How to Improve Cellophane's Performance in Humid Environments?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Challenges in Humidity

Cellophane, a versatile and widely used packaging material, faces significant challenges in humid environments. The primary issue stems from its inherent hygroscopic nature, which causes it to absorb moisture from the surrounding air. This absorption leads to several performance degradations that impact its effectiveness as a packaging solution.

One of the most prominent challenges is the loss of barrier properties. As cellophane absorbs moisture, its ability to act as an effective barrier against gases, odors, and other contaminants diminishes. This compromises the protection it offers to packaged goods, particularly in industries such as food and pharmaceuticals where maintaining product integrity is crucial.

The dimensional stability of cellophane is also adversely affected by humidity. As it absorbs moisture, the material tends to swell and distort, leading to changes in its size and shape. This can result in packaging that no longer fits properly or seals effectively, potentially exposing the contents to external elements or causing aesthetic issues.

Mechanical properties of cellophane are similarly impacted by high humidity. The material's tensile strength and tear resistance decrease as it absorbs moisture, making it more prone to damage during handling, transportation, or use. This reduction in structural integrity can lead to packaging failures and product spoilage.

The optical properties of cellophane are another area of concern in humid conditions. Moisture absorption can cause the material to become cloudy or hazy, reducing its transparency and affecting the visual appeal of packaged products. This is particularly problematic in applications where product visibility is a key selling point.

Adhesion is yet another challenge faced by cellophane in humid environments. Many adhesives used in packaging applications perform poorly when exposed to moisture, leading to seal failures and compromised package integrity. This can result in product contamination, spoilage, or leakage.

The biodegradability of cellophane, while generally considered an environmental advantage, can become a drawback in high-humidity conditions. Excessive moisture can accelerate the degradation process, potentially leading to premature breakdown of the packaging before the end of its intended lifecycle.

Addressing these challenges requires innovative approaches to improve cellophane's performance in humid environments. Potential solutions may involve surface treatments, composite structures, or the development of new moisture-resistant variants of cellophane. The goal is to enhance its barrier properties, dimensional stability, and mechanical strength while maintaining its desirable characteristics such as transparency and biodegradability.

One of the most prominent challenges is the loss of barrier properties. As cellophane absorbs moisture, its ability to act as an effective barrier against gases, odors, and other contaminants diminishes. This compromises the protection it offers to packaged goods, particularly in industries such as food and pharmaceuticals where maintaining product integrity is crucial.

The dimensional stability of cellophane is also adversely affected by humidity. As it absorbs moisture, the material tends to swell and distort, leading to changes in its size and shape. This can result in packaging that no longer fits properly or seals effectively, potentially exposing the contents to external elements or causing aesthetic issues.

Mechanical properties of cellophane are similarly impacted by high humidity. The material's tensile strength and tear resistance decrease as it absorbs moisture, making it more prone to damage during handling, transportation, or use. This reduction in structural integrity can lead to packaging failures and product spoilage.

The optical properties of cellophane are another area of concern in humid conditions. Moisture absorption can cause the material to become cloudy or hazy, reducing its transparency and affecting the visual appeal of packaged products. This is particularly problematic in applications where product visibility is a key selling point.

Adhesion is yet another challenge faced by cellophane in humid environments. Many adhesives used in packaging applications perform poorly when exposed to moisture, leading to seal failures and compromised package integrity. This can result in product contamination, spoilage, or leakage.

The biodegradability of cellophane, while generally considered an environmental advantage, can become a drawback in high-humidity conditions. Excessive moisture can accelerate the degradation process, potentially leading to premature breakdown of the packaging before the end of its intended lifecycle.

Addressing these challenges requires innovative approaches to improve cellophane's performance in humid environments. Potential solutions may involve surface treatments, composite structures, or the development of new moisture-resistant variants of cellophane. The goal is to enhance its barrier properties, dimensional stability, and mechanical strength while maintaining its desirable characteristics such as transparency and biodegradability.

Market Demand Analysis

The market demand for improved cellophane performance in humid environments has been steadily growing, driven by various factors across multiple industries. The packaging sector, in particular, has shown a significant interest in enhanced cellophane products that can maintain their integrity and functionality under high humidity conditions.

In the food packaging industry, there is a pressing need for moisture-resistant cellophane to extend the shelf life of products and prevent spoilage. As consumers increasingly demand fresh, minimally processed foods, manufacturers are seeking packaging solutions that can protect against humidity while maintaining product visibility. This trend is particularly evident in regions with tropical or subtropical climates, where ambient humidity levels are consistently high.

The pharmaceutical industry also presents a substantial market opportunity for humidity-resistant cellophane. Drug packaging requires materials that can protect sensitive medications from moisture, which can degrade active ingredients or alter drug efficacy. With the global pharmaceutical market expanding, especially in emerging economies with challenging climatic conditions, the demand for high-performance cellophane in this sector is expected to rise significantly.

Electronics manufacturers have shown growing interest in improved cellophane for protective packaging. As electronic devices become more sophisticated and sensitive to environmental factors, the need for packaging materials that can shield components from humidity during storage and transportation has increased. This is particularly crucial for products shipped to or manufactured in regions prone to high humidity levels.

The textile industry represents another potential market for enhanced cellophane. Garment packaging that can resist moisture penetration helps maintain the quality of fabrics and prevents issues such as mold growth during storage and shipping. This is especially important for high-value textiles and in the context of global supply chains that may involve exposure to varying humidity conditions.

Market research indicates that the global demand for specialty packaging films, including high-performance cellophane, is projected to grow at a compound annual growth rate (CAGR) of 4-5% over the next five years. This growth is largely attributed to the increasing awareness of sustainability issues and the push for biodegradable packaging options, of which cellophane is a prime candidate if its performance in humid conditions can be improved.

The Asia-Pacific region is expected to be a key driver of market growth, due to its rapidly expanding consumer goods and electronics industries, coupled with challenging climatic conditions. North America and Europe are also significant markets, with a focus on innovative, eco-friendly packaging solutions that can withstand various environmental stresses.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the development of cellophane with enhanced humidity resistance aligns well with the broader trend towards sustainable packaging materials. This presents an opportunity for manufacturers to differentiate their products and capture market share in an increasingly competitive packaging industry.

In the food packaging industry, there is a pressing need for moisture-resistant cellophane to extend the shelf life of products and prevent spoilage. As consumers increasingly demand fresh, minimally processed foods, manufacturers are seeking packaging solutions that can protect against humidity while maintaining product visibility. This trend is particularly evident in regions with tropical or subtropical climates, where ambient humidity levels are consistently high.

The pharmaceutical industry also presents a substantial market opportunity for humidity-resistant cellophane. Drug packaging requires materials that can protect sensitive medications from moisture, which can degrade active ingredients or alter drug efficacy. With the global pharmaceutical market expanding, especially in emerging economies with challenging climatic conditions, the demand for high-performance cellophane in this sector is expected to rise significantly.

Electronics manufacturers have shown growing interest in improved cellophane for protective packaging. As electronic devices become more sophisticated and sensitive to environmental factors, the need for packaging materials that can shield components from humidity during storage and transportation has increased. This is particularly crucial for products shipped to or manufactured in regions prone to high humidity levels.

The textile industry represents another potential market for enhanced cellophane. Garment packaging that can resist moisture penetration helps maintain the quality of fabrics and prevents issues such as mold growth during storage and shipping. This is especially important for high-value textiles and in the context of global supply chains that may involve exposure to varying humidity conditions.

Market research indicates that the global demand for specialty packaging films, including high-performance cellophane, is projected to grow at a compound annual growth rate (CAGR) of 4-5% over the next five years. This growth is largely attributed to the increasing awareness of sustainability issues and the push for biodegradable packaging options, of which cellophane is a prime candidate if its performance in humid conditions can be improved.

The Asia-Pacific region is expected to be a key driver of market growth, due to its rapidly expanding consumer goods and electronics industries, coupled with challenging climatic conditions. North America and Europe are also significant markets, with a focus on innovative, eco-friendly packaging solutions that can withstand various environmental stresses.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the development of cellophane with enhanced humidity resistance aligns well with the broader trend towards sustainable packaging materials. This presents an opportunity for manufacturers to differentiate their products and capture market share in an increasingly competitive packaging industry.

Current State and Limitations

Cellophane, a transparent film made from regenerated cellulose, has been widely used in packaging and various industrial applications. However, its performance in humid environments remains a significant challenge, limiting its broader adoption and effectiveness in certain scenarios.

The current state of cellophane technology offers several advantages, including transparency, biodegradability, and good barrier properties against gases and aromas. These characteristics make it an attractive option for food packaging and other applications where product visibility and environmental concerns are paramount. However, the material's susceptibility to moisture presents a major limitation that affects its overall performance and durability.

In humid environments, cellophane tends to absorb moisture from the air, leading to several undesirable effects. The material can become soft and lose its structural integrity, compromising its ability to protect packaged goods effectively. This moisture absorption also affects cellophane's barrier properties, potentially allowing the ingress of oxygen and other gases that can degrade the quality of packaged products.

Furthermore, the dimensional stability of cellophane is significantly impacted by humidity fluctuations. As it absorbs moisture, the material can swell and distort, leading to changes in size and shape. This instability can cause issues in manufacturing processes, packaging line efficiency, and overall product presentation.

Another limitation of cellophane in humid conditions is its reduced tensile strength and tear resistance. As the material absorbs moisture, its mechanical properties deteriorate, making it more prone to tearing and puncturing. This weakness not only affects the integrity of packaging but also limits cellophane's use in applications that require higher strength and durability.

The current technology also faces challenges in maintaining consistent performance across varying humidity levels. The material's properties can fluctuate significantly as environmental conditions change, making it difficult to ensure reliable performance in diverse climates and storage conditions.

Efforts to improve cellophane's performance in humid environments have focused on various approaches, including chemical modifications and coating technologies. However, these solutions often come with trade-offs, such as reduced biodegradability or increased production costs, which can limit their practical implementation.

The limitations of cellophane in humid environments have led to increased competition from alternative materials, such as synthetic polymers, which offer better moisture resistance. This competition has driven research and development efforts to enhance cellophane's properties while maintaining its eco-friendly characteristics.

The current state of cellophane technology offers several advantages, including transparency, biodegradability, and good barrier properties against gases and aromas. These characteristics make it an attractive option for food packaging and other applications where product visibility and environmental concerns are paramount. However, the material's susceptibility to moisture presents a major limitation that affects its overall performance and durability.

In humid environments, cellophane tends to absorb moisture from the air, leading to several undesirable effects. The material can become soft and lose its structural integrity, compromising its ability to protect packaged goods effectively. This moisture absorption also affects cellophane's barrier properties, potentially allowing the ingress of oxygen and other gases that can degrade the quality of packaged products.

Furthermore, the dimensional stability of cellophane is significantly impacted by humidity fluctuations. As it absorbs moisture, the material can swell and distort, leading to changes in size and shape. This instability can cause issues in manufacturing processes, packaging line efficiency, and overall product presentation.

Another limitation of cellophane in humid conditions is its reduced tensile strength and tear resistance. As the material absorbs moisture, its mechanical properties deteriorate, making it more prone to tearing and puncturing. This weakness not only affects the integrity of packaging but also limits cellophane's use in applications that require higher strength and durability.

The current technology also faces challenges in maintaining consistent performance across varying humidity levels. The material's properties can fluctuate significantly as environmental conditions change, making it difficult to ensure reliable performance in diverse climates and storage conditions.

Efforts to improve cellophane's performance in humid environments have focused on various approaches, including chemical modifications and coating technologies. However, these solutions often come with trade-offs, such as reduced biodegradability or increased production costs, which can limit their practical implementation.

The limitations of cellophane in humid environments have led to increased competition from alternative materials, such as synthetic polymers, which offer better moisture resistance. This competition has driven research and development efforts to enhance cellophane's properties while maintaining its eco-friendly characteristics.

Existing Moisture-Resistant Solutions

01 Improved barrier properties

Cellophane can be modified to enhance its barrier properties against moisture, gases, and other substances. This can be achieved through various methods such as coating, lamination, or chemical treatment. Improved barrier properties extend the shelf life of packaged products and protect them from external factors.- Improved barrier properties: Cellophane performance can be enhanced by improving its barrier properties against moisture, gases, and other environmental factors. This can be achieved through various coating techniques or by incorporating additives into the cellophane structure, resulting in increased shelf life for packaged products and better protection against external elements.

- Enhanced mechanical strength: The mechanical strength of cellophane can be improved through various methods, such as reinforcing the material with fibers or nanoparticles, or by modifying the manufacturing process. This results in increased durability, tear resistance, and overall performance in packaging and other applications.

- Biodegradability and eco-friendly properties: Cellophane's performance can be optimized for environmental sustainability by enhancing its biodegradability and eco-friendly properties. This includes developing cellophane variants that decompose more quickly in natural environments or incorporating additives that promote faster breakdown without compromising the material's functional properties.

- Optical and aesthetic improvements: Enhancing the optical and aesthetic properties of cellophane can improve its performance in various applications. This includes developing cellophane with improved clarity, gloss, and color retention, as well as incorporating special effects such as holographic patterns or color-changing properties for packaging and display purposes.

- Functional coatings and surface treatments: The performance of cellophane can be significantly enhanced through the application of functional coatings and surface treatments. These modifications can impart properties such as antimicrobial activity, heat-sealability, or improved printability, expanding the range of applications for cellophane in packaging and other industries.

02 Enhanced mechanical strength

Techniques have been developed to increase the mechanical strength of cellophane, making it more resistant to tearing and puncturing. This can involve reinforcing the material with additives, modifying the manufacturing process, or combining cellophane with other materials to create composite structures.Expand Specific Solutions03 Improved heat resistance

Cellophane's heat resistance can be enhanced through various methods, allowing it to maintain its integrity at higher temperatures. This improvement enables its use in applications involving heat sealing, sterilization, or hot-fill packaging processes.Expand Specific Solutions04 Biodegradability and environmental performance

Research has focused on improving the biodegradability of cellophane while maintaining its functional properties. This includes developing new formulations or treatments that accelerate decomposition in natural environments, reducing environmental impact without compromising performance.Expand Specific Solutions05 Optical and surface properties

Advancements have been made in enhancing the optical clarity, gloss, and surface properties of cellophane. These improvements can include anti-fog coatings, increased transparency, or modified surface textures for better printability and aesthetic appeal in packaging applications.Expand Specific Solutions

Key Industry Players

The cellophane performance improvement in humid environments represents a niche but growing market within the packaging industry. The technology is in a relatively early stage of development, with several key players actively researching solutions. Companies like UBE Corp., Kolon Industries, and BASF Corp. are at the forefront, leveraging their expertise in materials science and chemical engineering. The market size is modest but expanding, driven by increasing demand for sustainable packaging solutions. While the technology is not yet fully mature, significant progress has been made in enhancing cellophane's moisture resistance and barrier properties. Collaborative efforts between industry leaders and research institutions, such as South China University of Technology and Zhejiang Sci-Tech University, are accelerating innovation in this field.

BASF Corp.

Technical Solution: BASF has engineered a multi-layer cellophane structure to combat performance issues in humid environments. Their approach involves sandwiching a thin layer of moisture-resistant biopolymer between two layers of traditional cellophane. This intermediate layer is composed of modified starch or cellulose derivatives that have been chemically altered to increase hydrophobicity[6]. BASF has also developed a proprietary coating technology that applies a microscopic layer of biodegradable, water-repellent material to the cellophane surface. This coating is designed to maintain the material's flexibility and transparency while significantly reducing moisture absorption[7]. Additionally, the company has introduced a novel drying process that removes residual moisture from the cellophane more effectively, thereby improving its initial resistance to humid conditions[8].

Strengths: Maintains biodegradability, improves moisture resistance without significant changes to appearance or feel. Weaknesses: More complex manufacturing process, potentially higher production costs.

LG Chem Ltd.

Technical Solution: LG Chem has developed a novel approach to enhance cellophane's performance in humid conditions by incorporating hygroscopic nanoparticles into the cellulose matrix during the manufacturing process. These nanoparticles, typically made from materials like zeolites or metal-organic frameworks, are designed to absorb excess moisture from the surrounding environment, thereby maintaining the structural integrity of the cellophane[2]. The company has also implemented a cross-linking technique that creates additional bonds between cellulose chains, increasing the material's overall stability in high humidity[4]. Furthermore, LG Chem has developed a proprietary surface treatment that applies a thin, breathable polymer layer to the cellophane, which allows for gas exchange while repelling water molecules[5].

Strengths: Improved moisture resistance without significant changes to cellophane's core properties, potential for enhanced mechanical strength. Weaknesses: Complex manufacturing process, may affect recyclability of the material.

Core Innovations in Cellophane

Method for producing porous hollow fiber membrane for humidification

PatentWO2020004212A1

Innovation

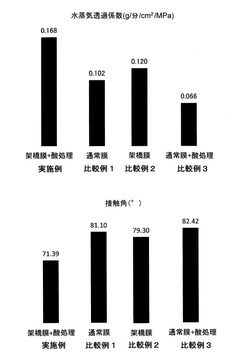

- A method involving dry-wet spinning of a spinning stock solution of polyphenylsulfone resin and hydrophilic polyvinylpyrrolidone, followed by cross-linking at 120-220°C and acid treatment in a controlled acidic solution, to enhance hydrophilicity and wettability while maintaining membrane strength and preventing hydrophilic substance elution.

Fuel cell for optimising air humidification

PatentActiveEP3341993A1

Innovation

- Incorporating hydrophilic components within the connection zones between flow collectors and active zones of the fuel cell, allowing moisture from anodic outlets to be redirected to cathodic inlets, thereby internally humidifying the membrane without external systems, and using materials like colloidal silica or perfluorosulfonic acid polymers to facilitate water diffusion.

Environmental Impact Assessment

The environmental impact of improving cellophane's performance in humid environments is a critical consideration. Cellophane, a biodegradable material derived from cellulose, has been widely used in packaging applications. However, its susceptibility to moisture has led to the development of various enhancement techniques, which may have both positive and negative environmental implications.

One of the primary environmental benefits of improving cellophane's humidity resistance is the potential reduction in food waste. Enhanced moisture barrier properties can extend the shelf life of packaged products, particularly in regions with high humidity. This improvement could lead to a decrease in spoilage and, consequently, a reduction in the amount of food discarded due to moisture-related degradation.

However, the methods used to enhance cellophane's performance may introduce new environmental challenges. Some approaches involve the application of synthetic coatings or the incorporation of non-biodegradable additives, which could compromise the material's inherent biodegradability. This alteration may result in increased persistence of cellophane in the environment, potentially contributing to plastic pollution if not properly managed.

The production processes for enhanced cellophane may also have environmental implications. Depending on the specific techniques employed, there could be increased energy consumption or the use of additional chemicals during manufacturing. These factors need to be carefully evaluated to ensure that the environmental benefits of improved performance outweigh any negative impacts associated with production.

Water usage is another important consideration. If the enhancement process requires additional water-intensive steps, it could strain local water resources, particularly in water-scarce regions. Conversely, if the improved cellophane reduces the need for double packaging or overwrapping, it could lead to an overall reduction in material usage and associated water consumption.

The end-of-life management of enhanced cellophane products is a crucial aspect of their environmental impact. While unmodified cellophane is biodegradable, alterations to improve humidity resistance may affect its compostability or recyclability. It is essential to develop enhancement techniques that maintain the material's ability to be processed through existing waste management systems without causing contamination or disruption.

In conclusion, the environmental impact of improving cellophane's performance in humid environments is multifaceted. While there are potential benefits in terms of reducing food waste and extending product shelf life, careful consideration must be given to the materials and processes used for enhancement. Striking a balance between performance improvement and environmental sustainability is crucial for the responsible development and application of enhanced cellophane products.

One of the primary environmental benefits of improving cellophane's humidity resistance is the potential reduction in food waste. Enhanced moisture barrier properties can extend the shelf life of packaged products, particularly in regions with high humidity. This improvement could lead to a decrease in spoilage and, consequently, a reduction in the amount of food discarded due to moisture-related degradation.

However, the methods used to enhance cellophane's performance may introduce new environmental challenges. Some approaches involve the application of synthetic coatings or the incorporation of non-biodegradable additives, which could compromise the material's inherent biodegradability. This alteration may result in increased persistence of cellophane in the environment, potentially contributing to plastic pollution if not properly managed.

The production processes for enhanced cellophane may also have environmental implications. Depending on the specific techniques employed, there could be increased energy consumption or the use of additional chemicals during manufacturing. These factors need to be carefully evaluated to ensure that the environmental benefits of improved performance outweigh any negative impacts associated with production.

Water usage is another important consideration. If the enhancement process requires additional water-intensive steps, it could strain local water resources, particularly in water-scarce regions. Conversely, if the improved cellophane reduces the need for double packaging or overwrapping, it could lead to an overall reduction in material usage and associated water consumption.

The end-of-life management of enhanced cellophane products is a crucial aspect of their environmental impact. While unmodified cellophane is biodegradable, alterations to improve humidity resistance may affect its compostability or recyclability. It is essential to develop enhancement techniques that maintain the material's ability to be processed through existing waste management systems without causing contamination or disruption.

In conclusion, the environmental impact of improving cellophane's performance in humid environments is multifaceted. While there are potential benefits in terms of reducing food waste and extending product shelf life, careful consideration must be given to the materials and processes used for enhancement. Striking a balance between performance improvement and environmental sustainability is crucial for the responsible development and application of enhanced cellophane products.

Regulatory Compliance Landscape

The regulatory compliance landscape for cellophane in humid environments is complex and multifaceted, involving various standards and regulations across different jurisdictions. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating cellophane used in food packaging. The FDA's Code of Federal Regulations Title 21, Part 177, Subpart B specifically addresses cellophane, outlining requirements for its composition and use in food contact applications. These regulations become particularly relevant when considering cellophane's performance in humid conditions, as moisture absorption can potentially affect its safety and efficacy as a food packaging material.

In the European Union, the European Food Safety Authority (EFSA) oversees the safety of food contact materials, including cellophane. The EU's Regulation (EC) No 1935/2004 provides a harmonized legal framework for all materials intended to come into contact with food. This regulation emphasizes the importance of ensuring that materials do not transfer their constituents to food in quantities that could endanger human health or change the composition of the food in an unacceptable way. Given cellophane's susceptibility to humidity, manufacturers must demonstrate compliance with these regulations under various environmental conditions.

Environmental regulations also come into play when considering improvements to cellophane's performance in humid environments. Many countries have implemented restrictions on certain chemicals that might be used to enhance cellophane's moisture resistance. For instance, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation impacts the types of additives that can be used in cellophane production. Similarly, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm.

As sustainability becomes an increasingly important factor in regulatory frameworks, any improvements to cellophane's humidity resistance must also consider end-of-life scenarios. The EU's Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging materials, including cellophane. Innovations in cellophane technology must therefore not only enhance performance but also maintain or improve recyclability to meet these regulatory requirements.

International standards, such as those set by the International Organization for Standardization (ISO), also influence the regulatory landscape. ISO 15106 and ISO 2528, which deal with the determination of water vapor transmission rate of plastic films and sheets, are particularly relevant for assessing cellophane's performance in humid conditions. Compliance with these standards is often necessary to meet regulatory requirements in various markets.

As global trade continues to expand, navigating the diverse regulatory landscape becomes increasingly challenging for cellophane manufacturers. Harmonization efforts, such as the Global Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize safety regulations across borders. However, significant differences in regulatory approaches between regions remain, necessitating a comprehensive understanding of local requirements when developing improved cellophane products for humid environments.

In the European Union, the European Food Safety Authority (EFSA) oversees the safety of food contact materials, including cellophane. The EU's Regulation (EC) No 1935/2004 provides a harmonized legal framework for all materials intended to come into contact with food. This regulation emphasizes the importance of ensuring that materials do not transfer their constituents to food in quantities that could endanger human health or change the composition of the food in an unacceptable way. Given cellophane's susceptibility to humidity, manufacturers must demonstrate compliance with these regulations under various environmental conditions.

Environmental regulations also come into play when considering improvements to cellophane's performance in humid environments. Many countries have implemented restrictions on certain chemicals that might be used to enhance cellophane's moisture resistance. For instance, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation impacts the types of additives that can be used in cellophane production. Similarly, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm.

As sustainability becomes an increasingly important factor in regulatory frameworks, any improvements to cellophane's humidity resistance must also consider end-of-life scenarios. The EU's Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging materials, including cellophane. Innovations in cellophane technology must therefore not only enhance performance but also maintain or improve recyclability to meet these regulatory requirements.

International standards, such as those set by the International Organization for Standardization (ISO), also influence the regulatory landscape. ISO 15106 and ISO 2528, which deal with the determination of water vapor transmission rate of plastic films and sheets, are particularly relevant for assessing cellophane's performance in humid conditions. Compliance with these standards is often necessary to meet regulatory requirements in various markets.

As global trade continues to expand, navigating the diverse regulatory landscape becomes increasingly challenging for cellophane manufacturers. Harmonization efforts, such as the Global Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize safety regulations across borders. However, significant differences in regulatory approaches between regions remain, necessitating a comprehensive understanding of local requirements when developing improved cellophane products for humid environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!