to advancements in biodegradable materials. As consumer awareness grows and regulations tighten, the eco-friendly cellophane market is expected to mature rapidly in the coming years.

Futamura Chemical Co., Ltd.

Technical Solution: Futamura Chemical Co., Ltd. has developed NatureFlex™, a range of renewable and compostable cellulose films derived from wood pulp. These films are designed as an eco-friendly alternative to traditional plastic cellophane. The production process involves dissolving wood pulp in an alkali solution, extruding it through a slit into an acid bath, and then treating it with softeners and plasticizers[1]. The resulting film is transparent, heat-sealable, and offers excellent barrier properties against moisture, gases, and aromas[2]. Futamura has also focused on improving the film's mechanical properties and heat resistance, making it suitable for various packaging applications[3].

Strengths: Renewable source material, biodegradable, excellent barrier properties. Weaknesses: Higher production costs compared to conventional plastics, limited heat resistance compared to some synthetic polymers.

University of British Columbia

Technical Solution: Researchers at the University of British Columbia have developed a novel approach to creating eco-friendly cellophane using nanocellulose. Their method involves extracting cellulose nanofibrils from wood pulp and forming them into a transparent, flexible film. The process utilizes a combination of mechanical and chemical treatments to break down the cellulose fibers into nanoscale dimensions[4]. The resulting nanocellulose film exhibits high strength, transparency, and barrier properties comparable to traditional cellophane. Additionally, the researchers have explored surface modifications to enhance the film's water resistance and compatibility with various packaging applications[5]. This innovative approach aims to create a sustainable alternative to petroleum-based plastics while maintaining the desirable properties of conventional cellophane.

Strengths: High strength-to-weight ratio, excellent optical properties, derived from renewable resources. Weaknesses: Scalability challenges, potential high production costs in the initial stages of commercialization.

Innovative Approaches in Biodegradable Film Technology

Ecotype environmental protection material and preparation method thereof

PatentActiveCN105348839A

Innovation

- Using a method that combines biological fermentation, chemical and physical processes, using fruits and vegetables fibers and low-density polyethylene and other materials, through the screw extrusion granulation process, we design reasonable formulas and process steps to increase the bonding strength of plant fibers and plastics. And add appropriate additives to prepare high-performance biomass composite materials.

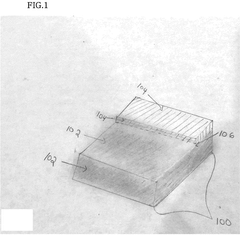

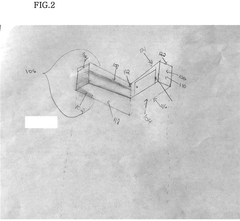

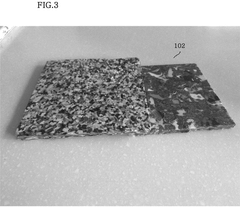

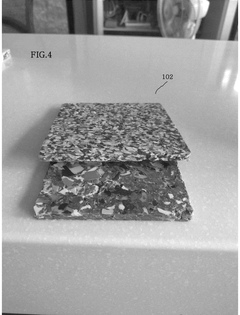

Composite material including a thermoplastic polymer resin, a wood-like thermoplastic elastomer, and a polyester-based adhesive

PatentPendingUS20240341475A1

Innovation

- A synthetic building material is created by coating recycled plastic with a CELLWOOD veneer, providing enhanced mechanical strength, insulation, and durability, which can be used in various shapes and forms, including as a decorative and insulating exterior layer, eliminating the need for separate siding and insulation.

Environmental Impact Assessment of Eco-Cellophane

The environmental impact assessment of eco-cellophane as a plastic alternative reveals promising potential for reducing the ecological footprint of packaging materials. Eco-cellophane, derived from renewable resources such as wood pulp or plant-based cellulose, offers a biodegradable and compostable solution to traditional petroleum-based plastics.

One of the primary environmental benefits of eco-cellophane is its reduced carbon footprint during production. Unlike conventional plastics, which rely heavily on fossil fuels, eco-cellophane utilizes renewable biomass sources. This shift significantly decreases greenhouse gas emissions associated with raw material extraction and processing.

The biodegradability of eco-cellophane addresses the critical issue of plastic pollution. While traditional plastics persist in the environment for hundreds of years, eco-cellophane can decompose within months under proper conditions. This characteristic substantially reduces the accumulation of plastic waste in landfills and marine ecosystems, mitigating the long-term environmental impact.

Water consumption and pollution are also important factors to consider. The production of eco-cellophane generally requires less water compared to some plastic manufacturing processes. Additionally, the absence of harmful chemicals in eco-cellophane production minimizes the risk of water pollution and toxic runoff.

Land use and deforestation concerns arise when sourcing raw materials for eco-cellophane. However, sustainable forestry practices and the use of agricultural by-products can mitigate these issues. Proper management of cellulose sources ensures the long-term viability of eco-cellophane production without compromising ecosystem integrity.

The end-of-life scenario for eco-cellophane presents significant environmental advantages. Its compostability allows for integration into existing organic waste management systems, reducing the burden on landfills and incineration facilities. When composted, eco-cellophane returns valuable nutrients to the soil, supporting agricultural productivity and soil health.

Energy consumption during the manufacturing process of eco-cellophane is an area that requires further optimization. While generally less energy-intensive than traditional plastic production, there is room for improvement in production efficiency to further reduce the overall environmental impact.

In conclusion, the environmental impact assessment of eco-cellophane demonstrates its potential as a sustainable alternative to conventional plastics. Its renewable sourcing, biodegradability, and reduced carbon footprint offer substantial environmental benefits. However, ongoing research and development are necessary to address remaining challenges and maximize the ecological advantages of this innovative material.

One of the primary environmental benefits of eco-cellophane is its reduced carbon footprint during production. Unlike conventional plastics, which rely heavily on fossil fuels, eco-cellophane utilizes renewable biomass sources. This shift significantly decreases greenhouse gas emissions associated with raw material extraction and processing.

The biodegradability of eco-cellophane addresses the critical issue of plastic pollution. While traditional plastics persist in the environment for hundreds of years, eco-cellophane can decompose within months under proper conditions. This characteristic substantially reduces the accumulation of plastic waste in landfills and marine ecosystems, mitigating the long-term environmental impact.

Water consumption and pollution are also important factors to consider. The production of eco-cellophane generally requires less water compared to some plastic manufacturing processes. Additionally, the absence of harmful chemicals in eco-cellophane production minimizes the risk of water pollution and toxic runoff.

Land use and deforestation concerns arise when sourcing raw materials for eco-cellophane. However, sustainable forestry practices and the use of agricultural by-products can mitigate these issues. Proper management of cellulose sources ensures the long-term viability of eco-cellophane production without compromising ecosystem integrity.

The end-of-life scenario for eco-cellophane presents significant environmental advantages. Its compostability allows for integration into existing organic waste management systems, reducing the burden on landfills and incineration facilities. When composted, eco-cellophane returns valuable nutrients to the soil, supporting agricultural productivity and soil health.

Energy consumption during the manufacturing process of eco-cellophane is an area that requires further optimization. While generally less energy-intensive than traditional plastic production, there is room for improvement in production efficiency to further reduce the overall environmental impact.

In conclusion, the environmental impact assessment of eco-cellophane demonstrates its potential as a sustainable alternative to conventional plastics. Its renewable sourcing, biodegradability, and reduced carbon footprint offer substantial environmental benefits. However, ongoing research and development are necessary to address remaining challenges and maximize the ecological advantages of this innovative material.

Regulatory Framework for Biodegradable Packaging Materials

The regulatory framework for biodegradable packaging materials is a critical aspect of the eco-friendly cellophane development process. As governments and environmental agencies worldwide increasingly focus on reducing plastic waste, new regulations and standards are being established to govern the production, use, and disposal of biodegradable alternatives.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard specifies the characteristics that a material must have to be considered "compostable" and provides a framework for testing and certification. Similarly, the ASTM D6400 standard in the United States outlines the specifications for compostable plastics.

Many countries have implemented or are in the process of implementing regulations that restrict the use of single-use plastics and promote biodegradable alternatives. For instance, France has banned single-use plastic packaging for most fruits and vegetables, encouraging the use of biodegradable alternatives like eco-friendly cellophane.

Certification systems play a crucial role in the regulatory landscape. Organizations such as TÜV Austria and the Biodegradable Products Institute (BPI) provide certification for compostable and biodegradable materials, helping manufacturers demonstrate compliance with relevant standards and regulations.

The regulatory framework also addresses the end-of-life management of biodegradable packaging materials. This includes guidelines for proper disposal, composting infrastructure requirements, and labeling standards to inform consumers about the correct disposal methods.

As the technology for eco-friendly cellophane advances, regulators are working to keep pace with new developments. This includes updating existing standards and creating new ones to address emerging materials and production methods. For example, there is ongoing work to develop standards specifically for marine biodegradable materials, recognizing the unique challenges posed by plastic pollution in aquatic environments.

Manufacturers of eco-friendly cellophane must navigate this complex regulatory landscape, ensuring their products meet the required standards for biodegradability, compostability, and overall environmental impact. This often involves extensive testing and certification processes, as well as ongoing compliance monitoring.

The regulatory framework also extends to the raw materials used in the production of eco-friendly cellophane. This includes regulations governing the sourcing of sustainable feedstocks, such as cellulose from responsibly managed forests or agricultural waste products.

As the demand for sustainable packaging solutions grows, it is likely that the regulatory framework will continue to evolve, potentially becoming more stringent and comprehensive. This ongoing development presents both challenges and opportunities for innovators in the field of eco-friendly cellophane, driving continuous improvement and innovation in biodegradable packaging materials.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard specifies the characteristics that a material must have to be considered "compostable" and provides a framework for testing and certification. Similarly, the ASTM D6400 standard in the United States outlines the specifications for compostable plastics.

Many countries have implemented or are in the process of implementing regulations that restrict the use of single-use plastics and promote biodegradable alternatives. For instance, France has banned single-use plastic packaging for most fruits and vegetables, encouraging the use of biodegradable alternatives like eco-friendly cellophane.

Certification systems play a crucial role in the regulatory landscape. Organizations such as TÜV Austria and the Biodegradable Products Institute (BPI) provide certification for compostable and biodegradable materials, helping manufacturers demonstrate compliance with relevant standards and regulations.

The regulatory framework also addresses the end-of-life management of biodegradable packaging materials. This includes guidelines for proper disposal, composting infrastructure requirements, and labeling standards to inform consumers about the correct disposal methods.

As the technology for eco-friendly cellophane advances, regulators are working to keep pace with new developments. This includes updating existing standards and creating new ones to address emerging materials and production methods. For example, there is ongoing work to develop standards specifically for marine biodegradable materials, recognizing the unique challenges posed by plastic pollution in aquatic environments.

Manufacturers of eco-friendly cellophane must navigate this complex regulatory landscape, ensuring their products meet the required standards for biodegradability, compostability, and overall environmental impact. This often involves extensive testing and certification processes, as well as ongoing compliance monitoring.

The regulatory framework also extends to the raw materials used in the production of eco-friendly cellophane. This includes regulations governing the sourcing of sustainable feedstocks, such as cellulose from responsibly managed forests or agricultural waste products.

As the demand for sustainable packaging solutions grows, it is likely that the regulatory framework will continue to evolve, potentially becoming more stringent and comprehensive. This ongoing development presents both challenges and opportunities for innovators in the field of eco-friendly cellophane, driving continuous improvement and innovation in biodegradable packaging materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!