How to Improve Aroma Retention in Cellophane Products?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aroma Retention Challenges

Aroma retention in cellophane products presents significant challenges due to the material's inherent properties and the volatile nature of aromatic compounds. Cellophane, a thin, transparent film made from regenerated cellulose, is widely used in packaging for its clarity and barrier properties. However, its ability to retain aromas is limited, which can impact the quality and shelf life of packaged products, particularly in the food and cosmetic industries.

One of the primary challenges in aroma retention is the permeability of cellophane to small molecules. While cellophane provides an excellent barrier against water and larger molecules, it struggles to contain smaller, volatile aromatic compounds. These compounds can easily diffuse through the cellophane structure, leading to aroma loss over time. This permeability issue is exacerbated by environmental factors such as temperature and humidity, which can accelerate the diffusion process.

Another significant challenge is the interaction between aromatic compounds and the cellophane material itself. Some aromatic molecules may adhere to the cellophane surface or become trapped within its structure, altering the intended aroma profile of the packaged product. This interaction can lead to changes in the product's sensory characteristics, potentially affecting consumer perception and satisfaction.

The chemical stability of aromatic compounds poses an additional challenge. Many aromas are susceptible to oxidation, hydrolysis, or other chemical reactions when exposed to air, light, or moisture. While cellophane can provide some protection against these elements, its barrier properties are not always sufficient to prevent degradation of sensitive aromatic compounds over extended periods.

Furthermore, the manufacturing process of cellophane products can impact aroma retention. High temperatures and mechanical stress during production may cause changes in the material's structure, potentially affecting its ability to retain aromas. Balancing the need for efficient production with optimal aroma retention properties requires careful consideration of processing parameters.

The diversity of aromatic compounds used in various products adds another layer of complexity to the challenge. Different aromas have varying molecular sizes, polarities, and chemical properties, making it difficult to develop a one-size-fits-all solution for aroma retention in cellophane products. This variability necessitates tailored approaches for different types of products and their specific aromatic profiles.

Lastly, regulatory considerations and consumer preferences for natural and sustainable packaging solutions further complicate the aroma retention challenge. Any modifications or additives used to enhance aroma retention must comply with food safety regulations and meet increasing consumer demands for eco-friendly packaging options.

One of the primary challenges in aroma retention is the permeability of cellophane to small molecules. While cellophane provides an excellent barrier against water and larger molecules, it struggles to contain smaller, volatile aromatic compounds. These compounds can easily diffuse through the cellophane structure, leading to aroma loss over time. This permeability issue is exacerbated by environmental factors such as temperature and humidity, which can accelerate the diffusion process.

Another significant challenge is the interaction between aromatic compounds and the cellophane material itself. Some aromatic molecules may adhere to the cellophane surface or become trapped within its structure, altering the intended aroma profile of the packaged product. This interaction can lead to changes in the product's sensory characteristics, potentially affecting consumer perception and satisfaction.

The chemical stability of aromatic compounds poses an additional challenge. Many aromas are susceptible to oxidation, hydrolysis, or other chemical reactions when exposed to air, light, or moisture. While cellophane can provide some protection against these elements, its barrier properties are not always sufficient to prevent degradation of sensitive aromatic compounds over extended periods.

Furthermore, the manufacturing process of cellophane products can impact aroma retention. High temperatures and mechanical stress during production may cause changes in the material's structure, potentially affecting its ability to retain aromas. Balancing the need for efficient production with optimal aroma retention properties requires careful consideration of processing parameters.

The diversity of aromatic compounds used in various products adds another layer of complexity to the challenge. Different aromas have varying molecular sizes, polarities, and chemical properties, making it difficult to develop a one-size-fits-all solution for aroma retention in cellophane products. This variability necessitates tailored approaches for different types of products and their specific aromatic profiles.

Lastly, regulatory considerations and consumer preferences for natural and sustainable packaging solutions further complicate the aroma retention challenge. Any modifications or additives used to enhance aroma retention must comply with food safety regulations and meet increasing consumer demands for eco-friendly packaging options.

Market Demand Analysis

The market demand for improved aroma retention in cellophane products has been steadily growing, driven by consumer preferences for long-lasting scents and the increasing use of fragranced packaging across various industries. The food and beverage sector, in particular, has shown significant interest in enhancing aroma retention capabilities to maintain product freshness and appeal.

Consumer packaged goods companies are actively seeking solutions to extend the shelf life of their scented products, recognizing that aroma retention is a key factor in customer satisfaction and brand loyalty. This demand is especially pronounced in the personal care and household products segments, where fragrance plays a crucial role in product differentiation and consumer experience.

The global market for scented packaging materials, including cellophane with enhanced aroma retention properties, is experiencing robust growth. This trend is fueled by the rising popularity of aromatherapy products, scented candles, and fragranced home goods. Manufacturers are increasingly investing in research and development to create innovative cellophane products that can effectively trap and slowly release aromas over extended periods.

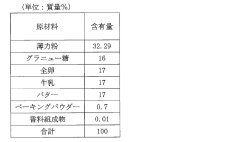

In the food industry, there is a growing demand for packaging solutions that can preserve the natural aromas of fresh produce, baked goods, and coffee. Cellophane with improved aroma retention capabilities offers a promising solution to this challenge, potentially reducing food waste and enhancing the overall consumer experience.

The e-commerce boom has further accelerated the need for better aroma retention in packaging materials. As online shopping for fragranced products continues to rise, brands are seeking ways to ensure that their products maintain their scent integrity during shipping and storage. This has created new opportunities for cellophane manufacturers to develop advanced aroma retention technologies.

Environmental concerns and sustainability trends are also shaping market demand. Consumers are increasingly looking for eco-friendly packaging options that do not compromise on functionality. This has led to a growing interest in biodegradable cellophane products with enhanced aroma retention properties, aligning with the broader shift towards sustainable packaging solutions in various industries.

The pharmaceutical and nutraceutical sectors represent another significant area of market demand for improved aroma retention in cellophane products. These industries require packaging solutions that can effectively mask unpleasant odors while preserving the integrity of the product inside. Enhanced aroma retention capabilities in cellophane could provide a competitive edge in this highly regulated market.

Consumer packaged goods companies are actively seeking solutions to extend the shelf life of their scented products, recognizing that aroma retention is a key factor in customer satisfaction and brand loyalty. This demand is especially pronounced in the personal care and household products segments, where fragrance plays a crucial role in product differentiation and consumer experience.

The global market for scented packaging materials, including cellophane with enhanced aroma retention properties, is experiencing robust growth. This trend is fueled by the rising popularity of aromatherapy products, scented candles, and fragranced home goods. Manufacturers are increasingly investing in research and development to create innovative cellophane products that can effectively trap and slowly release aromas over extended periods.

In the food industry, there is a growing demand for packaging solutions that can preserve the natural aromas of fresh produce, baked goods, and coffee. Cellophane with improved aroma retention capabilities offers a promising solution to this challenge, potentially reducing food waste and enhancing the overall consumer experience.

The e-commerce boom has further accelerated the need for better aroma retention in packaging materials. As online shopping for fragranced products continues to rise, brands are seeking ways to ensure that their products maintain their scent integrity during shipping and storage. This has created new opportunities for cellophane manufacturers to develop advanced aroma retention technologies.

Environmental concerns and sustainability trends are also shaping market demand. Consumers are increasingly looking for eco-friendly packaging options that do not compromise on functionality. This has led to a growing interest in biodegradable cellophane products with enhanced aroma retention properties, aligning with the broader shift towards sustainable packaging solutions in various industries.

The pharmaceutical and nutraceutical sectors represent another significant area of market demand for improved aroma retention in cellophane products. These industries require packaging solutions that can effectively mask unpleasant odors while preserving the integrity of the product inside. Enhanced aroma retention capabilities in cellophane could provide a competitive edge in this highly regulated market.

Current Limitations

Cellophane products, despite their widespread use in packaging, face significant challenges in retaining aromas effectively. One of the primary limitations is the inherent permeability of cellophane to small molecules, including those responsible for fragrances and flavors. This characteristic, while beneficial for certain applications, poses a substantial hurdle for products requiring long-term aroma retention.

The molecular structure of cellophane, composed of regenerated cellulose, contains microscopic pores that allow for the passage of gases and vapors. This porosity, while advantageous for breathability, leads to the gradual escape of aromatic compounds over time. The rate of aroma loss is influenced by factors such as temperature, humidity, and the specific chemical properties of the aromatic molecules involved.

Another limitation stems from cellophane's hydrophilic nature. Its affinity for water molecules can result in moisture absorption, which may accelerate the degradation of certain aroma compounds or alter their perceived intensity. This hygroscopic property can be particularly problematic in environments with fluctuating humidity levels, leading to inconsistent aroma retention across different storage conditions.

The surface properties of cellophane also present challenges for aroma retention. The relatively smooth surface of cellophane provides limited sites for the adsorption of aroma molecules, reducing the material's capacity to hold fragrances over extended periods. This limitation is especially pronounced when compared to materials with more complex surface structures that can physically trap aromatic compounds.

Furthermore, the chemical inertness of cellophane, while beneficial for many packaging applications, limits the options for chemical modifications that could enhance aroma retention. Unlike some synthetic polymers, cellophane does not readily form strong chemical bonds with most aroma compounds, resulting in weak interactions that fail to prevent the diffusion of these molecules through the material.

The thickness of cellophane films used in packaging also plays a role in aroma retention limitations. Thinner films, often preferred for their flexibility and cost-effectiveness, provide less of a barrier to aroma diffusion compared to thicker alternatives. However, increasing film thickness to improve retention can lead to other undesirable effects, such as reduced transparency or altered mechanical properties.

Lastly, the interaction between cellophane and common printing inks or adhesives used in packaging can sometimes interfere with aroma retention. Certain additives in these materials may compete with aroma compounds for adsorption sites or alter the surface properties of the cellophane, further complicating efforts to maintain fragrance integrity over time.

The molecular structure of cellophane, composed of regenerated cellulose, contains microscopic pores that allow for the passage of gases and vapors. This porosity, while advantageous for breathability, leads to the gradual escape of aromatic compounds over time. The rate of aroma loss is influenced by factors such as temperature, humidity, and the specific chemical properties of the aromatic molecules involved.

Another limitation stems from cellophane's hydrophilic nature. Its affinity for water molecules can result in moisture absorption, which may accelerate the degradation of certain aroma compounds or alter their perceived intensity. This hygroscopic property can be particularly problematic in environments with fluctuating humidity levels, leading to inconsistent aroma retention across different storage conditions.

The surface properties of cellophane also present challenges for aroma retention. The relatively smooth surface of cellophane provides limited sites for the adsorption of aroma molecules, reducing the material's capacity to hold fragrances over extended periods. This limitation is especially pronounced when compared to materials with more complex surface structures that can physically trap aromatic compounds.

Furthermore, the chemical inertness of cellophane, while beneficial for many packaging applications, limits the options for chemical modifications that could enhance aroma retention. Unlike some synthetic polymers, cellophane does not readily form strong chemical bonds with most aroma compounds, resulting in weak interactions that fail to prevent the diffusion of these molecules through the material.

The thickness of cellophane films used in packaging also plays a role in aroma retention limitations. Thinner films, often preferred for their flexibility and cost-effectiveness, provide less of a barrier to aroma diffusion compared to thicker alternatives. However, increasing film thickness to improve retention can lead to other undesirable effects, such as reduced transparency or altered mechanical properties.

Lastly, the interaction between cellophane and common printing inks or adhesives used in packaging can sometimes interfere with aroma retention. Certain additives in these materials may compete with aroma compounds for adsorption sites or alter the surface properties of the cellophane, further complicating efforts to maintain fragrance integrity over time.

Existing Retention Methods

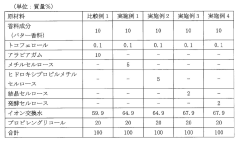

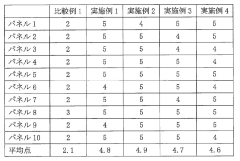

01 Incorporation of aroma-retaining materials in cellophane

Cellophane products can be enhanced with aroma-retaining properties by incorporating specific materials during the manufacturing process. These materials can include cyclodextrins, zeolites, or other porous substances that can trap and slowly release aromatic compounds. This technique allows for prolonged fragrance retention in cellophane-based packaging or products.- Cellophane packaging with aroma-retaining properties: Cellophane packaging materials are developed with specific properties to retain aromas of packaged products. These materials may incorporate additives or coatings that enhance their barrier properties against aroma compounds, ensuring that the fragrance of the packaged items remains intact for longer periods.

- Aroma-infused cellophane products: Cellophane products are infused with aromatic compounds to create scented packaging materials. These products may use microencapsulation techniques or direct incorporation of fragrances into the cellophane matrix, allowing for controlled release of aromas over time.

- Multilayer cellophane structures for aroma retention: Advanced multilayer cellophane structures are designed to improve aroma retention. These structures may combine different types of cellophane or incorporate additional layers of materials with complementary barrier properties to effectively trap and preserve aromatic compounds.

- Surface treatments for enhanced aroma retention in cellophane: Various surface treatments are applied to cellophane to enhance its aroma retention capabilities. These treatments may include plasma coating, chemical modifications, or the application of specialized films that improve the material's ability to hold and preserve fragrances.

- Aroma-controlled release systems in cellophane products: Innovative aroma-controlled release systems are incorporated into cellophane products. These systems may utilize smart polymers, nanostructures, or other advanced technologies to regulate the release of aromatic compounds, ensuring long-lasting fragrance retention and controlled dispersion.

02 Surface modification of cellophane for improved aroma retention

The surface of cellophane can be modified to improve its aroma retention capabilities. This can involve treatments such as plasma coating, chemical grafting, or the application of specialized films. These modifications create a more favorable surface for adhering aromatic compounds, enhancing the overall aroma retention of cellophane products.Expand Specific Solutions03 Encapsulation techniques for aroma retention in cellophane

Aroma compounds can be encapsulated within microscopic capsules or complexes that are then incorporated into cellophane products. This encapsulation protects the aromatic substances from degradation and allows for controlled release over time. Various encapsulation methods, such as spray drying or coacervation, can be employed to achieve this effect.Expand Specific Solutions04 Multilayer cellophane structures for enhanced aroma retention

Developing multilayer cellophane structures can significantly improve aroma retention. These structures may consist of different layers with varying properties, such as barrier layers to prevent aroma loss and absorbent layers to trap fragrances. The combination of these layers creates a more effective system for maintaining aromatic compounds within the cellophane product.Expand Specific Solutions05 Aroma-releasing mechanisms in cellophane products

Innovative mechanisms can be integrated into cellophane products to control the release of aromas. These may include moisture-activated systems, heat-triggered release, or mechanical activation methods. Such mechanisms allow for the strategic release of fragrances at specific times or under certain conditions, enhancing the user experience and extending the functional life of the aroma in cellophane products.Expand Specific Solutions

Key Industry Players

The aroma retention in cellophane products market is in a growth phase, driven by increasing demand for improved packaging solutions in various industries. The global market size for this technology is expanding, with a focus on enhancing product quality and shelf life. Technological maturity varies among key players, with companies like Dow Silicones Corp., Givaudan SA, and Henkel AG & Co. KGaA leading in innovation. These firms are developing advanced solutions for aroma encapsulation and controlled release. Other significant contributors include Symrise GmbH & Co. KG and Firmenich SA, who are leveraging their expertise in fragrances to address this challenge. The competitive landscape is characterized by ongoing research and development efforts to create more effective and sustainable aroma retention technologies for cellophane products.

Givaudan SA

Technical Solution: Givaudan has developed a proprietary technology called "Mechacaps" for improved aroma retention in cellophane products. This microencapsulation technique involves encasing fragrance molecules within microscopic capsules made of biodegradable polymers. The capsules are designed to rupture gradually, releasing the aroma over time. Givaudan has also implemented a "Smart Release" system that uses stimuli-responsive materials to control the release of fragrances based on environmental factors such as temperature or humidity[1][3]. Additionally, they have explored the use of cyclodextrins to form inclusion complexes with volatile aroma compounds, enhancing their stability and prolonging their release in cellophane-based packaging[2].

Strengths: Advanced microencapsulation technology, customizable release profiles, and expertise in fragrance chemistry. Weaknesses: Potential increased production costs and complexity in manufacturing processes.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a multi-layered approach to improve aroma retention in cellophane products. Their technology involves a combination of barrier coatings and active ingredients. The company uses a proprietary blend of modified starches and cellulose derivatives to create a thin, invisible barrier layer on the cellophane surface. This layer helps to reduce the permeation of aroma molecules. Additionally, Henkel has incorporated cyclodextrin-based molecular traps into the cellophane matrix, which can capture and slowly release fragrance compounds[4]. They have also explored the use of nanocomposite materials, such as clay-polymer hybrids, to enhance the barrier properties of cellophane while maintaining its transparency and flexibility[5].

Strengths: Comprehensive approach combining barrier technology and active ingredients, expertise in adhesives and coatings. Weaknesses: Potential challenges in maintaining cellophane's original properties, such as biodegradability.

Innovative Barrier Coatings

Composition for improving fragrance retention and method for producing the same

PatentActiveJP2021061827A

Innovation

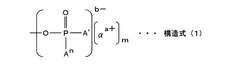

- Incorporating celluloses as active ingredients to enhance the retention of perfume ingredients, which can be combined with various perfume components to improve aroma and flavor stability during processing and storage.

Sheet, method for producing sheet, coating liquid, and single-layer film

PatentWO2025079289A1

Innovation

- A sheet with layers containing aroma components and first cellulose fine fibers, where the hydroxy groups of the cellulose fibers are modified with an ester of phosphorous acid, forming a dense three-dimensional network structure that suppresses the volatilization of aroma components. This approach eliminates the use of organic solvents and enhances the retention and sustained release of fragrances.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of aroma retention technologies for cellophane products. The food packaging industry, which extensively uses cellophane, is subject to stringent regulations to ensure consumer safety and product quality. In the context of improving aroma retention, manufacturers must navigate a complex landscape of national and international standards.

The U.S. Food and Drug Administration (FDA) regulates food contact materials, including cellophane, under the Federal Food, Drug, and Cosmetic Act. Any new additives or modifications to cellophane aimed at enhancing aroma retention must comply with FDA regulations. This includes demonstrating that the materials used are safe for food contact and do not migrate into the food at levels that could pose health risks.

In the European Union, the European Food Safety Authority (EFSA) oversees similar regulations. The EU Regulation No. 1935/2004 sets out the general principles of safety and inertness for all food contact materials. Additionally, specific measures for plastic materials are detailed in Regulation (EU) No. 10/2011, which may apply to certain cellophane products depending on their composition.

Manufacturers must also consider global harmonization efforts, such as those led by the Global Food Safety Initiative (GFSI). These initiatives aim to streamline compliance across different markets, reducing barriers to international trade while maintaining high safety standards.

Environmental regulations are increasingly relevant to aroma retention technologies. As sustainability becomes a key focus, any new methods for improving aroma retention must also consider their environmental impact. This includes compliance with regulations on recyclability, biodegradability, and the use of sustainable materials.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU is particularly important for chemical additives used in aroma retention. Manufacturers must ensure that any new substances introduced comply with REACH requirements, including registration and safety assessments.

Labeling regulations also come into play when improving aroma retention in cellophane products. If new technologies or additives are used, they may need to be disclosed on product labels, depending on regional requirements. This is particularly important for products marketed as "natural" or "organic," where specific regulations govern the use of additives and processing aids.

Compliance with Good Manufacturing Practices (GMPs) is essential throughout the development and production process. These practices ensure that products are consistently produced and controlled according to quality standards, which is crucial when implementing new aroma retention technologies.

As research progresses, it's vital to stay abreast of evolving regulations. Regulatory bodies frequently update their guidelines based on new scientific evidence, and companies must be prepared to adapt their aroma retention strategies accordingly. This may involve ongoing toxicological studies, migration testing, and continuous monitoring of regulatory developments worldwide.

The U.S. Food and Drug Administration (FDA) regulates food contact materials, including cellophane, under the Federal Food, Drug, and Cosmetic Act. Any new additives or modifications to cellophane aimed at enhancing aroma retention must comply with FDA regulations. This includes demonstrating that the materials used are safe for food contact and do not migrate into the food at levels that could pose health risks.

In the European Union, the European Food Safety Authority (EFSA) oversees similar regulations. The EU Regulation No. 1935/2004 sets out the general principles of safety and inertness for all food contact materials. Additionally, specific measures for plastic materials are detailed in Regulation (EU) No. 10/2011, which may apply to certain cellophane products depending on their composition.

Manufacturers must also consider global harmonization efforts, such as those led by the Global Food Safety Initiative (GFSI). These initiatives aim to streamline compliance across different markets, reducing barriers to international trade while maintaining high safety standards.

Environmental regulations are increasingly relevant to aroma retention technologies. As sustainability becomes a key focus, any new methods for improving aroma retention must also consider their environmental impact. This includes compliance with regulations on recyclability, biodegradability, and the use of sustainable materials.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU is particularly important for chemical additives used in aroma retention. Manufacturers must ensure that any new substances introduced comply with REACH requirements, including registration and safety assessments.

Labeling regulations also come into play when improving aroma retention in cellophane products. If new technologies or additives are used, they may need to be disclosed on product labels, depending on regional requirements. This is particularly important for products marketed as "natural" or "organic," where specific regulations govern the use of additives and processing aids.

Compliance with Good Manufacturing Practices (GMPs) is essential throughout the development and production process. These practices ensure that products are consistently produced and controlled according to quality standards, which is crucial when implementing new aroma retention technologies.

As research progresses, it's vital to stay abreast of evolving regulations. Regulatory bodies frequently update their guidelines based on new scientific evidence, and companies must be prepared to adapt their aroma retention strategies accordingly. This may involve ongoing toxicological studies, migration testing, and continuous monitoring of regulatory developments worldwide.

Sustainability Aspects

Sustainability has become a crucial aspect in the development and improvement of cellophane products, particularly in the context of aroma retention. As the global focus on environmental responsibility intensifies, the cellophane industry must adapt its practices to align with sustainable principles while maintaining product quality and functionality.

One of the primary sustainability concerns in aroma retention for cellophane products is the use of synthetic additives and coatings. Traditional methods often rely on petroleum-based compounds, which can have negative environmental impacts. To address this issue, researchers are exploring bio-based alternatives derived from renewable resources. These natural additives not only offer improved biodegradability but also have the potential to enhance aroma retention properties.

The production process of cellophane itself is another area where sustainability improvements can be made. By optimizing manufacturing techniques, companies can reduce energy consumption and minimize waste generation. This includes implementing closed-loop systems for water and solvent recovery, as well as utilizing more efficient drying methods that consume less energy while maintaining the integrity of aroma-retaining properties.

Packaging design plays a significant role in both aroma retention and sustainability. Innovative approaches to cellophane packaging are being developed to reduce material usage while improving barrier properties. This includes the use of multi-layer structures that incorporate thin, high-performance layers for aroma retention, combined with recyclable or compostable materials for the bulk of the packaging.

End-of-life considerations are becoming increasingly important in the sustainability of cellophane products. Research is being conducted on enhancing the biodegradability of cellophane without compromising its aroma retention capabilities. This involves developing new formulations that break down more readily in industrial composting facilities or even in home composting environments.

The circular economy concept is also being applied to cellophane production and use. Efforts are being made to create closed-loop systems where used cellophane products can be collected, processed, and reintegrated into the production cycle. This not only reduces waste but also decreases the demand for virgin raw materials, contributing to overall resource conservation.

Collaboration across the value chain is essential for advancing sustainability in cellophane aroma retention. Partnerships between raw material suppliers, manufacturers, and end-users are driving innovation in sustainable solutions. These collaborations often lead to the development of new technologies that balance environmental concerns with product performance, ensuring that improvements in aroma retention do not come at the cost of increased environmental impact.

One of the primary sustainability concerns in aroma retention for cellophane products is the use of synthetic additives and coatings. Traditional methods often rely on petroleum-based compounds, which can have negative environmental impacts. To address this issue, researchers are exploring bio-based alternatives derived from renewable resources. These natural additives not only offer improved biodegradability but also have the potential to enhance aroma retention properties.

The production process of cellophane itself is another area where sustainability improvements can be made. By optimizing manufacturing techniques, companies can reduce energy consumption and minimize waste generation. This includes implementing closed-loop systems for water and solvent recovery, as well as utilizing more efficient drying methods that consume less energy while maintaining the integrity of aroma-retaining properties.

Packaging design plays a significant role in both aroma retention and sustainability. Innovative approaches to cellophane packaging are being developed to reduce material usage while improving barrier properties. This includes the use of multi-layer structures that incorporate thin, high-performance layers for aroma retention, combined with recyclable or compostable materials for the bulk of the packaging.

End-of-life considerations are becoming increasingly important in the sustainability of cellophane products. Research is being conducted on enhancing the biodegradability of cellophane without compromising its aroma retention capabilities. This involves developing new formulations that break down more readily in industrial composting facilities or even in home composting environments.

The circular economy concept is also being applied to cellophane production and use. Efforts are being made to create closed-loop systems where used cellophane products can be collected, processed, and reintegrated into the production cycle. This not only reduces waste but also decreases the demand for virgin raw materials, contributing to overall resource conservation.

Collaboration across the value chain is essential for advancing sustainability in cellophane aroma retention. Partnerships between raw material suppliers, manufacturers, and end-users are driving innovation in sustainable solutions. These collaborations often lead to the development of new technologies that balance environmental concerns with product performance, ensuring that improvements in aroma retention do not come at the cost of increased environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!