How to Prepare for Future Disruptions with Half Wave Rectifiers?

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Evolution and Objectives

Half wave rectifiers have played a crucial role in the evolution of power electronics since their inception in the early 20th century. Initially developed as a simple means to convert alternating current (AC) to pulsating direct current (DC), these devices have undergone significant transformations to meet the ever-increasing demands of modern electronics and power systems.

The journey of half wave rectifiers began with the invention of the vacuum tube diode by John Ambrose Fleming in 1904. This breakthrough laid the foundation for the first practical half wave rectifier circuits. As technology progressed, semiconductor diodes replaced vacuum tubes, leading to more compact and efficient rectifier designs. The introduction of silicon diodes in the 1950s marked a significant milestone, offering improved performance and reliability.

Throughout the decades, the objectives of half wave rectifier development have consistently focused on enhancing efficiency, reducing power losses, and improving the quality of the output DC voltage. Engineers have strived to minimize the ripple in the output waveform, a characteristic challenge of half wave rectification. This pursuit has led to the integration of advanced filtering techniques and the exploration of novel materials for diode construction.

In recent years, the advent of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has opened new avenues for half wave rectifier design. These materials offer superior performance in terms of switching speed, temperature tolerance, and power handling capabilities, pushing the boundaries of what is possible with rectifier technology.

The ongoing trend towards miniaturization and increased power density in electronic devices has placed new demands on half wave rectifiers. Researchers and engineers are now focusing on developing ultra-compact rectifier solutions that can operate efficiently at higher frequencies and power levels. This evolution is crucial for supporting emerging technologies such as 5G communications, electric vehicles, and renewable energy systems.

Looking ahead, the objectives for future half wave rectifier development are multifaceted. There is a strong emphasis on improving energy efficiency to meet stringent environmental regulations and reduce overall power consumption. Additionally, there is a growing need for rectifiers capable of handling higher voltages and currents to support the increasing electrification of various industries.

Another key objective is to enhance the resilience and reliability of half wave rectifiers in the face of potential disruptions. This includes developing designs that can withstand electromagnetic interference, voltage surges, and extreme environmental conditions. As power grids become more complex and interconnected, the ability of rectifiers to maintain stable operation under varying conditions becomes paramount.

The journey of half wave rectifiers began with the invention of the vacuum tube diode by John Ambrose Fleming in 1904. This breakthrough laid the foundation for the first practical half wave rectifier circuits. As technology progressed, semiconductor diodes replaced vacuum tubes, leading to more compact and efficient rectifier designs. The introduction of silicon diodes in the 1950s marked a significant milestone, offering improved performance and reliability.

Throughout the decades, the objectives of half wave rectifier development have consistently focused on enhancing efficiency, reducing power losses, and improving the quality of the output DC voltage. Engineers have strived to minimize the ripple in the output waveform, a characteristic challenge of half wave rectification. This pursuit has led to the integration of advanced filtering techniques and the exploration of novel materials for diode construction.

In recent years, the advent of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has opened new avenues for half wave rectifier design. These materials offer superior performance in terms of switching speed, temperature tolerance, and power handling capabilities, pushing the boundaries of what is possible with rectifier technology.

The ongoing trend towards miniaturization and increased power density in electronic devices has placed new demands on half wave rectifiers. Researchers and engineers are now focusing on developing ultra-compact rectifier solutions that can operate efficiently at higher frequencies and power levels. This evolution is crucial for supporting emerging technologies such as 5G communications, electric vehicles, and renewable energy systems.

Looking ahead, the objectives for future half wave rectifier development are multifaceted. There is a strong emphasis on improving energy efficiency to meet stringent environmental regulations and reduce overall power consumption. Additionally, there is a growing need for rectifiers capable of handling higher voltages and currents to support the increasing electrification of various industries.

Another key objective is to enhance the resilience and reliability of half wave rectifiers in the face of potential disruptions. This includes developing designs that can withstand electromagnetic interference, voltage surges, and extreme environmental conditions. As power grids become more complex and interconnected, the ability of rectifiers to maintain stable operation under varying conditions becomes paramount.

Market Demand Analysis for Advanced Rectification

The market demand for advanced rectification technologies, particularly those involving half wave rectifiers, has been steadily growing across various industries. This surge is primarily driven by the increasing need for efficient power conversion and management systems in a world that is becoming increasingly electrified and digitalized.

In the automotive sector, the shift towards electric vehicles (EVs) has created a significant demand for advanced rectification solutions. Half wave rectifiers play a crucial role in EV charging systems, power management, and motor control circuits. As the EV market continues to expand, the demand for more efficient and compact rectification technologies is expected to grow proportionally.

The renewable energy sector, particularly solar and wind power generation, represents another major market for advanced rectification technologies. As these energy sources become more prevalent, the need for efficient power conversion and grid integration solutions increases. Half wave rectifiers are essential components in inverters and power conditioning units used in renewable energy systems.

In the telecommunications industry, the ongoing rollout of 5G networks has created a substantial demand for advanced power management solutions. Base stations and network equipment require efficient rectification technologies to manage power consumption and ensure reliable operation. The compact nature and efficiency of half wave rectifiers make them particularly suitable for these applications.

The consumer electronics market also contributes significantly to the demand for advanced rectification technologies. With the proliferation of smart devices, wearables, and Internet of Things (IoT) devices, there is a growing need for compact and efficient power management solutions. Half wave rectifiers are often employed in charging circuits and power supplies for these devices.

Industrial automation and robotics represent another sector driving the demand for advanced rectification technologies. As factories become increasingly automated and adopt Industry 4.0 principles, the need for reliable and efficient power management solutions grows. Half wave rectifiers are used in various industrial applications, including motor drives, power supplies, and control systems.

The healthcare sector, with its increasing reliance on advanced medical equipment and devices, also contributes to the market demand for rectification technologies. From diagnostic imaging equipment to patient monitoring systems, efficient power management is crucial for the reliable operation of medical devices.

Looking ahead, the market for advanced rectification technologies is expected to continue its growth trajectory. Factors such as the increasing adoption of renewable energy, the expansion of electric vehicle markets, and the ongoing digital transformation across industries will drive this growth. Additionally, emerging technologies like artificial intelligence, edge computing, and the Internet of Things will create new applications and use cases for advanced rectification solutions, further expanding the market potential.

In the automotive sector, the shift towards electric vehicles (EVs) has created a significant demand for advanced rectification solutions. Half wave rectifiers play a crucial role in EV charging systems, power management, and motor control circuits. As the EV market continues to expand, the demand for more efficient and compact rectification technologies is expected to grow proportionally.

The renewable energy sector, particularly solar and wind power generation, represents another major market for advanced rectification technologies. As these energy sources become more prevalent, the need for efficient power conversion and grid integration solutions increases. Half wave rectifiers are essential components in inverters and power conditioning units used in renewable energy systems.

In the telecommunications industry, the ongoing rollout of 5G networks has created a substantial demand for advanced power management solutions. Base stations and network equipment require efficient rectification technologies to manage power consumption and ensure reliable operation. The compact nature and efficiency of half wave rectifiers make them particularly suitable for these applications.

The consumer electronics market also contributes significantly to the demand for advanced rectification technologies. With the proliferation of smart devices, wearables, and Internet of Things (IoT) devices, there is a growing need for compact and efficient power management solutions. Half wave rectifiers are often employed in charging circuits and power supplies for these devices.

Industrial automation and robotics represent another sector driving the demand for advanced rectification technologies. As factories become increasingly automated and adopt Industry 4.0 principles, the need for reliable and efficient power management solutions grows. Half wave rectifiers are used in various industrial applications, including motor drives, power supplies, and control systems.

The healthcare sector, with its increasing reliance on advanced medical equipment and devices, also contributes to the market demand for rectification technologies. From diagnostic imaging equipment to patient monitoring systems, efficient power management is crucial for the reliable operation of medical devices.

Looking ahead, the market for advanced rectification technologies is expected to continue its growth trajectory. Factors such as the increasing adoption of renewable energy, the expansion of electric vehicle markets, and the ongoing digital transformation across industries will drive this growth. Additionally, emerging technologies like artificial intelligence, edge computing, and the Internet of Things will create new applications and use cases for advanced rectification solutions, further expanding the market potential.

Current Challenges in Half Wave Rectifier Technology

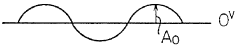

Half wave rectifiers, while fundamental in power electronics, face several challenges in the current technological landscape. One of the primary issues is their inherently low efficiency compared to full wave rectifiers. This inefficiency stems from the fact that half wave rectifiers only utilize one half of the AC cycle, resulting in significant power loss and increased heat generation.

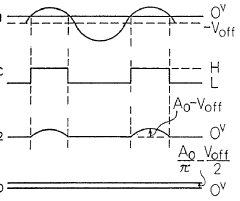

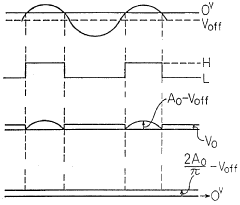

Another challenge lies in the high ripple content in the output voltage. The pulsating nature of the rectified waveform necessitates extensive filtering to achieve a smooth DC output, adding complexity and cost to the overall system. This ripple can lead to noise and interference issues in sensitive electronic applications, limiting the use of half wave rectifiers in high-precision circuits.

The non-linear behavior of half wave rectifiers poses difficulties in maintaining power quality. The rectification process introduces harmonic distortions into the power system, potentially causing electromagnetic interference and reducing the overall power factor. This non-linearity can lead to compliance issues with increasingly stringent power quality standards and regulations.

Voltage regulation is another area of concern. Half wave rectifiers are susceptible to voltage fluctuations in the input AC source, which can result in unstable DC output. This instability can be problematic in applications requiring consistent power supply, necessitating additional voltage regulation circuitry.

The limited power handling capability of half wave rectifiers presents challenges in high-power applications. The unidirectional current flow places stress on components during each cycle, limiting the maximum power that can be efficiently rectified. This constraint often requires the use of more robust and expensive components to manage thermal and electrical stresses.

Reverse recovery time of the rectifying diode is a critical factor affecting the performance of half wave rectifiers, especially at higher frequencies. Slow reverse recovery can lead to increased switching losses and reduced efficiency, limiting the applicability of half wave rectifiers in high-frequency power conversion systems.

Lastly, the environmental impact of half wave rectifiers is becoming increasingly important. Their lower efficiency translates to higher energy consumption and increased carbon footprint. As global emphasis on energy efficiency and sustainability grows, this aspect presents a significant challenge for the continued use of half wave rectifiers in many applications.

Another challenge lies in the high ripple content in the output voltage. The pulsating nature of the rectified waveform necessitates extensive filtering to achieve a smooth DC output, adding complexity and cost to the overall system. This ripple can lead to noise and interference issues in sensitive electronic applications, limiting the use of half wave rectifiers in high-precision circuits.

The non-linear behavior of half wave rectifiers poses difficulties in maintaining power quality. The rectification process introduces harmonic distortions into the power system, potentially causing electromagnetic interference and reducing the overall power factor. This non-linearity can lead to compliance issues with increasingly stringent power quality standards and regulations.

Voltage regulation is another area of concern. Half wave rectifiers are susceptible to voltage fluctuations in the input AC source, which can result in unstable DC output. This instability can be problematic in applications requiring consistent power supply, necessitating additional voltage regulation circuitry.

The limited power handling capability of half wave rectifiers presents challenges in high-power applications. The unidirectional current flow places stress on components during each cycle, limiting the maximum power that can be efficiently rectified. This constraint often requires the use of more robust and expensive components to manage thermal and electrical stresses.

Reverse recovery time of the rectifying diode is a critical factor affecting the performance of half wave rectifiers, especially at higher frequencies. Slow reverse recovery can lead to increased switching losses and reduced efficiency, limiting the applicability of half wave rectifiers in high-frequency power conversion systems.

Lastly, the environmental impact of half wave rectifiers is becoming increasingly important. Their lower efficiency translates to higher energy consumption and increased carbon footprint. As global emphasis on energy efficiency and sustainability grows, this aspect presents a significant challenge for the continued use of half wave rectifiers in many applications.

Existing Half Wave Rectifier Solutions

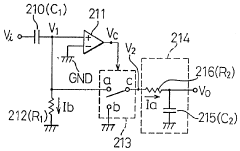

01 Circuit design and topology

Half-wave rectifiers are designed with specific circuit topologies to convert AC to pulsating DC. These designs often include diodes, transformers, and capacitors arranged in particular configurations to achieve efficient rectification. Various circuit arrangements are employed to optimize performance and reduce ripple in the output voltage.- Circuit design and topology: Half-wave rectifiers are designed with specific circuit topologies to convert AC to pulsating DC. These designs often include diodes, transformers, and capacitors to achieve efficient rectification. Various circuit configurations are employed to optimize performance and reduce ripple in the output voltage.

- Power supply applications: Half-wave rectifiers are commonly used in power supply systems for various electronic devices. They are integrated into AC-DC converters, battery chargers, and other power management circuits. These rectifiers play a crucial role in providing DC power from AC sources in many consumer and industrial applications.

- Efficiency improvements: Researchers and engineers focus on improving the efficiency of half-wave rectifiers. This includes developing new semiconductor materials, optimizing component selection, and implementing advanced control strategies. Efforts are made to reduce power losses, improve voltage regulation, and enhance overall system performance.

- Integration with other circuits: Half-wave rectifiers are often integrated with other electronic circuits to create more complex systems. This includes combining rectifiers with voltage regulators, filters, and protection circuits. Such integration enhances functionality and improves the overall performance of electronic devices and power systems.

- Specialized applications: Half-wave rectifiers find use in specialized applications beyond general power supplies. These include RF signal detection, sensor circuits, and energy harvesting systems. In these applications, the rectifiers are often modified or optimized to meet specific requirements such as high-frequency operation or low-power consumption.

02 Power supply applications

Half-wave rectifiers are commonly used in power supply circuits for various electronic devices. They are employed in AC-DC conversion for low-power applications, battery charging systems, and as part of more complex power management circuits. These rectifiers can be found in consumer electronics, industrial equipment, and automotive systems.Expand Specific Solutions03 Efficiency improvements

Researchers and engineers continually work on improving the efficiency of half-wave rectifiers. This includes developing new semiconductor materials for diodes, implementing advanced control strategies, and integrating additional components to reduce power losses. Efforts are also made to minimize electromagnetic interference and improve overall system reliability.Expand Specific Solutions04 Integration with other circuit elements

Half-wave rectifiers are often integrated with other circuit elements to create more complex power management systems. This includes combining rectifiers with voltage regulators, filters, and protection circuits. Such integration can lead to more compact designs, improved performance, and enhanced functionality in various applications.Expand Specific Solutions05 Specialized applications

Half-wave rectifiers find use in specialized applications beyond general power supplies. These include RF signal detection in radio receivers, peak detectors in measurement equipment, and as part of motor control circuits. In these applications, the rectifiers may be designed with specific characteristics to meet unique requirements of the system.Expand Specific Solutions

Key Players in Rectifier Industry

The market for half wave rectifiers is in a mature stage, with established players like Siemens, Bosch, and Panasonic dominating the landscape. The global market size is estimated to be in the billions, driven by increasing demand in power electronics and renewable energy sectors. Technologically, half wave rectifiers are well-understood, but innovation continues in efficiency and miniaturization. Companies like STMicroelectronics and Infineon Technologies are at the forefront of developing advanced semiconductor-based rectifier solutions, while research institutions like CNRS and Shandong University contribute to fundamental advancements. The competitive landscape is characterized by a mix of large conglomerates and specialized semiconductor firms, with ongoing R&D efforts focused on improving performance and reducing costs.

Siemens Corp.

Technical Solution: Siemens has developed advanced half-wave rectifier solutions for industrial and power distribution applications. Their SINAMICS rectifier units incorporate intelligent control systems that optimize power factor and reduce harmonics[12]. Siemens has also introduced modular rectifier designs that allow for easy scalability and maintenance in large-scale power systems[13]. To address future disruptions, Siemens is focusing on integrating their rectifiers with IoT platforms, enabling real-time monitoring and predictive maintenance. They are also exploring the use of AI algorithms to dynamically adjust rectifier parameters based on grid conditions and load demands, improving overall system efficiency and stability[14]. Additionally, Siemens is investing in research on high-voltage SiC devices to enhance the performance of their rectifiers in medium and high-voltage applications[15].

Strengths: Robust industrial-grade solutions, advanced control systems, scalability, and integration with IoT platforms. Weaknesses: Potentially higher costs for smaller-scale applications, complexity in implementation for some users.

Robert Bosch GmbH

Technical Solution: Bosch has developed innovative half-wave rectifier solutions primarily focused on automotive and industrial applications. Their rectifier designs incorporate advanced thermal management techniques and high-reliability packaging suitable for harsh environments[16]. Bosch has also introduced smart rectifier modules that integrate current and temperature sensing capabilities, enabling real-time monitoring and protection[17]. To prepare for future disruptions, Bosch is investing in wide bandgap semiconductor technologies, particularly silicon carbide, to improve the efficiency and power density of their rectifiers[18]. They are also exploring the integration of their rectifiers with vehicle-to-grid (V2G) technologies, anticipating the growing importance of bidirectional power flow in electric vehicles[19]. Additionally, Bosch is developing AI-driven prognostics systems to predict rectifier failures and optimize maintenance schedules in industrial settings[20].

Strengths: Robust designs for harsh environments, integrated sensing capabilities, focus on automotive and industrial applications. Weaknesses: Potentially limited focus on consumer electronics applications, higher costs for specialized automotive-grade components.

Core Innovations in Half Wave Rectification

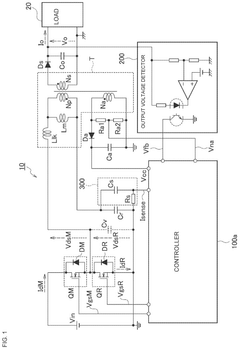

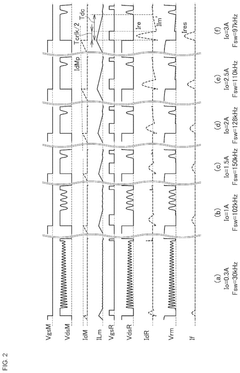

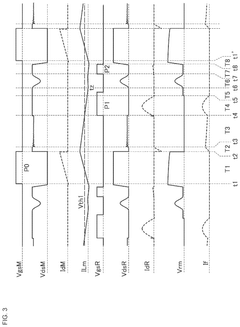

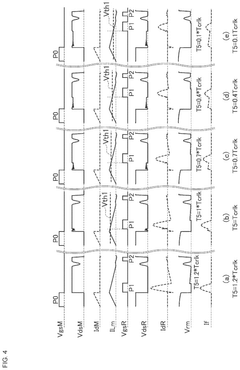

Semiconductor apparatus having half-wave rectifier LLC converter

PatentPendingUS20250038657A1

Innovation

- The half-wave rectifier LLC converter and control IC implement a control method where the resonant switch is controlled twice during the off period of the main switch, with specific timing adjustments to minimize circulating current. This includes a flyback period where the resonant switch is turned on to allow resonant current flow, and a subsequent period where the resonant switch is turned off during the excitation current charging period.

Half-wave rectifier circuit

PatentInactiveUS5579214A

Innovation

- The proposed half-wave rectifier circuit design includes a capacitor to remove DC components, a comparator with an operational amplifier and capacitor to accumulate offset voltage, and a switch circuit with high input impedance during the OFF state to eliminate the influence of offset voltage, ensuring accurate output voltage generation.

Regulatory Framework for Power Electronics

The regulatory framework for power electronics plays a crucial role in shaping the future of half wave rectifiers and their ability to address potential disruptions. As the power electronics industry continues to evolve, regulatory bodies worldwide are adapting their guidelines to ensure safety, efficiency, and reliability in electrical systems.

One of the primary focuses of regulatory frameworks is the harmonization of standards across different regions. This effort aims to facilitate global trade and technological advancement while maintaining consistent safety and performance requirements. For half wave rectifiers, this means adhering to international standards such as IEC 60950 for safety and IEC 61000 for electromagnetic compatibility.

Energy efficiency regulations are becoming increasingly stringent, driving the development of more efficient half wave rectifier designs. The European Union's Ecodesign Directive and the U.S. Department of Energy's appliance and equipment standards are examples of regulatory initiatives that impact the power electronics industry. These regulations often set minimum efficiency requirements for various electronic devices, indirectly influencing the design and implementation of half wave rectifiers.

Power quality standards are another critical aspect of the regulatory framework. As the grid becomes more complex with the integration of renewable energy sources and smart grid technologies, regulations are evolving to address issues such as harmonic distortion and power factor correction. Half wave rectifiers, known for their simplicity but also for introducing harmonics, must be designed to comply with these standards to minimize their impact on power quality.

Electromagnetic compatibility (EMC) regulations are becoming more comprehensive to address the increasing density of electronic devices in modern environments. For half wave rectifiers, this means implementing design strategies to reduce electromagnetic interference (EMI) and ensure compliance with EMC standards such as FCC Part 15 in the United States or CISPR 22 in Europe.

Safety regulations continue to be a cornerstone of the regulatory framework for power electronics. These regulations cover aspects such as electrical isolation, thermal management, and protection against electric shock. For half wave rectifiers, this translates into requirements for proper insulation, overload protection, and safe operating temperatures.

As the Internet of Things (IoT) and smart grid technologies advance, new regulations are emerging to address cybersecurity concerns in power electronics. While half wave rectifiers are relatively simple devices, their integration into more complex systems may require compliance with cybersecurity standards to prevent unauthorized access or manipulation of power systems.

Looking ahead, regulatory frameworks are likely to evolve to address emerging technologies and challenges. This may include regulations specific to wide bandgap semiconductors, which are increasingly used in power electronics, or guidelines for the recycling and disposal of electronic components to promote sustainability in the industry.

One of the primary focuses of regulatory frameworks is the harmonization of standards across different regions. This effort aims to facilitate global trade and technological advancement while maintaining consistent safety and performance requirements. For half wave rectifiers, this means adhering to international standards such as IEC 60950 for safety and IEC 61000 for electromagnetic compatibility.

Energy efficiency regulations are becoming increasingly stringent, driving the development of more efficient half wave rectifier designs. The European Union's Ecodesign Directive and the U.S. Department of Energy's appliance and equipment standards are examples of regulatory initiatives that impact the power electronics industry. These regulations often set minimum efficiency requirements for various electronic devices, indirectly influencing the design and implementation of half wave rectifiers.

Power quality standards are another critical aspect of the regulatory framework. As the grid becomes more complex with the integration of renewable energy sources and smart grid technologies, regulations are evolving to address issues such as harmonic distortion and power factor correction. Half wave rectifiers, known for their simplicity but also for introducing harmonics, must be designed to comply with these standards to minimize their impact on power quality.

Electromagnetic compatibility (EMC) regulations are becoming more comprehensive to address the increasing density of electronic devices in modern environments. For half wave rectifiers, this means implementing design strategies to reduce electromagnetic interference (EMI) and ensure compliance with EMC standards such as FCC Part 15 in the United States or CISPR 22 in Europe.

Safety regulations continue to be a cornerstone of the regulatory framework for power electronics. These regulations cover aspects such as electrical isolation, thermal management, and protection against electric shock. For half wave rectifiers, this translates into requirements for proper insulation, overload protection, and safe operating temperatures.

As the Internet of Things (IoT) and smart grid technologies advance, new regulations are emerging to address cybersecurity concerns in power electronics. While half wave rectifiers are relatively simple devices, their integration into more complex systems may require compliance with cybersecurity standards to prevent unauthorized access or manipulation of power systems.

Looking ahead, regulatory frameworks are likely to evolve to address emerging technologies and challenges. This may include regulations specific to wide bandgap semiconductors, which are increasingly used in power electronics, or guidelines for the recycling and disposal of electronic components to promote sustainability in the industry.

Environmental Impact of Rectifier Technologies

The environmental impact of rectifier technologies, particularly half-wave rectifiers, is a critical consideration in the context of preparing for future disruptions. These devices, while essential in power electronics, can have significant ecological implications that must be addressed to ensure sustainable technological advancement.

Half-wave rectifiers, by their nature, are less efficient than full-wave rectifiers, resulting in higher energy losses during the conversion process. This inefficiency translates to increased power consumption and, consequently, a larger carbon footprint. As global energy demands continue to rise, the cumulative effect of these losses becomes increasingly significant, contributing to greenhouse gas emissions and climate change.

The manufacturing process of rectifiers also raises environmental concerns. The production of semiconductor materials used in rectifiers, such as silicon and germanium, involves energy-intensive processes and the use of potentially harmful chemicals. Mining and refining these materials can lead to habitat destruction, soil contamination, and water pollution if not managed responsibly.

Electronic waste (e-waste) is another crucial environmental issue associated with rectifier technologies. As electronic devices become obsolete or malfunction, improper disposal of rectifiers and associated components can release toxic substances into the environment. Heavy metals and other hazardous materials can leach into soil and water systems, posing risks to ecosystems and human health.

To mitigate these environmental impacts, several strategies can be employed. Improving the efficiency of half-wave rectifiers through advanced design and materials can reduce energy losses and overall power consumption. Research into more environmentally friendly semiconductor materials and manufacturing processes can help minimize the ecological footprint of rectifier production.

Implementing robust recycling and e-waste management programs is essential to address the end-of-life issues associated with rectifiers. Developing circular economy models for electronic components can help recover valuable materials and reduce the need for new resource extraction. Additionally, promoting the use of more efficient rectifier technologies, such as synchronous rectifiers, can lead to significant energy savings in various applications.

As we prepare for future disruptions, it is crucial to consider the long-term environmental sustainability of rectifier technologies. This includes investing in research and development of eco-friendly alternatives, implementing stricter environmental regulations in manufacturing, and fostering a culture of responsible consumption and disposal of electronic devices containing rectifiers.

Half-wave rectifiers, by their nature, are less efficient than full-wave rectifiers, resulting in higher energy losses during the conversion process. This inefficiency translates to increased power consumption and, consequently, a larger carbon footprint. As global energy demands continue to rise, the cumulative effect of these losses becomes increasingly significant, contributing to greenhouse gas emissions and climate change.

The manufacturing process of rectifiers also raises environmental concerns. The production of semiconductor materials used in rectifiers, such as silicon and germanium, involves energy-intensive processes and the use of potentially harmful chemicals. Mining and refining these materials can lead to habitat destruction, soil contamination, and water pollution if not managed responsibly.

Electronic waste (e-waste) is another crucial environmental issue associated with rectifier technologies. As electronic devices become obsolete or malfunction, improper disposal of rectifiers and associated components can release toxic substances into the environment. Heavy metals and other hazardous materials can leach into soil and water systems, posing risks to ecosystems and human health.

To mitigate these environmental impacts, several strategies can be employed. Improving the efficiency of half-wave rectifiers through advanced design and materials can reduce energy losses and overall power consumption. Research into more environmentally friendly semiconductor materials and manufacturing processes can help minimize the ecological footprint of rectifier production.

Implementing robust recycling and e-waste management programs is essential to address the end-of-life issues associated with rectifiers. Developing circular economy models for electronic components can help recover valuable materials and reduce the need for new resource extraction. Additionally, promoting the use of more efficient rectifier technologies, such as synchronous rectifiers, can lead to significant energy savings in various applications.

As we prepare for future disruptions, it is crucial to consider the long-term environmental sustainability of rectifier technologies. This includes investing in research and development of eco-friendly alternatives, implementing stricter environmental regulations in manufacturing, and fostering a culture of responsible consumption and disposal of electronic devices containing rectifiers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!