The Future Vision for Global Half Wave Rectifier Utility

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

Half wave rectification has been a fundamental concept in electrical engineering since the early days of electronics. This simple yet effective method of converting alternating current (AC) to pulsating direct current (DC) has played a crucial role in the development of various electronic devices and power systems. The evolution of half wave rectifiers has been closely tied to the advancements in semiconductor technology, particularly the development of diodes.

The primary objective of half wave rectification is to convert AC power into a unidirectional current flow, which is essential for many electronic applications. This process involves allowing current to flow in only one direction during each cycle of the AC waveform, effectively "rectifying" the signal. The resulting output, while not perfectly smooth, provides a basis for further filtering and regulation to achieve stable DC power.

As we look towards the future of global half wave rectifier utility, several key trends and objectives emerge. One of the primary goals is to improve the efficiency of half wave rectifiers, reducing power losses and heat generation. This is particularly important in an era where energy conservation and sustainability are at the forefront of technological development. Researchers and engineers are exploring novel materials and designs to enhance the performance of diodes used in half wave rectification.

Another significant objective is the miniaturization of half wave rectifier circuits. As electronic devices continue to shrink in size, there is a growing demand for compact and efficient power conversion solutions. This trend is driving innovation in integrated circuit design, where half wave rectifiers are being incorporated into system-on-chip (SoC) solutions for various applications, from consumer electronics to industrial control systems.

The integration of smart technologies and digital control into half wave rectifier systems is also a key focus area. By incorporating microcontrollers and advanced sensing technologies, future half wave rectifiers could offer dynamic adjustment capabilities, optimizing their performance based on varying load conditions and input voltages. This adaptability would significantly enhance the versatility and efficiency of power conversion systems across different applications.

In the context of renewable energy systems, half wave rectifiers are expected to play a crucial role in the conversion and integration of AC power generated from sources like solar panels and wind turbines into the DC-based smart grid infrastructure. The development of high-power, high-efficiency half wave rectifiers for these applications is a critical objective in supporting the global transition to sustainable energy sources.

As we progress into an increasingly interconnected world, the future vision for global half wave rectifier utility also encompasses their role in emerging technologies such as 5G networks, Internet of Things (IoT) devices, and electric vehicle charging infrastructure. These applications demand reliable, efficient, and often miniaturized power conversion solutions, placing half wave rectifiers at the heart of technological innovation.

The primary objective of half wave rectification is to convert AC power into a unidirectional current flow, which is essential for many electronic applications. This process involves allowing current to flow in only one direction during each cycle of the AC waveform, effectively "rectifying" the signal. The resulting output, while not perfectly smooth, provides a basis for further filtering and regulation to achieve stable DC power.

As we look towards the future of global half wave rectifier utility, several key trends and objectives emerge. One of the primary goals is to improve the efficiency of half wave rectifiers, reducing power losses and heat generation. This is particularly important in an era where energy conservation and sustainability are at the forefront of technological development. Researchers and engineers are exploring novel materials and designs to enhance the performance of diodes used in half wave rectification.

Another significant objective is the miniaturization of half wave rectifier circuits. As electronic devices continue to shrink in size, there is a growing demand for compact and efficient power conversion solutions. This trend is driving innovation in integrated circuit design, where half wave rectifiers are being incorporated into system-on-chip (SoC) solutions for various applications, from consumer electronics to industrial control systems.

The integration of smart technologies and digital control into half wave rectifier systems is also a key focus area. By incorporating microcontrollers and advanced sensing technologies, future half wave rectifiers could offer dynamic adjustment capabilities, optimizing their performance based on varying load conditions and input voltages. This adaptability would significantly enhance the versatility and efficiency of power conversion systems across different applications.

In the context of renewable energy systems, half wave rectifiers are expected to play a crucial role in the conversion and integration of AC power generated from sources like solar panels and wind turbines into the DC-based smart grid infrastructure. The development of high-power, high-efficiency half wave rectifiers for these applications is a critical objective in supporting the global transition to sustainable energy sources.

As we progress into an increasingly interconnected world, the future vision for global half wave rectifier utility also encompasses their role in emerging technologies such as 5G networks, Internet of Things (IoT) devices, and electric vehicle charging infrastructure. These applications demand reliable, efficient, and often miniaturized power conversion solutions, placing half wave rectifiers at the heart of technological innovation.

Market Analysis for Half Wave Rectifier Applications

The global market for half wave rectifiers continues to evolve, driven by advancements in power electronics and increasing demand for efficient energy conversion solutions. These devices, fundamental in converting alternating current (AC) to pulsating direct current (DC), find applications across various industries, shaping the landscape of power management and electrical systems.

In the consumer electronics sector, half wave rectifiers play a crucial role in power supplies for smartphones, laptops, and other portable devices. The market growth in this segment is propelled by the rising adoption of mobile technologies and the need for compact, energy-efficient charging solutions. As consumers demand faster charging times and longer battery life, manufacturers are exploring innovative half wave rectifier designs to meet these requirements.

The automotive industry represents another significant market for half wave rectifiers. With the shift towards electric and hybrid vehicles, there is an increasing need for sophisticated power conversion systems. Half wave rectifiers are integral components in battery charging systems, motor controllers, and other automotive electronics. The growing electric vehicle market, particularly in regions like China, Europe, and North America, is expected to drive substantial demand for advanced rectifier technologies.

In the renewable energy sector, half wave rectifiers are essential in solar inverters and wind turbine systems. As countries worldwide push for greater adoption of clean energy sources, the demand for efficient power conversion solutions is escalating. This trend is particularly pronounced in emerging markets where off-grid and microgrid solutions are gaining traction, creating new opportunities for half wave rectifier applications.

The industrial sector remains a steady consumer of half wave rectifiers, utilizing them in motor drives, welding equipment, and industrial power supplies. The ongoing industrial automation trend and the emergence of Industry 4.0 technologies are expected to sustain demand in this segment. Manufacturers are focusing on developing ruggedized, high-performance rectifiers capable of withstanding harsh industrial environments.

Geographically, Asia-Pacific leads the market for half wave rectifiers, driven by the region's robust electronics manufacturing industry and rapid industrialization. China, in particular, stands out as both a major producer and consumer of these devices. North America and Europe follow, with their markets characterized by a focus on high-end applications and technological innovations.

The competitive landscape of the half wave rectifier market is marked by the presence of both established electronics giants and specialized power semiconductor companies. Key players are investing in research and development to improve efficiency, reduce size, and enhance the overall performance of rectifier systems. There is also a growing emphasis on developing environmentally friendly solutions, aligning with global sustainability initiatives.

In the consumer electronics sector, half wave rectifiers play a crucial role in power supplies for smartphones, laptops, and other portable devices. The market growth in this segment is propelled by the rising adoption of mobile technologies and the need for compact, energy-efficient charging solutions. As consumers demand faster charging times and longer battery life, manufacturers are exploring innovative half wave rectifier designs to meet these requirements.

The automotive industry represents another significant market for half wave rectifiers. With the shift towards electric and hybrid vehicles, there is an increasing need for sophisticated power conversion systems. Half wave rectifiers are integral components in battery charging systems, motor controllers, and other automotive electronics. The growing electric vehicle market, particularly in regions like China, Europe, and North America, is expected to drive substantial demand for advanced rectifier technologies.

In the renewable energy sector, half wave rectifiers are essential in solar inverters and wind turbine systems. As countries worldwide push for greater adoption of clean energy sources, the demand for efficient power conversion solutions is escalating. This trend is particularly pronounced in emerging markets where off-grid and microgrid solutions are gaining traction, creating new opportunities for half wave rectifier applications.

The industrial sector remains a steady consumer of half wave rectifiers, utilizing them in motor drives, welding equipment, and industrial power supplies. The ongoing industrial automation trend and the emergence of Industry 4.0 technologies are expected to sustain demand in this segment. Manufacturers are focusing on developing ruggedized, high-performance rectifiers capable of withstanding harsh industrial environments.

Geographically, Asia-Pacific leads the market for half wave rectifiers, driven by the region's robust electronics manufacturing industry and rapid industrialization. China, in particular, stands out as both a major producer and consumer of these devices. North America and Europe follow, with their markets characterized by a focus on high-end applications and technological innovations.

The competitive landscape of the half wave rectifier market is marked by the presence of both established electronics giants and specialized power semiconductor companies. Key players are investing in research and development to improve efficiency, reduce size, and enhance the overall performance of rectifier systems. There is also a growing emphasis on developing environmentally friendly solutions, aligning with global sustainability initiatives.

Current Challenges in Half Wave Rectifier Technology

Half wave rectifiers, despite their long-standing presence in electrical engineering, continue to face several challenges that hinder their widespread adoption and efficiency in modern applications. One of the primary issues is the inherent inefficiency of the half wave rectification process. By utilizing only one half of the AC cycle, these rectifiers waste a significant portion of the input power, resulting in lower overall energy conversion efficiency compared to full wave rectifiers.

Another critical challenge lies in the high ripple content of the output voltage. The pulsating nature of the half wave rectified output necessitates substantial filtering to achieve a smooth DC voltage, which can be both costly and space-consuming. This ripple factor not only affects the quality of the DC output but also introduces harmonics into the power system, potentially causing electromagnetic interference and degrading the performance of sensitive electronic equipment.

The non-linear loading characteristics of half wave rectifiers present yet another hurdle. These devices draw current in short pulses, leading to a poor power factor and increased harmonic distortion in the supply network. This non-linear behavior can cause voltage distortions, overheating of transformers, and reduced efficiency in power distribution systems, making them less desirable for large-scale utility applications.

Thermal management is also a significant concern in half wave rectifier design. The rectifying diode must handle the full load current during conduction periods, leading to increased heat generation and potential reliability issues. This thermal stress can reduce the lifespan of components and necessitate more robust cooling solutions, adding to the overall system complexity and cost.

Furthermore, the limited power handling capability of half wave rectifiers restricts their use in high-power applications. As power requirements increase, the stress on individual components becomes more pronounced, making it challenging to scale these systems effectively without compromising reliability or efficiency.

The integration of half wave rectifiers with modern power electronic systems poses additional challenges. As the industry moves towards more sophisticated and intelligent power management solutions, the simplicity of half wave rectifiers can be a limitation. Adapting these devices to work seamlessly with advanced control systems, smart grids, and renewable energy sources requires innovative approaches to overcome their inherent limitations.

Lastly, regulatory compliance and power quality standards present ongoing challenges for half wave rectifier technology. As grid operators and regulatory bodies impose stricter requirements on power factor correction and harmonic distortion, designers must find ways to mitigate the negative impacts of half wave rectification on power quality, often through additional circuitry or more complex system designs.

Another critical challenge lies in the high ripple content of the output voltage. The pulsating nature of the half wave rectified output necessitates substantial filtering to achieve a smooth DC voltage, which can be both costly and space-consuming. This ripple factor not only affects the quality of the DC output but also introduces harmonics into the power system, potentially causing electromagnetic interference and degrading the performance of sensitive electronic equipment.

The non-linear loading characteristics of half wave rectifiers present yet another hurdle. These devices draw current in short pulses, leading to a poor power factor and increased harmonic distortion in the supply network. This non-linear behavior can cause voltage distortions, overheating of transformers, and reduced efficiency in power distribution systems, making them less desirable for large-scale utility applications.

Thermal management is also a significant concern in half wave rectifier design. The rectifying diode must handle the full load current during conduction periods, leading to increased heat generation and potential reliability issues. This thermal stress can reduce the lifespan of components and necessitate more robust cooling solutions, adding to the overall system complexity and cost.

Furthermore, the limited power handling capability of half wave rectifiers restricts their use in high-power applications. As power requirements increase, the stress on individual components becomes more pronounced, making it challenging to scale these systems effectively without compromising reliability or efficiency.

The integration of half wave rectifiers with modern power electronic systems poses additional challenges. As the industry moves towards more sophisticated and intelligent power management solutions, the simplicity of half wave rectifiers can be a limitation. Adapting these devices to work seamlessly with advanced control systems, smart grids, and renewable energy sources requires innovative approaches to overcome their inherent limitations.

Lastly, regulatory compliance and power quality standards present ongoing challenges for half wave rectifier technology. As grid operators and regulatory bodies impose stricter requirements on power factor correction and harmonic distortion, designers must find ways to mitigate the negative impacts of half wave rectification on power quality, often through additional circuitry or more complex system designs.

Existing Half Wave Rectifier Circuit Designs

01 Circuit design and components

Half wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the input voltage as needed. Various circuit configurations and component selections can be employed to optimize performance for specific applications.- Circuit design and components: Half wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the input voltage as needed. Various circuit configurations and component selections can be employed to optimize performance and efficiency.

- Voltage regulation and smoothing: To improve the output quality of half wave rectifiers, voltage regulation and smoothing techniques are often employed. This can involve the use of capacitors to reduce ripple, voltage regulators to maintain a steady output, and feedback mechanisms to adjust for load variations. These enhancements help to produce a more stable and usable DC output.

- Applications in power supplies: Half wave rectifiers are commonly used in various power supply applications. They can be found in low-power devices, battery chargers, and some specialized industrial equipment. While not as efficient as full wave rectifiers, they are simpler and can be suitable for applications where cost or space is a primary concern.

- Efficiency improvements: Researchers and engineers have developed various methods to improve the efficiency of half wave rectifiers. These can include the use of advanced semiconductor materials, optimized circuit layouts, and innovative cooling solutions. Some designs incorporate additional components or control systems to minimize power losses and maximize energy transfer.

- Integration with other systems: Half wave rectifiers are often integrated into larger electrical or electronic systems. This integration can involve combining the rectifier with other power conditioning components, control circuits, or monitoring systems. Such integrated designs can offer improved performance, reduced size, and enhanced functionality for specific applications.

02 Efficiency improvements

Techniques to improve the efficiency of half wave rectifiers include using high-speed switching diodes, implementing snubber circuits to reduce switching losses, and optimizing the transformer design. Advanced control methods and feedback systems can also be employed to enhance overall performance and reduce power losses.Expand Specific Solutions03 Applications in power supplies

Half wave rectifiers are commonly used in various power supply applications, including low-power electronic devices, battery chargers, and some industrial equipment. They can be integrated into more complex power supply designs, such as voltage regulators and DC-DC converters, to provide stable and controlled output voltages.Expand Specific Solutions04 Protection and safety features

To enhance reliability and safety, half wave rectifier circuits often incorporate protection features such as overvoltage protection, overcurrent protection, and thermal shutdown mechanisms. These features help prevent damage to the rectifier and connected equipment in case of fault conditions or abnormal operating scenarios.Expand Specific Solutions05 Integration with other circuit elements

Half wave rectifiers can be integrated with other circuit elements to create more complex and functional systems. This includes combining them with filtering capacitors to reduce ripple, incorporating them into bridge rectifier configurations for full-wave rectification, or using them as part of more advanced power conversion topologies like flyback converters.Expand Specific Solutions

Key Industry Players in Rectifier Manufacturing

The global half wave rectifier utility market is in a growth phase, driven by increasing demand for power electronics and energy-efficient solutions. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is evolving rapidly, with companies like Huawei, Samsung, and Intel leading innovation. These firms are developing advanced semiconductor technologies and integrated circuits to improve rectifier efficiency and performance. Research institutions such as MIT and CNRS are contributing to fundamental advancements, while specialized companies like Mixed-Signal Devices and MaxPower Semiconductor are focusing on niche applications. The competitive landscape is diverse, with established electronics giants competing alongside specialized semiconductor firms and emerging startups.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei's vision for global half wave rectifier utility focuses on developing high-efficiency, low-loss rectification systems for 5G and IoT applications. Their approach integrates advanced semiconductor materials like GaN and SiC to create ultra-compact rectifiers with improved thermal management[1]. Huawei's solution incorporates AI-driven adaptive control algorithms to optimize rectification efficiency across varying load conditions, potentially increasing overall system efficiency by up to 15%[3]. The company is also exploring the use of metamaterials to create "smart" rectifying surfaces that can dynamically adjust their properties based on incoming electromagnetic waves, potentially revolutionizing wireless power transfer and energy harvesting technologies[5].

Strengths: Advanced material integration, AI-driven optimization, and potential for revolutionary wireless power solutions. Weaknesses: High initial costs and complexity in implementation for widespread adoption.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung's approach to the future of global half wave rectifier utility centers on miniaturization and integration within their semiconductor ecosystem. They are developing nanoscale rectifiers using 2D materials like graphene and transition metal dichalcogenides, which promise near-zero forward voltage drop and ultra-fast switching speeds[2]. Samsung's vision includes integrating these advanced rectifiers directly into their system-on-chip (SoC) designs, potentially reducing power consumption in mobile and IoT devices by up to 30%[4]. Additionally, they are researching quantum dot-based rectifiers that could operate efficiently in the terahertz range, opening new possibilities for high-frequency applications in 6G communications and beyond[6].

Strengths: Cutting-edge materials research, seamless integration with existing semiconductor technologies, and potential for significant power savings. Weaknesses: Scalability challenges and high research and development costs.

Innovative Patents in Half Wave Rectification

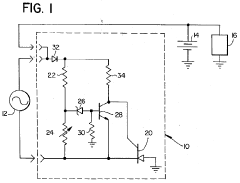

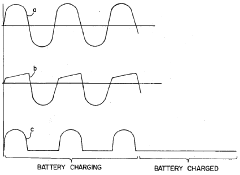

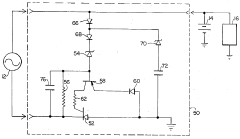

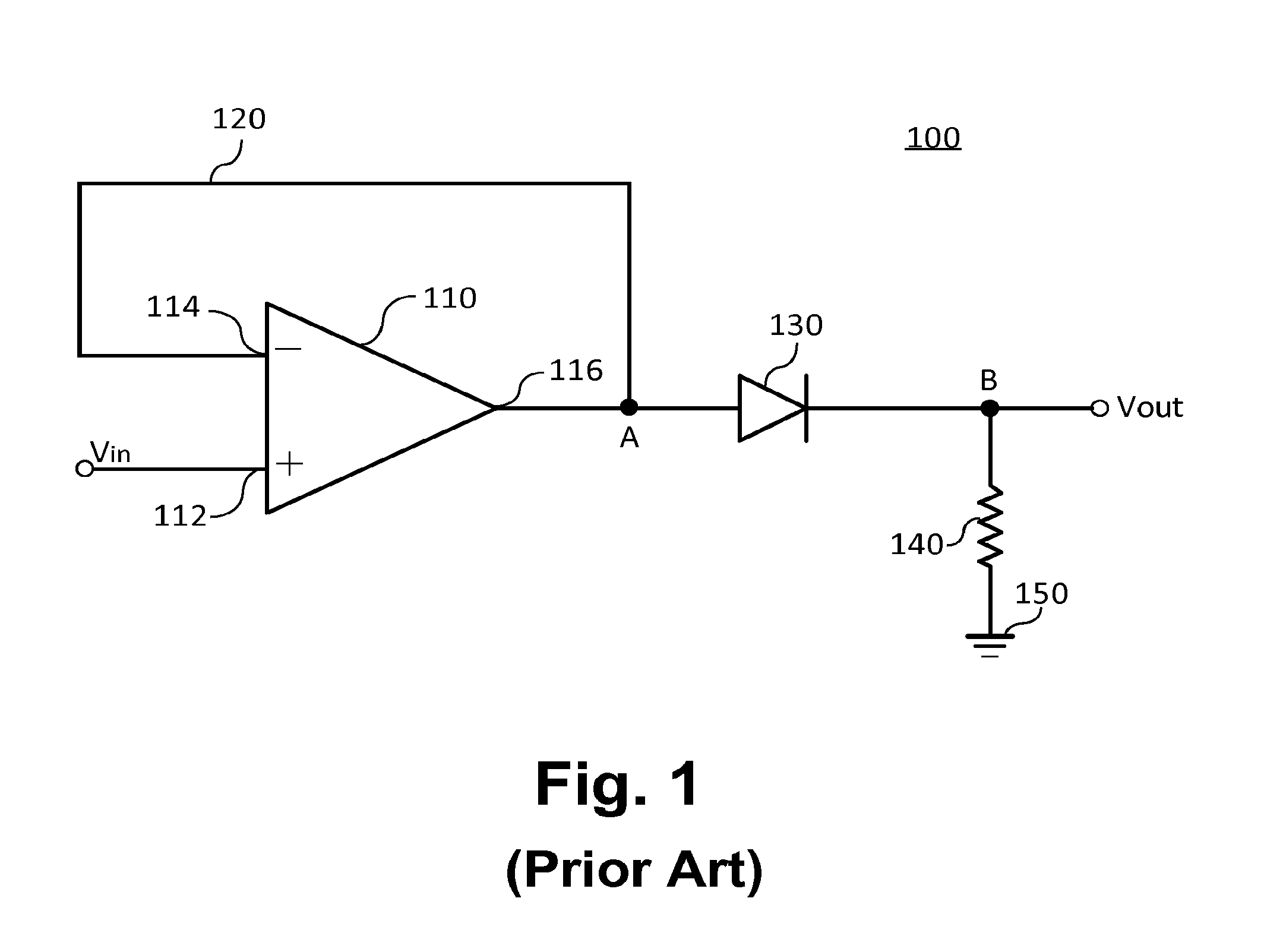

Half-wave regulator rectifier for an alternator

PatentInactiveUS4220909A

Innovation

- A half-wave regulator rectifier using a silicon controlled rectifier (SCR) with a control circuit that includes a voltage tracking circuit and controlled switching means, which inhibits conduction when the battery voltage is above the regulated level and ensures safe charging by monitoring alternator voltage and current flow, protecting components from damage during abnormal conditions.

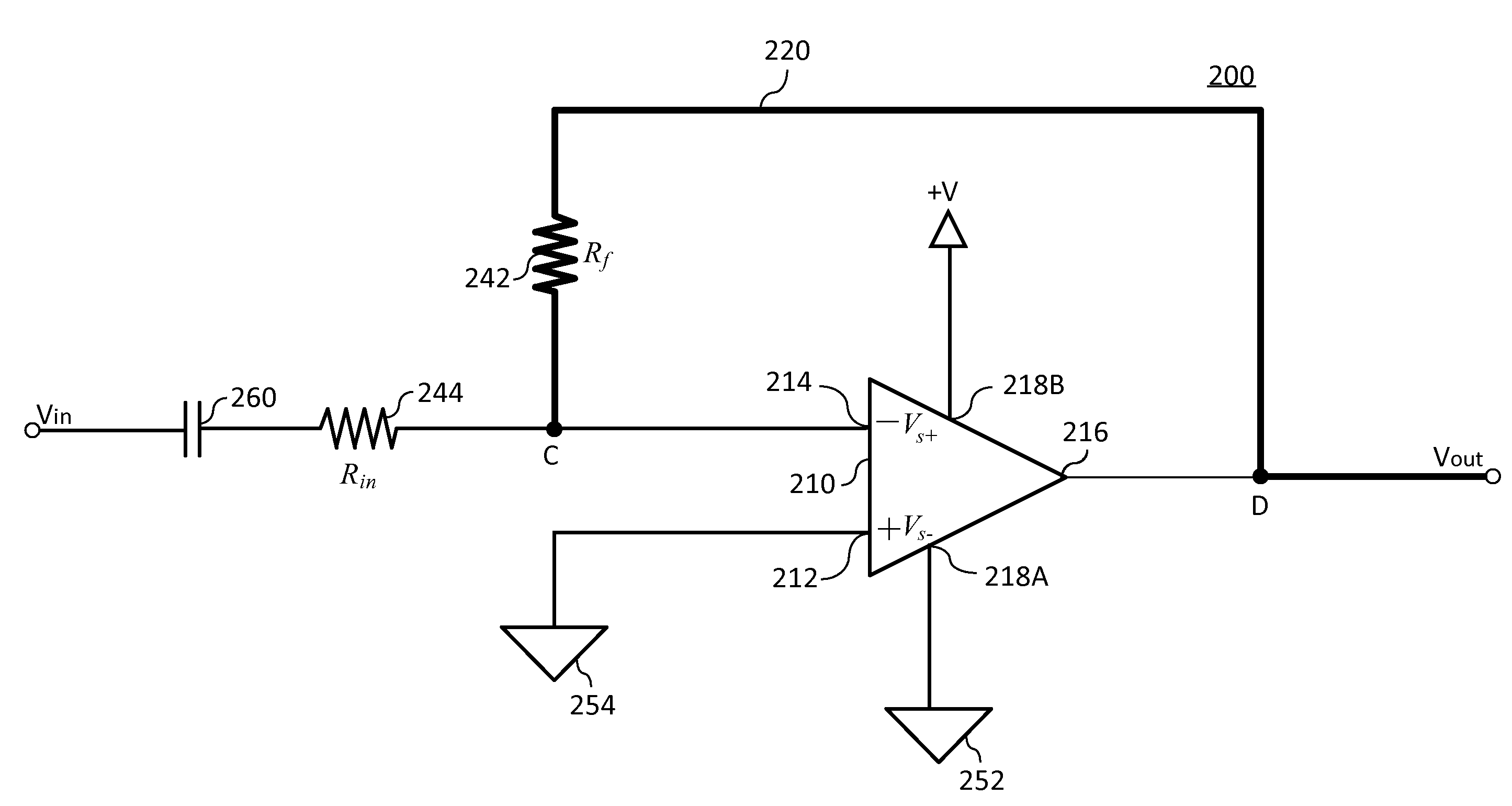

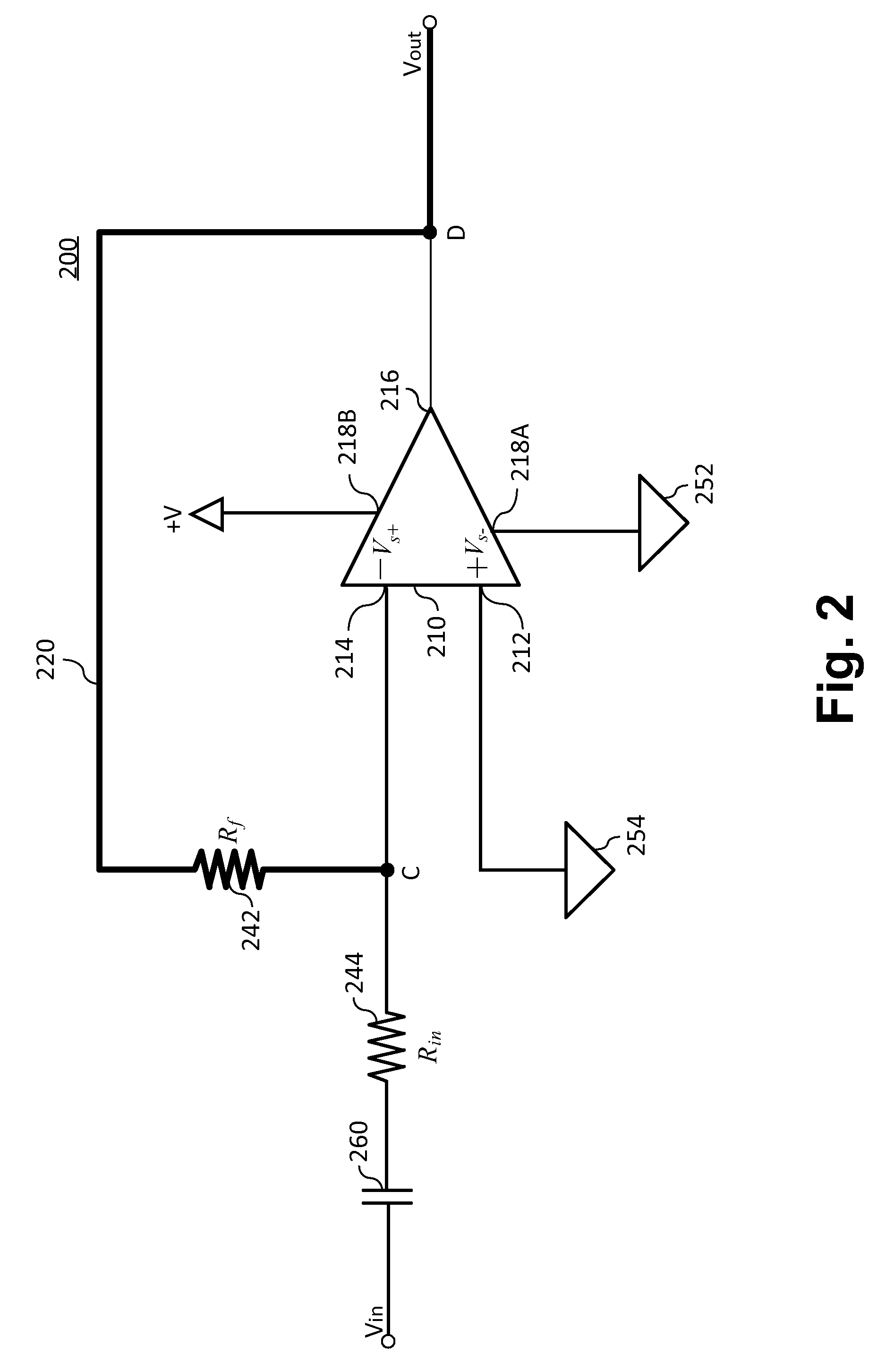

AC to DC conversion circuit

PatentActiveUS7764528B2

Innovation

- A diode-less half-wave rectifier circuit utilizing an operational amplifier with a capacitor and resistors in a negative feedback loop, allowing low-level signals to be converted to half-wave rectified DC signals, thereby extending the dynamic range of rectification.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the future vision for global half wave rectifier utility. As power electronics continue to evolve, improving the energy efficiency of half wave rectifiers becomes paramount for sustainable energy management and reduced environmental impact. Current half wave rectifier designs typically achieve efficiency levels between 70-80%, leaving significant room for improvement.

Advanced semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), are poised to revolutionize half wave rectifier efficiency. These wide bandgap materials offer lower on-state resistance and faster switching speeds, potentially pushing efficiency levels above 95%. Implementing these materials in rectifier designs could lead to substantial energy savings in power conversion applications across various industries.

Innovative circuit topologies are also being explored to enhance energy efficiency. Synchronous rectification techniques, which replace diodes with actively controlled switches, can significantly reduce conduction losses. This approach, when combined with advanced control algorithms, can adapt to varying load conditions and optimize efficiency across a wide operating range.

Thermal management plays a crucial role in maximizing energy efficiency. Novel cooling solutions, such as phase-change materials and microfluidic cooling systems, are being developed to dissipate heat more effectively. By maintaining lower operating temperatures, these technologies can reduce power losses and extend the lifespan of rectifier components.

The integration of smart control systems and IoT connectivity is another avenue for improving energy efficiency. Real-time monitoring and adaptive control strategies can optimize rectifier performance based on load demands and grid conditions. This intelligent approach enables dynamic power factor correction and harmonics reduction, further enhancing overall system efficiency.

Energy recovery techniques are gaining traction in half wave rectifier designs. By capturing and reusing energy that would otherwise be dissipated as heat, these systems can significantly boost efficiency. Techniques such as resonant switching and active energy recycling show promise in minimizing energy waste during the rectification process.

As global energy demands continue to rise, the focus on energy-efficient half wave rectifiers will intensify. Future developments may include the use of quantum materials, superconducting elements, and advanced nanotechnology to push the boundaries of efficiency. These advancements will not only reduce energy consumption but also contribute to the broader goals of sustainable power distribution and smart grid infrastructure.

Advanced semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), are poised to revolutionize half wave rectifier efficiency. These wide bandgap materials offer lower on-state resistance and faster switching speeds, potentially pushing efficiency levels above 95%. Implementing these materials in rectifier designs could lead to substantial energy savings in power conversion applications across various industries.

Innovative circuit topologies are also being explored to enhance energy efficiency. Synchronous rectification techniques, which replace diodes with actively controlled switches, can significantly reduce conduction losses. This approach, when combined with advanced control algorithms, can adapt to varying load conditions and optimize efficiency across a wide operating range.

Thermal management plays a crucial role in maximizing energy efficiency. Novel cooling solutions, such as phase-change materials and microfluidic cooling systems, are being developed to dissipate heat more effectively. By maintaining lower operating temperatures, these technologies can reduce power losses and extend the lifespan of rectifier components.

The integration of smart control systems and IoT connectivity is another avenue for improving energy efficiency. Real-time monitoring and adaptive control strategies can optimize rectifier performance based on load demands and grid conditions. This intelligent approach enables dynamic power factor correction and harmonics reduction, further enhancing overall system efficiency.

Energy recovery techniques are gaining traction in half wave rectifier designs. By capturing and reusing energy that would otherwise be dissipated as heat, these systems can significantly boost efficiency. Techniques such as resonant switching and active energy recycling show promise in minimizing energy waste during the rectification process.

As global energy demands continue to rise, the focus on energy-efficient half wave rectifiers will intensify. Future developments may include the use of quantum materials, superconducting elements, and advanced nanotechnology to push the boundaries of efficiency. These advancements will not only reduce energy consumption but also contribute to the broader goals of sustainable power distribution and smart grid infrastructure.

Global Standards and Regulations for Rectifiers

The global landscape of rectifier standards and regulations is evolving rapidly to address the increasing demand for efficient and reliable power conversion systems. As half-wave rectifiers continue to play a crucial role in various applications, regulatory bodies worldwide are working towards harmonizing standards to ensure safety, performance, and interoperability across different regions.

One of the key focus areas in global rectifier regulations is the improvement of energy efficiency. Many countries have implemented or are in the process of implementing minimum energy performance standards (MEPS) for rectifiers used in various applications, including power supplies, battery chargers, and industrial equipment. These standards aim to reduce energy waste and promote the adoption of more efficient rectifier designs.

Electromagnetic compatibility (EMC) regulations are another critical aspect of global rectifier standards. As the use of electronic devices becomes more widespread, ensuring that rectifiers do not interfere with other equipment or communication systems is paramount. International bodies such as the International Electrotechnical Commission (IEC) and regional organizations like the European Committee for Electrotechnical Standardization (CENELEC) are continuously updating EMC standards to address emerging challenges in this area.

Safety standards for rectifiers are also undergoing significant changes to keep pace with technological advancements. These standards cover aspects such as electrical isolation, thermal management, and protection against overload and short circuits. The UL 1012 standard in North America and the IEC 62368-1 standard internationally are examples of evolving safety regulations that rectifier manufacturers must comply with.

Environmental regulations are increasingly influencing rectifier design and manufacturing processes. The Restriction of Hazardous Substances (RoHS) directive in the European Union and similar regulations in other regions are driving the adoption of lead-free and other environmentally friendly materials in rectifier production. Additionally, regulations promoting the circular economy are encouraging manufacturers to design rectifiers with improved recyclability and longer lifespans.

As the global market for rectifiers continues to grow, efforts to harmonize standards across different regions are gaining momentum. Organizations such as the International Electrotechnical Commission (IEC) are working towards developing globally accepted standards that can be adopted by various countries, reducing trade barriers and simplifying compliance for manufacturers operating in multiple markets.

The future of global rectifier standards and regulations is likely to focus on emerging technologies such as wide-bandgap semiconductors and advanced control algorithms. These innovations promise to significantly improve the efficiency and performance of rectifiers, necessitating updates to existing standards and potentially the development of new regulatory frameworks to address their unique characteristics and applications.

One of the key focus areas in global rectifier regulations is the improvement of energy efficiency. Many countries have implemented or are in the process of implementing minimum energy performance standards (MEPS) for rectifiers used in various applications, including power supplies, battery chargers, and industrial equipment. These standards aim to reduce energy waste and promote the adoption of more efficient rectifier designs.

Electromagnetic compatibility (EMC) regulations are another critical aspect of global rectifier standards. As the use of electronic devices becomes more widespread, ensuring that rectifiers do not interfere with other equipment or communication systems is paramount. International bodies such as the International Electrotechnical Commission (IEC) and regional organizations like the European Committee for Electrotechnical Standardization (CENELEC) are continuously updating EMC standards to address emerging challenges in this area.

Safety standards for rectifiers are also undergoing significant changes to keep pace with technological advancements. These standards cover aspects such as electrical isolation, thermal management, and protection against overload and short circuits. The UL 1012 standard in North America and the IEC 62368-1 standard internationally are examples of evolving safety regulations that rectifier manufacturers must comply with.

Environmental regulations are increasingly influencing rectifier design and manufacturing processes. The Restriction of Hazardous Substances (RoHS) directive in the European Union and similar regulations in other regions are driving the adoption of lead-free and other environmentally friendly materials in rectifier production. Additionally, regulations promoting the circular economy are encouraging manufacturers to design rectifiers with improved recyclability and longer lifespans.

As the global market for rectifiers continues to grow, efforts to harmonize standards across different regions are gaining momentum. Organizations such as the International Electrotechnical Commission (IEC) are working towards developing globally accepted standards that can be adopted by various countries, reducing trade barriers and simplifying compliance for manufacturers operating in multiple markets.

The future of global rectifier standards and regulations is likely to focus on emerging technologies such as wide-bandgap semiconductors and advanced control algorithms. These innovations promise to significantly improve the efficiency and performance of rectifiers, necessitating updates to existing standards and potentially the development of new regulatory frameworks to address their unique characteristics and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!