How to Foster Innovation in Half Wave Rectifier Technologies?

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Evolution and Objectives

Half wave rectifiers have been a fundamental component in electronic circuits since the early days of electrical engineering. The evolution of these devices has been closely tied to the development of semiconductor technology and power electronics. Initially, vacuum tube diodes were used for rectification, but the advent of solid-state electronics in the mid-20th century led to the widespread adoption of semiconductor diodes in half wave rectifier circuits.

The primary objective of half wave rectifiers is to convert alternating current (AC) into pulsating direct current (DC). This conversion is crucial in many applications, including power supplies, signal processing, and energy harvesting systems. As technology has advanced, the goals for half wave rectifier technologies have expanded beyond basic AC to DC conversion.

One of the key evolutionary trends in half wave rectifier technology has been the pursuit of higher efficiency. Early rectifiers suffered from significant power losses, primarily due to the forward voltage drop across the diode. The development of Schottky diodes and synchronous rectification techniques has greatly improved efficiency, reducing power losses and heat generation.

Another important objective in the evolution of half wave rectifiers has been the miniaturization of components. As electronic devices have become smaller and more portable, there has been a growing demand for compact rectifier solutions. This has led to the development of integrated circuit rectifiers and the use of advanced packaging techniques to reduce the overall footprint of rectifier circuits.

The need for higher power handling capabilities has also driven innovation in half wave rectifier technologies. Modern applications, such as electric vehicle charging and renewable energy systems, require rectifiers that can handle much higher currents and voltages than their predecessors. This has spurred research into new semiconductor materials and device structures capable of withstanding higher power levels.

Improving the quality of the rectified output has been another key objective. Traditional half wave rectifiers produce a pulsating DC output with significant ripple, which can be problematic in sensitive applications. Advanced filtering techniques and the integration of smoothing capacitors have been developed to produce cleaner DC outputs.

Looking towards the future, the objectives for half wave rectifier technologies are likely to focus on further improvements in efficiency, power density, and integration with other circuit components. There is also a growing interest in developing "smart" rectifiers that can adapt to varying input conditions and load requirements, potentially incorporating digital control and monitoring capabilities.

In conclusion, the evolution of half wave rectifier technologies has been driven by a continuous push for better performance, smaller size, and wider applicability. As we look to foster innovation in this field, it is crucial to consider these historical trends and future objectives, focusing on solutions that address the ever-increasing demands of modern electronic systems.

The primary objective of half wave rectifiers is to convert alternating current (AC) into pulsating direct current (DC). This conversion is crucial in many applications, including power supplies, signal processing, and energy harvesting systems. As technology has advanced, the goals for half wave rectifier technologies have expanded beyond basic AC to DC conversion.

One of the key evolutionary trends in half wave rectifier technology has been the pursuit of higher efficiency. Early rectifiers suffered from significant power losses, primarily due to the forward voltage drop across the diode. The development of Schottky diodes and synchronous rectification techniques has greatly improved efficiency, reducing power losses and heat generation.

Another important objective in the evolution of half wave rectifiers has been the miniaturization of components. As electronic devices have become smaller and more portable, there has been a growing demand for compact rectifier solutions. This has led to the development of integrated circuit rectifiers and the use of advanced packaging techniques to reduce the overall footprint of rectifier circuits.

The need for higher power handling capabilities has also driven innovation in half wave rectifier technologies. Modern applications, such as electric vehicle charging and renewable energy systems, require rectifiers that can handle much higher currents and voltages than their predecessors. This has spurred research into new semiconductor materials and device structures capable of withstanding higher power levels.

Improving the quality of the rectified output has been another key objective. Traditional half wave rectifiers produce a pulsating DC output with significant ripple, which can be problematic in sensitive applications. Advanced filtering techniques and the integration of smoothing capacitors have been developed to produce cleaner DC outputs.

Looking towards the future, the objectives for half wave rectifier technologies are likely to focus on further improvements in efficiency, power density, and integration with other circuit components. There is also a growing interest in developing "smart" rectifiers that can adapt to varying input conditions and load requirements, potentially incorporating digital control and monitoring capabilities.

In conclusion, the evolution of half wave rectifier technologies has been driven by a continuous push for better performance, smaller size, and wider applicability. As we look to foster innovation in this field, it is crucial to consider these historical trends and future objectives, focusing on solutions that address the ever-increasing demands of modern electronic systems.

Market Analysis for Improved Rectification

The market for improved rectification technologies, particularly in half-wave rectifiers, is experiencing significant growth driven by the increasing demand for efficient power conversion in various industries. The global power electronics market, which includes rectifiers, is projected to reach $40 billion by 2025, with a compound annual growth rate of 5.5%. This growth is primarily fueled by the rapid expansion of renewable energy systems, electric vehicles, and consumer electronics.

In the renewable energy sector, half-wave rectifiers play a crucial role in converting AC power generated by solar panels and wind turbines into usable DC power. As countries worldwide push for greater adoption of clean energy, the demand for more efficient rectification technologies is expected to surge. The solar inverter market alone is anticipated to exceed $9 billion by 2024, presenting a substantial opportunity for innovative half-wave rectifier solutions.

The automotive industry, particularly the electric vehicle (EV) segment, is another key driver for improved rectification technologies. With global EV sales projected to reach 26 million units by 2030, the need for high-efficiency power conversion systems in charging infrastructure and onboard vehicle systems is becoming increasingly critical. Enhanced half-wave rectifier technologies can contribute to faster charging times and improved overall energy efficiency in EVs.

Consumer electronics represent another significant market for advanced rectification technologies. The proliferation of smartphones, tablets, and other portable devices has created a demand for more efficient power adapters and chargers. Improved half-wave rectifiers can help reduce energy losses during AC-DC conversion, leading to faster charging times and lower power consumption.

Industrial applications, including motor drives and power supplies, also present substantial opportunities for innovation in half-wave rectifier technologies. The industrial power supply market is expected to grow at a CAGR of 6.3% through 2025, driven by the increasing automation and digitalization of manufacturing processes.

To capitalize on these market opportunities, companies developing improved half-wave rectifier technologies should focus on addressing key customer pain points. These include reducing power losses, improving thermal management, enhancing reliability, and minimizing electromagnetic interference. Additionally, there is a growing demand for compact and lightweight rectifier solutions, particularly in portable and space-constrained applications.

The market analysis reveals that while silicon-based rectifiers continue to dominate, there is increasing interest in wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) for high-performance rectification. These materials offer superior switching speeds and lower power losses, making them attractive for applications requiring high efficiency and high-temperature operation.

In the renewable energy sector, half-wave rectifiers play a crucial role in converting AC power generated by solar panels and wind turbines into usable DC power. As countries worldwide push for greater adoption of clean energy, the demand for more efficient rectification technologies is expected to surge. The solar inverter market alone is anticipated to exceed $9 billion by 2024, presenting a substantial opportunity for innovative half-wave rectifier solutions.

The automotive industry, particularly the electric vehicle (EV) segment, is another key driver for improved rectification technologies. With global EV sales projected to reach 26 million units by 2030, the need for high-efficiency power conversion systems in charging infrastructure and onboard vehicle systems is becoming increasingly critical. Enhanced half-wave rectifier technologies can contribute to faster charging times and improved overall energy efficiency in EVs.

Consumer electronics represent another significant market for advanced rectification technologies. The proliferation of smartphones, tablets, and other portable devices has created a demand for more efficient power adapters and chargers. Improved half-wave rectifiers can help reduce energy losses during AC-DC conversion, leading to faster charging times and lower power consumption.

Industrial applications, including motor drives and power supplies, also present substantial opportunities for innovation in half-wave rectifier technologies. The industrial power supply market is expected to grow at a CAGR of 6.3% through 2025, driven by the increasing automation and digitalization of manufacturing processes.

To capitalize on these market opportunities, companies developing improved half-wave rectifier technologies should focus on addressing key customer pain points. These include reducing power losses, improving thermal management, enhancing reliability, and minimizing electromagnetic interference. Additionally, there is a growing demand for compact and lightweight rectifier solutions, particularly in portable and space-constrained applications.

The market analysis reveals that while silicon-based rectifiers continue to dominate, there is increasing interest in wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) for high-performance rectification. These materials offer superior switching speeds and lower power losses, making them attractive for applications requiring high efficiency and high-temperature operation.

Current Challenges in Half Wave Rectification

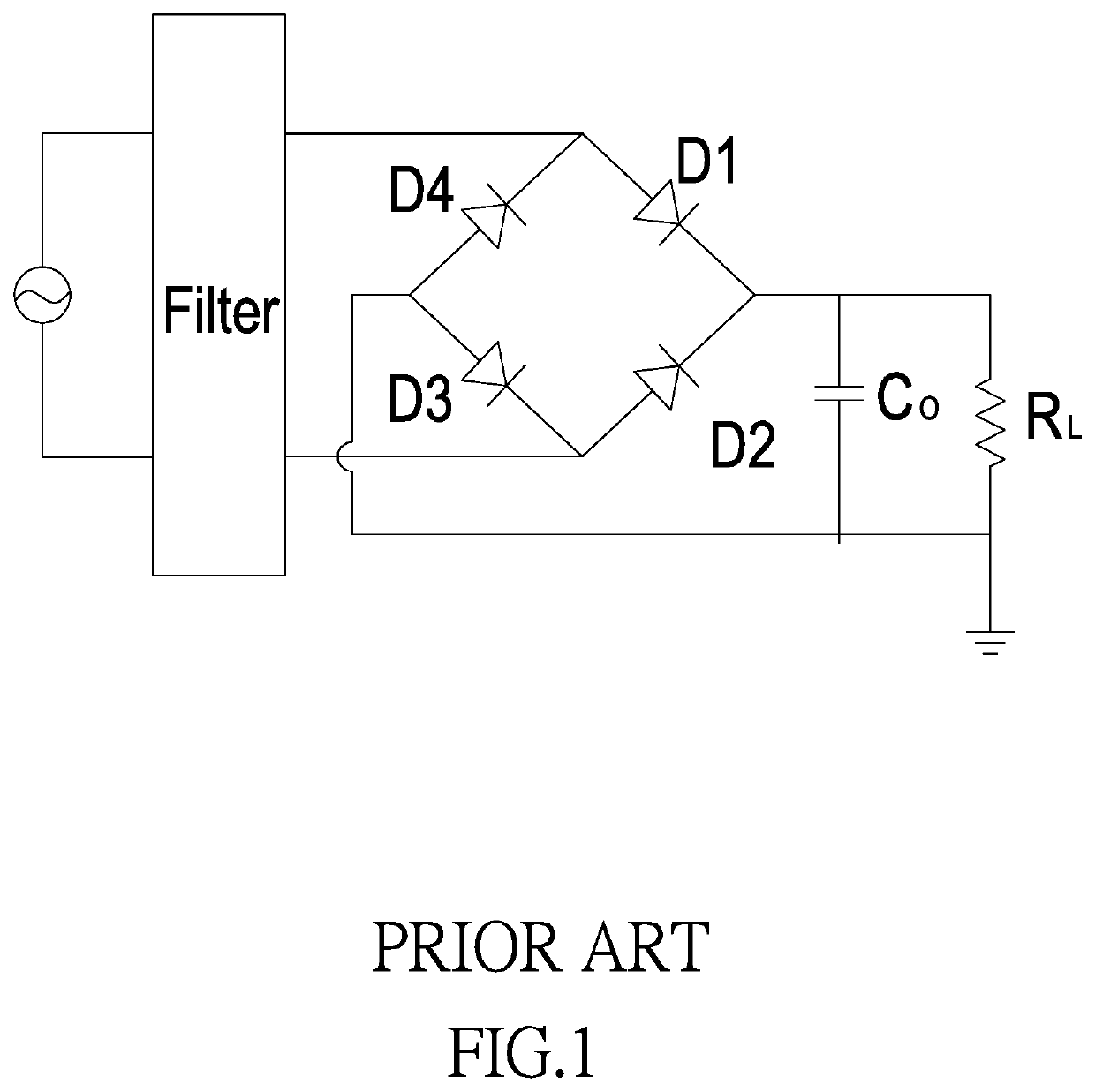

Half wave rectification, while a fundamental technique in power electronics, faces several challenges that impede its widespread adoption and efficiency. One of the primary issues is the inherent inefficiency of the process. By utilizing only one half of the AC cycle, half wave rectifiers waste a significant portion of the input power, resulting in lower overall efficiency compared to full wave rectification methods.

Another challenge lies in the pulsating nature of the output voltage. The intermittent current flow creates a ripple in the DC output, which can be problematic for sensitive electronic devices requiring a smooth, constant voltage supply. This ripple effect necessitates additional filtering components, increasing the complexity and cost of the circuit design.

The presence of harmonics in the output waveform presents yet another hurdle. These harmonics can cause electromagnetic interference (EMI) and introduce noise into the system, potentially affecting the performance of nearby electronic equipment. Mitigating these harmonics often requires sophisticated filtering techniques, further complicating the circuit design and increasing production costs.

Power factor correction is also a significant challenge in half wave rectifier technologies. The non-linear nature of the rectification process leads to poor power factor, which can result in increased energy consumption and higher electricity bills for end-users. Addressing this issue typically involves implementing power factor correction circuits, adding to the overall complexity and cost of the system.

Thermal management poses another obstacle in half wave rectifier designs. The pulsating current flow can lead to uneven heating of components, potentially causing thermal stress and reducing the lifespan of the rectifier. Effective heat dissipation strategies are crucial to ensure reliable operation and longevity of the device.

Furthermore, the limited power handling capability of half wave rectifiers restricts their application in high-power scenarios. As power requirements increase, the components used in half wave rectification may struggle to handle the higher currents and voltages, necessitating the use of more robust and expensive components or alternative rectification methods.

Lastly, the reverse recovery time of diodes used in half wave rectifiers can impact the overall efficiency and performance of the circuit. During the transition from forward to reverse bias, diodes require a finite time to stop conducting, which can lead to power losses and reduced efficiency. Improving diode characteristics or exploring alternative semiconductor technologies could help address this challenge and enhance the overall performance of half wave rectifier systems.

Another challenge lies in the pulsating nature of the output voltage. The intermittent current flow creates a ripple in the DC output, which can be problematic for sensitive electronic devices requiring a smooth, constant voltage supply. This ripple effect necessitates additional filtering components, increasing the complexity and cost of the circuit design.

The presence of harmonics in the output waveform presents yet another hurdle. These harmonics can cause electromagnetic interference (EMI) and introduce noise into the system, potentially affecting the performance of nearby electronic equipment. Mitigating these harmonics often requires sophisticated filtering techniques, further complicating the circuit design and increasing production costs.

Power factor correction is also a significant challenge in half wave rectifier technologies. The non-linear nature of the rectification process leads to poor power factor, which can result in increased energy consumption and higher electricity bills for end-users. Addressing this issue typically involves implementing power factor correction circuits, adding to the overall complexity and cost of the system.

Thermal management poses another obstacle in half wave rectifier designs. The pulsating current flow can lead to uneven heating of components, potentially causing thermal stress and reducing the lifespan of the rectifier. Effective heat dissipation strategies are crucial to ensure reliable operation and longevity of the device.

Furthermore, the limited power handling capability of half wave rectifiers restricts their application in high-power scenarios. As power requirements increase, the components used in half wave rectification may struggle to handle the higher currents and voltages, necessitating the use of more robust and expensive components or alternative rectification methods.

Lastly, the reverse recovery time of diodes used in half wave rectifiers can impact the overall efficiency and performance of the circuit. During the transition from forward to reverse bias, diodes require a finite time to stop conducting, which can lead to power losses and reduced efficiency. Improving diode characteristics or exploring alternative semiconductor technologies could help address this challenge and enhance the overall performance of half wave rectifier systems.

State-of-the-Art Half Wave Rectifier Designs

01 Improved efficiency and power factor correction

Innovations in half-wave rectifier designs focus on enhancing efficiency and power factor correction. These improvements involve advanced circuit configurations and control strategies to minimize energy losses and optimize power conversion. Such designs often incorporate feedback mechanisms and adaptive control algorithms to maintain high performance across varying load conditions.- Improved efficiency and power factor correction: Innovations in half-wave rectifier designs focus on enhancing efficiency and power factor correction. These improvements involve advanced circuit configurations and control strategies to minimize power losses and optimize energy conversion. Such designs often incorporate power factor correction techniques to reduce harmonic distortion and improve overall system performance.

- Integration with other power electronics components: Modern half-wave rectifier innovations involve integration with other power electronics components to create more compact and versatile systems. These integrated designs may combine rectification with voltage regulation, filtering, or power conversion stages. Such integration can lead to reduced component count, improved reliability, and enhanced overall system functionality.

- Novel semiconductor device implementations: Advancements in semiconductor technology have led to novel implementations of half-wave rectifiers using advanced devices. These innovations may utilize wide-bandgap semiconductors, such as silicon carbide or gallium nitride, or employ new device structures to achieve higher efficiency, faster switching speeds, and improved thermal performance.

- Specialized applications and adaptations: Half-wave rectifier innovations have been developed for specialized applications, such as high-frequency power supplies, renewable energy systems, or automotive electronics. These adaptations may involve unique circuit topologies, control algorithms, or protection mechanisms tailored to specific industry requirements or operating conditions.

- Enhanced protection and reliability features: Recent innovations in half-wave rectifiers focus on improving protection and reliability. These advancements may include overvoltage and overcurrent protection circuits, thermal management solutions, or fault detection and isolation mechanisms. Such features aim to enhance the longevity and robustness of rectifier systems in various operating environments.

02 Integration with other power electronics components

Modern half-wave rectifier innovations involve integration with other power electronics components to create more compact and versatile systems. These integrated designs may combine rectification with voltage regulation, power factor correction, and protection circuits in a single package. This approach reduces overall system complexity, improves reliability, and enables more efficient use of space in electronic devices.Expand Specific Solutions03 Application-specific optimizations

Half-wave rectifier innovations are being tailored for specific applications, such as LED drivers, battery chargers, and renewable energy systems. These optimizations involve customizing the rectifier design to meet the unique requirements of each application, including voltage and current characteristics, efficiency targets, and environmental considerations. Such application-specific designs often result in improved performance and reduced costs for the overall system.Expand Specific Solutions04 Advanced semiconductor materials and topologies

Innovations in half-wave rectifiers leverage advanced semiconductor materials and novel circuit topologies to improve performance. These developments include the use of wide-bandgap semiconductors, such as silicon carbide and gallium nitride, which offer higher efficiency and faster switching speeds. New circuit topologies are also being explored to reduce losses and improve power quality in rectification processes.Expand Specific Solutions05 Smart control and monitoring systems

Modern half-wave rectifier innovations incorporate smart control and monitoring systems to enhance performance and reliability. These systems use microcontrollers or digital signal processors to implement advanced control algorithms, real-time monitoring, and fault detection. Such intelligent rectifiers can adapt to changing operating conditions, predict potential failures, and optimize their performance over time, leading to improved efficiency and longer operational life.Expand Specific Solutions

Key Players in Rectifier Industry

The half wave rectifier technology market is in a mature stage, with established players and well-defined applications. However, innovation remains crucial for addressing efficiency improvements and emerging applications. The global market size for rectifier technologies is estimated to be in the billions of dollars, driven by power electronics and renewable energy sectors. Technologically, companies like IBM, Sony, and Huawei are at the forefront, leveraging their R&D capabilities to develop advanced rectifier solutions. Academic institutions such as Zhejiang University and the Technical University of Denmark are also contributing significantly to research in this field, focusing on novel materials and designs to enhance rectifier performance and efficiency.

International Business Machines Corp.

Technical Solution: IBM has been innovating in half wave rectifier technologies through their advanced semiconductor research. They have developed a novel approach using silicon-germanium (SiGe) heterojunction bipolar transistors (HBTs) to create high-performance half wave rectifiers. This technology allows for higher operating frequencies and improved power efficiency in RF and microwave applications[1]. IBM's rectifier design incorporates advanced bandgap engineering techniques to optimize the device's forward voltage drop and reverse recovery characteristics, resulting in significantly reduced power losses[3]. Additionally, IBM has explored the integration of these rectifiers with their quantum computing technologies, potentially enabling more efficient power management in future quantum systems[5].

Strengths: Advanced semiconductor expertise, integration with quantum technologies. Weaknesses: Potentially high production costs, limited to high-end applications.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has been at the forefront of innovating half wave rectifier technologies, particularly in the context of 5G and IoT applications. They have developed a novel approach using gallium nitride (GaN) based devices to create high-efficiency rectifiers for wireless power transfer systems[2]. Huawei's rectifier design incorporates advanced packaging techniques and thermal management solutions to optimize performance in compact form factors. Their research has also focused on improving the rectifier's efficiency across a wide range of input power levels, making it suitable for various IoT devices with different power requirements[4]. Furthermore, Huawei has explored the integration of artificial intelligence algorithms to dynamically adjust rectifier parameters based on real-time operating conditions, potentially leading to adaptive and more efficient power conversion systems[6].

Strengths: Strong focus on 5G and IoT applications, advanced GaN technology. Weaknesses: Potential geopolitical challenges, heavy reliance on semiconductor supply chains.

Breakthrough Patents in Rectification

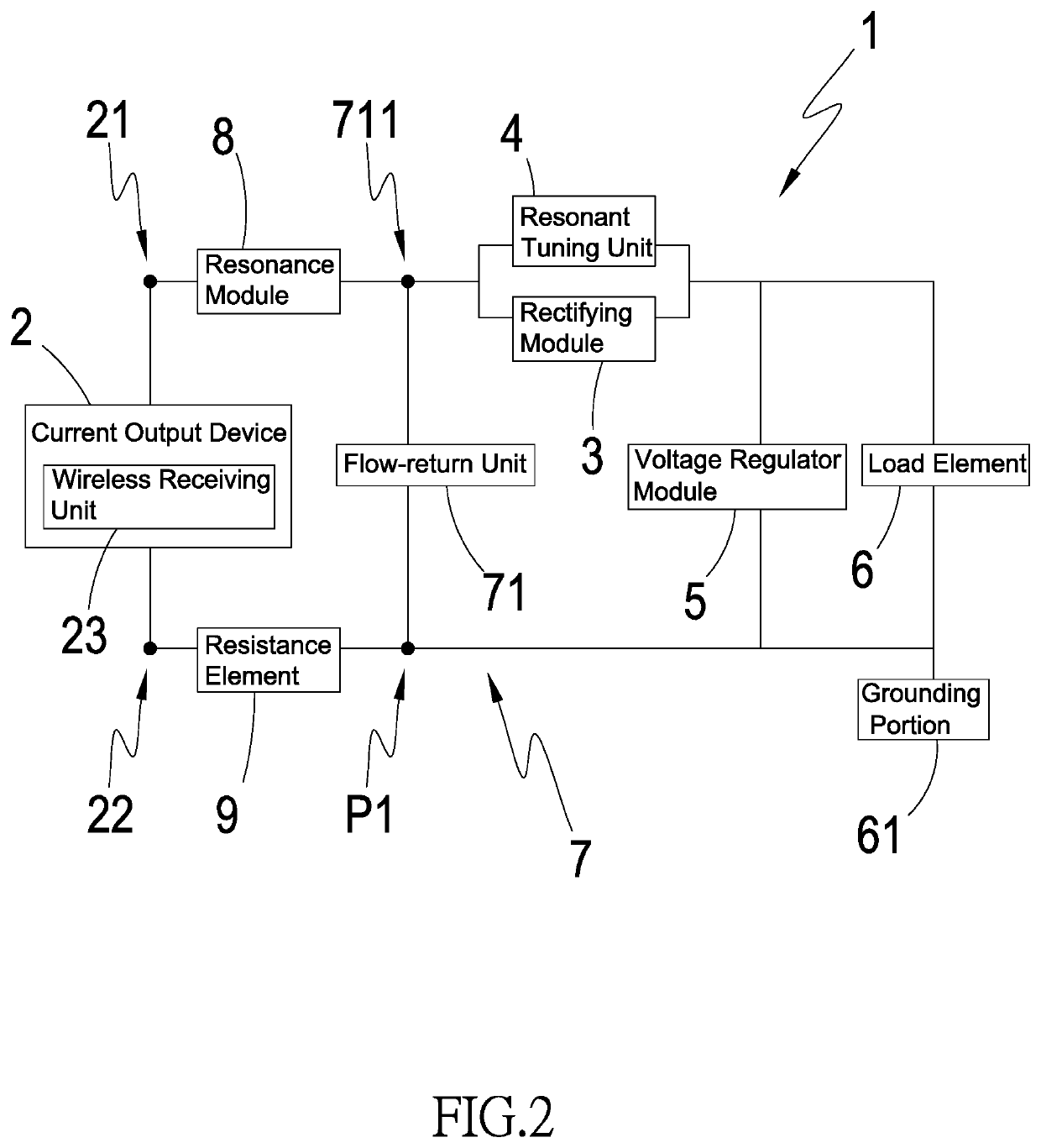

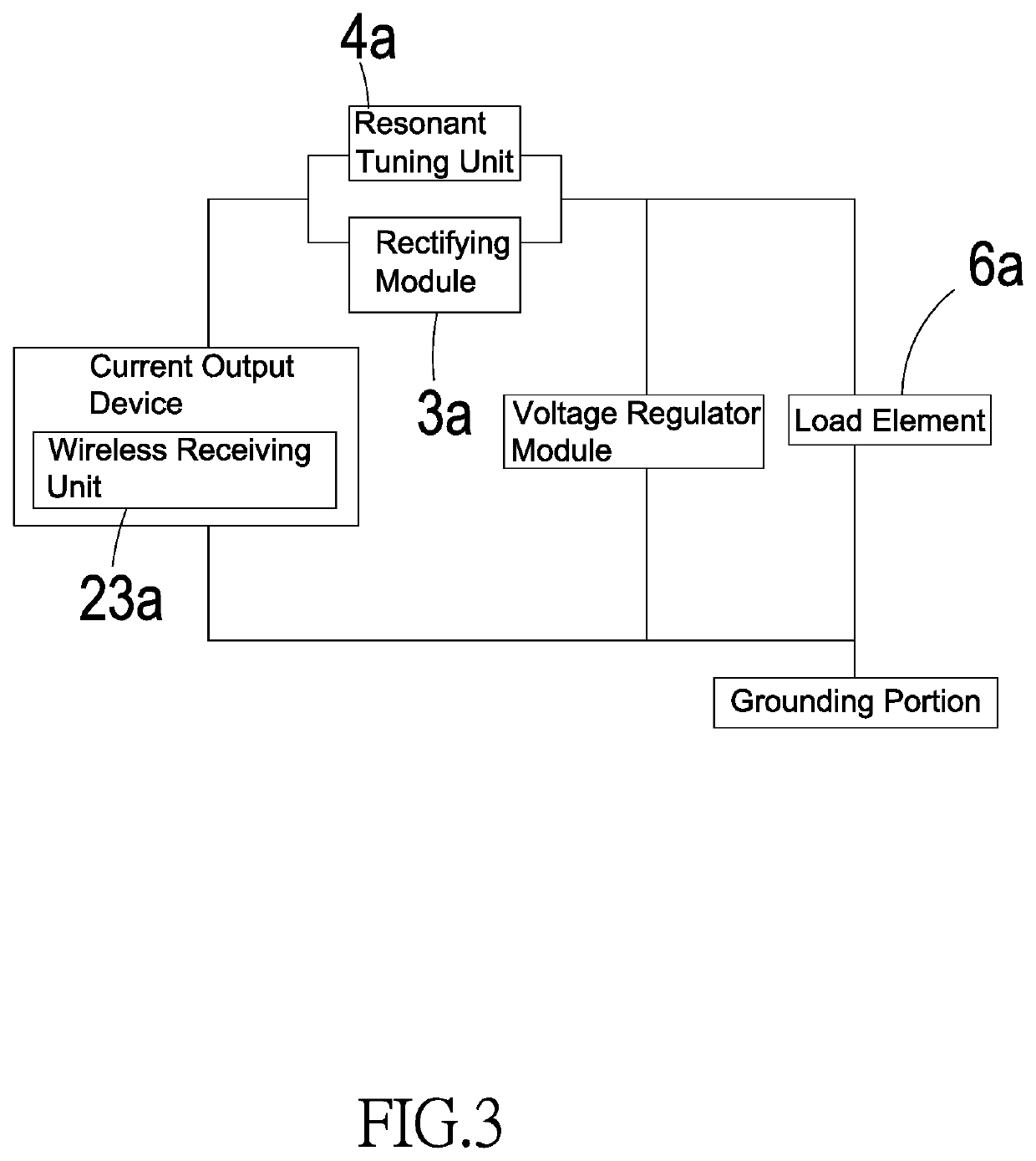

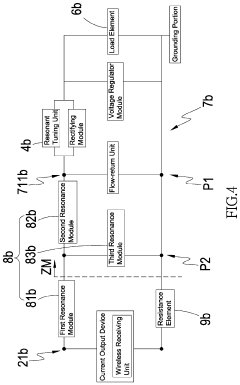

High-frequency half-wave rectifier system of low-harmonicity and high-efficiency

PatentInactiveUS10594205B2

Innovation

- A high-frequency half-wave rectifier system with a simplified structure and reduced electronic components, utilizing a resonant tuning unit and voltage regulator module to control the duty cycle and capacitance, thereby reducing harmonic content and electromagnetic interference, and improving conversion efficiency.

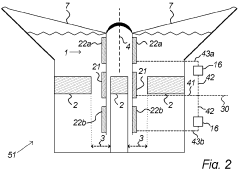

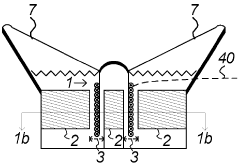

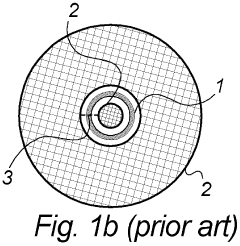

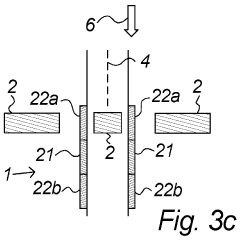

A method and system for driving a voice coil of a loudspeaker

PatentActiveGB2591767A

Innovation

- A voice coil driving system with segmented voice coil sections, where a centre voice coil section and auxiliary voice coil sections are driven by centre and auxiliary driving signals, respectively, with rectifying units attenuating or blocking currents in specific directions to minimize power consumption and heating by only powering sections within the air gap.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the development and innovation of half-wave rectifier technologies. As power electronics continue to play an increasingly important role in various applications, from consumer electronics to industrial systems, the need for more efficient rectification processes becomes paramount. Half-wave rectifiers, while simple in design, have traditionally been less efficient compared to full-wave rectifiers due to their inherent nature of utilizing only half of the input waveform.

To foster innovation in this area, researchers and engineers are focusing on several key aspects of energy efficiency. One primary area of improvement is the reduction of forward voltage drop across the rectifying diode. This can be achieved through the use of advanced semiconductor materials and novel device structures, such as Schottky diodes or synchronous rectification techniques. By minimizing the voltage drop, the overall power loss during the rectification process can be significantly reduced.

Another important consideration is the management of reverse recovery losses. When a diode switches from its conducting state to its blocking state, there is a brief period where a reverse current flows, leading to additional power dissipation. Innovations in diode design, such as the development of ultra-fast recovery diodes or the implementation of soft recovery techniques, can help mitigate these losses and improve overall efficiency.

The optimization of circuit topology is also crucial for enhancing energy efficiency in half-wave rectifier applications. This includes the careful selection and design of passive components, such as inductors and capacitors, to minimize parasitic losses and improve power factor. Additionally, the integration of intelligent control systems can enable dynamic adjustment of rectifier operation based on load conditions, further optimizing energy utilization.

Thermal management is another critical aspect of energy efficiency in half-wave rectifiers. As power density increases, effective heat dissipation becomes essential to maintain optimal performance and reliability. Innovations in thermal design, such as advanced packaging techniques and the use of high thermal conductivity materials, can significantly improve the overall efficiency of the rectification system.

Furthermore, the exploration of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), offers promising avenues for improving the energy efficiency of half-wave rectifiers. These materials exhibit superior electrical properties, including higher breakdown voltages and lower on-state resistances, which can lead to reduced conduction losses and improved overall system efficiency.

In conclusion, fostering innovation in half-wave rectifier technologies with a focus on energy efficiency requires a multifaceted approach. By addressing key areas such as device-level improvements, circuit optimization, thermal management, and the adoption of advanced materials, significant strides can be made in enhancing the performance and efficiency of these fundamental power electronic components.

To foster innovation in this area, researchers and engineers are focusing on several key aspects of energy efficiency. One primary area of improvement is the reduction of forward voltage drop across the rectifying diode. This can be achieved through the use of advanced semiconductor materials and novel device structures, such as Schottky diodes or synchronous rectification techniques. By minimizing the voltage drop, the overall power loss during the rectification process can be significantly reduced.

Another important consideration is the management of reverse recovery losses. When a diode switches from its conducting state to its blocking state, there is a brief period where a reverse current flows, leading to additional power dissipation. Innovations in diode design, such as the development of ultra-fast recovery diodes or the implementation of soft recovery techniques, can help mitigate these losses and improve overall efficiency.

The optimization of circuit topology is also crucial for enhancing energy efficiency in half-wave rectifier applications. This includes the careful selection and design of passive components, such as inductors and capacitors, to minimize parasitic losses and improve power factor. Additionally, the integration of intelligent control systems can enable dynamic adjustment of rectifier operation based on load conditions, further optimizing energy utilization.

Thermal management is another critical aspect of energy efficiency in half-wave rectifiers. As power density increases, effective heat dissipation becomes essential to maintain optimal performance and reliability. Innovations in thermal design, such as advanced packaging techniques and the use of high thermal conductivity materials, can significantly improve the overall efficiency of the rectification system.

Furthermore, the exploration of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), offers promising avenues for improving the energy efficiency of half-wave rectifiers. These materials exhibit superior electrical properties, including higher breakdown voltages and lower on-state resistances, which can lead to reduced conduction losses and improved overall system efficiency.

In conclusion, fostering innovation in half-wave rectifier technologies with a focus on energy efficiency requires a multifaceted approach. By addressing key areas such as device-level improvements, circuit optimization, thermal management, and the adoption of advanced materials, significant strides can be made in enhancing the performance and efficiency of these fundamental power electronic components.

Emerging Applications for Half Wave Rectifiers

Half wave rectifiers, traditionally used in power supply circuits, are finding new applications in emerging technologies. In the field of energy harvesting, these devices are being adapted to capture and convert ambient energy from various sources. For instance, researchers are exploring the use of half wave rectifiers in piezoelectric energy harvesting systems, where mechanical vibrations are converted into electrical energy. This application shows promise in powering small, low-energy devices in remote or hard-to-reach locations.

In the rapidly growing Internet of Things (IoT) sector, half wave rectifiers are being integrated into wireless power transfer systems. These systems enable the charging of IoT devices without physical connections, utilizing electromagnetic fields for power transmission. The simplicity and efficiency of half wave rectifiers make them suitable for compact, low-power IoT devices, potentially extending battery life and reducing maintenance requirements.

The automotive industry is also exploring innovative applications for half wave rectifiers. In electric and hybrid vehicles, these components are being investigated for use in regenerative braking systems. By efficiently converting the kinetic energy of a decelerating vehicle into electrical energy, half wave rectifiers could contribute to improved energy recovery and overall vehicle efficiency.

In the field of renewable energy, half wave rectifiers are finding applications in solar power systems. Researchers are developing novel photovoltaic cell designs that incorporate half wave rectification to improve energy conversion efficiency. This approach could lead to more cost-effective and efficient solar panels, potentially accelerating the adoption of solar energy.

Biomedical engineering presents another frontier for half wave rectifier innovation. These devices are being explored for use in implantable medical devices, such as pacemakers and neurostimulators. The compact nature and simplicity of half wave rectifiers make them suitable for miniaturized, low-power medical implants that can harvest energy from the human body, potentially eliminating the need for battery replacement surgeries.

In telecommunications, half wave rectifiers are being investigated for use in advanced antenna designs. By integrating these components into antenna systems, researchers aim to improve signal reception and transmission efficiency, particularly in high-frequency applications such as 5G networks.

These emerging applications demonstrate the versatility and potential of half wave rectifier technologies beyond their traditional uses. As research continues, we can expect to see further innovations and novel applications across various industries, driving the need for continued development and optimization of half wave rectifier technologies.

In the rapidly growing Internet of Things (IoT) sector, half wave rectifiers are being integrated into wireless power transfer systems. These systems enable the charging of IoT devices without physical connections, utilizing electromagnetic fields for power transmission. The simplicity and efficiency of half wave rectifiers make them suitable for compact, low-power IoT devices, potentially extending battery life and reducing maintenance requirements.

The automotive industry is also exploring innovative applications for half wave rectifiers. In electric and hybrid vehicles, these components are being investigated for use in regenerative braking systems. By efficiently converting the kinetic energy of a decelerating vehicle into electrical energy, half wave rectifiers could contribute to improved energy recovery and overall vehicle efficiency.

In the field of renewable energy, half wave rectifiers are finding applications in solar power systems. Researchers are developing novel photovoltaic cell designs that incorporate half wave rectification to improve energy conversion efficiency. This approach could lead to more cost-effective and efficient solar panels, potentially accelerating the adoption of solar energy.

Biomedical engineering presents another frontier for half wave rectifier innovation. These devices are being explored for use in implantable medical devices, such as pacemakers and neurostimulators. The compact nature and simplicity of half wave rectifiers make them suitable for miniaturized, low-power medical implants that can harvest energy from the human body, potentially eliminating the need for battery replacement surgeries.

In telecommunications, half wave rectifiers are being investigated for use in advanced antenna designs. By integrating these components into antenna systems, researchers aim to improve signal reception and transmission efficiency, particularly in high-frequency applications such as 5G networks.

These emerging applications demonstrate the versatility and potential of half wave rectifier technologies beyond their traditional uses. As research continues, we can expect to see further innovations and novel applications across various industries, driving the need for continued development and optimization of half wave rectifier technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!