How to Develop PVDF for Advanced Wearable Glucose Monitoring?

PVDF in Glucose Monitoring: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material for advanced wearable glucose monitoring systems, marking a significant advancement in the field of diabetes management. The development of PVDF for this application stems from the growing need for non-invasive, continuous glucose monitoring solutions that offer improved accuracy, comfort, and user compliance. This technological evolution aligns with the broader trend of personalized healthcare and the increasing prevalence of diabetes worldwide.

The primary objective in developing PVDF for glucose monitoring is to leverage its unique piezoelectric properties to create highly sensitive, flexible, and biocompatible sensors. These sensors aim to detect minute changes in glucose levels through the skin, eliminating the need for frequent blood sampling. The goal is to integrate PVDF-based sensors into wearable devices that can provide real-time, accurate glucose measurements, enabling better diabetes management and reducing the risk of complications associated with poor glycemic control.

The journey of PVDF in glucose monitoring began with the recognition of its exceptional piezoelectric response and its ability to be fabricated into thin, flexible films. These characteristics make PVDF an ideal candidate for wearable sensor applications. As research progressed, scientists and engineers focused on enhancing PVDF's selectivity towards glucose molecules and improving its long-term stability in physiological environments.

Recent technological advancements have paved the way for the development of PVDF-based glucose sensors with increased sensitivity and reliability. These include the incorporation of nanoparticles to enhance glucose binding, surface modification techniques to improve biocompatibility, and the development of novel electrode designs to optimize signal transduction. The integration of PVDF sensors with wireless communication technologies and data analytics platforms represents another crucial aspect of this technological evolution, enabling seamless data transmission and interpretation.

The development of PVDF for glucose monitoring is driven by several key factors, including the rising global diabetes prevalence, increasing healthcare costs, and the demand for non-invasive monitoring solutions. Additionally, advancements in materials science, nanotechnology, and bioelectronics have accelerated progress in this field. The ultimate aim is to create a wearable glucose monitoring system that combines accuracy, comfort, and ease of use, potentially revolutionizing diabetes management and improving the quality of life for millions of people worldwide.

As research continues, the focus remains on overcoming challenges such as sensor durability, long-term accuracy, and integration with existing diabetes management systems. The successful development of PVDF-based wearable glucose monitors holds the promise of transforming diabetes care, offering a more patient-friendly approach to glucose monitoring and paving the way for more effective disease management strategies.

Market Analysis for Wearable Glucose Monitors

The wearable glucose monitoring market has experienced significant growth in recent years, driven by the increasing prevalence of diabetes and the growing demand for non-invasive, continuous glucose monitoring solutions. This market segment is expected to continue its upward trajectory, with projections indicating substantial expansion over the next decade.

The global wearable glucose monitoring market is primarily segmented into two categories: continuous glucose monitoring (CGM) systems and flash glucose monitoring systems. CGM systems have gained considerable traction due to their ability to provide real-time glucose readings and trend data, enabling better diabetes management. Flash glucose monitoring systems, while less frequent in data collection, offer a more cost-effective alternative and have found a niche in certain patient populations.

Key factors driving market growth include the rising diabetic population worldwide, increasing awareness about the importance of continuous glucose monitoring, and technological advancements in sensor technology and data analytics. The integration of artificial intelligence and machine learning algorithms into glucose monitoring devices has further enhanced their accuracy and predictive capabilities, making them more appealing to both patients and healthcare providers.

The market landscape is characterized by a mix of established medical device companies and innovative startups. Major players in this space include Dexcom, Abbott Laboratories, Medtronic, and Senseonics, among others. These companies are continuously investing in research and development to improve their product offerings and gain a competitive edge.

Geographically, North America currently dominates the wearable glucose monitoring market, followed by Europe. This is primarily due to the high prevalence of diabetes in these regions, coupled with advanced healthcare infrastructure and favorable reimbursement policies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing healthcare expenditure, rising diabetes prevalence, and growing awareness about advanced monitoring technologies.

Despite the positive market outlook, several challenges persist. These include the high cost of wearable glucose monitoring devices, concerns about accuracy and reliability, and the need for frequent calibration in some systems. Additionally, regulatory hurdles and reimbursement issues in certain regions can impact market growth.

The development of PVDF (Polyvinylidene Fluoride) for advanced wearable glucose monitoring presents an exciting opportunity within this market. PVDF's unique properties, such as high piezoelectric response, biocompatibility, and chemical stability, make it a promising material for next-generation glucose sensors. The integration of PVDF-based sensors into wearable devices could potentially address some of the existing challenges in glucose monitoring, such as improved accuracy, longer sensor life, and enhanced comfort for users.

Current PVDF Technology and Challenges

Polyvinylidene fluoride (PVDF) has emerged as a promising material for advanced wearable glucose monitoring systems due to its unique properties. However, the current state of PVDF technology faces several challenges that need to be addressed for its successful implementation in this application.

One of the primary challenges is improving the sensitivity and selectivity of PVDF-based sensors for glucose detection. While PVDF exhibits excellent piezoelectric and pyroelectric properties, enhancing its specificity towards glucose molecules remains a significant hurdle. Researchers are exploring various surface modification techniques and nanocomposite formulations to overcome this limitation.

Another critical challenge lies in the integration of PVDF into flexible and stretchable substrates suitable for wearable devices. The inherent rigidity of PVDF films can compromise the comfort and conformability of wearable glucose monitors. Developing methods to create ultrathin PVDF layers or incorporating PVDF nanofibers into flexible matrices are active areas of research to address this issue.

The long-term stability and reliability of PVDF-based sensors in physiological environments pose additional challenges. Exposure to sweat, temperature fluctuations, and mechanical stress can affect the performance and longevity of these sensors. Efforts are underway to develop protective coatings and encapsulation techniques to enhance the durability of PVDF-based glucose monitoring systems.

Furthermore, the current manufacturing processes for PVDF sensors often involve complex and costly procedures, limiting their scalability for mass production. Simplifying fabrication methods and exploring novel manufacturing techniques, such as 3D printing or roll-to-roll processing, are crucial for the widespread adoption of PVDF-based wearable glucose monitors.

The biocompatibility and potential long-term effects of PVDF on skin contact are also areas of concern. While PVDF is generally considered biocompatible, prolonged exposure in wearable applications requires further investigation to ensure user safety and comfort.

Additionally, the power requirements for PVDF-based sensors present a challenge in developing self-powered wearable glucose monitors. Integrating energy harvesting mechanisms or designing ultra-low-power sensing systems are essential for creating practical and user-friendly devices.

Lastly, the current PVDF technology faces competition from other emerging materials and sensing approaches in the field of wearable glucose monitoring. Continuous innovation and performance improvements are necessary to establish PVDF as a leading material in this application space.

Addressing these challenges requires interdisciplinary collaboration between materials scientists, biomedical engineers, and device manufacturers. Overcoming these hurdles will pave the way for the development of advanced PVDF-based wearable glucose monitoring systems that offer improved accuracy, comfort, and user experience.

Existing PVDF-based Glucose Sensing Solutions

01 PVDF-based glucose sensing membranes

PVDF is used as a base material for creating glucose sensing membranes. These membranes are functionalized with glucose-responsive elements to enable selective and sensitive glucose detection. The PVDF structure provides mechanical stability and allows for the incorporation of various sensing components.- PVDF-based glucose sensing membranes: PVDF is used as a base material for creating glucose sensing membranes. These membranes are functionalized with glucose-responsive elements to enable selective and sensitive glucose detection. The PVDF structure provides mechanical stability and allows for the incorporation of various sensing components.

- PVDF nanofiber electrodes for glucose monitoring: PVDF nanofibers are utilized to create electrodes for glucose monitoring devices. These nanofiber-based electrodes offer high surface area and improved sensitivity for glucose detection. The electrospinning process is often employed to fabricate these PVDF nanofiber structures.

- PVDF-based wearable glucose sensors: PVDF is incorporated into wearable glucose monitoring devices due to its flexibility and biocompatibility. These sensors can be integrated into clothing or attached directly to the skin, allowing for continuous glucose monitoring in a non-invasive or minimally invasive manner.

- PVDF composites for enhanced glucose sensing: Composite materials combining PVDF with other functional components are developed to enhance glucose sensing performance. These composites may include conductive materials, enzymes, or nanoparticles to improve sensitivity, selectivity, and stability of glucose monitoring systems.

- PVDF membrane modification for glucose selectivity: Various modification techniques are applied to PVDF membranes to improve their selectivity towards glucose. These modifications may involve surface functionalization, grafting of glucose-responsive polymers, or incorporation of molecular recognition elements to enhance the specificity of glucose detection.

02 PVDF nanofiber electrodes for glucose monitoring

PVDF nanofibers are utilized to create electrodes for glucose monitoring devices. These nanofiber-based electrodes offer high surface area and improved sensitivity for glucose detection. The unique properties of PVDF nanofibers enhance the overall performance of glucose sensors.Expand Specific Solutions03 PVDF-based composite materials for glucose sensors

Composite materials incorporating PVDF and other functional components are developed for glucose sensing applications. These composites combine the beneficial properties of PVDF with additional materials to enhance sensor performance, stability, and selectivity towards glucose.Expand Specific Solutions04 PVDF membrane modification for improved glucose detection

Various modification techniques are applied to PVDF membranes to enhance their glucose sensing capabilities. These modifications include surface treatments, incorporation of nanoparticles, and grafting of functional groups to improve selectivity and sensitivity towards glucose.Expand Specific Solutions05 PVDF-based wearable glucose monitoring devices

PVDF is utilized in the development of wearable glucose monitoring devices. The flexibility and biocompatibility of PVDF make it suitable for creating comfortable and non-invasive glucose sensors that can be integrated into wearable platforms for continuous glucose monitoring.Expand Specific Solutions

Key Players in PVDF and Glucose Monitoring

The development of PVDF for advanced wearable glucose monitoring is in a growth phase, with increasing market size due to rising diabetes prevalence. The technology is progressing towards maturity, with key players like Abbott Diabetes Care, Inc. and DexCom, Inc. leading innovation. Academic institutions such as Zhejiang University and Xiamen University are contributing to research advancements. The competitive landscape is diverse, including established medical device companies, emerging startups like Movano, Inc., and tech giants like Samsung Electronics Co., Ltd. This multifaceted competition is driving rapid technological progress, focusing on improving sensor accuracy, miniaturization, and user comfort for non-invasive glucose monitoring solutions.

Abbott Diabetes Care, Inc.

DexCom, Inc.

Innovative PVDF Modifications for Glucose Detection

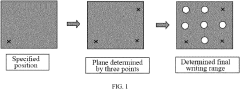

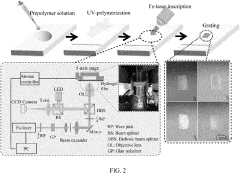

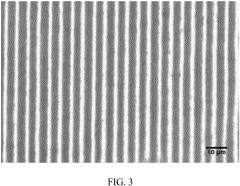

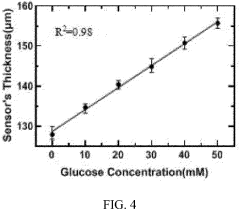

- A wearable hydrogel glucose sensor is fabricated using polyacrylamide hydrogel with phenylboronic acid and femtosecond laser grating inscription, allowing non-invasive glucose monitoring through tear fluid analysis without affecting vision.

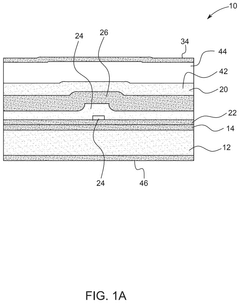

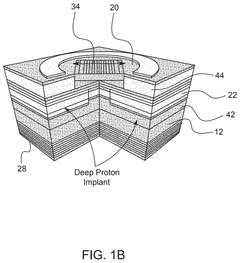

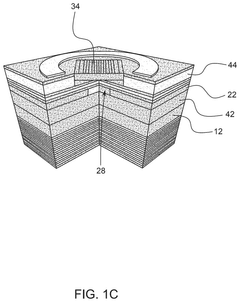

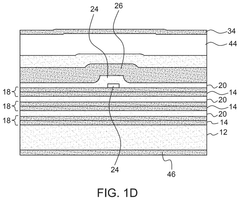

- A wearable electronic device incorporating a VCSEL laser with active regions, p-n junctions, and tunnel junctions, housed in a wearable format to measure glucose levels and other health parameters.

Regulatory Framework for Wearable Medical Devices

The regulatory framework for wearable medical devices, including those utilizing PVDF for glucose monitoring, is a complex and evolving landscape. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing these devices. The FDA classifies wearable glucose monitors as Class II medical devices, requiring premarket notification (510(k)) or De Novo classification requests.

For PVDF-based wearable glucose monitors, manufacturers must demonstrate substantial equivalence to a predicate device or prove the device's safety and effectiveness through clinical data. The FDA's guidance on "Mobile Medical Applications" and "General Wellness: Policy for Low Risk Devices" provides additional regulatory context for these devices.

In the European Union, the Medical Device Regulation (MDR) governs wearable medical devices. PVDF-based glucose monitors would likely fall under Class IIa or IIb, depending on their specific functionality and invasiveness. Manufacturers must obtain CE marking through a conformity assessment procedure, which includes a quality management system audit and technical documentation review by a Notified Body.

International standards such as ISO 13485 for quality management systems and IEC 60601-1 for medical electrical equipment safety are essential for global regulatory compliance. Specific to glucose monitoring, ISO 15197 provides requirements for in vitro glucose monitoring systems.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in the EU and the Health Insurance Portability and Accountability Act (HIPAA) in the US, are critical considerations for wearable devices that collect and transmit personal health data.

Regulatory bodies are increasingly focusing on software as a medical device (SaMD) regulations, which may apply to the software components of PVDF-based wearable glucose monitors. The International Medical Device Regulators Forum (IMDRF) has published guidance documents on SaMD, which are being adopted by regulatory agencies worldwide.

As wearable technology advances, regulatory frameworks are adapting to address new challenges. For instance, the FDA's Digital Health Innovation Action Plan aims to streamline the regulatory process for digital health technologies, potentially benefiting innovative devices like PVDF-based glucose monitors.

Manufacturers developing PVDF for advanced wearable glucose monitoring must navigate these regulatory requirements carefully, ensuring compliance throughout the product development lifecycle. Early engagement with regulatory bodies and continuous monitoring of evolving guidelines are crucial for successful market entry and sustained compliance.

Biocompatibility and Long-term Stability of PVDF Sensors

The biocompatibility and long-term stability of PVDF sensors are crucial factors in developing advanced wearable glucose monitoring devices. PVDF, or polyvinylidene fluoride, has shown promising potential in this application due to its unique properties, including piezoelectricity, flexibility, and chemical stability.

Biocompatibility is a primary concern for any material used in wearable medical devices. PVDF has demonstrated good biocompatibility in various studies, showing minimal adverse reactions when in contact with human skin or tissue. This is attributed to its inert nature and resistance to chemical degradation. However, further research is needed to fully understand the long-term effects of PVDF on skin health and potential allergic reactions in a diverse population.

The long-term stability of PVDF sensors is another critical aspect that requires thorough investigation. PVDF exhibits excellent mechanical properties and resistance to environmental factors, which contribute to its durability in wearable applications. However, the constant exposure to sweat, skin oils, and mechanical stress in a wearable glucose monitoring device poses unique challenges.

To enhance the long-term stability of PVDF sensors, researchers are exploring various strategies. One approach involves the development of protective coatings that can shield the PVDF material from environmental factors while maintaining its sensing capabilities. These coatings must be carefully designed to ensure they do not interfere with glucose detection or compromise the flexibility of the sensor.

Another area of focus is the optimization of PVDF film structure and composition. By fine-tuning the crystalline structure and incorporating specific additives, researchers aim to improve the material's resistance to degradation and maintain its sensing performance over extended periods. This includes investigating different PVDF copolymers and blends that may offer superior stability without sacrificing sensitivity.

The integration of PVDF sensors with other materials and components in a wearable device also plays a crucial role in their long-term stability. Careful consideration must be given to the interface between the PVDF sensor and other elements, such as electrodes and encapsulation materials, to prevent delamination or degradation over time.

Continuous monitoring and self-diagnostic capabilities are being explored to ensure the reliability of PVDF-based glucose sensors. By incorporating mechanisms to detect and compensate for sensor drift or degradation, the overall stability and accuracy of the monitoring system can be significantly improved.

As research in this field progresses, it is essential to conduct comprehensive long-term studies that simulate real-world usage conditions. These studies should evaluate the performance, biocompatibility, and stability of PVDF sensors over extended periods, considering factors such as temperature fluctuations, humidity, and mechanical stress encountered in daily wear.