How to Enhance PVDF Functionality in Solar Cells?

PVDF in Solar Cells: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in the field of solar cell technology, offering unique properties that contribute to enhanced performance and durability. The evolution of PVDF in solar applications can be traced back to its initial use as a protective backsheet material, which has since expanded to include more advanced functionalities within the cell structure itself.

The primary objective in enhancing PVDF functionality in solar cells is to leverage its piezoelectric, ferroelectric, and high dielectric constant properties to improve overall cell efficiency and longevity. Researchers aim to optimize PVDF's role in charge separation, electron transport, and encapsulation to address key challenges in photovoltaic technology.

PVDF's development in solar applications has been driven by the increasing demand for more efficient and durable photovoltaic systems. As the global push for renewable energy intensifies, the solar industry seeks materials that can withstand harsh environmental conditions while maintaining high performance over extended periods. PVDF's excellent weather resistance, UV stability, and chemical inertness make it an ideal candidate for addressing these requirements.

The technical evolution of PVDF in solar cells has seen significant milestones, including the development of PVDF nanocomposites, the exploration of various PVDF crystal phases (β, γ, and δ), and the integration of PVDF-based materials into different layers of the solar cell structure. Each advancement has contributed to incremental improvements in cell efficiency, stability, and lifespan.

Current research focuses on several key areas to further enhance PVDF functionality. These include optimizing PVDF nanostructures to improve light trapping and charge collection, developing novel PVDF-based electron transport layers, and exploring PVDF's potential in perovskite solar cells as a stabilizing agent. Additionally, efforts are being made to enhance PVDF's compatibility with other materials used in solar cell fabrication to create more efficient and cost-effective manufacturing processes.

The ultimate goal of enhancing PVDF functionality in solar cells is to contribute to the development of next-generation photovoltaic technologies that offer higher efficiency, improved durability, and reduced production costs. By addressing these aspects, researchers aim to accelerate the adoption of solar energy and support the global transition to sustainable power sources.

Market Analysis for PVDF-Enhanced Solar Cells

The market for PVDF-enhanced solar cells is experiencing significant growth, driven by the increasing demand for high-efficiency and durable photovoltaic technologies. PVDF (Polyvinylidene fluoride) has emerged as a promising material for enhancing the performance and longevity of solar cells, particularly in the areas of encapsulation and backsheet applications.

The global solar energy market is projected to reach $223.3 billion by 2026, with a compound annual growth rate (CAGR) of 20.5% from 2021 to 2026. Within this broader market, PVDF-enhanced solar cells are carving out a growing niche. The unique properties of PVDF, including its excellent weather resistance, UV stability, and chemical inertness, make it an attractive option for improving solar cell efficiency and lifespan.

One of the key drivers for the adoption of PVDF in solar cells is the increasing focus on sustainability and long-term performance. As solar installations are expected to last for 25 years or more, materials that can withstand harsh environmental conditions and maintain their properties over time are in high demand. PVDF meets these requirements, offering superior protection against moisture ingress and UV degradation compared to traditional materials.

The market for PVDF-enhanced solar cells is particularly strong in regions with challenging environmental conditions, such as coastal areas with high salt spray or desert regions with intense UV exposure. These areas require solar panels with enhanced durability and resistance to corrosion, making PVDF an ideal choice for manufacturers targeting these markets.

In terms of market segmentation, PVDF is finding applications in both crystalline silicon and thin-film solar technologies. The crystalline silicon segment currently dominates the market, but thin-film technologies are expected to see rapid growth in the coming years, presenting new opportunities for PVDF integration.

The Asia-Pacific region leads the market for PVDF-enhanced solar cells, driven by the massive solar energy deployments in China and India. North America and Europe follow, with increasing adoption of high-efficiency solar technologies and stringent quality standards favoring the use of advanced materials like PVDF.

Key market players in the PVDF-enhanced solar cell sector include major chemical companies producing PVDF, such as Arkema, Solvay, and Kureha, as well as solar panel manufacturers incorporating PVDF into their products. Collaborations between material suppliers and solar cell manufacturers are becoming more common, driving innovation and market expansion.

Looking ahead, the market for PVDF-enhanced solar cells is expected to continue its growth trajectory, supported by ongoing research and development efforts to further improve PVDF functionality in solar applications. As the solar energy industry continues to mature and focus on long-term performance and reliability, materials like PVDF that can enhance these aspects are likely to see increased adoption and market penetration.

Current PVDF Limitations in Photovoltaic Applications

Polyvinylidene fluoride (PVDF) has gained significant attention in photovoltaic applications due to its unique properties, including high dielectric constant, excellent mechanical strength, and good thermal stability. However, several limitations currently hinder its full potential in solar cell technology.

One of the primary challenges is PVDF's inherent crystalline structure. While its semi-crystalline nature contributes to its mechanical strength, it also results in reduced charge carrier mobility and increased recombination rates. This crystallinity can impede the efficient transport of electrons and holes within the solar cell, ultimately limiting the device's overall performance and power conversion efficiency.

Another limitation lies in PVDF's hydrophobic nature. Although this property enhances its durability and resistance to environmental factors, it can lead to poor interfacial contact with other layers in the solar cell structure. This inadequate adhesion may result in decreased charge transfer efficiency and increased series resistance, negatively impacting the cell's performance.

The piezoelectric properties of PVDF, while beneficial in certain applications, can pose challenges in photovoltaic devices. The piezoelectric effect can introduce unwanted electrical noise and potential instability in the solar cell's output, particularly under mechanical stress or vibration. This limitation necessitates careful consideration in the design and implementation of PVDF-based solar cells, especially for applications in dynamic environments.

Furthermore, PVDF's relatively low thermal conductivity can lead to heat accumulation within the solar cell structure. As photovoltaic efficiency is temperature-dependent, this thermal management issue can result in decreased performance, especially in high-temperature operating conditions or under intense solar radiation.

The processing of PVDF for solar cell applications also presents challenges. Its high melting point and limited solubility in common solvents can complicate the fabrication process, making it difficult to achieve uniform and thin films necessary for optimal solar cell performance. This limitation often requires specialized processing techniques, potentially increasing manufacturing complexity and costs.

Lastly, while PVDF exhibits good UV stability, prolonged exposure to intense solar radiation can still lead to degradation over time. This gradual deterioration may affect the long-term reliability and performance of PVDF-based solar cells, necessitating the development of enhanced stabilization strategies or protective measures to ensure sustained efficiency throughout the device's operational lifetime.

Existing PVDF Enhancement Techniques for Solar Cells

01 Piezoelectric properties of PVDF

PVDF exhibits strong piezoelectric properties, making it suitable for various sensing and actuating applications. Its ability to convert mechanical stress into electrical signals and vice versa allows for the development of sensors, transducers, and energy harvesting devices.- Piezoelectric properties of PVDF: PVDF exhibits strong piezoelectric properties, making it suitable for various applications in sensors, actuators, and energy harvesting devices. Its ability to convert mechanical stress into electrical energy and vice versa is utilized in the development of advanced electronic components and systems.

- PVDF in membrane technology: PVDF is widely used in membrane technology due to its excellent chemical resistance, thermal stability, and mechanical strength. It is employed in water treatment, gas separation, and filtration processes, offering high performance and durability in various industrial applications.

- PVDF in energy storage applications: PVDF and its copolymers are utilized in energy storage devices, particularly in lithium-ion batteries. The material serves as a binder for electrode materials and as a separator, enhancing the overall performance and safety of battery systems.

- Surface modification of PVDF: Various surface modification techniques are applied to PVDF to enhance its properties for specific applications. These modifications can improve hydrophilicity, biocompatibility, or introduce functional groups, expanding the material's potential in fields such as biomedical engineering and advanced coatings.

- PVDF in composite materials: PVDF is incorporated into composite materials to enhance their properties. By combining PVDF with other polymers, nanoparticles, or fibers, novel materials with improved mechanical, thermal, or electrical characteristics are developed for use in aerospace, automotive, and construction industries.

02 PVDF in membrane technology

PVDF is widely used in membrane technology due to its excellent chemical resistance and thermal stability. It is employed in water treatment, gas separation, and filtration processes, offering high performance and durability in various environmental conditions.Expand Specific Solutions03 PVDF in energy storage applications

PVDF and its copolymers are utilized in energy storage devices such as lithium-ion batteries and supercapacitors. The material's high dielectric constant and good mechanical properties make it suitable for electrode binders and separator membranes, enhancing the overall performance of energy storage systems.Expand Specific Solutions04 Surface modification of PVDF

Various surface modification techniques are applied to PVDF to enhance its functionality for specific applications. These modifications can improve hydrophilicity, biocompatibility, or introduce specific functional groups, expanding the material's use in biomedical, coating, and adhesive applications.Expand Specific Solutions05 PVDF in electronic and optical devices

PVDF's unique properties make it suitable for use in electronic and optical devices. Its ferroelectric behavior and transparency in thin film form allow for applications in non-volatile memory, optical sensors, and display technologies.Expand Specific Solutions

Key Players in PVDF Solar Cell Industry

The enhancement of PVDF functionality in solar cells is a competitive field in the maturing photovoltaic industry. The market is experiencing steady growth, driven by increasing demand for efficient and durable solar technologies. Major players like Applied Materials, Inc., Maxeon Solar Pte Ltd., and LG Electronics, Inc. are investing heavily in research and development to improve PVDF performance. The technology's maturity is advancing, with companies such as Arkema, Inc. and 3M Innovative Properties Co. leading innovations in PVDF formulations. Academic institutions like Massachusetts Institute of Technology and Zhejiang University are also contributing significantly to the field, pushing the boundaries of PVDF applications in solar cells.

Applied Materials, Inc.

Maxeon Solar Pte Ltd.

Innovative PVDF Modifications for Photovoltaic Efficiency

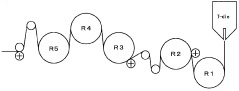

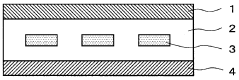

- The use of polyvinylidene fluoride (PVDF) as the outermost backsheet layer in photovoltaic modules, which can be coextruded, laminated, or applied as a solvent or aqueous coating, providing improved adhesion and eliminating the need for adhesive layers or surface treatments, and can be functionalized for enhanced performance.

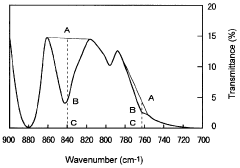

- A PVDF film with a crystal structure comprising 10% or more β-type crystals, as determined by infrared absorption spectrum, and having specific tensile elastic modulus properties, is produced using a method involving rapid cooling and heat treatment to prevent heat wrinkles during lamination.

Environmental Impact of PVDF in Solar Cell Production

The environmental impact of PVDF (Polyvinylidene Fluoride) in solar cell production is a critical consideration as the photovoltaic industry continues to expand. PVDF plays a crucial role in enhancing the performance and durability of solar cells, but its production and use also raise environmental concerns that must be addressed.

PVDF manufacturing processes involve the use of fluorine-based chemicals, which can contribute to greenhouse gas emissions and potential environmental contamination if not properly managed. The production of PVDF requires significant energy inputs, primarily derived from fossil fuels, leading to carbon dioxide emissions and contributing to climate change. Additionally, the synthesis of PVDF may generate hazardous waste products that require careful handling and disposal to prevent soil and water pollution.

However, the use of PVDF in solar cells also offers environmental benefits that partially offset these concerns. PVDF's excellent weather resistance and durability significantly extend the lifespan of solar panels, reducing the need for frequent replacements and minimizing waste generation. This longevity contributes to the overall sustainability of solar energy systems and helps to improve their life-cycle environmental performance.

The application of PVDF coatings on solar cells enhances their resistance to UV radiation, moisture, and chemical degradation. This protective function not only improves the efficiency and reliability of solar panels but also reduces the need for maintenance and replacement, further minimizing the environmental impact associated with manufacturing and disposing of solar cell components.

In terms of end-of-life considerations, the recycling of PVDF-containing solar panels presents both challenges and opportunities. While PVDF is a thermoplastic and theoretically recyclable, the complex composition of solar panels makes the separation and recovery of PVDF challenging. Developing efficient recycling technologies for PVDF and other solar panel components is crucial to minimize waste and promote a circular economy in the photovoltaic industry.

Research into more environmentally friendly alternatives to PVDF is ongoing, with a focus on bio-based polymers and green chemistry approaches. These efforts aim to reduce the environmental footprint of solar cell production while maintaining or improving the functional benefits provided by PVDF. However, any potential alternatives must undergo rigorous testing to ensure they meet the stringent performance and durability requirements of solar cell applications.

As the solar energy sector continues to grow, balancing the environmental impacts of PVDF production with its benefits in solar cell performance remains a key challenge. Ongoing efforts to optimize manufacturing processes, improve recycling technologies, and develop sustainable alternatives will be crucial in enhancing the overall environmental sustainability of solar energy systems.

Cost-Benefit Analysis of Enhanced PVDF Solar Cells

The cost-benefit analysis of enhanced PVDF solar cells reveals a complex interplay of economic factors and technological advancements. Initial implementation costs for incorporating enhanced PVDF into solar cell manufacturing processes are significant, primarily due to the need for specialized equipment and materials. However, these upfront expenses are offset by the long-term benefits of improved solar cell efficiency and durability.

Enhanced PVDF solar cells demonstrate superior performance in harsh environmental conditions, leading to extended operational lifespans. This longevity translates to reduced replacement and maintenance costs over time, contributing to a more favorable total cost of ownership for solar energy systems. The improved efficiency of PVDF-enhanced cells also results in higher energy yields per unit area, potentially reducing the overall footprint required for solar installations.

From a market perspective, the enhanced functionality of PVDF solar cells commands a premium price point. While this may initially limit adoption to high-end applications, economies of scale are expected to drive down production costs as the technology matures. The increased durability and efficiency of these cells make them particularly attractive for large-scale solar farms and installations in challenging environments, where the benefits of enhanced performance can justify the higher initial investment.

Environmental benefits also factor into the cost-benefit equation. The extended lifespan of PVDF-enhanced solar cells reduces electronic waste and the need for frequent replacements, aligning with sustainability goals and potentially offering advantages in markets with strict environmental regulations. Additionally, the improved efficiency contributes to a faster return on investment in terms of energy production and carbon offset.

However, challenges remain in scaling up production and optimizing manufacturing processes to reduce costs. Research and development investments are necessary to further enhance PVDF functionality and explore new applications. The cost-benefit analysis must also consider potential shifts in the competitive landscape, as alternative materials and technologies may emerge to challenge PVDF's position in the solar cell market.

In conclusion, while the initial costs of implementing enhanced PVDF in solar cells are substantial, the long-term benefits in efficiency, durability, and environmental impact present a compelling case for investment. As the technology matures and production scales up, the cost-benefit ratio is expected to improve, potentially positioning PVDF-enhanced solar cells as a key player in the future of renewable energy technologies.