Half Wave Rectifier Efficiency Enhancement Techniques

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

Half-wave rectification has been a fundamental technique in power electronics since the early days of electrical engineering. This process, which converts alternating current (AC) to pulsating direct current (DC), has played a crucial role in the development of various electronic devices and power systems. The evolution of half-wave rectifiers has been driven by the increasing demand for more efficient and compact power conversion solutions across multiple industries.

The primary objective of research on half-wave rectifier efficiency enhancement techniques is to address the inherent limitations of traditional half-wave rectification. These limitations include low power efficiency, high harmonic content, and poor utilization of the input waveform. As energy conservation and power quality become increasingly important in modern applications, there is a growing need to improve the performance of half-wave rectifiers.

The development of half-wave rectifiers can be traced back to the invention of the vacuum tube diode in the early 20th century. Since then, the technology has progressed through several key stages, including the introduction of solid-state semiconductor diodes, the integration of control circuits, and the implementation of advanced switching techniques. Each of these advancements has contributed to incremental improvements in efficiency and performance.

Current research efforts in half-wave rectifier efficiency enhancement are focused on several key areas. These include the development of novel semiconductor materials with lower forward voltage drops, the implementation of advanced control algorithms to optimize switching timing, and the integration of passive components to reduce losses and improve power factor. Additionally, researchers are exploring the potential of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), to further enhance the efficiency and power density of half-wave rectifiers.

The ongoing technological evolution in this field is driven by the need to meet increasingly stringent energy efficiency standards and the demand for more compact and reliable power conversion solutions. As electronic devices become more prevalent and energy-intensive, the importance of efficient power conversion techniques, including improved half-wave rectification, continues to grow.

Looking ahead, the future of half-wave rectifier efficiency enhancement techniques is likely to involve a combination of material science advancements, innovative circuit topologies, and intelligent control strategies. The ultimate goal is to develop half-wave rectifiers that can achieve near-ideal efficiency while maintaining simplicity, reliability, and cost-effectiveness. This research has far-reaching implications for various applications, ranging from consumer electronics to industrial power systems and renewable energy integration.

The primary objective of research on half-wave rectifier efficiency enhancement techniques is to address the inherent limitations of traditional half-wave rectification. These limitations include low power efficiency, high harmonic content, and poor utilization of the input waveform. As energy conservation and power quality become increasingly important in modern applications, there is a growing need to improve the performance of half-wave rectifiers.

The development of half-wave rectifiers can be traced back to the invention of the vacuum tube diode in the early 20th century. Since then, the technology has progressed through several key stages, including the introduction of solid-state semiconductor diodes, the integration of control circuits, and the implementation of advanced switching techniques. Each of these advancements has contributed to incremental improvements in efficiency and performance.

Current research efforts in half-wave rectifier efficiency enhancement are focused on several key areas. These include the development of novel semiconductor materials with lower forward voltage drops, the implementation of advanced control algorithms to optimize switching timing, and the integration of passive components to reduce losses and improve power factor. Additionally, researchers are exploring the potential of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), to further enhance the efficiency and power density of half-wave rectifiers.

The ongoing technological evolution in this field is driven by the need to meet increasingly stringent energy efficiency standards and the demand for more compact and reliable power conversion solutions. As electronic devices become more prevalent and energy-intensive, the importance of efficient power conversion techniques, including improved half-wave rectification, continues to grow.

Looking ahead, the future of half-wave rectifier efficiency enhancement techniques is likely to involve a combination of material science advancements, innovative circuit topologies, and intelligent control strategies. The ultimate goal is to develop half-wave rectifiers that can achieve near-ideal efficiency while maintaining simplicity, reliability, and cost-effectiveness. This research has far-reaching implications for various applications, ranging from consumer electronics to industrial power systems and renewable energy integration.

Market Demand Analysis for Efficient Rectifiers

The market demand for efficient rectifiers, particularly those utilizing half-wave rectification techniques, has been steadily increasing across various industries. This growth is primarily driven by the rising need for power-efficient electronic devices and systems in both consumer and industrial applications. The global power electronics market, which includes rectifiers as a crucial component, is projected to reach significant market value in the coming years, with a substantial portion attributed to rectifier technologies.

In the consumer electronics sector, the demand for efficient rectifiers is particularly strong. As portable devices become more powerful and feature-rich, there is an increasing need for compact and energy-efficient power conversion solutions. Half-wave rectifiers, when optimized for efficiency, can play a crucial role in extending battery life and reducing heat generation in smartphones, tablets, and wearable devices.

The automotive industry is another major driver of demand for efficient rectifiers. With the rapid growth of electric and hybrid vehicles, there is a pressing need for high-efficiency power conversion systems. Improved half-wave rectifier technologies can contribute to better energy management in these vehicles, potentially extending driving range and reducing charging times.

In the renewable energy sector, particularly in solar and wind power systems, efficient rectifiers are essential for maximizing energy harvesting and conversion. As the world shifts towards cleaner energy sources, the demand for high-performance rectifiers in power inverters and converters is expected to grow significantly.

The industrial automation sector also presents a substantial market for efficient rectifiers. As factories and manufacturing processes become increasingly electrified and digitized, the need for reliable and efficient power conversion solutions grows. Enhanced half-wave rectifier technologies can contribute to improved energy efficiency in industrial power supplies, motor drives, and control systems.

Telecommunications infrastructure, including 5G networks, represents another area of growing demand for efficient rectifiers. The expansion of data centers and network equipment requires power supplies with higher efficiency and reliability, where advanced rectifier technologies can play a crucial role.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for efficient rectifiers, driven by rapid industrialization, increasing adoption of consumer electronics, and significant investments in renewable energy infrastructure. North America and Europe are also substantial markets, with a focus on high-performance and energy-efficient solutions across various industries.

The demand for efficient rectifiers is further bolstered by increasingly stringent energy efficiency regulations and standards worldwide. Governments and regulatory bodies are pushing for higher power conversion efficiencies, which is driving innovation in rectifier technologies, including half-wave rectification techniques.

In the consumer electronics sector, the demand for efficient rectifiers is particularly strong. As portable devices become more powerful and feature-rich, there is an increasing need for compact and energy-efficient power conversion solutions. Half-wave rectifiers, when optimized for efficiency, can play a crucial role in extending battery life and reducing heat generation in smartphones, tablets, and wearable devices.

The automotive industry is another major driver of demand for efficient rectifiers. With the rapid growth of electric and hybrid vehicles, there is a pressing need for high-efficiency power conversion systems. Improved half-wave rectifier technologies can contribute to better energy management in these vehicles, potentially extending driving range and reducing charging times.

In the renewable energy sector, particularly in solar and wind power systems, efficient rectifiers are essential for maximizing energy harvesting and conversion. As the world shifts towards cleaner energy sources, the demand for high-performance rectifiers in power inverters and converters is expected to grow significantly.

The industrial automation sector also presents a substantial market for efficient rectifiers. As factories and manufacturing processes become increasingly electrified and digitized, the need for reliable and efficient power conversion solutions grows. Enhanced half-wave rectifier technologies can contribute to improved energy efficiency in industrial power supplies, motor drives, and control systems.

Telecommunications infrastructure, including 5G networks, represents another area of growing demand for efficient rectifiers. The expansion of data centers and network equipment requires power supplies with higher efficiency and reliability, where advanced rectifier technologies can play a crucial role.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for efficient rectifiers, driven by rapid industrialization, increasing adoption of consumer electronics, and significant investments in renewable energy infrastructure. North America and Europe are also substantial markets, with a focus on high-performance and energy-efficient solutions across various industries.

The demand for efficient rectifiers is further bolstered by increasingly stringent energy efficiency regulations and standards worldwide. Governments and regulatory bodies are pushing for higher power conversion efficiencies, which is driving innovation in rectifier technologies, including half-wave rectification techniques.

Current Challenges in Half Wave Rectification

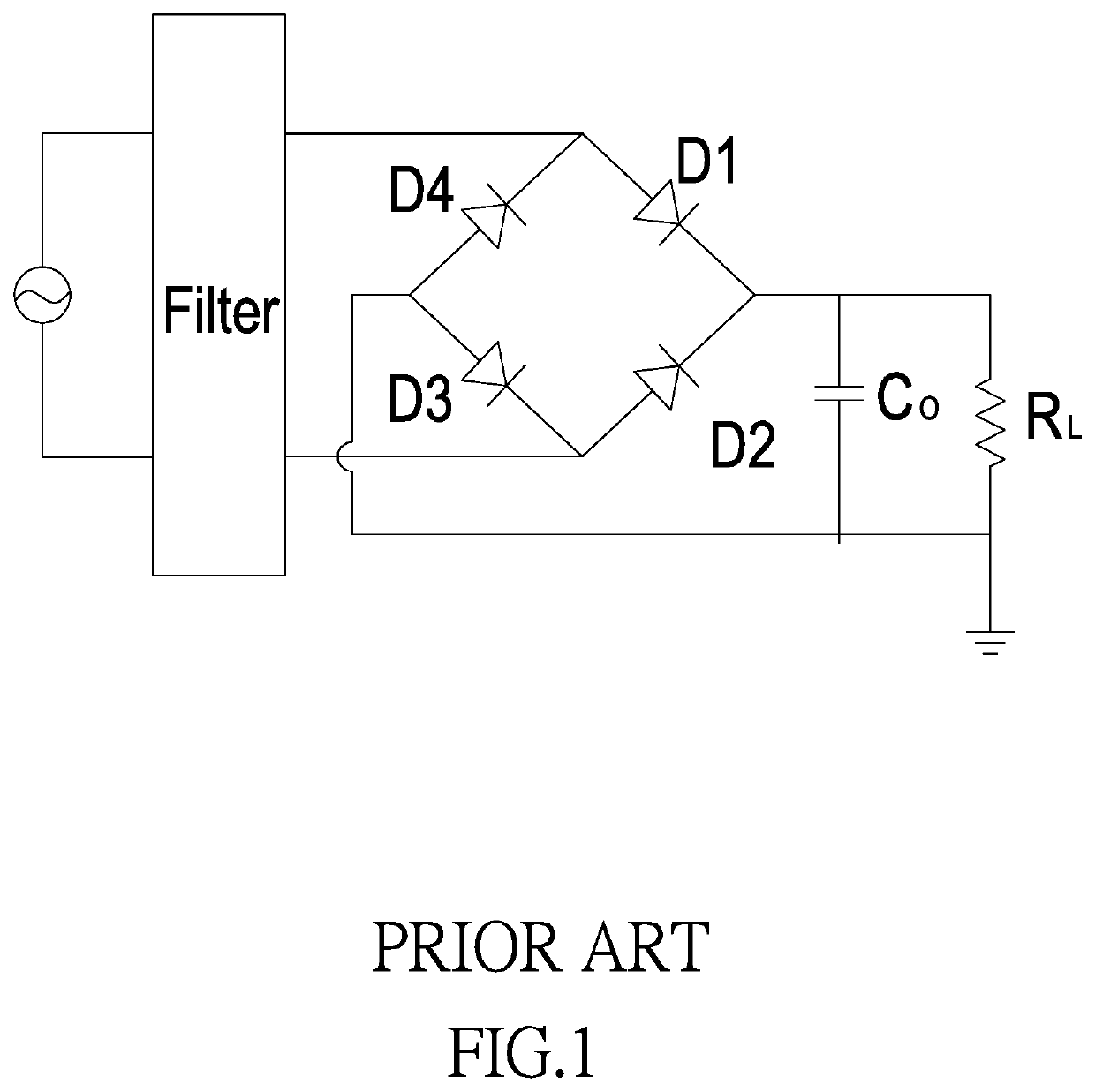

Half wave rectification, while a fundamental technique in power electronics, faces several significant challenges that limit its efficiency and applicability in modern systems. One of the primary issues is the inherent power loss associated with the rectification process. During the negative half-cycle of the AC input, the diode in a half wave rectifier blocks current flow, effectively wasting half of the input power. This results in a low power utilization factor, typically around 40.6%, which is inadequate for many high-efficiency applications.

Another challenge is the high ripple content in the output voltage. The pulsating nature of the half wave rectified output requires substantial filtering to achieve a smooth DC voltage, adding complexity and cost to the overall system. The large ripple factor, approximately 1.21, necessitates the use of larger capacitors or more sophisticated filtering techniques, which can increase the size and weight of the power supply unit.

The poor form factor of the half wave rectified output, about 1.57, leads to increased harmonic distortion. This distortion can cause electromagnetic interference (EMI) issues, potentially affecting nearby electronic equipment and necessitating additional EMI suppression measures. The harmonic content also contributes to lower power quality, which is particularly problematic in grid-connected applications.

Voltage regulation is another area of concern in half wave rectifiers. The output voltage tends to fluctuate with changes in load or input voltage, making it challenging to maintain a stable DC output without additional voltage regulation circuitry. This instability can be critical in applications requiring precise voltage control, such as in sensitive electronic devices or measurement equipment.

The low transformer utilization factor in half wave rectification systems is also a significant drawback. With only half of the secondary winding being used at any given time, the transformer operates inefficiently, leading to increased size and cost for a given power rating. This inefficiency is particularly pronounced in high-power applications, where transformer size and cost are critical factors.

Heat management presents another challenge, especially in high-current applications. The rectifying diode must handle the full load current during conduction, leading to significant heat generation. This necessitates careful thermal design and potentially larger heat sinks, impacting the overall size and cost of the rectifier system.

Lastly, the unidirectional current flow in half wave rectifiers can cause DC saturation in transformers, potentially leading to core saturation and increased losses. This effect can reduce the overall system efficiency and reliability, particularly in applications with varying load conditions or where the transformer is operating near its design limits.

Another challenge is the high ripple content in the output voltage. The pulsating nature of the half wave rectified output requires substantial filtering to achieve a smooth DC voltage, adding complexity and cost to the overall system. The large ripple factor, approximately 1.21, necessitates the use of larger capacitors or more sophisticated filtering techniques, which can increase the size and weight of the power supply unit.

The poor form factor of the half wave rectified output, about 1.57, leads to increased harmonic distortion. This distortion can cause electromagnetic interference (EMI) issues, potentially affecting nearby electronic equipment and necessitating additional EMI suppression measures. The harmonic content also contributes to lower power quality, which is particularly problematic in grid-connected applications.

Voltage regulation is another area of concern in half wave rectifiers. The output voltage tends to fluctuate with changes in load or input voltage, making it challenging to maintain a stable DC output without additional voltage regulation circuitry. This instability can be critical in applications requiring precise voltage control, such as in sensitive electronic devices or measurement equipment.

The low transformer utilization factor in half wave rectification systems is also a significant drawback. With only half of the secondary winding being used at any given time, the transformer operates inefficiently, leading to increased size and cost for a given power rating. This inefficiency is particularly pronounced in high-power applications, where transformer size and cost are critical factors.

Heat management presents another challenge, especially in high-current applications. The rectifying diode must handle the full load current during conduction, leading to significant heat generation. This necessitates careful thermal design and potentially larger heat sinks, impacting the overall size and cost of the rectifier system.

Lastly, the unidirectional current flow in half wave rectifiers can cause DC saturation in transformers, potentially leading to core saturation and increased losses. This effect can reduce the overall system efficiency and reliability, particularly in applications with varying load conditions or where the transformer is operating near its design limits.

Existing Efficiency Enhancement Solutions

01 Circuit design optimization

Improving the efficiency of half-wave rectifiers through optimized circuit design. This includes using advanced components, reducing parasitic elements, and implementing innovative topologies to minimize power losses and enhance overall performance.- Circuit design for improved efficiency: Optimizing the circuit design of half-wave rectifiers can significantly improve their efficiency. This includes using advanced components, reducing parasitic losses, and implementing innovative topologies to minimize power dissipation during the rectification process.

- Voltage regulation techniques: Implementing effective voltage regulation techniques in half-wave rectifiers can enhance their efficiency. This may involve using feedback control systems, voltage stabilization circuits, or adaptive regulation methods to maintain consistent output voltage and reduce energy losses.

- Filtering and smoothing methods: Employing advanced filtering and smoothing techniques can improve the output quality of half-wave rectifiers, thereby increasing their overall efficiency. This includes using capacitor-based smoothing circuits, LC filters, or active filtering methods to reduce ripple and harmonics in the output.

- Semiconductor device optimization: Optimizing the semiconductor devices used in half-wave rectifiers can lead to improved efficiency. This involves selecting high-performance diodes or transistors with low forward voltage drop, fast switching characteristics, and minimal reverse recovery losses.

- Thermal management and cooling solutions: Implementing effective thermal management and cooling solutions can enhance the efficiency of half-wave rectifiers by reducing power losses due to heat generation. This may include using heat sinks, forced-air cooling, or advanced thermal interface materials to dissipate heat more effectively.

02 Voltage regulation techniques

Implementing voltage regulation techniques to stabilize the output of half-wave rectifiers. This involves using feedback mechanisms, voltage-sensing circuits, and adaptive control strategies to maintain consistent output voltage and improve efficiency across varying load conditions.Expand Specific Solutions03 Filtering and smoothing methods

Employing advanced filtering and smoothing methods to reduce ripple and improve the quality of the rectified output. This includes using capacitive and inductive filters, as well as active filtering techniques to minimize harmonics and enhance overall efficiency.Expand Specific Solutions04 Semiconductor device improvements

Enhancing the efficiency of half-wave rectifiers through advancements in semiconductor device technology. This involves using high-performance diodes, MOSFETs, or other semiconductor components with lower forward voltage drops and faster switching characteristics.Expand Specific Solutions05 Thermal management and cooling

Implementing effective thermal management and cooling strategies to improve the efficiency of half-wave rectifiers. This includes optimizing heat dissipation, using advanced cooling techniques, and designing thermally efficient layouts to reduce power losses due to temperature effects.Expand Specific Solutions

Key Players in Power Electronics Industry

The research on half wave rectifier efficiency enhancement techniques is in a mature stage of development, with a significant market size due to its widespread application in power electronics. The technology's maturity is evident from the involvement of established institutions and companies across various sectors. Universities like Technical University of Denmark, South China University of Technology, and Massachusetts Institute of Technology are actively contributing to advancements in this field. Major industry players such as State Grid Corp. of China, Infineon Technologies, and Samsung Electronics are also investing in research and development to improve rectifier efficiency. The competitive landscape is diverse, with contributions from both academic and commercial entities, indicating a well-developed ecosystem for innovation in this technology.

Technical University of Denmark

Technical Solution: The Technical University of Denmark has developed an innovative approach to enhance half-wave rectifier efficiency through the implementation of a novel switching technique. Their method involves the use of a high-frequency switching mechanism that reduces conduction losses during the non-conducting half-cycle. This technique employs advanced power electronic devices, such as silicon carbide (SiC) or gallium nitride (GaN) transistors, to achieve faster switching speeds and lower on-state resistance[1]. The university's research team has also integrated a sophisticated control algorithm that optimizes the switching timing based on the input waveform characteristics, further improving overall efficiency[3].

Strengths: High efficiency gains, especially at higher frequencies; adaptable to various input waveforms. Weaknesses: Increased complexity in control circuitry; potential for electromagnetic interference (EMI) due to high-frequency switching.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute Ltd. has pioneered a multi-stage half-wave rectifier design that significantly enhances efficiency. Their approach incorporates a series of cascaded rectifier stages, each optimized for a specific voltage range. This design utilizes advanced semiconductor materials, including silicon carbide (SiC) diodes, which offer lower forward voltage drops and faster recovery times[2]. The institute has also developed a proprietary thermal management system that effectively dissipates heat from the rectifier components, allowing for higher power handling capabilities without compromising efficiency[5]. Additionally, they have implemented an intelligent power factor correction (PFC) circuit that works in tandem with the rectifier stages to minimize harmonic distortion and improve overall power quality[7].

Strengths: High efficiency across a wide range of input voltages; improved power quality and reduced harmonics. Weaknesses: Increased component count and system complexity; potentially higher initial cost compared to traditional designs.

Core Innovations in Half Wave Rectification

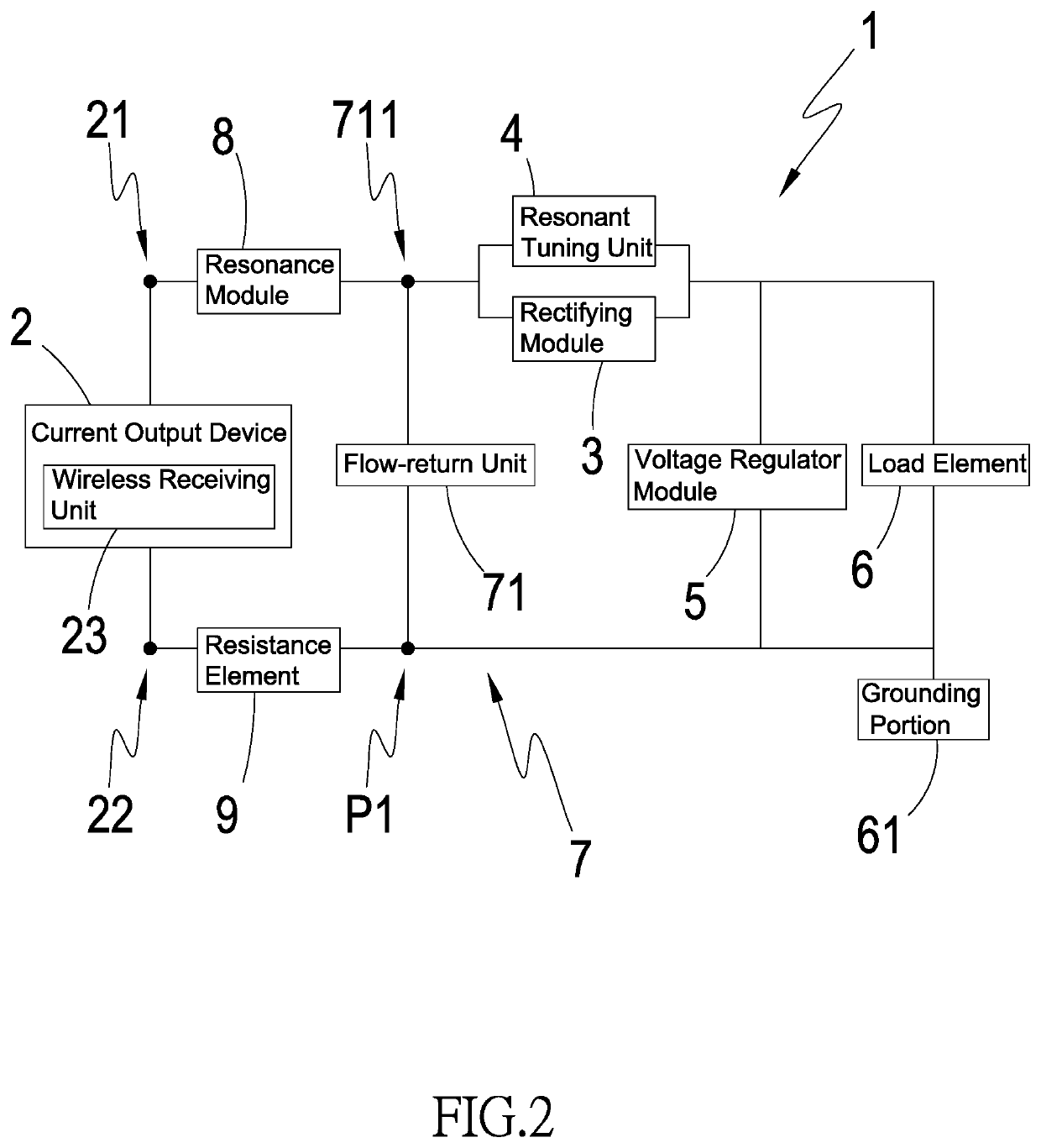

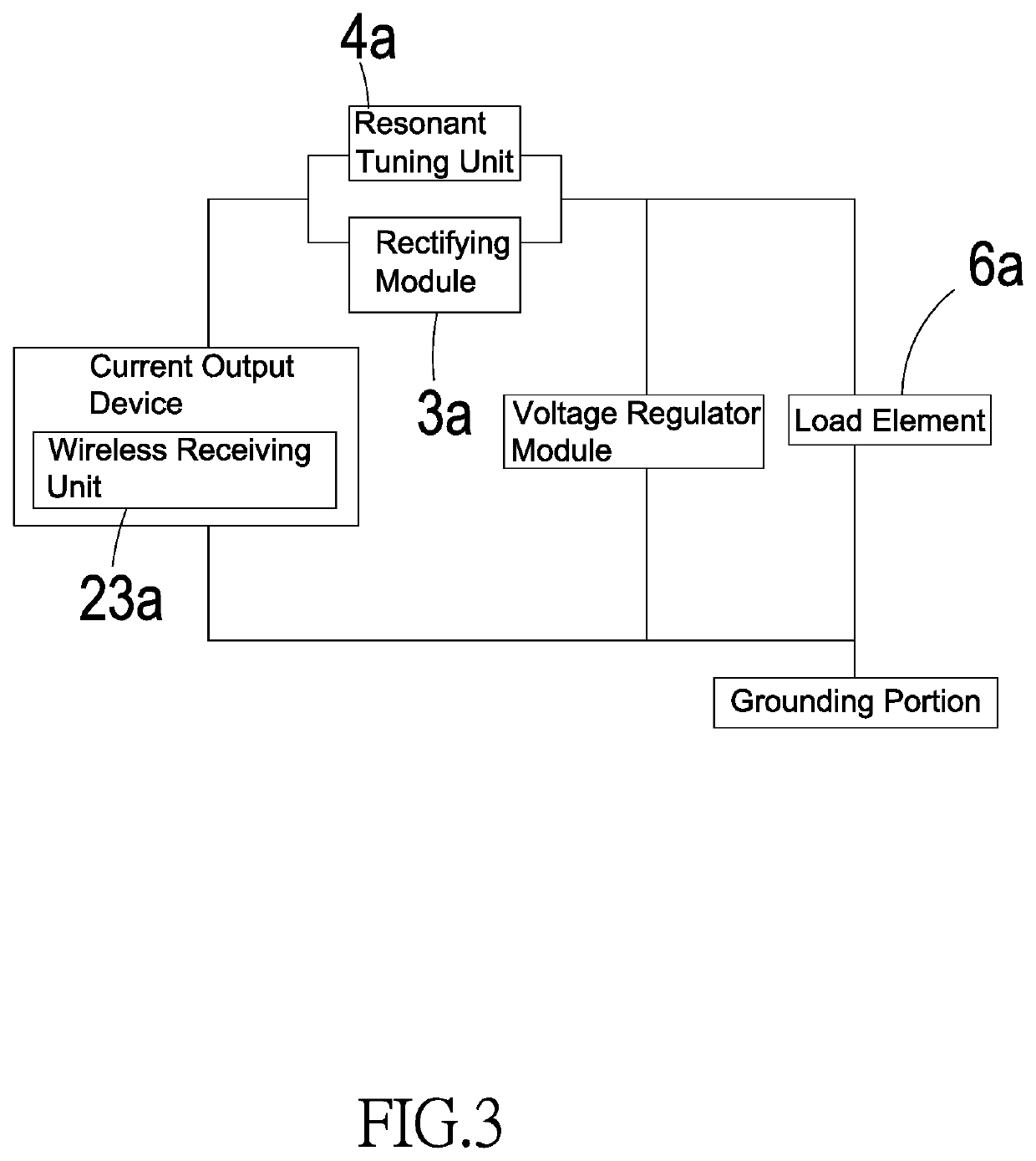

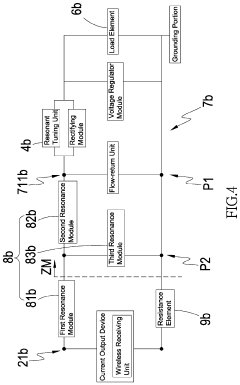

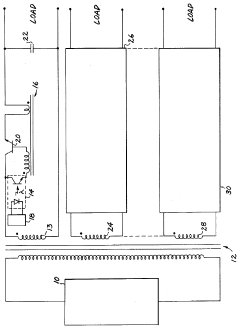

High-frequency half-wave rectifier system of low-harmonicity and high-efficiency

PatentInactiveUS10594205B2

Innovation

- A high-frequency half-wave rectifier system with a simplified structure and reduced electronic components, utilizing a resonant tuning unit and voltage regulator module to control the duty cycle and capacitance, thereby reducing harmonic content and electromagnetic interference, and improving conversion efficiency.

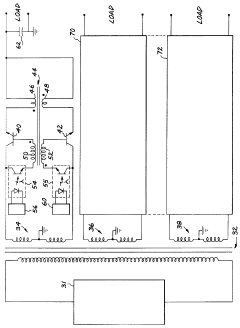

High efficiency rectifier with multiple outputs

PatentInactiveUS4323962A

Innovation

- The use of transistors as rectifying elements, driven into deep saturation for low forward drop, allows for independent control of multiple output voltages by phase control action in both half-wave and full-wave rectifiers, coupled to independent windings on a common transformer excited by a single source, achieving efficient voltage control.

Regulatory Standards for Power Electronics

Power electronics, including half-wave rectifiers, are subject to various regulatory standards aimed at ensuring safety, efficiency, and electromagnetic compatibility. These standards play a crucial role in shaping the design and implementation of power electronic devices, including efficiency enhancement techniques for half-wave rectifiers.

One of the primary regulatory bodies for power electronics is the International Electrotechnical Commission (IEC). The IEC has established several standards relevant to power electronics, such as IEC 61000 for electromagnetic compatibility and IEC 62477 for safety requirements for power electronic converter systems and equipment. These standards set guidelines for electromagnetic emissions, immunity, and safety considerations that must be adhered to when designing and implementing half-wave rectifier efficiency enhancement techniques.

In the United States, the Federal Communications Commission (FCC) regulates electromagnetic emissions from electronic devices, including power electronics. The FCC Part 15 rules govern unintentional radiators, which include power supplies and rectifiers. Compliance with these regulations is essential when developing efficiency enhancement techniques for half-wave rectifiers to ensure they do not cause harmful interference to other electronic devices.

Energy efficiency standards also play a significant role in power electronics regulation. The U.S. Department of Energy (DOE) has established minimum efficiency standards for various types of power supplies under the Energy Policy and Conservation Act. While these standards may not directly apply to all half-wave rectifier applications, they set benchmarks for energy efficiency that influence the development of efficiency enhancement techniques.

The European Union's Ecodesign Directive (2009/125/EC) sets requirements for the environmental performance of energy-related products, including power supplies. This directive has led to the implementation of specific regulations for external power supplies, which may indirectly influence the development of efficiency enhancement techniques for half-wave rectifiers used in these applications.

Harmonized standards, such as those developed by the European Committee for Electrotechnical Standardization (CENELEC), provide a means for manufacturers to demonstrate compliance with EU directives. For instance, EN 61000-3-2 sets limits for harmonic current emissions, which is particularly relevant for power electronic devices like rectifiers.

Safety standards, such as UL 1012 for power units other than Class 2 and IEC 61010 for safety requirements for electrical equipment for measurement, control, and laboratory use, also impact the design of power electronic devices. These standards ensure that efficiency enhancement techniques do not compromise the safety of the device or its users.

As the field of power electronics continues to evolve, regulatory standards are also adapting to address new technologies and challenges. For instance, the increasing focus on renewable energy and smart grid technologies is leading to the development of new standards that may impact future efficiency enhancement techniques for half-wave rectifiers and other power electronic devices.

One of the primary regulatory bodies for power electronics is the International Electrotechnical Commission (IEC). The IEC has established several standards relevant to power electronics, such as IEC 61000 for electromagnetic compatibility and IEC 62477 for safety requirements for power electronic converter systems and equipment. These standards set guidelines for electromagnetic emissions, immunity, and safety considerations that must be adhered to when designing and implementing half-wave rectifier efficiency enhancement techniques.

In the United States, the Federal Communications Commission (FCC) regulates electromagnetic emissions from electronic devices, including power electronics. The FCC Part 15 rules govern unintentional radiators, which include power supplies and rectifiers. Compliance with these regulations is essential when developing efficiency enhancement techniques for half-wave rectifiers to ensure they do not cause harmful interference to other electronic devices.

Energy efficiency standards also play a significant role in power electronics regulation. The U.S. Department of Energy (DOE) has established minimum efficiency standards for various types of power supplies under the Energy Policy and Conservation Act. While these standards may not directly apply to all half-wave rectifier applications, they set benchmarks for energy efficiency that influence the development of efficiency enhancement techniques.

The European Union's Ecodesign Directive (2009/125/EC) sets requirements for the environmental performance of energy-related products, including power supplies. This directive has led to the implementation of specific regulations for external power supplies, which may indirectly influence the development of efficiency enhancement techniques for half-wave rectifiers used in these applications.

Harmonized standards, such as those developed by the European Committee for Electrotechnical Standardization (CENELEC), provide a means for manufacturers to demonstrate compliance with EU directives. For instance, EN 61000-3-2 sets limits for harmonic current emissions, which is particularly relevant for power electronic devices like rectifiers.

Safety standards, such as UL 1012 for power units other than Class 2 and IEC 61010 for safety requirements for electrical equipment for measurement, control, and laboratory use, also impact the design of power electronic devices. These standards ensure that efficiency enhancement techniques do not compromise the safety of the device or its users.

As the field of power electronics continues to evolve, regulatory standards are also adapting to address new technologies and challenges. For instance, the increasing focus on renewable energy and smart grid technologies is leading to the development of new standards that may impact future efficiency enhancement techniques for half-wave rectifiers and other power electronic devices.

Environmental Impact of Rectifier Efficiency

The environmental impact of rectifier efficiency is a critical consideration in the development and implementation of half-wave rectifier technologies. As the global focus on sustainability and energy conservation intensifies, the efficiency of power conversion systems, including rectifiers, plays a crucial role in reducing overall energy consumption and associated environmental footprints.

Inefficient rectifiers contribute to increased power losses, which translate directly into higher energy consumption. This, in turn, leads to greater demand for electricity generation, often relying on fossil fuel-based power plants. The resultant increase in greenhouse gas emissions exacerbates climate change concerns and contributes to air pollution. Moreover, the heat generated by inefficient rectifiers necessitates additional cooling systems, further compounding energy consumption and environmental impact.

The production of rectifiers also has environmental implications. Manufacturing processes involve the use of various materials, including semiconductors, metals, and plastics. Inefficient rectifiers require larger components to handle higher power dissipation, leading to increased material consumption and associated environmental costs in terms of resource extraction, processing, and disposal.

Enhancing rectifier efficiency can significantly mitigate these environmental impacts. Improved efficiency reduces power losses, decreasing the overall energy demand and associated emissions. This reduction in energy consumption cascades through the entire power distribution system, from generation to end-use, resulting in a cumulative positive environmental effect.

Furthermore, efficient rectifiers generate less heat, reducing the need for cooling systems and their associated energy consumption. This not only decreases the direct energy footprint but also minimizes the use of refrigerants, some of which have high global warming potential.

The adoption of more efficient rectifier technologies can also lead to a reduction in electronic waste. Higher efficiency often correlates with longer device lifespans and reduced failure rates, thereby decreasing the frequency of replacements and the volume of electronic waste entering landfills or requiring recycling.

In the context of renewable energy systems, such as solar panels and wind turbines, efficient rectifiers play a crucial role in maximizing the energy harvested from these clean sources. By minimizing conversion losses, they enhance the overall efficiency of renewable energy systems, making them more viable alternatives to fossil fuel-based power generation.

As regulations and standards evolve to address environmental concerns, the emphasis on rectifier efficiency is likely to increase. This may drive further innovations in materials science, circuit design, and manufacturing processes, potentially leading to breakthroughs that could have far-reaching implications for energy efficiency across various industries.

Inefficient rectifiers contribute to increased power losses, which translate directly into higher energy consumption. This, in turn, leads to greater demand for electricity generation, often relying on fossil fuel-based power plants. The resultant increase in greenhouse gas emissions exacerbates climate change concerns and contributes to air pollution. Moreover, the heat generated by inefficient rectifiers necessitates additional cooling systems, further compounding energy consumption and environmental impact.

The production of rectifiers also has environmental implications. Manufacturing processes involve the use of various materials, including semiconductors, metals, and plastics. Inefficient rectifiers require larger components to handle higher power dissipation, leading to increased material consumption and associated environmental costs in terms of resource extraction, processing, and disposal.

Enhancing rectifier efficiency can significantly mitigate these environmental impacts. Improved efficiency reduces power losses, decreasing the overall energy demand and associated emissions. This reduction in energy consumption cascades through the entire power distribution system, from generation to end-use, resulting in a cumulative positive environmental effect.

Furthermore, efficient rectifiers generate less heat, reducing the need for cooling systems and their associated energy consumption. This not only decreases the direct energy footprint but also minimizes the use of refrigerants, some of which have high global warming potential.

The adoption of more efficient rectifier technologies can also lead to a reduction in electronic waste. Higher efficiency often correlates with longer device lifespans and reduced failure rates, thereby decreasing the frequency of replacements and the volume of electronic waste entering landfills or requiring recycling.

In the context of renewable energy systems, such as solar panels and wind turbines, efficient rectifiers play a crucial role in maximizing the energy harvested from these clean sources. By minimizing conversion losses, they enhance the overall efficiency of renewable energy systems, making them more viable alternatives to fossil fuel-based power generation.

As regulations and standards evolve to address environmental concerns, the emphasis on rectifier efficiency is likely to increase. This may drive further innovations in materials science, circuit design, and manufacturing processes, potentially leading to breakthroughs that could have far-reaching implications for energy efficiency across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!