How to Maximize Efficiency in Half Wave Rectifiers?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

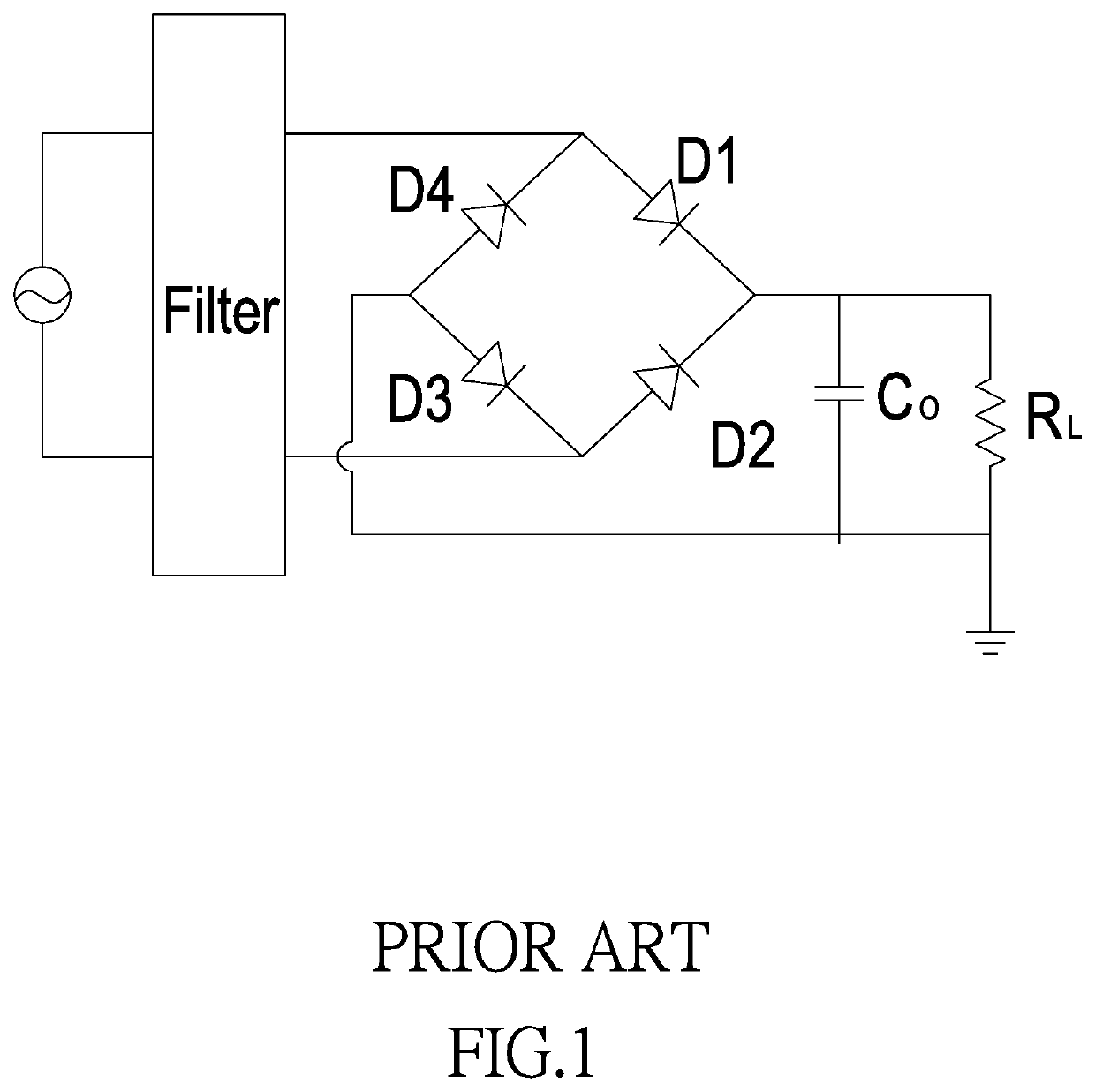

Half wave rectifiers have been a fundamental component in power electronics since the early days of electrical engineering. These devices play a crucial role in converting alternating current (AC) to pulsating direct current (DC), serving as the building blocks for various power supply systems. The evolution of half wave rectifiers can be traced back to the invention of vacuum tube diodes in the early 20th century, which paved the way for more efficient and compact semiconductor-based rectifiers.

As technology progressed, the focus shifted towards improving the efficiency and performance of half wave rectifiers. The primary objective in maximizing efficiency is to reduce power losses during the rectification process, thereby increasing the overall system efficiency. This goal has become increasingly important in recent years due to the growing emphasis on energy conservation and the proliferation of battery-powered devices.

The technical evolution of half wave rectifiers has been driven by advancements in semiconductor materials and device structures. From the early selenium and copper oxide rectifiers to modern silicon and wide-bandgap semiconductor diodes, each iteration has brought improvements in forward voltage drop, reverse recovery time, and overall efficiency. The introduction of Schottky diodes, for instance, marked a significant milestone in reducing forward voltage drop and improving high-frequency performance.

Current research and development efforts in half wave rectifier technology are focused on several key areas. These include the exploration of novel semiconductor materials, such as gallium nitride (GaN) and silicon carbide (SiC), which offer superior electrical properties compared to traditional silicon. Additionally, there is ongoing work on optimizing circuit topologies and control strategies to minimize switching losses and improve power factor correction.

The quest for maximizing efficiency in half wave rectifiers is not limited to the device level but extends to the entire power conversion system. This holistic approach involves considering factors such as thermal management, electromagnetic interference (EMI) reduction, and integration with other power electronics components. As a result, the development of more efficient half wave rectifiers has far-reaching implications for various applications, ranging from consumer electronics to industrial power systems and renewable energy installations.

In the context of emerging technologies, the role of half wave rectifiers in wireless power transfer systems and energy harvesting applications has gained significant attention. These new frontiers present unique challenges and opportunities for innovation in rectifier design, pushing the boundaries of efficiency and miniaturization. The ongoing research in these areas aims to enable more efficient and compact power solutions for the next generation of electronic devices and systems.

As technology progressed, the focus shifted towards improving the efficiency and performance of half wave rectifiers. The primary objective in maximizing efficiency is to reduce power losses during the rectification process, thereby increasing the overall system efficiency. This goal has become increasingly important in recent years due to the growing emphasis on energy conservation and the proliferation of battery-powered devices.

The technical evolution of half wave rectifiers has been driven by advancements in semiconductor materials and device structures. From the early selenium and copper oxide rectifiers to modern silicon and wide-bandgap semiconductor diodes, each iteration has brought improvements in forward voltage drop, reverse recovery time, and overall efficiency. The introduction of Schottky diodes, for instance, marked a significant milestone in reducing forward voltage drop and improving high-frequency performance.

Current research and development efforts in half wave rectifier technology are focused on several key areas. These include the exploration of novel semiconductor materials, such as gallium nitride (GaN) and silicon carbide (SiC), which offer superior electrical properties compared to traditional silicon. Additionally, there is ongoing work on optimizing circuit topologies and control strategies to minimize switching losses and improve power factor correction.

The quest for maximizing efficiency in half wave rectifiers is not limited to the device level but extends to the entire power conversion system. This holistic approach involves considering factors such as thermal management, electromagnetic interference (EMI) reduction, and integration with other power electronics components. As a result, the development of more efficient half wave rectifiers has far-reaching implications for various applications, ranging from consumer electronics to industrial power systems and renewable energy installations.

In the context of emerging technologies, the role of half wave rectifiers in wireless power transfer systems and energy harvesting applications has gained significant attention. These new frontiers present unique challenges and opportunities for innovation in rectifier design, pushing the boundaries of efficiency and miniaturization. The ongoing research in these areas aims to enable more efficient and compact power solutions for the next generation of electronic devices and systems.

Market Demand Analysis for Efficient Rectifiers

The market demand for efficient rectifiers, particularly half-wave rectifiers, has been steadily growing across various industries. This demand is primarily driven by the increasing need for power conversion and management in electronic devices, renewable energy systems, and industrial applications. As energy efficiency becomes a critical factor in product design and operation, the focus on maximizing the efficiency of rectifiers has intensified.

In the consumer electronics sector, the proliferation of portable devices and the push for faster charging technologies have created a significant market for high-efficiency rectifiers. Manufacturers are seeking ways to reduce power loss and heat generation in their products, leading to a demand for rectifiers that can operate at higher frequencies with minimal energy dissipation.

The automotive industry represents another major market for efficient rectifiers. With the rapid growth of electric and hybrid vehicles, there is an increased need for power electronics that can handle high voltages and currents while maintaining optimal efficiency. Half-wave rectifiers play a crucial role in battery management systems and power conversion units within these vehicles.

Renewable energy systems, particularly solar and wind power installations, rely heavily on efficient power conversion. The market for rectifiers in this sector is expanding as more countries invest in clean energy infrastructure. Efficient half-wave rectifiers are essential components in inverters and power conditioning units, contributing to the overall system efficiency and economic viability of renewable energy projects.

Industrial applications, including motor drives, uninterruptible power supplies (UPS), and power factor correction circuits, also contribute significantly to the demand for efficient rectifiers. These applications often require high power handling capabilities combined with minimal energy loss, driving the need for advanced rectifier technologies.

The telecommunications industry, with its extensive network of base stations and data centers, represents another substantial market for efficient rectifiers. As 5G networks continue to expand, the demand for power-efficient components, including rectifiers, is expected to grow to support the increased energy requirements of these systems.

Market analysis indicates that the global power electronics market, which includes rectifiers, is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is largely attributed to the increasing adoption of electric vehicles, renewable energy systems, and the ongoing digital transformation across industries.

As efficiency standards become more stringent and energy costs continue to rise, the market is likely to favor innovative rectifier designs that can deliver higher efficiency, reduced size, and improved thermal management. This trend is expected to drive research and development efforts in areas such as wide-bandgap semiconductors, advanced circuit topologies, and intelligent control strategies for half-wave rectifiers.

In the consumer electronics sector, the proliferation of portable devices and the push for faster charging technologies have created a significant market for high-efficiency rectifiers. Manufacturers are seeking ways to reduce power loss and heat generation in their products, leading to a demand for rectifiers that can operate at higher frequencies with minimal energy dissipation.

The automotive industry represents another major market for efficient rectifiers. With the rapid growth of electric and hybrid vehicles, there is an increased need for power electronics that can handle high voltages and currents while maintaining optimal efficiency. Half-wave rectifiers play a crucial role in battery management systems and power conversion units within these vehicles.

Renewable energy systems, particularly solar and wind power installations, rely heavily on efficient power conversion. The market for rectifiers in this sector is expanding as more countries invest in clean energy infrastructure. Efficient half-wave rectifiers are essential components in inverters and power conditioning units, contributing to the overall system efficiency and economic viability of renewable energy projects.

Industrial applications, including motor drives, uninterruptible power supplies (UPS), and power factor correction circuits, also contribute significantly to the demand for efficient rectifiers. These applications often require high power handling capabilities combined with minimal energy loss, driving the need for advanced rectifier technologies.

The telecommunications industry, with its extensive network of base stations and data centers, represents another substantial market for efficient rectifiers. As 5G networks continue to expand, the demand for power-efficient components, including rectifiers, is expected to grow to support the increased energy requirements of these systems.

Market analysis indicates that the global power electronics market, which includes rectifiers, is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is largely attributed to the increasing adoption of electric vehicles, renewable energy systems, and the ongoing digital transformation across industries.

As efficiency standards become more stringent and energy costs continue to rise, the market is likely to favor innovative rectifier designs that can deliver higher efficiency, reduced size, and improved thermal management. This trend is expected to drive research and development efforts in areas such as wide-bandgap semiconductors, advanced circuit topologies, and intelligent control strategies for half-wave rectifiers.

Current Challenges in Half Wave Rectification

Half wave rectifiers, while simple in design, face several challenges that limit their efficiency and overall performance. One of the primary issues is the low utilization of the input waveform. Since these rectifiers only conduct during one half of the AC cycle, they effectively waste half of the available power, resulting in a theoretical maximum efficiency of only 40.6%.

Another significant challenge is the high ripple content in the output voltage. The pulsating nature of the rectified waveform leads to a substantial AC component superimposed on the DC output. This ripple not only reduces the quality of the DC supply but also necessitates more extensive filtering, which can further decrease efficiency and increase system complexity.

The forward voltage drop across the rectifying diode presents an additional hurdle. This voltage drop, typically around 0.7V for silicon diodes, becomes particularly problematic in low-voltage applications, where it can constitute a significant portion of the output voltage, further reducing efficiency.

Reverse recovery time of the diode is another factor impacting efficiency. During the transition from forward to reverse bias, the diode takes a finite time to stop conducting, leading to reverse current flow and power loss. This effect becomes more pronounced at higher frequencies, limiting the rectifier's performance in high-frequency applications.

Temperature sensitivity of semiconductor devices used in half wave rectifiers poses challenges in maintaining consistent performance across varying operating conditions. As temperature increases, the forward voltage drop of the diode decreases, potentially leading to increased current flow and power dissipation.

The non-linear characteristics of diodes contribute to harmonic distortion in the rectified output. This distortion can be particularly problematic in applications requiring high signal purity, such as audio systems or precision measurement equipment.

Voltage regulation is another area of concern. The output voltage of a half wave rectifier tends to vary significantly with changes in load current, necessitating additional regulation circuitry to maintain a stable output voltage. This not only adds complexity but can also introduce further inefficiencies.

Lastly, the pulsating current drawn from the source in half wave rectification can lead to increased electromagnetic interference (EMI) and potentially cause issues with power factor in AC mains applications. This may necessitate additional EMI filtering and power factor correction circuitry, further complicating the design and potentially reducing overall system efficiency.

Another significant challenge is the high ripple content in the output voltage. The pulsating nature of the rectified waveform leads to a substantial AC component superimposed on the DC output. This ripple not only reduces the quality of the DC supply but also necessitates more extensive filtering, which can further decrease efficiency and increase system complexity.

The forward voltage drop across the rectifying diode presents an additional hurdle. This voltage drop, typically around 0.7V for silicon diodes, becomes particularly problematic in low-voltage applications, where it can constitute a significant portion of the output voltage, further reducing efficiency.

Reverse recovery time of the diode is another factor impacting efficiency. During the transition from forward to reverse bias, the diode takes a finite time to stop conducting, leading to reverse current flow and power loss. This effect becomes more pronounced at higher frequencies, limiting the rectifier's performance in high-frequency applications.

Temperature sensitivity of semiconductor devices used in half wave rectifiers poses challenges in maintaining consistent performance across varying operating conditions. As temperature increases, the forward voltage drop of the diode decreases, potentially leading to increased current flow and power dissipation.

The non-linear characteristics of diodes contribute to harmonic distortion in the rectified output. This distortion can be particularly problematic in applications requiring high signal purity, such as audio systems or precision measurement equipment.

Voltage regulation is another area of concern. The output voltage of a half wave rectifier tends to vary significantly with changes in load current, necessitating additional regulation circuitry to maintain a stable output voltage. This not only adds complexity but can also introduce further inefficiencies.

Lastly, the pulsating current drawn from the source in half wave rectification can lead to increased electromagnetic interference (EMI) and potentially cause issues with power factor in AC mains applications. This may necessitate additional EMI filtering and power factor correction circuitry, further complicating the design and potentially reducing overall system efficiency.

Existing Efficiency Enhancement Techniques

01 Improved circuit designs for half-wave rectifiers

Various circuit designs have been developed to enhance the efficiency of half-wave rectifiers. These designs may include modifications to the basic circuit structure, such as the addition of capacitors or inductors, to reduce power losses and improve overall performance. Some designs focus on optimizing the rectification process to minimize voltage drops and increase power output.- Circuit design for improved efficiency: Half-wave rectifiers can be designed with specific circuit configurations to enhance their efficiency. This may include the use of capacitors for smoothing output, optimized diode selection, and careful component placement to minimize losses. Advanced circuit designs can significantly improve the overall performance and energy conversion efficiency of half-wave rectifiers.

- Voltage regulation techniques: Implementing voltage regulation techniques in half-wave rectifiers can improve their efficiency by maintaining a stable output voltage. This may involve the use of feedback loops, voltage-sensing circuits, and control mechanisms to adjust the rectifier's operation based on load conditions. Proper voltage regulation can reduce energy waste and improve the overall efficiency of the rectification process.

- Thermal management for efficiency improvement: Effective thermal management in half-wave rectifiers can significantly impact their efficiency. This includes the use of heat sinks, thermal compounds, and proper component layout to dissipate heat efficiently. By reducing thermal losses and maintaining optimal operating temperatures, the overall efficiency of the rectifier can be improved.

- Advanced semiconductor materials: The use of advanced semiconductor materials in half-wave rectifiers can lead to improved efficiency. Materials with lower forward voltage drop and faster switching characteristics can reduce conduction losses and switching losses, respectively. This results in higher overall efficiency of the rectification process.

- Synchronous rectification techniques: Implementing synchronous rectification techniques in half-wave rectifiers can significantly improve their efficiency. This involves replacing traditional diodes with actively controlled switches, such as MOSFETs, which can reduce conduction losses. Synchronous rectification allows for better control of the rectification process and can lead to higher overall system efficiency.

02 Use of advanced semiconductor materials

The efficiency of half-wave rectifiers can be improved by utilizing advanced semiconductor materials. These materials may have lower forward voltage drops, faster switching speeds, or better thermal characteristics, leading to reduced power losses and improved overall efficiency. Some designs incorporate novel semiconductor structures or doping techniques to enhance rectifier performance.Expand Specific Solutions03 Integration of control and monitoring systems

Incorporating control and monitoring systems into half-wave rectifier designs can lead to improved efficiency. These systems may include feedback loops, voltage regulation mechanisms, or intelligent control algorithms that optimize rectifier operation based on load conditions. Some designs feature integrated circuits or microcontrollers to implement advanced control strategies.Expand Specific Solutions04 Thermal management techniques

Effective thermal management is crucial for maintaining high efficiency in half-wave rectifiers. Various techniques have been developed to improve heat dissipation and reduce thermal losses. These may include advanced cooling systems, improved packaging designs, or the use of thermally conductive materials to enhance heat transfer and maintain optimal operating temperatures.Expand Specific Solutions05 Optimization for specific applications

Half-wave rectifier designs can be optimized for specific applications to improve efficiency. This may involve tailoring the rectifier characteristics to match the requirements of particular power systems, such as renewable energy sources or motor drives. Some designs focus on minimizing losses in specific frequency ranges or under varying load conditions to maximize overall system efficiency.Expand Specific Solutions

Key Players in Power Electronics Industry

The competition landscape for maximizing efficiency in half wave rectifiers is characterized by a mature market with established players and ongoing technological advancements. The market size is substantial, driven by the widespread use of rectifiers in power electronics across various industries. Companies like Samsung Electronics, Fujitsu, and Huawei Technologies are at the forefront, leveraging their extensive R&D capabilities to improve rectifier efficiency. Smaller specialized firms such as Mixed-Signal Devices, Inc. are also contributing innovative solutions. The technology's maturity is evident, with continuous incremental improvements rather than disruptive changes, focusing on reducing power losses and enhancing overall system performance.

Telefonaktiebolaget LM Ericsson

Technical Solution: Ericsson has focused on improving half-wave rectifier efficiency in telecommunications power systems through the implementation of digital control techniques. Their approach utilizes high-speed microcontrollers to implement adaptive power factor correction (PFC) algorithms that work in conjunction with the half-wave rectification process. This digital control system continuously monitors the input voltage and current waveforms, adjusting the rectification timing and PFC parameters in real-time to optimize efficiency across a wide range of operating conditions. Ericsson's system also incorporates advanced EMI reduction techniques, such as spread spectrum frequency modulation, to minimize electromagnetic interference while maintaining high efficiency. The company reports that their digitally controlled half-wave rectifiers can achieve power factor values above 0.98 and overall system efficiencies exceeding 94% in telecom power applications [7][8].

Strengths: High efficiency and power factor; adaptability to varying input conditions; reduced EMI. Weaknesses: Increased complexity due to digital control; potentially higher cost for implementation in simpler systems.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an innovative approach to maximizing efficiency in half-wave rectifiers by integrating them with energy harvesting technologies. Their system combines traditional half-wave rectification with a secondary energy recovery circuit that captures and utilizes the energy typically lost during the non-conducting half of the AC cycle. This recovered energy is stored in high-efficiency supercapacitors and then used to supplement the main power output or to power auxiliary systems. Samsung's design also incorporates advanced power management ICs that optimize the energy flow between the rectifier, recovery circuit, and load. The company claims that this integrated energy harvesting approach can improve overall system efficiency by up to 15% in certain applications, particularly in low-power IoT devices and wireless charging systems [9][10].

Strengths: Significant efficiency improvement through energy recovery; well-suited for low-power applications. Weaknesses: Increased system complexity; may not be cost-effective for high-power applications.

Core Innovations in Half Wave Rectifier Design

Half-wave rectifier circuit

PatentInactiveUS3936720A

Innovation

- A high-gain differential amplifier-based half-wave rectifier circuit operating from a single power supply, eliminating the need for voltage regulation and reducing temperature dependence, with resistor ratios optimized to minimize errors and achieve minimal output voltage drop.

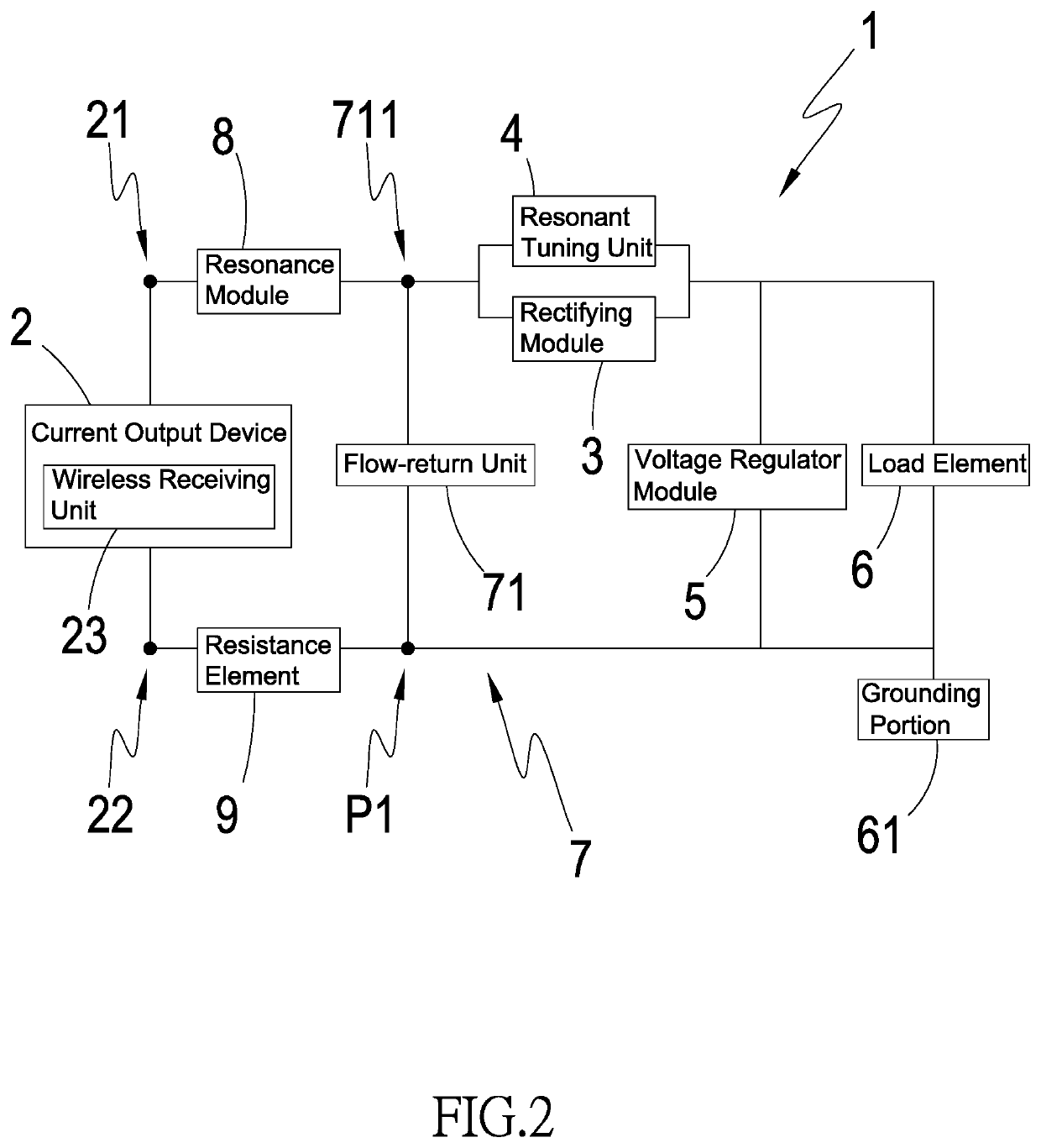

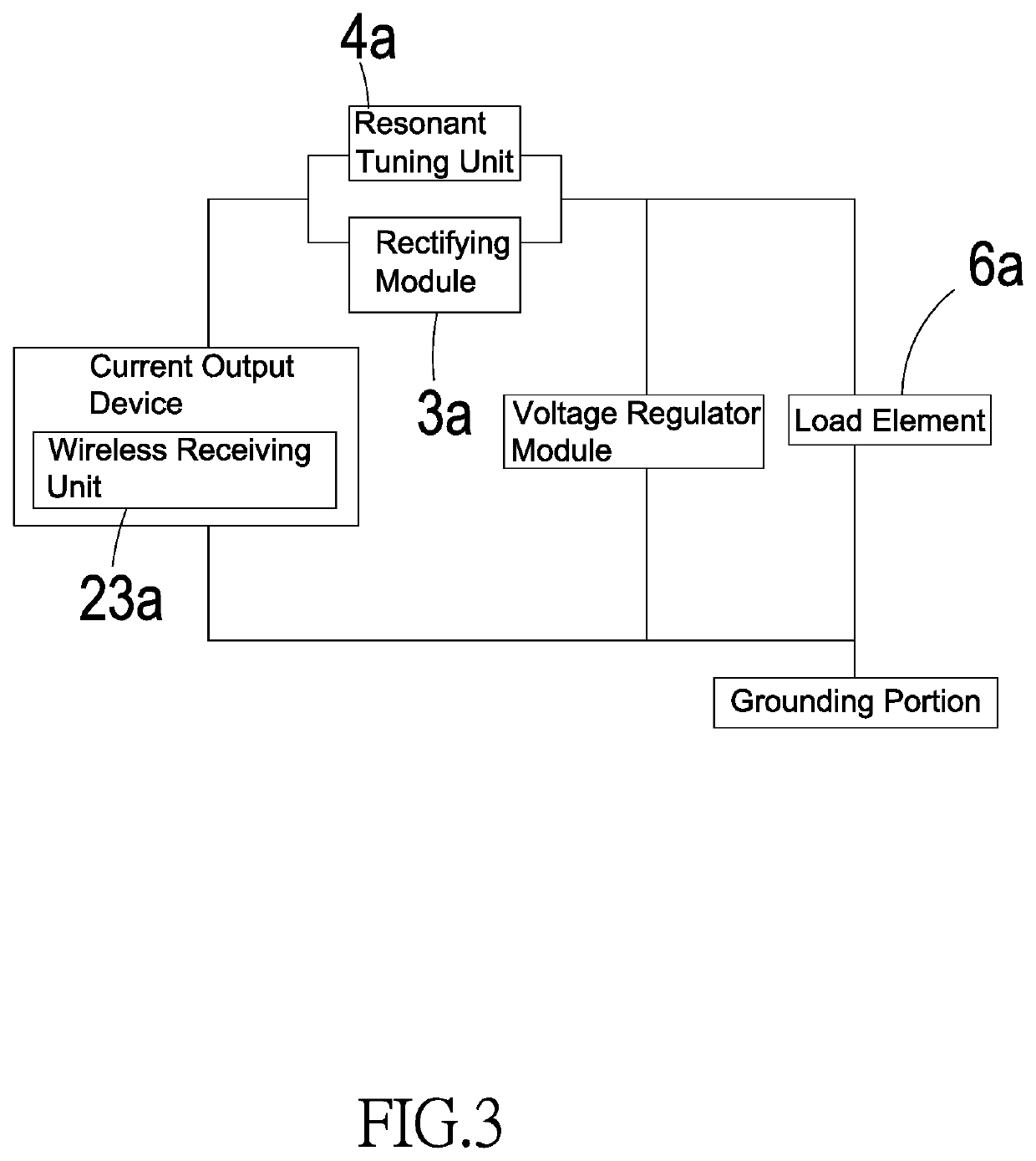

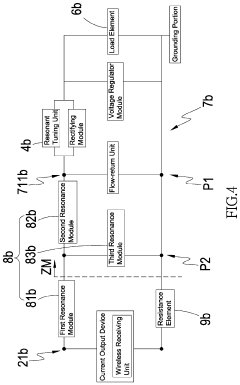

High-frequency half-wave rectifier system of low-harmonicity and high-efficiency

PatentInactiveUS10594205B2

Innovation

- A high-frequency half-wave rectifier system with a simplified structure and reduced electronic components, utilizing a resonant tuning unit and voltage regulator module to control the duty cycle and capacitance, thereby reducing harmonic content and electromagnetic interference, and improving conversion efficiency.

Thermal Management Strategies

Thermal management is a critical aspect of maximizing efficiency in half wave rectifiers. As these devices convert alternating current to pulsating direct current, they generate heat that can significantly impact performance and reliability. Effective thermal management strategies are essential to maintain optimal operating temperatures and ensure long-term stability of the rectifier circuit.

One key approach to thermal management in half wave rectifiers is the use of heat sinks. These passive cooling devices increase the surface area available for heat dissipation, allowing for more efficient transfer of thermal energy to the surrounding environment. Proper selection and design of heat sinks, considering factors such as material thermal conductivity, fin geometry, and surface area, can greatly enhance the cooling capacity of the rectifier system.

Active cooling methods can also be employed to further improve thermal management. Forced-air cooling, utilizing fans or blowers, can significantly increase heat dissipation rates compared to natural convection alone. In more demanding applications, liquid cooling systems may be implemented, offering even greater cooling capacity and temperature control.

Thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between the rectifier components and cooling solutions. High-performance thermal greases, pads, or phase-change materials can minimize thermal resistance at interfaces, ensuring efficient heat conduction from the heat-generating components to the cooling system.

Strategic component placement and PCB design are essential considerations in thermal management. Proper spacing between heat-generating components and the use of thermal vias can help distribute heat more evenly across the board, preventing localized hot spots. Additionally, the selection of PCB materials with higher thermal conductivity can aid in heat spreading and dissipation.

Temperature monitoring and control systems can be integrated to dynamically manage thermal conditions. Thermistors or temperature sensors can provide real-time feedback, allowing for adaptive cooling strategies or thermal throttling to maintain safe operating temperatures under varying load conditions.

In high-power applications, advanced cooling techniques such as thermoelectric cooling or heat pipes may be considered. These methods can provide more precise temperature control or enable heat transfer over longer distances, respectively, offering solutions for challenging thermal management scenarios in half wave rectifier designs.

By implementing a comprehensive thermal management strategy that combines passive and active cooling methods, optimized materials and design choices, and intelligent temperature control, the efficiency and reliability of half wave rectifiers can be significantly enhanced. This approach not only improves performance but also extends the operational lifespan of the rectifier system, making it a critical consideration in the design and implementation of these power conversion devices.

One key approach to thermal management in half wave rectifiers is the use of heat sinks. These passive cooling devices increase the surface area available for heat dissipation, allowing for more efficient transfer of thermal energy to the surrounding environment. Proper selection and design of heat sinks, considering factors such as material thermal conductivity, fin geometry, and surface area, can greatly enhance the cooling capacity of the rectifier system.

Active cooling methods can also be employed to further improve thermal management. Forced-air cooling, utilizing fans or blowers, can significantly increase heat dissipation rates compared to natural convection alone. In more demanding applications, liquid cooling systems may be implemented, offering even greater cooling capacity and temperature control.

Thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between the rectifier components and cooling solutions. High-performance thermal greases, pads, or phase-change materials can minimize thermal resistance at interfaces, ensuring efficient heat conduction from the heat-generating components to the cooling system.

Strategic component placement and PCB design are essential considerations in thermal management. Proper spacing between heat-generating components and the use of thermal vias can help distribute heat more evenly across the board, preventing localized hot spots. Additionally, the selection of PCB materials with higher thermal conductivity can aid in heat spreading and dissipation.

Temperature monitoring and control systems can be integrated to dynamically manage thermal conditions. Thermistors or temperature sensors can provide real-time feedback, allowing for adaptive cooling strategies or thermal throttling to maintain safe operating temperatures under varying load conditions.

In high-power applications, advanced cooling techniques such as thermoelectric cooling or heat pipes may be considered. These methods can provide more precise temperature control or enable heat transfer over longer distances, respectively, offering solutions for challenging thermal management scenarios in half wave rectifier designs.

By implementing a comprehensive thermal management strategy that combines passive and active cooling methods, optimized materials and design choices, and intelligent temperature control, the efficiency and reliability of half wave rectifiers can be significantly enhanced. This approach not only improves performance but also extends the operational lifespan of the rectifier system, making it a critical consideration in the design and implementation of these power conversion devices.

Environmental Impact of Rectifier Efficiency

The environmental impact of rectifier efficiency is a critical consideration in the development and implementation of half wave rectifiers. As energy consumption and sustainability become increasingly important global concerns, the efficiency of electronic components plays a significant role in reducing overall environmental footprint.

Inefficient rectifiers contribute to increased power losses, which in turn lead to higher energy consumption. This increased energy demand translates to greater strain on power generation systems, potentially resulting in higher greenhouse gas emissions if the energy source is not renewable. Moreover, the heat generated by inefficient rectifiers can necessitate additional cooling systems, further increasing energy consumption and environmental impact.

The production of rectifiers also has environmental implications. More efficient rectifiers often require advanced materials and manufacturing processes, which may have their own environmental costs. However, these initial environmental investments are typically offset by the long-term benefits of improved efficiency during operation.

In the context of half wave rectifiers, maximizing efficiency can lead to substantial environmental benefits. By reducing power losses and improving overall system performance, efficient half wave rectifiers can contribute to decreased energy consumption across various applications. This is particularly important in large-scale industrial settings where even small improvements in efficiency can result in significant energy savings over time.

Furthermore, the environmental impact extends beyond energy consumption. Efficient rectifiers tend to have longer operational lifespans, reducing the frequency of replacement and associated electronic waste. This reduction in e-waste is crucial, as improper disposal of electronic components can lead to soil and water contamination due to the presence of hazardous materials.

The push for greater rectifier efficiency also drives innovation in materials science and circuit design. Research into novel semiconductor materials and advanced circuit topologies not only improves rectifier performance but can also lead to breakthroughs applicable to other areas of electronics, potentially yielding broader environmental benefits.

As regulations and consumer demand for energy-efficient products continue to grow, the environmental impact of rectifier efficiency becomes an increasingly important factor in product design and market competitiveness. Companies that prioritize efficiency in their rectifier designs may gain a competitive edge while simultaneously contributing to global sustainability efforts.

In conclusion, the environmental impact of rectifier efficiency is multifaceted, encompassing energy consumption, resource utilization, waste reduction, and innovation potential. By focusing on maximizing efficiency in half wave rectifiers, engineers and manufacturers can make significant contributions to environmental sustainability while also improving product performance and economic viability.

Inefficient rectifiers contribute to increased power losses, which in turn lead to higher energy consumption. This increased energy demand translates to greater strain on power generation systems, potentially resulting in higher greenhouse gas emissions if the energy source is not renewable. Moreover, the heat generated by inefficient rectifiers can necessitate additional cooling systems, further increasing energy consumption and environmental impact.

The production of rectifiers also has environmental implications. More efficient rectifiers often require advanced materials and manufacturing processes, which may have their own environmental costs. However, these initial environmental investments are typically offset by the long-term benefits of improved efficiency during operation.

In the context of half wave rectifiers, maximizing efficiency can lead to substantial environmental benefits. By reducing power losses and improving overall system performance, efficient half wave rectifiers can contribute to decreased energy consumption across various applications. This is particularly important in large-scale industrial settings where even small improvements in efficiency can result in significant energy savings over time.

Furthermore, the environmental impact extends beyond energy consumption. Efficient rectifiers tend to have longer operational lifespans, reducing the frequency of replacement and associated electronic waste. This reduction in e-waste is crucial, as improper disposal of electronic components can lead to soil and water contamination due to the presence of hazardous materials.

The push for greater rectifier efficiency also drives innovation in materials science and circuit design. Research into novel semiconductor materials and advanced circuit topologies not only improves rectifier performance but can also lead to breakthroughs applicable to other areas of electronics, potentially yielding broader environmental benefits.

As regulations and consumer demand for energy-efficient products continue to grow, the environmental impact of rectifier efficiency becomes an increasingly important factor in product design and market competitiveness. Companies that prioritize efficiency in their rectifier designs may gain a competitive edge while simultaneously contributing to global sustainability efforts.

In conclusion, the environmental impact of rectifier efficiency is multifaceted, encompassing energy consumption, resource utilization, waste reduction, and innovation potential. By focusing on maximizing efficiency in half wave rectifiers, engineers and manufacturers can make significant contributions to environmental sustainability while also improving product performance and economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!