How to Innovate Solar Inverter Heat Management?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Thermal Management Evolution and Objectives

Solar inverter thermal management has evolved significantly over the past decades, driven by the rapid growth of the solar energy industry and the increasing demand for more efficient and reliable power conversion systems. The primary objective of thermal management in solar inverters is to maintain optimal operating temperatures for electronic components, ensuring their longevity and performance while maximizing overall system efficiency.

In the early stages of solar inverter development, thermal management primarily relied on passive cooling techniques such as heat sinks and natural convection. As inverter capacities increased and power densities rose, more advanced cooling methods became necessary. This led to the introduction of forced-air cooling systems, which utilized fans to enhance heat dissipation and improve thermal performance.

The evolution of thermal management in solar inverters has been closely tied to advancements in semiconductor technology and power electronics. The transition from traditional silicon-based components to wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has significantly impacted thermal management strategies. These new materials offer higher temperature tolerance and improved efficiency, allowing for more compact inverter designs and reduced cooling requirements.

Another key objective in solar inverter thermal management is to enhance reliability and reduce maintenance needs. This has led to the development of more robust cooling solutions, including liquid cooling systems for high-power applications. Liquid cooling offers superior heat transfer capabilities and allows for more uniform temperature distribution, addressing hotspots that can compromise inverter performance and lifespan.

The integration of advanced thermal modeling and simulation tools has become crucial in the design process of modern solar inverters. These tools enable engineers to optimize component placement, airflow, and heat dissipation pathways, resulting in more efficient thermal management solutions. Additionally, the incorporation of smart thermal management systems, which utilize sensors and adaptive control algorithms, has further improved the ability to maintain optimal operating temperatures under varying environmental conditions.

As the solar energy industry continues to grow and evolve, the objectives for thermal management in solar inverters are expanding beyond mere temperature control. Current goals include minimizing energy consumption of cooling systems, reducing acoustic noise, and improving overall system reliability. Furthermore, there is an increasing focus on developing environmentally friendly cooling solutions that minimize the use of harmful refrigerants and reduce the overall carbon footprint of solar energy systems.

Looking ahead, the future objectives of solar inverter thermal management are likely to include the development of even more compact and efficient designs, integration with energy storage systems, and adaptation to diverse environmental conditions. As solar installations expand into new geographical areas and applications, thermal management solutions will need to address challenges such as extreme temperatures, high humidity, and dusty environments while maintaining optimal performance and reliability.

In the early stages of solar inverter development, thermal management primarily relied on passive cooling techniques such as heat sinks and natural convection. As inverter capacities increased and power densities rose, more advanced cooling methods became necessary. This led to the introduction of forced-air cooling systems, which utilized fans to enhance heat dissipation and improve thermal performance.

The evolution of thermal management in solar inverters has been closely tied to advancements in semiconductor technology and power electronics. The transition from traditional silicon-based components to wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has significantly impacted thermal management strategies. These new materials offer higher temperature tolerance and improved efficiency, allowing for more compact inverter designs and reduced cooling requirements.

Another key objective in solar inverter thermal management is to enhance reliability and reduce maintenance needs. This has led to the development of more robust cooling solutions, including liquid cooling systems for high-power applications. Liquid cooling offers superior heat transfer capabilities and allows for more uniform temperature distribution, addressing hotspots that can compromise inverter performance and lifespan.

The integration of advanced thermal modeling and simulation tools has become crucial in the design process of modern solar inverters. These tools enable engineers to optimize component placement, airflow, and heat dissipation pathways, resulting in more efficient thermal management solutions. Additionally, the incorporation of smart thermal management systems, which utilize sensors and adaptive control algorithms, has further improved the ability to maintain optimal operating temperatures under varying environmental conditions.

As the solar energy industry continues to grow and evolve, the objectives for thermal management in solar inverters are expanding beyond mere temperature control. Current goals include minimizing energy consumption of cooling systems, reducing acoustic noise, and improving overall system reliability. Furthermore, there is an increasing focus on developing environmentally friendly cooling solutions that minimize the use of harmful refrigerants and reduce the overall carbon footprint of solar energy systems.

Looking ahead, the future objectives of solar inverter thermal management are likely to include the development of even more compact and efficient designs, integration with energy storage systems, and adaptation to diverse environmental conditions. As solar installations expand into new geographical areas and applications, thermal management solutions will need to address challenges such as extreme temperatures, high humidity, and dusty environments while maintaining optimal performance and reliability.

Market Demand for Efficient Solar Inverter Cooling

The market demand for efficient solar inverter cooling solutions has been steadily increasing in recent years, driven by the rapid growth of the solar energy sector and the need for more reliable and high-performance photovoltaic systems. As solar installations become larger and more complex, the importance of effective heat management in inverters has become a critical factor in ensuring optimal system performance and longevity.

Solar inverters play a crucial role in converting direct current (DC) generated by solar panels into alternating current (AC) for use in homes, businesses, and the power grid. However, this conversion process generates significant heat, which can negatively impact the efficiency and lifespan of the inverter if not properly managed. As a result, there is a growing demand for innovative cooling solutions that can maintain optimal operating temperatures and enhance overall system reliability.

The market for solar inverter cooling technologies is closely tied to the broader solar energy market, which has been experiencing robust growth globally. According to industry reports, the global solar inverter market is projected to expand at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is primarily driven by increasing investments in renewable energy infrastructure, government incentives for solar adoption, and the declining costs of solar technology.

Within this expanding market, there is a particular emphasis on developing more efficient and cost-effective cooling solutions for solar inverters. Traditional cooling methods, such as forced air cooling and liquid cooling, are being challenged by innovative approaches that offer improved performance and reduced maintenance requirements. This has led to a surge in research and development activities focused on advanced thermal management techniques, including phase change materials, heat pipes, and advanced heat sink designs.

The demand for efficient solar inverter cooling is further fueled by the trend towards higher power density inverters, which generate more heat in smaller form factors. As solar installations become more compact and integrated into urban environments, there is a growing need for cooling solutions that can effectively dissipate heat while maintaining a small footprint.

Moreover, the increasing deployment of solar energy in extreme climates and remote locations has heightened the importance of robust cooling systems that can operate reliably under challenging environmental conditions. This has created opportunities for innovative cooling technologies that can withstand high temperatures, dust, humidity, and other adverse factors without compromising performance.

In conclusion, the market demand for efficient solar inverter cooling solutions is driven by the overall growth of the solar energy sector, the push for higher efficiency and reliability in photovoltaic systems, and the need to address the thermal challenges posed by evolving inverter designs and installation environments. As the industry continues to advance, the development of innovative heat management technologies will play a crucial role in shaping the future of solar energy systems and their widespread adoption.

Solar inverters play a crucial role in converting direct current (DC) generated by solar panels into alternating current (AC) for use in homes, businesses, and the power grid. However, this conversion process generates significant heat, which can negatively impact the efficiency and lifespan of the inverter if not properly managed. As a result, there is a growing demand for innovative cooling solutions that can maintain optimal operating temperatures and enhance overall system reliability.

The market for solar inverter cooling technologies is closely tied to the broader solar energy market, which has been experiencing robust growth globally. According to industry reports, the global solar inverter market is projected to expand at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is primarily driven by increasing investments in renewable energy infrastructure, government incentives for solar adoption, and the declining costs of solar technology.

Within this expanding market, there is a particular emphasis on developing more efficient and cost-effective cooling solutions for solar inverters. Traditional cooling methods, such as forced air cooling and liquid cooling, are being challenged by innovative approaches that offer improved performance and reduced maintenance requirements. This has led to a surge in research and development activities focused on advanced thermal management techniques, including phase change materials, heat pipes, and advanced heat sink designs.

The demand for efficient solar inverter cooling is further fueled by the trend towards higher power density inverters, which generate more heat in smaller form factors. As solar installations become more compact and integrated into urban environments, there is a growing need for cooling solutions that can effectively dissipate heat while maintaining a small footprint.

Moreover, the increasing deployment of solar energy in extreme climates and remote locations has heightened the importance of robust cooling systems that can operate reliably under challenging environmental conditions. This has created opportunities for innovative cooling technologies that can withstand high temperatures, dust, humidity, and other adverse factors without compromising performance.

In conclusion, the market demand for efficient solar inverter cooling solutions is driven by the overall growth of the solar energy sector, the push for higher efficiency and reliability in photovoltaic systems, and the need to address the thermal challenges posed by evolving inverter designs and installation environments. As the industry continues to advance, the development of innovative heat management technologies will play a crucial role in shaping the future of solar energy systems and their widespread adoption.

Current Challenges in Solar Inverter Heat Dissipation

Solar inverter heat management faces several critical challenges that hinder the efficiency and longevity of photovoltaic systems. One of the primary issues is the increasing power density of modern inverters, which results in higher heat generation within compact enclosures. This trend towards miniaturization, while beneficial for installation flexibility, exacerbates thermal management difficulties.

The intermittent nature of solar energy production poses another significant challenge. Inverters must cope with varying loads throughout the day, leading to fluctuating heat generation patterns. This dynamic thermal environment complicates the design of effective cooling systems, as they must be capable of adapting to these changing conditions while maintaining optimal performance.

Environmental factors also play a crucial role in heat dissipation challenges. Solar inverters are often installed in outdoor settings, exposing them to a wide range of ambient temperatures and weather conditions. Extreme heat, humidity, and dust can severely impact the efficiency of traditional cooling methods, necessitating more robust and adaptable thermal management solutions.

The reliability and lifespan of electronic components within solar inverters are directly affected by operating temperatures. Excessive heat can lead to premature component failure, reduced efficiency, and increased maintenance costs. This challenge is particularly acute for power semiconductors, capacitors, and other heat-sensitive elements that are critical to inverter functionality.

Another hurdle in solar inverter heat management is the balance between cooling effectiveness and energy consumption. Active cooling systems, while often more efficient at heat dissipation, consume additional energy that reduces the overall system efficiency. Passive cooling methods, on the other hand, may not provide sufficient thermal management for high-power inverters, especially in challenging environmental conditions.

The need for silent operation in residential and urban installations further complicates heat management strategies. Noise restrictions limit the use of certain active cooling technologies, such as high-speed fans, forcing designers to explore alternative, quieter cooling methods that may be less effective or more costly.

Lastly, the cost-effectiveness of heat management solutions remains a significant challenge. Advanced thermal management technologies must be balanced against the overall system cost to ensure the economic viability of solar energy projects. This often leads to compromises in cooling efficiency to maintain competitive pricing, potentially impacting long-term reliability and performance.

The intermittent nature of solar energy production poses another significant challenge. Inverters must cope with varying loads throughout the day, leading to fluctuating heat generation patterns. This dynamic thermal environment complicates the design of effective cooling systems, as they must be capable of adapting to these changing conditions while maintaining optimal performance.

Environmental factors also play a crucial role in heat dissipation challenges. Solar inverters are often installed in outdoor settings, exposing them to a wide range of ambient temperatures and weather conditions. Extreme heat, humidity, and dust can severely impact the efficiency of traditional cooling methods, necessitating more robust and adaptable thermal management solutions.

The reliability and lifespan of electronic components within solar inverters are directly affected by operating temperatures. Excessive heat can lead to premature component failure, reduced efficiency, and increased maintenance costs. This challenge is particularly acute for power semiconductors, capacitors, and other heat-sensitive elements that are critical to inverter functionality.

Another hurdle in solar inverter heat management is the balance between cooling effectiveness and energy consumption. Active cooling systems, while often more efficient at heat dissipation, consume additional energy that reduces the overall system efficiency. Passive cooling methods, on the other hand, may not provide sufficient thermal management for high-power inverters, especially in challenging environmental conditions.

The need for silent operation in residential and urban installations further complicates heat management strategies. Noise restrictions limit the use of certain active cooling technologies, such as high-speed fans, forcing designers to explore alternative, quieter cooling methods that may be less effective or more costly.

Lastly, the cost-effectiveness of heat management solutions remains a significant challenge. Advanced thermal management technologies must be balanced against the overall system cost to ensure the economic viability of solar energy projects. This often leads to compromises in cooling efficiency to maintain competitive pricing, potentially impacting long-term reliability and performance.

Existing Heat Management Techniques for Solar Inverters

01 Heat dissipation through structural design

Solar inverters can be designed with specific structural features to enhance heat dissipation. This includes the use of heat sinks, ventilation channels, and optimized component layouts to improve airflow and thermal management. Such designs help to efficiently remove heat from critical components, maintaining optimal operating temperatures and improving overall system reliability.- Heat dissipation through structural design: Solar inverters can be designed with specific structural features to enhance heat dissipation. This includes the use of heat sinks, ventilation channels, and optimized component layouts to improve airflow and thermal management. Such designs help to efficiently remove heat from critical components, ensuring better performance and longevity of the inverter.

- Active cooling systems: Implementing active cooling systems in solar inverters can significantly improve heat management. These systems may include fans, liquid cooling, or thermoelectric coolers to actively remove heat from the inverter components. Active cooling allows for more precise temperature control and can handle higher heat loads, especially in high-power applications or harsh environments.

- Thermal management materials and coatings: The use of advanced thermal management materials and coatings can enhance heat dissipation in solar inverters. This includes the application of thermally conductive materials, phase change materials, or specialized coatings that improve heat transfer and radiation. These materials can be integrated into various components of the inverter to optimize overall thermal performance.

- Intelligent thermal management systems: Incorporating intelligent thermal management systems into solar inverters can provide adaptive and efficient heat control. These systems may use sensors, microcontrollers, and algorithms to monitor temperature and adjust cooling mechanisms accordingly. This approach allows for dynamic heat management based on operating conditions and environmental factors, optimizing energy efficiency and inverter performance.

- Modular and distributed inverter designs: Adopting modular and distributed inverter designs can improve overall heat management in solar power systems. By dividing the inverter functionality into smaller units or modules, heat generation can be distributed more evenly, reducing localized hot spots. This approach also allows for more flexible cooling solutions and can enhance system reliability by preventing single-point thermal failures.

02 Active cooling systems

Implementing active cooling systems in solar inverters can significantly improve heat management. These systems may include fans, liquid cooling, or thermoelectric coolers to actively remove heat from sensitive components. Active cooling allows for more precise temperature control and can be particularly effective in high-power or high-ambient temperature applications.Expand Specific Solutions03 Thermal management materials and coatings

The use of advanced thermal management materials and coatings can enhance heat dissipation in solar inverters. This includes the application of thermally conductive materials, phase change materials, or specialized coatings that improve heat transfer and radiation. These materials can be integrated into various components of the inverter to optimize thermal performance.Expand Specific Solutions04 Intelligent thermal management systems

Incorporating intelligent thermal management systems into solar inverters can provide adaptive and efficient heat control. These systems may use sensors, microcontrollers, and algorithms to monitor temperatures, adjust cooling mechanisms, and optimize power output based on thermal conditions. This approach allows for dynamic heat management and can improve overall system efficiency and longevity.Expand Specific Solutions05 Modular and distributed inverter designs

Adopting modular and distributed inverter designs can help manage heat more effectively in solar power systems. By dividing the inverter into smaller units or distributing conversion tasks across multiple components, heat generation can be spread out and more easily dissipated. This approach can also improve system reliability and scalability.Expand Specific Solutions

Key Players in Solar Inverter Cooling Solutions

The solar inverter heat management technology market is in a growth phase, driven by increasing adoption of solar energy systems globally. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like Huawei Digital Power, Fronius International, and SMA Solar Technology leading innovation. These firms are developing more efficient and reliable heat management solutions for solar inverters. However, the technology is not yet fully mature, as evidenced by ongoing research and development efforts from companies such as Fraunhofer-Gesellschaft and Advanced Energy Industries. The competitive landscape is diverse, with both established electronics giants like LG Innotek and specialized solar technology firms vying for market share.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei has developed an innovative approach to solar inverter heat management through its Smart PV Solution. This system utilizes advanced thermal management techniques, including intelligent fan control and optimized heat sink designs. The inverters employ a multi-level topology that reduces switching losses and heat generation[1]. Additionally, Huawei has implemented a unique natural cooling system that leverages convection currents to dissipate heat effectively, reducing the need for active cooling in many scenarios[2]. The company has also integrated AI-driven predictive maintenance algorithms that monitor temperature patterns and adjust operations to prevent overheating, thereby extending the inverter's lifespan and improving overall system reliability[3].

Strengths: Advanced AI-driven thermal management, reduced energy consumption for cooling, and improved system reliability. Weaknesses: Potential higher initial costs and complexity in implementation for smaller scale installations.

Fronius International GmbH

Technical Solution: Fronius has developed the SnapINverter technology, which incorporates innovative heat management solutions. The design features a separated cooling channel that isolates heat-sensitive components from power electronics[7]. This approach allows for more efficient heat dissipation and prolongs the lifespan of critical components. Fronius also utilizes phase-change materials in some models to absorb excess heat during peak operation, releasing it slowly during lower load periods[8]. The company's inverters employ intelligent power management algorithms that adjust output based on temperature and load conditions, optimizing performance while minimizing heat generation[9].

Strengths: Efficient heat isolation, innovative use of phase-change materials, and intelligent power management. Weaknesses: Potential complexity in maintenance and repair due to advanced cooling systems.

Innovative Thermal Management Patents for Solar Inverters

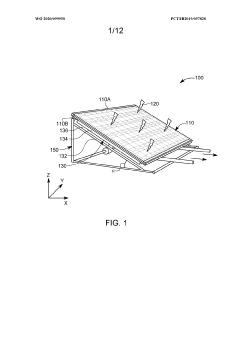

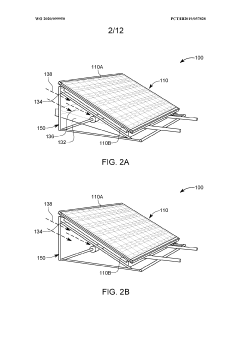

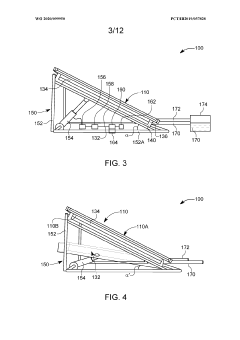

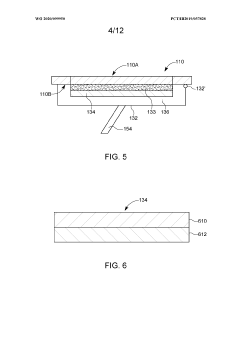

System and method for cooling photovoltaic panel with atmospheric water

PatentWO2020099950A1

Innovation

- An integrated photovoltaic panel-water sorption layer system that uses a water sorption layer attached to the back face of the panel to evaporate absorbed atmospheric water, cooling the panel and generating fresh water through condensation, with a sealed chamber mechanism for efficient water replenishment.

Heating device

PatentWO2017134763A1

Innovation

- A heating device with a hot water mixing valve and control unit that determines the maximum heat storage temperature, allowing for precise temperature control of the hot water heat storage tank, ensuring user comfort and efficient energy use by mixing return water with output water from the tank, thereby optimizing the storage and utilization of solar-generated heat.

Environmental Impact of Solar Inverter Cooling Methods

The environmental impact of solar inverter cooling methods is a critical consideration in the ongoing efforts to innovate heat management solutions for these essential components of solar energy systems. Traditional cooling methods, such as forced air cooling and liquid cooling, have varying degrees of environmental consequences that must be carefully evaluated.

Forced air cooling, while simple and cost-effective, often relies on energy-intensive fans that contribute to increased power consumption and noise pollution. This method may also require frequent filter replacements, leading to additional waste generation. Furthermore, in dusty environments, the efficiency of air cooling can be compromised, potentially reducing the overall performance of the solar inverter system.

Liquid cooling systems, on the other hand, offer improved thermal management but come with their own set of environmental challenges. The use of coolants, particularly those containing harmful chemicals, poses risks of leakage and contamination. Proper disposal of these coolants at the end of the system's lifecycle is crucial to prevent soil and water pollution. Additionally, the manufacturing and transportation of specialized cooling components contribute to the carbon footprint of the solar inverter.

Passive cooling techniques, such as heat sinks and phase change materials, present a more environmentally friendly approach. These methods require no additional energy input and have minimal maintenance needs, reducing long-term environmental impact. However, their effectiveness may be limited in extreme temperature conditions, potentially affecting the inverter's performance and lifespan.

The choice of materials for cooling systems also plays a significant role in environmental impact. The use of recyclable or biodegradable materials in heat sinks and enclosures can greatly reduce the end-of-life environmental burden. Moreover, the adoption of natural cooling methods, such as geothermal heat exchange or ambient air cooling in suitable climates, can further minimize the ecological footprint of solar inverter installations.

As the solar energy industry continues to grow, the cumulative environmental impact of inverter cooling methods becomes increasingly significant. Innovations in this area must focus on developing solutions that not only enhance thermal management but also align with sustainable practices. This includes exploring advanced materials with superior thermal properties, optimizing system designs for natural convection, and integrating smart cooling technologies that adapt to environmental conditions to minimize energy consumption.

The environmental impact assessment of cooling methods should also consider the entire lifecycle of the solar inverter system, from production to decommissioning. This holistic approach ensures that improvements in one area do not lead to unintended consequences in another, ultimately contributing to the overall sustainability of solar energy technology.

Forced air cooling, while simple and cost-effective, often relies on energy-intensive fans that contribute to increased power consumption and noise pollution. This method may also require frequent filter replacements, leading to additional waste generation. Furthermore, in dusty environments, the efficiency of air cooling can be compromised, potentially reducing the overall performance of the solar inverter system.

Liquid cooling systems, on the other hand, offer improved thermal management but come with their own set of environmental challenges. The use of coolants, particularly those containing harmful chemicals, poses risks of leakage and contamination. Proper disposal of these coolants at the end of the system's lifecycle is crucial to prevent soil and water pollution. Additionally, the manufacturing and transportation of specialized cooling components contribute to the carbon footprint of the solar inverter.

Passive cooling techniques, such as heat sinks and phase change materials, present a more environmentally friendly approach. These methods require no additional energy input and have minimal maintenance needs, reducing long-term environmental impact. However, their effectiveness may be limited in extreme temperature conditions, potentially affecting the inverter's performance and lifespan.

The choice of materials for cooling systems also plays a significant role in environmental impact. The use of recyclable or biodegradable materials in heat sinks and enclosures can greatly reduce the end-of-life environmental burden. Moreover, the adoption of natural cooling methods, such as geothermal heat exchange or ambient air cooling in suitable climates, can further minimize the ecological footprint of solar inverter installations.

As the solar energy industry continues to grow, the cumulative environmental impact of inverter cooling methods becomes increasingly significant. Innovations in this area must focus on developing solutions that not only enhance thermal management but also align with sustainable practices. This includes exploring advanced materials with superior thermal properties, optimizing system designs for natural convection, and integrating smart cooling technologies that adapt to environmental conditions to minimize energy consumption.

The environmental impact assessment of cooling methods should also consider the entire lifecycle of the solar inverter system, from production to decommissioning. This holistic approach ensures that improvements in one area do not lead to unintended consequences in another, ultimately contributing to the overall sustainability of solar energy technology.

Cost-Efficiency Analysis of Thermal Management Solutions

The cost-efficiency analysis of thermal management solutions for solar inverters is a critical aspect of innovation in this field. Traditional cooling methods, such as forced air cooling and liquid cooling, have been widely used but often come with significant costs and energy consumption. A comprehensive analysis reveals that passive cooling techniques, such as heat sinks and phase change materials, offer a more cost-effective approach in many scenarios.

Heat sinks, for instance, provide a simple and low-maintenance solution. Their initial cost is relatively low, and they require no additional energy input during operation. However, their effectiveness can be limited in high-temperature environments or for high-power inverters. Advanced heat sink designs, incorporating optimized fin structures and high-conductivity materials like aluminum or copper, can improve performance while maintaining cost-effectiveness.

Phase change materials (PCMs) present an innovative approach to thermal management. These materials absorb excess heat during peak operation and release it during cooler periods, effectively smoothing out temperature fluctuations. While the initial investment in PCMs may be higher than traditional heat sinks, their long-term cost-efficiency is notable due to improved inverter lifespan and reduced maintenance needs.

Hybrid cooling solutions, combining passive and active elements, offer a balanced approach to cost-efficiency. For example, a system using heat pipes in conjunction with a small fan can provide effective cooling at a fraction of the energy cost of traditional forced air systems. The initial investment may be higher, but the reduced operational costs and improved reliability often result in a lower total cost of ownership over the inverter's lifetime.

Advanced thermal interface materials (TIMs) play a crucial role in enhancing the cost-efficiency of cooling solutions. High-performance TIMs improve heat transfer between components and cooling systems, allowing for more efficient use of cooling resources. While premium TIMs may increase initial costs, they can significantly reduce the overall cooling system requirements, leading to long-term savings.

When considering cost-efficiency, it's essential to factor in the entire lifecycle of the inverter. Solutions that may seem more expensive initially can often prove more economical over time due to improved reliability, reduced maintenance, and lower operational costs. Additionally, the environmental impact and sustainability of cooling solutions should be considered, as these factors can influence long-term costs and market acceptance.

Heat sinks, for instance, provide a simple and low-maintenance solution. Their initial cost is relatively low, and they require no additional energy input during operation. However, their effectiveness can be limited in high-temperature environments or for high-power inverters. Advanced heat sink designs, incorporating optimized fin structures and high-conductivity materials like aluminum or copper, can improve performance while maintaining cost-effectiveness.

Phase change materials (PCMs) present an innovative approach to thermal management. These materials absorb excess heat during peak operation and release it during cooler periods, effectively smoothing out temperature fluctuations. While the initial investment in PCMs may be higher than traditional heat sinks, their long-term cost-efficiency is notable due to improved inverter lifespan and reduced maintenance needs.

Hybrid cooling solutions, combining passive and active elements, offer a balanced approach to cost-efficiency. For example, a system using heat pipes in conjunction with a small fan can provide effective cooling at a fraction of the energy cost of traditional forced air systems. The initial investment may be higher, but the reduced operational costs and improved reliability often result in a lower total cost of ownership over the inverter's lifetime.

Advanced thermal interface materials (TIMs) play a crucial role in enhancing the cost-efficiency of cooling solutions. High-performance TIMs improve heat transfer between components and cooling systems, allowing for more efficient use of cooling resources. While premium TIMs may increase initial costs, they can significantly reduce the overall cooling system requirements, leading to long-term savings.

When considering cost-efficiency, it's essential to factor in the entire lifecycle of the inverter. Solutions that may seem more expensive initially can often prove more economical over time due to improved reliability, reduced maintenance, and lower operational costs. Additionally, the environmental impact and sustainability of cooling solutions should be considered, as these factors can influence long-term costs and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!