Impact of Half Wave Rectifiers on Electrical Safety

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

Half-wave rectifiers have played a significant role in the development of electrical and electronic systems since their inception in the early 20th century. These devices, which convert alternating current (AC) to pulsating direct current (DC), have been instrumental in shaping the landscape of power electronics and electrical safety.

The evolution of half-wave rectifiers can be traced back to the invention of the vacuum tube diode by John Ambrose Fleming in 1904. This breakthrough paved the way for the development of more efficient and reliable rectification systems. As technology progressed, semiconductor diodes replaced vacuum tubes, leading to smaller, more efficient, and cost-effective rectifier designs.

The primary objective of half-wave rectifiers in the context of electrical safety is to provide a means of converting AC power to DC power while minimizing potential hazards associated with electrical systems. This conversion process is crucial in many applications, including power supplies for electronic devices, battery charging systems, and various industrial processes.

Over the years, the focus on electrical safety has intensified, prompting researchers and engineers to explore the impact of half-wave rectifiers on overall system safety. Key areas of investigation include the reduction of electromagnetic interference (EMI), mitigation of voltage spikes, and improvement of power quality.

One of the main challenges in the field of half-wave rectifiers and electrical safety is the management of harmonic distortion. The non-linear nature of rectification processes can introduce harmonics into the power system, potentially leading to increased power losses, equipment overheating, and reduced system efficiency. Addressing these issues has become a primary goal in the ongoing development of rectifier technology.

The technological trajectory of half-wave rectifiers has been marked by continuous improvements in efficiency, reliability, and safety features. Modern designs incorporate advanced materials and control strategies to enhance performance while maintaining strict safety standards. The integration of smart technologies and digital control systems has further expanded the capabilities of half-wave rectifiers, allowing for real-time monitoring and adaptive operation in response to changing load conditions.

As we look towards the future, the objectives for half-wave rectifier technology in the realm of electrical safety are multifaceted. These include further reducing electromagnetic emissions, improving power factor correction, and enhancing overall system reliability. Additionally, there is a growing emphasis on developing rectifier systems that are compatible with renewable energy sources and smart grid technologies, ensuring their relevance in the evolving landscape of sustainable power systems.

The evolution of half-wave rectifiers can be traced back to the invention of the vacuum tube diode by John Ambrose Fleming in 1904. This breakthrough paved the way for the development of more efficient and reliable rectification systems. As technology progressed, semiconductor diodes replaced vacuum tubes, leading to smaller, more efficient, and cost-effective rectifier designs.

The primary objective of half-wave rectifiers in the context of electrical safety is to provide a means of converting AC power to DC power while minimizing potential hazards associated with electrical systems. This conversion process is crucial in many applications, including power supplies for electronic devices, battery charging systems, and various industrial processes.

Over the years, the focus on electrical safety has intensified, prompting researchers and engineers to explore the impact of half-wave rectifiers on overall system safety. Key areas of investigation include the reduction of electromagnetic interference (EMI), mitigation of voltage spikes, and improvement of power quality.

One of the main challenges in the field of half-wave rectifiers and electrical safety is the management of harmonic distortion. The non-linear nature of rectification processes can introduce harmonics into the power system, potentially leading to increased power losses, equipment overheating, and reduced system efficiency. Addressing these issues has become a primary goal in the ongoing development of rectifier technology.

The technological trajectory of half-wave rectifiers has been marked by continuous improvements in efficiency, reliability, and safety features. Modern designs incorporate advanced materials and control strategies to enhance performance while maintaining strict safety standards. The integration of smart technologies and digital control systems has further expanded the capabilities of half-wave rectifiers, allowing for real-time monitoring and adaptive operation in response to changing load conditions.

As we look towards the future, the objectives for half-wave rectifier technology in the realm of electrical safety are multifaceted. These include further reducing electromagnetic emissions, improving power factor correction, and enhancing overall system reliability. Additionally, there is a growing emphasis on developing rectifier systems that are compatible with renewable energy sources and smart grid technologies, ensuring their relevance in the evolving landscape of sustainable power systems.

Market Demand for Electrical Safety Solutions

The market demand for electrical safety solutions has been steadily increasing due to the growing awareness of potential hazards associated with electrical systems and the stringent regulations imposed by governments worldwide. The impact of half wave rectifiers on electrical safety has become a significant concern in various industries, driving the need for advanced safety measures and technologies.

In the industrial sector, the demand for electrical safety solutions has surged as manufacturing processes become more automated and reliant on complex electrical systems. Companies are increasingly investing in safety devices and monitoring systems to prevent accidents, reduce downtime, and ensure compliance with safety standards. The automotive industry, in particular, has seen a rise in demand for electrical safety solutions, especially with the growing popularity of electric vehicles.

The construction industry has also contributed to the market growth, with an increased focus on implementing robust electrical safety measures in both residential and commercial buildings. This trend is driven by the need to protect occupants from electrical hazards and meet stringent building codes and regulations.

The healthcare sector has emerged as another significant driver of demand for electrical safety solutions. Hospitals and medical facilities require highly reliable and safe electrical systems to ensure uninterrupted operation of critical equipment and protect patients and staff from potential electrical hazards.

The rise of smart homes and the Internet of Things (IoT) has created new opportunities in the consumer market for electrical safety solutions. Homeowners are increasingly investing in smart circuit breakers, ground fault circuit interrupters (GFCIs), and other safety devices to protect their property and loved ones from electrical accidents.

The global electrical safety market has shown consistent growth, with North America and Europe leading in terms of market share. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years due to increasing industrialization and urbanization.

Key factors driving the market demand include the implementation of stringent safety regulations, the growing emphasis on workplace safety, and the increasing adoption of electrical safety devices in various end-use industries. The market is also benefiting from technological advancements, such as the integration of IoT and artificial intelligence in safety devices, which offer improved monitoring and predictive maintenance capabilities.

As the awareness of the impact of half wave rectifiers on electrical safety continues to grow, there is an increasing demand for solutions that can mitigate the associated risks. This has led to the development of more sophisticated rectifier designs, advanced filtering techniques, and improved safety monitoring systems to ensure the reliable and safe operation of electrical equipment across various applications.

In the industrial sector, the demand for electrical safety solutions has surged as manufacturing processes become more automated and reliant on complex electrical systems. Companies are increasingly investing in safety devices and monitoring systems to prevent accidents, reduce downtime, and ensure compliance with safety standards. The automotive industry, in particular, has seen a rise in demand for electrical safety solutions, especially with the growing popularity of electric vehicles.

The construction industry has also contributed to the market growth, with an increased focus on implementing robust electrical safety measures in both residential and commercial buildings. This trend is driven by the need to protect occupants from electrical hazards and meet stringent building codes and regulations.

The healthcare sector has emerged as another significant driver of demand for electrical safety solutions. Hospitals and medical facilities require highly reliable and safe electrical systems to ensure uninterrupted operation of critical equipment and protect patients and staff from potential electrical hazards.

The rise of smart homes and the Internet of Things (IoT) has created new opportunities in the consumer market for electrical safety solutions. Homeowners are increasingly investing in smart circuit breakers, ground fault circuit interrupters (GFCIs), and other safety devices to protect their property and loved ones from electrical accidents.

The global electrical safety market has shown consistent growth, with North America and Europe leading in terms of market share. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years due to increasing industrialization and urbanization.

Key factors driving the market demand include the implementation of stringent safety regulations, the growing emphasis on workplace safety, and the increasing adoption of electrical safety devices in various end-use industries. The market is also benefiting from technological advancements, such as the integration of IoT and artificial intelligence in safety devices, which offer improved monitoring and predictive maintenance capabilities.

As the awareness of the impact of half wave rectifiers on electrical safety continues to grow, there is an increasing demand for solutions that can mitigate the associated risks. This has led to the development of more sophisticated rectifier designs, advanced filtering techniques, and improved safety monitoring systems to ensure the reliable and safe operation of electrical equipment across various applications.

Current Challenges in Half Wave Rectifier Safety

Half wave rectifiers, while fundamental in power electronics, present several significant challenges in terms of electrical safety. One of the primary concerns is the generation of harmonics, particularly even harmonics, which can lead to increased electromagnetic interference (EMI) and power quality issues. These harmonics can cause overheating in transformers and motors, potentially leading to equipment failure and safety hazards.

Another critical challenge is the inefficient use of the transformer's core in half wave rectification. This inefficiency results in higher magnetizing currents, which can lead to core saturation and increased heat generation. The excess heat not only reduces the overall efficiency of the system but also poses a fire risk if not properly managed.

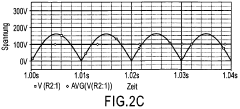

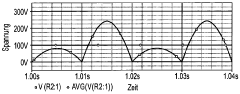

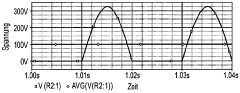

The pulsating nature of the output from half wave rectifiers introduces ripple voltage, which can be problematic for sensitive electronic equipment. This ripple can cause instability in voltage-sensitive devices and may lead to malfunctions or shortened lifespan of connected equipment. In safety-critical applications, such instabilities could have severe consequences.

Voltage regulation is another significant challenge. Half wave rectifiers are inherently poor at maintaining a stable DC output voltage under varying load conditions. This can lead to overvoltage situations, potentially damaging connected equipment or creating shock hazards for users.

The unidirectional current flow in half wave rectifiers can cause DC offset in transformers, leading to core saturation and increased heating. This not only reduces efficiency but also increases the risk of transformer failure, which can be a serious safety concern in high-power applications.

Furthermore, the discontinuous current draw of half wave rectifiers can cause voltage spikes in the AC supply line. These spikes can stress insulation, potentially leading to breakdown and creating shock hazards. They can also interfere with other equipment connected to the same power source, causing operational issues and potential safety risks.

In terms of component stress, the diodes used in half wave rectifiers must withstand high peak inverse voltages, which can lead to premature failure if not properly rated. Diode failures can result in short circuits or open circuits, both of which pose significant safety risks in terms of fire hazards or equipment malfunction.

Lastly, the inherent inefficiency of half wave rectifiers means that they generate more heat for a given power output compared to full wave rectifiers. This increased heat generation necessitates more robust cooling solutions, without which there is an elevated risk of thermal runaway and potential fire hazards.

Another critical challenge is the inefficient use of the transformer's core in half wave rectification. This inefficiency results in higher magnetizing currents, which can lead to core saturation and increased heat generation. The excess heat not only reduces the overall efficiency of the system but also poses a fire risk if not properly managed.

The pulsating nature of the output from half wave rectifiers introduces ripple voltage, which can be problematic for sensitive electronic equipment. This ripple can cause instability in voltage-sensitive devices and may lead to malfunctions or shortened lifespan of connected equipment. In safety-critical applications, such instabilities could have severe consequences.

Voltage regulation is another significant challenge. Half wave rectifiers are inherently poor at maintaining a stable DC output voltage under varying load conditions. This can lead to overvoltage situations, potentially damaging connected equipment or creating shock hazards for users.

The unidirectional current flow in half wave rectifiers can cause DC offset in transformers, leading to core saturation and increased heating. This not only reduces efficiency but also increases the risk of transformer failure, which can be a serious safety concern in high-power applications.

Furthermore, the discontinuous current draw of half wave rectifiers can cause voltage spikes in the AC supply line. These spikes can stress insulation, potentially leading to breakdown and creating shock hazards. They can also interfere with other equipment connected to the same power source, causing operational issues and potential safety risks.

In terms of component stress, the diodes used in half wave rectifiers must withstand high peak inverse voltages, which can lead to premature failure if not properly rated. Diode failures can result in short circuits or open circuits, both of which pose significant safety risks in terms of fire hazards or equipment malfunction.

Lastly, the inherent inefficiency of half wave rectifiers means that they generate more heat for a given power output compared to full wave rectifiers. This increased heat generation necessitates more robust cooling solutions, without which there is an elevated risk of thermal runaway and potential fire hazards.

Existing Safety Measures for Half Wave Rectifiers

01 Overcurrent protection in half-wave rectifier circuits

Implementing overcurrent protection mechanisms in half-wave rectifier circuits is crucial for electrical safety. This can involve using fuses, circuit breakers, or current-limiting devices to prevent excessive current flow that could damage components or pose safety risks.- Overcurrent protection in half-wave rectifier circuits: Implementing overcurrent protection mechanisms in half-wave rectifier circuits is crucial for electrical safety. This can include fuses, circuit breakers, or current-limiting devices that prevent excessive current flow, protecting both the rectifier and connected components from damage due to short circuits or overloads.

- Voltage regulation and stabilization: Incorporating voltage regulation and stabilization techniques in half-wave rectifier designs enhances electrical safety by preventing voltage spikes and fluctuations. This can involve using zener diodes, voltage regulators, or feedback control systems to maintain a stable output voltage within safe operating limits.

- Isolation and insulation techniques: Employing proper isolation and insulation techniques in half-wave rectifier circuits is essential for electrical safety. This includes using transformers for galvanic isolation, implementing appropriate creepage and clearance distances, and selecting insulation materials suitable for the operating voltage and environmental conditions.

- Thermal management and heat dissipation: Effective thermal management and heat dissipation in half-wave rectifier designs are crucial for maintaining electrical safety. This involves proper component selection, heatsink design, and thermal modeling to prevent overheating, which can lead to component failure or fire hazards.

- EMI/EMC considerations for half-wave rectifiers: Addressing electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues in half-wave rectifier circuits is important for electrical safety. This includes implementing proper shielding, filtering, and grounding techniques to minimize electromagnetic emissions and susceptibility, ensuring compliance with safety standards and regulations.

02 Isolation and insulation techniques

Ensuring proper isolation and insulation in half-wave rectifier designs is essential for electrical safety. This includes using appropriate insulation materials, maintaining safe distances between components, and implementing isolation transformers to prevent electric shock hazards.Expand Specific Solutions03 Thermal management and heat dissipation

Effective thermal management and heat dissipation are critical for the safe operation of half-wave rectifiers. This involves using heat sinks, proper ventilation, and temperature monitoring to prevent overheating and potential fire hazards.Expand Specific Solutions04 Voltage regulation and stabilization

Implementing voltage regulation and stabilization techniques in half-wave rectifier circuits helps maintain safe and consistent output voltage levels. This can include using voltage regulators, Zener diodes, or feedback control systems to prevent voltage spikes and ensure stable operation.Expand Specific Solutions05 Electromagnetic interference (EMI) reduction

Minimizing electromagnetic interference in half-wave rectifier designs is important for electrical safety and compliance with regulations. This can involve using EMI filters, proper shielding, and layout techniques to reduce electromagnetic emissions and improve overall system reliability.Expand Specific Solutions

Key Players in Electrical Safety Industry

The impact of half wave rectifiers on electrical safety is a critical issue in the evolving power electronics landscape. The market for this technology is in a mature stage, with established players like State Grid Corp. of China and Siemens Corp. dominating the field. The global market size for rectifiers is substantial, driven by increasing demand for power conversion solutions across various industries. Technologically, companies such as Huawei Technologies and Infineon Technologies are pushing the boundaries with advanced semiconductor designs, improving efficiency and safety features. Research institutions like China Electric Power Research Institute and Beijing Jiaotong University are contributing to the development of next-generation rectifier technologies, focusing on enhancing electrical safety and performance.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed advanced half-wave rectifier systems with enhanced safety features for large-scale power distribution networks. Their approach incorporates intelligent monitoring and fault detection mechanisms to mitigate risks associated with half-wave rectification. The company has implemented a multi-layered protection scheme that includes surge arresters, advanced circuit breakers, and real-time power quality analysis systems[1]. This comprehensive solution addresses potential issues such as DC offset, harmonic distortion, and transformer saturation that can arise from half-wave rectifiers in power systems[3]. State Grid has also pioneered the use of smart grid technologies to dynamically adjust rectifier operations based on load conditions and system stability requirements[5].

Strengths: Extensive experience in large-scale power systems, advanced monitoring capabilities, and integration with smart grid technologies. Weaknesses: High implementation costs and complexity in retrofitting existing infrastructure.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute Ltd. has focused on developing innovative solutions to address the safety challenges posed by half-wave rectifiers in power systems. Their approach combines advanced power electronic devices with sophisticated control algorithms and system-level protection schemes. The institute has developed high-performance silicon carbide (SiC) diodes specifically optimized for half-wave rectifier applications, offering improved efficiency and reduced electromagnetic emissions[1]. They have also implemented adaptive control strategies that dynamically adjust rectifier parameters based on real-time power quality measurements, minimizing the impact of harmonics and DC offset on the grid[3]. The institute's research has led to the development of novel fault detection and isolation techniques for half-wave rectifier systems, significantly enhancing overall electrical safety[5]. Furthermore, they have pioneered the use of artificial intelligence and machine learning algorithms to predict and prevent potential safety issues in rectifier-based power conversion systems[7].

Strengths: Cutting-edge research in power electronics, advanced control algorithms, and integration of AI technologies. Weaknesses: Some solutions may be at the research stage and not yet fully commercialized.

Innovative Safety Technologies for Rectifiers

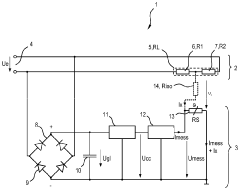

Electric circuit and household appliance

PatentWO2010000767A1

Innovation

- The implementation of a half-wave rectifier in the DC circuit, which can include a single diode or triac, reduces or eliminates the influence of AC currents on measurement accuracy by minimizing leakage currents, and the use of a low-pass filter further enhances measurement precision by filtering out ripple effects.

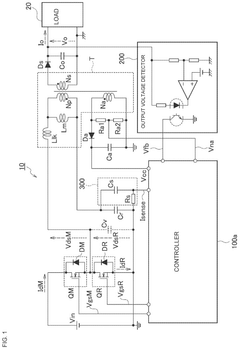

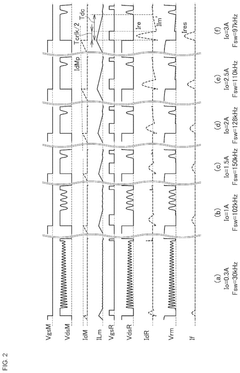

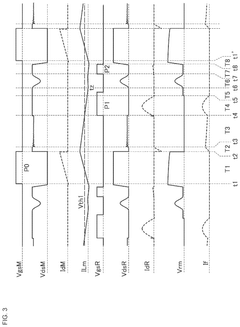

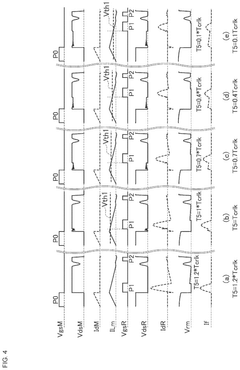

Semiconductor apparatus having half-wave rectifier LLC converter

PatentPendingUS20250038657A1

Innovation

- The half-wave rectifier LLC converter and control IC implement a control method where the resonant switch is controlled twice during the off period of the main switch, with specific timing adjustments to minimize circulating current. This includes a flyback period where the resonant switch is turned on to allow resonant current flow, and a subsequent period where the resonant switch is turned off during the excitation current charging period.

Regulatory Framework for Electrical Safety

The regulatory framework for electrical safety plays a crucial role in mitigating the potential risks associated with half wave rectifiers and other electrical devices. This framework encompasses a comprehensive set of standards, guidelines, and regulations designed to ensure the safe design, installation, and operation of electrical systems.

At the international level, organizations such as the International Electrotechnical Commission (IEC) develop and maintain global standards for electrical safety. These standards provide a foundation for national regulatory bodies to establish their own safety requirements. The IEC 60364 series, for instance, sets forth guidelines for low-voltage electrical installations, which are particularly relevant to the use of half wave rectifiers in various applications.

In the United States, the National Electrical Code (NEC), published by the National Fire Protection Association (NFPA), serves as the primary regulatory document for electrical safety. The NEC addresses various aspects of electrical installations, including wiring methods, equipment specifications, and protection against electrical hazards. Specific provisions within the NEC may apply to the use of half wave rectifiers, particularly in terms of grounding, overcurrent protection, and voltage regulation.

The Occupational Safety and Health Administration (OSHA) also plays a significant role in enforcing electrical safety regulations in workplace environments. OSHA's electrical standards (29 CFR 1910 Subpart S) outline requirements for safe work practices, personal protective equipment, and the proper use of electrical equipment, including devices that incorporate half wave rectifiers.

In the European Union, the Low Voltage Directive (LVD) 2014/35/EU establishes safety objectives for electrical equipment operating within certain voltage limits. This directive applies to a wide range of electrical devices, including those utilizing half wave rectifiers, and mandates compliance with essential safety requirements before products can be placed on the EU market.

Many countries have established their own regulatory bodies and standards organizations to oversee electrical safety. For example, in the United Kingdom, the Institution of Engineering and Technology (IET) publishes the Wiring Regulations (BS 7671), which provide detailed requirements for electrical installations and are widely adopted across the industry.

These regulatory frameworks are continually evolving to address new technologies and emerging safety concerns. As the use of half wave rectifiers and other power electronic devices becomes more prevalent in various applications, regulatory bodies are likely to update their standards to specifically address the unique safety challenges posed by these components.

Compliance with these regulations is typically enforced through a combination of product certification processes, regular inspections, and penalties for non-compliance. Manufacturers, installers, and end-users of electrical equipment incorporating half wave rectifiers must remain vigilant in adhering to these safety standards to minimize the risk of electrical accidents and ensure the protection of both personnel and property.

At the international level, organizations such as the International Electrotechnical Commission (IEC) develop and maintain global standards for electrical safety. These standards provide a foundation for national regulatory bodies to establish their own safety requirements. The IEC 60364 series, for instance, sets forth guidelines for low-voltage electrical installations, which are particularly relevant to the use of half wave rectifiers in various applications.

In the United States, the National Electrical Code (NEC), published by the National Fire Protection Association (NFPA), serves as the primary regulatory document for electrical safety. The NEC addresses various aspects of electrical installations, including wiring methods, equipment specifications, and protection against electrical hazards. Specific provisions within the NEC may apply to the use of half wave rectifiers, particularly in terms of grounding, overcurrent protection, and voltage regulation.

The Occupational Safety and Health Administration (OSHA) also plays a significant role in enforcing electrical safety regulations in workplace environments. OSHA's electrical standards (29 CFR 1910 Subpart S) outline requirements for safe work practices, personal protective equipment, and the proper use of electrical equipment, including devices that incorporate half wave rectifiers.

In the European Union, the Low Voltage Directive (LVD) 2014/35/EU establishes safety objectives for electrical equipment operating within certain voltage limits. This directive applies to a wide range of electrical devices, including those utilizing half wave rectifiers, and mandates compliance with essential safety requirements before products can be placed on the EU market.

Many countries have established their own regulatory bodies and standards organizations to oversee electrical safety. For example, in the United Kingdom, the Institution of Engineering and Technology (IET) publishes the Wiring Regulations (BS 7671), which provide detailed requirements for electrical installations and are widely adopted across the industry.

These regulatory frameworks are continually evolving to address new technologies and emerging safety concerns. As the use of half wave rectifiers and other power electronic devices becomes more prevalent in various applications, regulatory bodies are likely to update their standards to specifically address the unique safety challenges posed by these components.

Compliance with these regulations is typically enforced through a combination of product certification processes, regular inspections, and penalties for non-compliance. Manufacturers, installers, and end-users of electrical equipment incorporating half wave rectifiers must remain vigilant in adhering to these safety standards to minimize the risk of electrical accidents and ensure the protection of both personnel and property.

Environmental Impact of Rectifier Technologies

The environmental impact of rectifier technologies, particularly half-wave rectifiers, extends beyond their primary function of converting alternating current (AC) to direct current (DC). These devices play a crucial role in various electrical systems, but their operation can have significant environmental implications.

Half-wave rectifiers, while simple in design, are less efficient compared to full-wave rectifiers. This inefficiency leads to increased power consumption and heat generation, contributing to higher energy demands and potentially greater carbon emissions from power plants. The wasted energy dissipates as heat, which can contribute to local thermal pollution and increase the need for cooling systems in industrial settings.

The manufacturing process of rectifiers involves the use of various materials, including semiconductors, metals, and plastics. The extraction and processing of these raw materials can have substantial environmental impacts, such as habitat destruction, water pollution, and greenhouse gas emissions. Additionally, the production of semiconductor components often requires the use of hazardous chemicals and energy-intensive processes, further contributing to environmental concerns.

The disposal of rectifiers at the end of their lifecycle presents another environmental challenge. Electronic waste (e-waste) containing rectifiers can release harmful substances into the environment if not properly managed. Toxic materials like lead, mercury, and cadmium can leach into soil and water systems, posing risks to ecosystems and human health.

However, advancements in rectifier technology are addressing some of these environmental concerns. More efficient designs, such as synchronous rectifiers, are reducing energy losses and heat generation. The use of alternative materials and improved manufacturing processes are also helping to minimize the environmental footprint of rectifier production.

Recycling initiatives for electronic components, including rectifiers, are becoming more prevalent. These programs aim to recover valuable materials and reduce the amount of e-waste sent to landfills. However, the complex nature of electronic components often makes recycling challenging and energy-intensive.

In conclusion, while half-wave rectifiers and other rectifier technologies are essential for modern electrical systems, their environmental impact is multifaceted. From energy inefficiencies to manufacturing processes and e-waste concerns, the environmental implications of these devices are significant. Ongoing research and development in this field are focused on improving efficiency, reducing material usage, and enhancing recyclability to mitigate these environmental impacts.

Half-wave rectifiers, while simple in design, are less efficient compared to full-wave rectifiers. This inefficiency leads to increased power consumption and heat generation, contributing to higher energy demands and potentially greater carbon emissions from power plants. The wasted energy dissipates as heat, which can contribute to local thermal pollution and increase the need for cooling systems in industrial settings.

The manufacturing process of rectifiers involves the use of various materials, including semiconductors, metals, and plastics. The extraction and processing of these raw materials can have substantial environmental impacts, such as habitat destruction, water pollution, and greenhouse gas emissions. Additionally, the production of semiconductor components often requires the use of hazardous chemicals and energy-intensive processes, further contributing to environmental concerns.

The disposal of rectifiers at the end of their lifecycle presents another environmental challenge. Electronic waste (e-waste) containing rectifiers can release harmful substances into the environment if not properly managed. Toxic materials like lead, mercury, and cadmium can leach into soil and water systems, posing risks to ecosystems and human health.

However, advancements in rectifier technology are addressing some of these environmental concerns. More efficient designs, such as synchronous rectifiers, are reducing energy losses and heat generation. The use of alternative materials and improved manufacturing processes are also helping to minimize the environmental footprint of rectifier production.

Recycling initiatives for electronic components, including rectifiers, are becoming more prevalent. These programs aim to recover valuable materials and reduce the amount of e-waste sent to landfills. However, the complex nature of electronic components often makes recycling challenging and energy-intensive.

In conclusion, while half-wave rectifiers and other rectifier technologies are essential for modern electrical systems, their environmental impact is multifaceted. From energy inefficiencies to manufacturing processes and e-waste concerns, the environmental implications of these devices are significant. Ongoing research and development in this field are focused on improving efficiency, reducing material usage, and enhancing recyclability to mitigate these environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!