How to Implement a Half Wave Rectifier in Low-Power Devices?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

Half wave rectification has been a fundamental technique in electrical engineering since the early days of electronics. This process, which converts alternating current (AC) to pulsating direct current (DC), has evolved significantly over the years, particularly in its application to low-power devices. The historical progression of half wave rectifiers can be traced from early vacuum tube diodes to modern semiconductor-based solutions, each iteration bringing improvements in efficiency, size, and power consumption.

The primary objective in implementing half wave rectifiers in low-power devices is to achieve efficient AC to DC conversion while minimizing energy loss and component size. This goal aligns with the broader trend in electronics towards miniaturization and energy efficiency. As portable and IoT devices become increasingly prevalent, the demand for compact, energy-efficient power conversion solutions has intensified, driving innovation in half wave rectifier design.

Current technological trends in this field focus on enhancing the performance of half wave rectifiers through advanced materials and circuit designs. Researchers are exploring the use of novel semiconductor materials, such as gallium nitride (GaN) and silicon carbide (SiC), which offer superior electrical properties compared to traditional silicon. These materials enable higher switching frequencies and lower on-state resistances, potentially leading to more efficient and compact rectifier designs.

Another significant trend is the integration of smart control mechanisms into rectifier circuits. These intelligent systems can dynamically adjust the rectification process based on load conditions, input voltage variations, and temperature, optimizing efficiency across a wide range of operating conditions. This adaptive approach is particularly valuable in low-power devices, where energy conservation is crucial.

The evolution of half wave rectifiers is also closely tied to advancements in power management integrated circuits (PMICs). Modern PMICs often incorporate sophisticated half wave rectifier designs alongside other power conversion and regulation functions, offering comprehensive power solutions for low-power devices in a single chip.

Looking forward, the field of half wave rectification in low-power devices is likely to see continued innovation driven by the demands of emerging technologies such as wearable electronics, implantable medical devices, and energy harvesting systems. These applications require ultra-low power consumption and minimal heat generation, pushing the boundaries of rectifier design and efficiency.

In conclusion, the implementation of half wave rectifiers in low-power devices represents a critical area of technological development, with implications for a wide range of electronic products and systems. As research progresses, we can expect to see further improvements in efficiency, size reduction, and integration, enabling the next generation of energy-efficient, compact electronic devices.

The primary objective in implementing half wave rectifiers in low-power devices is to achieve efficient AC to DC conversion while minimizing energy loss and component size. This goal aligns with the broader trend in electronics towards miniaturization and energy efficiency. As portable and IoT devices become increasingly prevalent, the demand for compact, energy-efficient power conversion solutions has intensified, driving innovation in half wave rectifier design.

Current technological trends in this field focus on enhancing the performance of half wave rectifiers through advanced materials and circuit designs. Researchers are exploring the use of novel semiconductor materials, such as gallium nitride (GaN) and silicon carbide (SiC), which offer superior electrical properties compared to traditional silicon. These materials enable higher switching frequencies and lower on-state resistances, potentially leading to more efficient and compact rectifier designs.

Another significant trend is the integration of smart control mechanisms into rectifier circuits. These intelligent systems can dynamically adjust the rectification process based on load conditions, input voltage variations, and temperature, optimizing efficiency across a wide range of operating conditions. This adaptive approach is particularly valuable in low-power devices, where energy conservation is crucial.

The evolution of half wave rectifiers is also closely tied to advancements in power management integrated circuits (PMICs). Modern PMICs often incorporate sophisticated half wave rectifier designs alongside other power conversion and regulation functions, offering comprehensive power solutions for low-power devices in a single chip.

Looking forward, the field of half wave rectification in low-power devices is likely to see continued innovation driven by the demands of emerging technologies such as wearable electronics, implantable medical devices, and energy harvesting systems. These applications require ultra-low power consumption and minimal heat generation, pushing the boundaries of rectifier design and efficiency.

In conclusion, the implementation of half wave rectifiers in low-power devices represents a critical area of technological development, with implications for a wide range of electronic products and systems. As research progresses, we can expect to see further improvements in efficiency, size reduction, and integration, enabling the next generation of energy-efficient, compact electronic devices.

Low-Power Device Market Analysis

The low-power device market has experienced significant growth in recent years, driven by the increasing demand for energy-efficient and portable electronic devices. This market segment encompasses a wide range of products, including wearables, IoT sensors, medical devices, and consumer electronics. The global low-power device market was valued at $69.3 billion in 2020 and is projected to reach $114.7 billion by 2026, growing at a CAGR of 8.9% during the forecast period.

One of the key factors driving this market growth is the rising adoption of IoT devices across various industries. These devices require efficient power management solutions to extend battery life and reduce overall energy consumption. The implementation of half-wave rectifiers in low-power devices plays a crucial role in meeting these requirements, as they offer a simple and effective method for converting AC to DC power with minimal energy loss.

The consumer electronics sector remains the largest contributor to the low-power device market, accounting for approximately 35% of the total market share. Smartphones, tablets, and wearables are the primary drivers in this segment, with manufacturers continuously seeking ways to improve battery life and reduce power consumption. The integration of half-wave rectifiers in these devices can significantly enhance their energy efficiency and overall performance.

The industrial and healthcare sectors are also experiencing rapid growth in the adoption of low-power devices. Industrial IoT sensors and medical wearables are becoming increasingly prevalent, creating new opportunities for half-wave rectifier implementations. These sectors are expected to grow at CAGRs of 12.3% and 10.7%, respectively, over the next five years.

Geographically, North America and Asia-Pacific dominate the low-power device market, collectively accounting for over 60% of the global market share. The Asia-Pacific region, in particular, is expected to witness the highest growth rate due to the presence of major semiconductor manufacturers and the rapid adoption of IoT technologies in countries like China, Japan, and South Korea.

The competitive landscape of the low-power device market is characterized by the presence of both established players and innovative startups. Key market players include Texas Instruments, Analog Devices, STMicroelectronics, and Maxim Integrated. These companies are investing heavily in research and development to create more efficient and compact half-wave rectifier solutions for low-power devices.

As the demand for energy-efficient devices continues to grow, the market for half-wave rectifiers in low-power applications is expected to expand further. This trend is likely to drive innovation in rectifier design, leading to more advanced and efficient solutions that can meet the evolving needs of the low-power device market.

One of the key factors driving this market growth is the rising adoption of IoT devices across various industries. These devices require efficient power management solutions to extend battery life and reduce overall energy consumption. The implementation of half-wave rectifiers in low-power devices plays a crucial role in meeting these requirements, as they offer a simple and effective method for converting AC to DC power with minimal energy loss.

The consumer electronics sector remains the largest contributor to the low-power device market, accounting for approximately 35% of the total market share. Smartphones, tablets, and wearables are the primary drivers in this segment, with manufacturers continuously seeking ways to improve battery life and reduce power consumption. The integration of half-wave rectifiers in these devices can significantly enhance their energy efficiency and overall performance.

The industrial and healthcare sectors are also experiencing rapid growth in the adoption of low-power devices. Industrial IoT sensors and medical wearables are becoming increasingly prevalent, creating new opportunities for half-wave rectifier implementations. These sectors are expected to grow at CAGRs of 12.3% and 10.7%, respectively, over the next five years.

Geographically, North America and Asia-Pacific dominate the low-power device market, collectively accounting for over 60% of the global market share. The Asia-Pacific region, in particular, is expected to witness the highest growth rate due to the presence of major semiconductor manufacturers and the rapid adoption of IoT technologies in countries like China, Japan, and South Korea.

The competitive landscape of the low-power device market is characterized by the presence of both established players and innovative startups. Key market players include Texas Instruments, Analog Devices, STMicroelectronics, and Maxim Integrated. These companies are investing heavily in research and development to create more efficient and compact half-wave rectifier solutions for low-power devices.

As the demand for energy-efficient devices continues to grow, the market for half-wave rectifiers in low-power applications is expected to expand further. This trend is likely to drive innovation in rectifier design, leading to more advanced and efficient solutions that can meet the evolving needs of the low-power device market.

Current Challenges in Half Wave Rectification

Half wave rectification in low-power devices faces several significant challenges that hinder its efficient implementation and widespread adoption. One of the primary issues is the inherent power loss associated with the rectification process. In low-power applications, where energy conservation is crucial, even small losses can have a substantial impact on overall system performance.

The forward voltage drop across the rectifying diode presents a major obstacle. This voltage drop, typically around 0.6-0.7V for silicon diodes, results in significant power dissipation and reduced efficiency. In low-power scenarios, this loss can represent a considerable portion of the available input voltage, limiting the usable output and potentially compromising the device's functionality.

Another challenge lies in the selection of appropriate components for low-power rectification. Traditional silicon diodes may not be suitable due to their relatively high forward voltage drop. While Schottky diodes offer lower forward voltage, they often suffer from higher reverse leakage currents, which can be problematic in energy-harvesting applications or battery-powered devices with long standby times.

The issue of reverse recovery time also poses difficulties in half wave rectification for low-power devices. During the transition from forward to reverse bias, diodes require a finite time to stop conducting. This reverse recovery time can lead to additional power losses and distortions in the rectified output, particularly at higher frequencies.

Temperature sensitivity is another critical factor affecting half wave rectifiers in low-power applications. The characteristics of semiconductor devices, including diodes, can vary significantly with temperature changes. This variability can lead to inconsistent performance and reduced reliability, especially in environments with fluctuating temperatures.

The limited voltage swing in low-power systems presents yet another challenge. With reduced input voltages, the rectified output may not reach the required levels for powering subsequent stages or charging storage elements efficiently. This limitation can necessitate additional voltage boosting circuitry, further complicating the design and potentially increasing power consumption.

Electromagnetic interference (EMI) and noise susceptibility are also concerns in half wave rectification for low-power devices. The pulsating nature of the rectified output can generate harmonics and introduce noise into the system. In sensitive low-power applications, such as wireless sensors or medical devices, this interference can degrade overall performance and reliability.

Addressing these challenges requires innovative approaches and careful design considerations. Researchers and engineers are exploring various techniques, such as active rectification, synchronous rectification, and the use of advanced materials like gallium nitride (GaN) to overcome these limitations and improve the efficiency of half wave rectification in low-power devices.

The forward voltage drop across the rectifying diode presents a major obstacle. This voltage drop, typically around 0.6-0.7V for silicon diodes, results in significant power dissipation and reduced efficiency. In low-power scenarios, this loss can represent a considerable portion of the available input voltage, limiting the usable output and potentially compromising the device's functionality.

Another challenge lies in the selection of appropriate components for low-power rectification. Traditional silicon diodes may not be suitable due to their relatively high forward voltage drop. While Schottky diodes offer lower forward voltage, they often suffer from higher reverse leakage currents, which can be problematic in energy-harvesting applications or battery-powered devices with long standby times.

The issue of reverse recovery time also poses difficulties in half wave rectification for low-power devices. During the transition from forward to reverse bias, diodes require a finite time to stop conducting. This reverse recovery time can lead to additional power losses and distortions in the rectified output, particularly at higher frequencies.

Temperature sensitivity is another critical factor affecting half wave rectifiers in low-power applications. The characteristics of semiconductor devices, including diodes, can vary significantly with temperature changes. This variability can lead to inconsistent performance and reduced reliability, especially in environments with fluctuating temperatures.

The limited voltage swing in low-power systems presents yet another challenge. With reduced input voltages, the rectified output may not reach the required levels for powering subsequent stages or charging storage elements efficiently. This limitation can necessitate additional voltage boosting circuitry, further complicating the design and potentially increasing power consumption.

Electromagnetic interference (EMI) and noise susceptibility are also concerns in half wave rectification for low-power devices. The pulsating nature of the rectified output can generate harmonics and introduce noise into the system. In sensitive low-power applications, such as wireless sensors or medical devices, this interference can degrade overall performance and reliability.

Addressing these challenges requires innovative approaches and careful design considerations. Researchers and engineers are exploring various techniques, such as active rectification, synchronous rectification, and the use of advanced materials like gallium nitride (GaN) to overcome these limitations and improve the efficiency of half wave rectification in low-power devices.

Existing Half Wave Rectifier Implementations

01 Circuit design and components

Half-wave rectifiers are designed using specific circuit components and configurations. These typically include diodes, transformers, and capacitors arranged in a way to convert alternating current (AC) to pulsating direct current (DC). The circuit allows current to flow in one direction during the positive half-cycle of the AC input, while blocking it during the negative half-cycle.- Circuit design and components: Half wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the voltage as needed. Various circuit configurations and component selections can be employed to optimize performance and efficiency.

- Power supply applications: Half wave rectifiers are commonly used in power supply circuits for various electronic devices. They can be found in low-power applications, such as small household appliances, as well as in more complex systems like industrial equipment. The rectified output can be further smoothed and regulated to provide stable DC power for different loads.

- Efficiency improvements: Researchers and engineers have developed various techniques to improve the efficiency of half wave rectifiers. These improvements may include the use of advanced semiconductor materials, optimized circuit layouts, and the integration of additional components to reduce power losses and enhance overall performance.

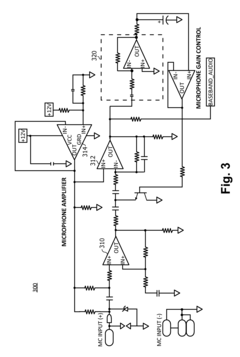

- Integration with other circuits: Half wave rectifiers can be integrated with other circuit elements to create more complex power management systems. This integration may involve combining the rectifier with voltage regulators, filters, or control circuits to achieve specific power output characteristics or to meet particular application requirements.

- Specialized applications: Half wave rectifiers find use in specialized applications beyond general power supplies. These may include RF signal detection, sensor circuits, or specific industrial processes. In these cases, the rectifier's characteristics are tailored to meet the unique demands of the application, such as high-frequency operation or precise voltage control.

02 Power supply applications

Half-wave rectifiers are commonly used in power supply applications. They can be found in various electronic devices and systems that require DC power from an AC source. These rectifiers are often part of larger power supply units that may include additional components for voltage regulation and smoothing.Expand Specific Solutions03 Efficiency and performance improvements

Researchers and engineers have developed various methods to improve the efficiency and performance of half-wave rectifiers. These improvements may include the use of advanced materials, optimized circuit designs, and innovative control strategies to reduce power losses and enhance overall system performance.Expand Specific Solutions04 Integration with other electronic systems

Half-wave rectifiers are often integrated into more complex electronic systems. They can be found in combination with other circuit elements such as voltage regulators, filters, and control circuits to provide specific functionalities in various applications, including power management, signal processing, and energy harvesting.Expand Specific Solutions05 Miniaturization and packaging

There is a trend towards miniaturization and improved packaging of half-wave rectifier circuits. This includes the development of compact, integrated solutions that combine multiple functions in a single package, as well as the use of advanced manufacturing techniques to reduce size and improve reliability.Expand Specific Solutions

Key Players in Low-Power Rectification

The implementation of half wave rectifiers in low-power devices is currently in a mature stage of development, with a well-established market and proven technologies. The global market for low-power rectifiers is experiencing steady growth, driven by increasing demand for energy-efficient electronics. Key players in this field include Texas Instruments, NEC Corporation, and Mitsubishi Electric, who are continuously innovating to improve efficiency and reduce power consumption. These companies have developed advanced semiconductor technologies and integrated circuit solutions that enable highly efficient half wave rectification in compact, low-power devices. The competitive landscape is characterized by ongoing research and development efforts to enhance performance, miniaturization, and cost-effectiveness of rectifier components for various low-power applications.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced half-wave rectifier solutions for low-power devices, focusing on efficiency and miniaturization. Their approach utilizes high-performance Schottky diodes with ultra-low forward voltage drop, typically less than 0.3V [1]. This allows for improved power conversion efficiency in low-voltage applications. TI also incorporates synchronous rectification techniques, replacing diodes with MOSFETs controlled by intelligent gate drivers [2]. This further reduces power losses and improves overall system efficiency. Additionally, TI has implemented integrated circuit solutions that combine the rectifier, voltage regulator, and control logic on a single chip, significantly reducing component count and PCB footprint [3].

Strengths: High efficiency, small form factor, and integrated solutions. Weaknesses: Potentially higher cost compared to discrete component implementations, and increased complexity in design and manufacturing.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed innovative half-wave rectifier designs for low-power devices, particularly in the context of energy harvesting and IoT applications. Their approach utilizes advanced semiconductor materials, such as gallium nitride (GaN), to create high-efficiency rectifiers with minimal forward voltage drop [4]. Huawei has also implemented adaptive threshold techniques that dynamically adjust the rectifier's operating point based on input voltage levels, optimizing efficiency across a wide range of input conditions [5]. Furthermore, they have integrated these rectifiers with ultra-low-power management circuits, enabling efficient energy storage and utilization in battery-less IoT devices [6].

Strengths: High efficiency in energy harvesting applications, adaptability to varying input conditions. Weaknesses: Potentially higher production costs due to advanced materials, and limited applicability outside of specific low-power scenarios.

Core Innovations in Low-Power Rectification

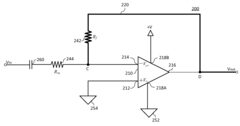

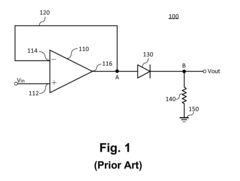

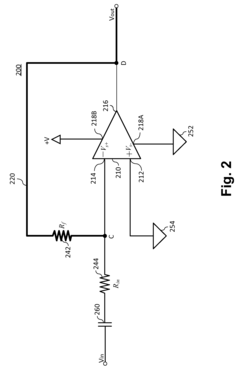

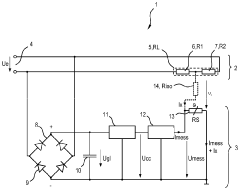

Ac to DC conversion circuit

PatentActiveUS20090080224A1

Innovation

- A diode-less half-wave rectifier circuit utilizing an operational amplifier with a capacitor and resistors in a negative feedback loop, allowing low-level signals to be converted to DC without clipping, thereby extending the dynamic range of rectification.

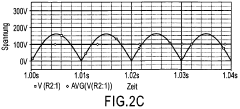

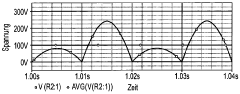

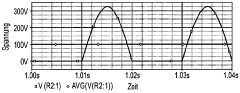

Electric circuit and household appliance

PatentWO2010000767A1

Innovation

- The implementation of a half-wave rectifier in the DC circuit, which can include a single diode or triac, reduces or eliminates the influence of AC currents on measurement accuracy by minimizing leakage currents, and the use of a low-pass filter further enhances measurement precision by filtering out ripple effects.

Power Consumption Optimization Strategies

Power consumption optimization is a critical aspect of implementing half-wave rectifiers in low-power devices. To achieve optimal energy efficiency, several strategies can be employed. One key approach is the selection of appropriate components with low power consumption characteristics. This includes choosing diodes with low forward voltage drop and minimal reverse leakage current, as well as utilizing low-power operational amplifiers for signal conditioning.

Another effective strategy is the implementation of adaptive power management techniques. By dynamically adjusting the rectifier's operating parameters based on the input signal characteristics and load requirements, power consumption can be significantly reduced during periods of low activity or standby modes. This can be achieved through the use of intelligent control circuits that monitor the input signal and adjust the rectifier's bias conditions accordingly.

Circuit topology optimization also plays a crucial role in minimizing power consumption. Employing techniques such as synchronous rectification can substantially improve efficiency by replacing the traditional diode with a low-resistance MOSFET switch. This approach reduces conduction losses and enhances overall system performance, particularly in applications with low output voltages.

The integration of energy harvesting techniques can further optimize power consumption in half-wave rectifier implementations. By capturing and utilizing ambient energy sources, such as electromagnetic fields or thermal gradients, the overall power requirements of the device can be reduced. This approach is particularly beneficial in ultra-low-power applications where battery life extension is critical.

Implementing advanced power-gating techniques can also contribute to power consumption optimization. By selectively powering down non-essential circuit blocks when not in use, standby power consumption can be minimized. This can be achieved through the use of power switches and intelligent control logic that manages the power distribution within the device.

Finally, the application of advanced semiconductor technologies, such as silicon-on-insulator (SOI) or high-k metal gate processes, can lead to significant improvements in power efficiency. These technologies offer reduced parasitic capacitances and lower leakage currents, resulting in improved overall power consumption characteristics for the half-wave rectifier circuit.

By combining these power consumption optimization strategies, designers can create highly efficient half-wave rectifier implementations suitable for low-power devices, extending battery life and enhancing overall system performance.

Another effective strategy is the implementation of adaptive power management techniques. By dynamically adjusting the rectifier's operating parameters based on the input signal characteristics and load requirements, power consumption can be significantly reduced during periods of low activity or standby modes. This can be achieved through the use of intelligent control circuits that monitor the input signal and adjust the rectifier's bias conditions accordingly.

Circuit topology optimization also plays a crucial role in minimizing power consumption. Employing techniques such as synchronous rectification can substantially improve efficiency by replacing the traditional diode with a low-resistance MOSFET switch. This approach reduces conduction losses and enhances overall system performance, particularly in applications with low output voltages.

The integration of energy harvesting techniques can further optimize power consumption in half-wave rectifier implementations. By capturing and utilizing ambient energy sources, such as electromagnetic fields or thermal gradients, the overall power requirements of the device can be reduced. This approach is particularly beneficial in ultra-low-power applications where battery life extension is critical.

Implementing advanced power-gating techniques can also contribute to power consumption optimization. By selectively powering down non-essential circuit blocks when not in use, standby power consumption can be minimized. This can be achieved through the use of power switches and intelligent control logic that manages the power distribution within the device.

Finally, the application of advanced semiconductor technologies, such as silicon-on-insulator (SOI) or high-k metal gate processes, can lead to significant improvements in power efficiency. These technologies offer reduced parasitic capacitances and lower leakage currents, resulting in improved overall power consumption characteristics for the half-wave rectifier circuit.

By combining these power consumption optimization strategies, designers can create highly efficient half-wave rectifier implementations suitable for low-power devices, extending battery life and enhancing overall system performance.

Thermal Management in Low-Power Rectifiers

Thermal management is a critical aspect of implementing half-wave rectifiers in low-power devices. As these devices often operate in compact environments with limited cooling capabilities, efficient heat dissipation becomes paramount to ensure optimal performance and longevity. The primary sources of heat generation in half-wave rectifiers are the diode and the load resistor, which can lead to increased power consumption and reduced efficiency if not properly managed.

One of the key strategies for thermal management in low-power rectifiers is the selection of appropriate components. Low-forward voltage Schottky diodes are often preferred due to their reduced power dissipation compared to standard silicon diodes. These diodes exhibit lower voltage drops during conduction, resulting in less heat generation. Additionally, the use of surface-mount components can improve thermal conductivity to the printed circuit board (PCB), facilitating better heat dissipation.

PCB design plays a crucial role in thermal management. Implementing thermal vias and copper pours can significantly enhance heat dissipation from the rectifier components to the board's ground plane. This technique helps distribute heat more evenly across the PCB, preventing localized hot spots. In some cases, the use of a multi-layer PCB with dedicated thermal layers can further improve heat dissipation capabilities.

For applications requiring enhanced thermal performance, the integration of small heat sinks or thermal pads can be considered. These passive cooling solutions can be particularly effective when combined with strategic component placement and PCB design techniques. In extremely space-constrained designs, thermally conductive encapsulants or potting compounds may be employed to improve heat transfer from the components to the device's exterior.

Advanced thermal management techniques for low-power rectifiers include the use of temperature-dependent resistors (thermistors) to regulate current flow based on temperature changes. This approach can help prevent thermal runaway in scenarios where ambient temperatures fluctuate significantly. Additionally, implementing temperature monitoring and thermal shutdown features can protect the device from damage due to overheating.

In recent years, the development of novel materials and packaging technologies has further enhanced thermal management capabilities in low-power rectifiers. For instance, the use of advanced ceramic substrates with high thermal conductivity can improve heat dissipation in ultra-compact designs. Similarly, the adoption of chip-scale packaging techniques allows for better thermal coupling between the rectifier components and the PCB, facilitating more efficient heat transfer.

As low-power devices continue to evolve, with increasing demands for miniaturization and higher efficiency, thermal management in half-wave rectifiers remains an active area of research and development. Future advancements may include the integration of microfluidic cooling channels within PCBs or the development of smart thermal management systems that dynamically adjust rectifier performance based on real-time temperature data.

One of the key strategies for thermal management in low-power rectifiers is the selection of appropriate components. Low-forward voltage Schottky diodes are often preferred due to their reduced power dissipation compared to standard silicon diodes. These diodes exhibit lower voltage drops during conduction, resulting in less heat generation. Additionally, the use of surface-mount components can improve thermal conductivity to the printed circuit board (PCB), facilitating better heat dissipation.

PCB design plays a crucial role in thermal management. Implementing thermal vias and copper pours can significantly enhance heat dissipation from the rectifier components to the board's ground plane. This technique helps distribute heat more evenly across the PCB, preventing localized hot spots. In some cases, the use of a multi-layer PCB with dedicated thermal layers can further improve heat dissipation capabilities.

For applications requiring enhanced thermal performance, the integration of small heat sinks or thermal pads can be considered. These passive cooling solutions can be particularly effective when combined with strategic component placement and PCB design techniques. In extremely space-constrained designs, thermally conductive encapsulants or potting compounds may be employed to improve heat transfer from the components to the device's exterior.

Advanced thermal management techniques for low-power rectifiers include the use of temperature-dependent resistors (thermistors) to regulate current flow based on temperature changes. This approach can help prevent thermal runaway in scenarios where ambient temperatures fluctuate significantly. Additionally, implementing temperature monitoring and thermal shutdown features can protect the device from damage due to overheating.

In recent years, the development of novel materials and packaging technologies has further enhanced thermal management capabilities in low-power rectifiers. For instance, the use of advanced ceramic substrates with high thermal conductivity can improve heat dissipation in ultra-compact designs. Similarly, the adoption of chip-scale packaging techniques allows for better thermal coupling between the rectifier components and the PCB, facilitating more efficient heat transfer.

As low-power devices continue to evolve, with increasing demands for miniaturization and higher efficiency, thermal management in half-wave rectifiers remains an active area of research and development. Future advancements may include the integration of microfluidic cooling channels within PCBs or the development of smart thermal management systems that dynamically adjust rectifier performance based on real-time temperature data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!