How to Innovate with Blended Cellophane Formulations?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Formulation Evolution and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and industrial applications for over a century. The evolution of cellophane formulations has been driven by the need for improved performance, sustainability, and cost-effectiveness. Initially developed in the early 1900s, cellophane's basic composition remained relatively unchanged for decades, consisting primarily of cellulose, glycerin, and water.

The objectives for innovating with blended cellophane formulations have shifted significantly over time. In the mid-20th century, the focus was on enhancing moisture resistance and mechanical strength to expand cellophane's applications in food packaging. This led to the development of coated cellophane variants, incorporating materials like nitrocellulose and polyvinyl alcohol to improve barrier properties.

As environmental concerns gained prominence in the late 20th and early 21st centuries, the objectives of cellophane formulation innovation shifted towards sustainability. Researchers began exploring bio-based additives and alternative cellulose sources to reduce the environmental impact of cellophane production. This trend has continued, with recent objectives including the development of fully biodegradable cellophane blends that maintain the material's desirable properties.

Another key objective in recent years has been the enhancement of cellophane's functional properties through blending with other materials. This includes improving its heat-sealability, printability, and compatibility with various adhesives. The goal is to create versatile cellophane formulations that can compete with synthetic plastics in a wider range of applications.

The current landscape of cellophane formulation innovation is characterized by a focus on nanotechnology and smart materials. Objectives now include the incorporation of nanoparticles to enhance barrier properties and mechanical strength, as well as the development of cellophane blends with responsive characteristics, such as color-changing indicators for food freshness.

Looking forward, the objectives for innovating with blended cellophane formulations are likely to revolve around circular economy principles. This includes developing formulations that are not only biodegradable but also easily recyclable or compostable. Additionally, there is a growing interest in cellophane blends that can be produced using waste materials or agricultural by-products, aligning with broader sustainability goals.

In conclusion, the evolution of cellophane formulations has been marked by a continuous drive for improvement, with objectives shifting from basic performance enhancements to complex, multifunctional, and environmentally conscious innovations. The future of cellophane blends lies in striking a balance between advanced functionality, sustainability, and economic viability.

The objectives for innovating with blended cellophane formulations have shifted significantly over time. In the mid-20th century, the focus was on enhancing moisture resistance and mechanical strength to expand cellophane's applications in food packaging. This led to the development of coated cellophane variants, incorporating materials like nitrocellulose and polyvinyl alcohol to improve barrier properties.

As environmental concerns gained prominence in the late 20th and early 21st centuries, the objectives of cellophane formulation innovation shifted towards sustainability. Researchers began exploring bio-based additives and alternative cellulose sources to reduce the environmental impact of cellophane production. This trend has continued, with recent objectives including the development of fully biodegradable cellophane blends that maintain the material's desirable properties.

Another key objective in recent years has been the enhancement of cellophane's functional properties through blending with other materials. This includes improving its heat-sealability, printability, and compatibility with various adhesives. The goal is to create versatile cellophane formulations that can compete with synthetic plastics in a wider range of applications.

The current landscape of cellophane formulation innovation is characterized by a focus on nanotechnology and smart materials. Objectives now include the incorporation of nanoparticles to enhance barrier properties and mechanical strength, as well as the development of cellophane blends with responsive characteristics, such as color-changing indicators for food freshness.

Looking forward, the objectives for innovating with blended cellophane formulations are likely to revolve around circular economy principles. This includes developing formulations that are not only biodegradable but also easily recyclable or compostable. Additionally, there is a growing interest in cellophane blends that can be produced using waste materials or agricultural by-products, aligning with broader sustainability goals.

In conclusion, the evolution of cellophane formulations has been marked by a continuous drive for improvement, with objectives shifting from basic performance enhancements to complex, multifunctional, and environmentally conscious innovations. The future of cellophane blends lies in striking a balance between advanced functionality, sustainability, and economic viability.

Market Analysis for Blended Cellophane Products

The market for blended cellophane products has shown significant growth potential in recent years, driven by increasing demand for sustainable packaging solutions across various industries. The global cellophane market, including blended formulations, is expected to expand at a steady rate due to its biodegradable and compostable properties, aligning with the growing consumer preference for eco-friendly packaging materials.

In the food packaging sector, blended cellophane products have gained traction due to their excellent barrier properties against moisture and gases, ensuring extended shelf life for perishable goods. The confectionery and bakery industries, in particular, have embraced these materials for their transparency and ability to maintain product freshness. Additionally, the pharmaceutical industry has shown increased interest in blended cellophane formulations for drug packaging, owing to their superior moisture resistance and compatibility with various sterilization methods.

The personal care and cosmetics sector represents another promising market for blended cellophane products. With the rising demand for sustainable packaging solutions in this industry, manufacturers are exploring innovative cellophane blends that offer both functionality and environmental benefits. These materials are being used for packaging items such as soaps, bath products, and cosmetic accessories, appealing to environmentally conscious consumers.

The textile industry has also emerged as a potential growth area for blended cellophane products. Manufacturers are exploring the use of cellophane-based fibers in fabric production, offering unique properties such as moisture-wicking and biodegradability. This trend is particularly evident in the development of sustainable fashion and technical textiles.

Geographically, Asia-Pacific is expected to be the fastest-growing market for blended cellophane products, driven by rapid industrialization, increasing population, and growing awareness of sustainable packaging solutions. North America and Europe continue to be significant markets, with stringent regulations promoting the adoption of biodegradable packaging materials.

However, the market faces challenges such as competition from other biodegradable materials like PLA (polylactic acid) and the need for continuous innovation to improve the performance characteristics of blended cellophane formulations. To address these challenges, manufacturers are investing in research and development to enhance the mechanical properties, barrier performance, and overall versatility of blended cellophane products.

In the food packaging sector, blended cellophane products have gained traction due to their excellent barrier properties against moisture and gases, ensuring extended shelf life for perishable goods. The confectionery and bakery industries, in particular, have embraced these materials for their transparency and ability to maintain product freshness. Additionally, the pharmaceutical industry has shown increased interest in blended cellophane formulations for drug packaging, owing to their superior moisture resistance and compatibility with various sterilization methods.

The personal care and cosmetics sector represents another promising market for blended cellophane products. With the rising demand for sustainable packaging solutions in this industry, manufacturers are exploring innovative cellophane blends that offer both functionality and environmental benefits. These materials are being used for packaging items such as soaps, bath products, and cosmetic accessories, appealing to environmentally conscious consumers.

The textile industry has also emerged as a potential growth area for blended cellophane products. Manufacturers are exploring the use of cellophane-based fibers in fabric production, offering unique properties such as moisture-wicking and biodegradability. This trend is particularly evident in the development of sustainable fashion and technical textiles.

Geographically, Asia-Pacific is expected to be the fastest-growing market for blended cellophane products, driven by rapid industrialization, increasing population, and growing awareness of sustainable packaging solutions. North America and Europe continue to be significant markets, with stringent regulations promoting the adoption of biodegradable packaging materials.

However, the market faces challenges such as competition from other biodegradable materials like PLA (polylactic acid) and the need for continuous innovation to improve the performance characteristics of blended cellophane formulations. To address these challenges, manufacturers are investing in research and development to enhance the mechanical properties, barrier performance, and overall versatility of blended cellophane products.

Current Challenges in Cellophane Blending Technology

The cellophane blending technology, while innovative, faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is achieving consistent blend uniformity across different batches. The heterogeneous nature of cellophane materials, coupled with variations in their physical and chemical properties, makes it difficult to maintain a uniform distribution of components in the blended formulations.

Another critical challenge lies in the compatibility issues between different types of cellophane and additives used in the blending process. The interaction between these components can lead to unexpected changes in the final product's properties, such as reduced transparency, altered mechanical strength, or compromised barrier properties. This unpredictability often results in increased production costs and quality control issues.

The processing conditions for blended cellophane formulations present another set of challenges. The temperature sensitivity of cellophane makes it susceptible to degradation during high-temperature blending processes. Balancing the need for effective mixing with the preservation of cellophane's inherent properties requires precise control over processing parameters, which can be technically demanding and energy-intensive.

Scalability remains a significant hurdle in cellophane blending technology. While laboratory-scale blending may yield promising results, translating these successes to industrial-scale production often encounters unforeseen complications. Issues such as increased processing times, equipment limitations, and the need for specialized machinery can impede the commercial viability of blended cellophane products.

Environmental concerns also pose challenges to the advancement of cellophane blending technology. The use of certain additives or processing aids may compromise the biodegradability of the final product, conflicting with the growing demand for sustainable packaging solutions. Developing eco-friendly blending techniques that maintain the desired properties of cellophane while ensuring environmental compatibility is an ongoing challenge for researchers and manufacturers alike.

Furthermore, the regulatory landscape surrounding novel cellophane formulations adds another layer of complexity. Ensuring compliance with food contact regulations, especially for packaging applications, requires extensive testing and documentation. The time and resources needed to navigate these regulatory requirements can slow down innovation and market entry for new blended cellophane products.

Lastly, the cost-effectiveness of blended cellophane formulations remains a significant challenge. The additional processing steps, specialized equipment, and potential for increased raw material costs can make blended cellophane products less economically competitive compared to traditional alternatives. Striking a balance between enhanced performance and cost-effectiveness is crucial for the commercial success of these innovative formulations.

Another critical challenge lies in the compatibility issues between different types of cellophane and additives used in the blending process. The interaction between these components can lead to unexpected changes in the final product's properties, such as reduced transparency, altered mechanical strength, or compromised barrier properties. This unpredictability often results in increased production costs and quality control issues.

The processing conditions for blended cellophane formulations present another set of challenges. The temperature sensitivity of cellophane makes it susceptible to degradation during high-temperature blending processes. Balancing the need for effective mixing with the preservation of cellophane's inherent properties requires precise control over processing parameters, which can be technically demanding and energy-intensive.

Scalability remains a significant hurdle in cellophane blending technology. While laboratory-scale blending may yield promising results, translating these successes to industrial-scale production often encounters unforeseen complications. Issues such as increased processing times, equipment limitations, and the need for specialized machinery can impede the commercial viability of blended cellophane products.

Environmental concerns also pose challenges to the advancement of cellophane blending technology. The use of certain additives or processing aids may compromise the biodegradability of the final product, conflicting with the growing demand for sustainable packaging solutions. Developing eco-friendly blending techniques that maintain the desired properties of cellophane while ensuring environmental compatibility is an ongoing challenge for researchers and manufacturers alike.

Furthermore, the regulatory landscape surrounding novel cellophane formulations adds another layer of complexity. Ensuring compliance with food contact regulations, especially for packaging applications, requires extensive testing and documentation. The time and resources needed to navigate these regulatory requirements can slow down innovation and market entry for new blended cellophane products.

Lastly, the cost-effectiveness of blended cellophane formulations remains a significant challenge. The additional processing steps, specialized equipment, and potential for increased raw material costs can make blended cellophane products less economically competitive compared to traditional alternatives. Striking a balance between enhanced performance and cost-effectiveness is crucial for the commercial success of these innovative formulations.

Existing Blended Cellophane Formulation Methods

01 Blended cellophane compositions

Various formulations of blended cellophane materials are developed to enhance properties such as strength, flexibility, and barrier characteristics. These blends may incorporate different types of cellulose derivatives or other compatible polymers to achieve desired performance characteristics for packaging and other applications.- Blended cellophane compositions: Various formulations of blended cellophane materials are developed to enhance specific properties such as strength, flexibility, or barrier characteristics. These blends may incorporate different types of cellulose or other compatible polymers to achieve desired performance attributes for packaging or industrial applications.

- Manufacturing processes for blended cellophane: Innovative manufacturing techniques are employed to produce blended cellophane formulations. These processes may involve specialized extrusion methods, solvent casting, or other novel approaches to ensure uniform blending and optimal material properties in the final product.

- Additives for enhanced cellophane properties: Various additives are incorporated into cellophane blends to improve specific characteristics such as moisture resistance, heat sealability, or biodegradability. These additives may include plasticizers, cross-linking agents, or nanoparticles to tailor the cellophane's performance for particular applications.

- Biodegradable cellophane formulations: Development of environmentally friendly cellophane blends that maintain desired functional properties while offering improved biodegradability. These formulations may incorporate natural polymers or additives that facilitate breakdown in various environmental conditions without compromising performance during use.

- Applications of blended cellophane: Exploration of novel applications for blended cellophane formulations across various industries. These may include advanced packaging solutions, electronic components, medical devices, or other specialized uses that leverage the unique properties of customized cellophane blends.

02 Manufacturing processes for blended cellophane

Innovative manufacturing techniques are employed to produce blended cellophane formulations. These processes may involve specialized extrusion methods, solution casting, or other novel approaches to ensure uniform blending and optimal properties in the final product.Expand Specific Solutions03 Additives and modifiers in cellophane blends

Various additives and modifiers are incorporated into cellophane blends to enhance specific properties. These may include plasticizers, stabilizers, colorants, or functional additives that improve moisture resistance, heat sealability, or other desired characteristics of the blended cellophane.Expand Specific Solutions04 Applications of blended cellophane formulations

Blended cellophane formulations find diverse applications in packaging, medical devices, and other industries. The tailored properties of these blends make them suitable for specific use cases, such as food packaging with enhanced barrier properties or biodegradable materials for environmentally friendly applications.Expand Specific Solutions05 Biodegradable and sustainable cellophane blends

Research focuses on developing biodegradable and sustainable blended cellophane formulations. These environmentally friendly blends may incorporate bio-based materials or be designed for improved compostability and reduced environmental impact while maintaining desired functional properties.Expand Specific Solutions

Key Industry Players in Cellophane Manufacturing

The innovation landscape for blended cellophane formulations is in a growth phase, with increasing market size driven by demand for sustainable packaging solutions. The technology is moderately mature, with established players like DuPont de Nemours and International Paper leading research and development efforts. Emerging companies such as Codexis and Novozymes are leveraging biotechnology to enhance cellophane properties. The market is characterized by a mix of large chemical corporations and specialized materials firms, indicating a competitive environment with potential for further technological advancements and market expansion.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed innovative blended cellophane formulations using their proprietary bio-based materials. Their approach involves incorporating renewable plant-based polymers into traditional cellophane to enhance biodegradability and reduce environmental impact. The company has implemented a novel extrusion process that allows for precise control of the blend ratios, resulting in films with tailored properties such as improved barrier performance and heat-sealability[1]. DuPont's formulations also include additives that enhance UV resistance and anti-static properties, expanding the potential applications of cellophane in packaging and industrial uses[2]. The company has reported a 30% reduction in fossil fuel-based content in their new cellophane blends while maintaining comparable strength and clarity to conventional products[3].

Strengths: Leverages DuPont's extensive expertise in materials science and polymer technology. Improves sustainability profile of cellophane products. Weaknesses: May face challenges in scaling up production and managing costs of bio-based materials.

International Paper Co.

Technical Solution: International Paper has developed a novel approach to blended cellophane formulations by integrating their expertise in cellulose-based materials. Their innovation focuses on creating cellophane blends that incorporate recycled cellulose fibers, improving the sustainability profile of the final product. The company has implemented a proprietary dissolution and regeneration process that allows for the incorporation of up to 30% recycled content without compromising the film's transparency or mechanical properties[7]. International Paper's formulation also includes natural plasticizers derived from plant-based sources, further enhancing the eco-friendly nature of their cellophane blends. The company has reported a 25% reduction in water consumption during the manufacturing process compared to traditional cellophane production methods[8].

Strengths: Leverages existing expertise in cellulose-based materials. Improves sustainability through the use of recycled content. Weaknesses: May face challenges in maintaining consistent quality with varying recycled material inputs.

Innovative Approaches in Cellophane Blending

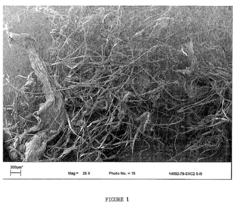

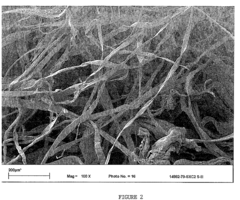

Fibrous blend and methods of preparation

PatentActiveUS7591891B2

Innovation

- A fibrous blend of mixed polymer fibers, comprising carboxyalkyl cellulose and galactomannan or glucomannan polymers, is developed, which is biodegradable, inexpensive, and reduces gel blocking by incorporating cellulose fibers, enhancing liquid wicking and retention capabilities.

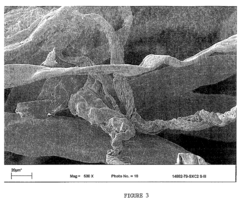

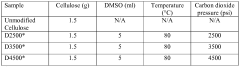

Modified cellulose, methods of manufacture thereof and articles comprising the same

PatentWO2013086111A1

Innovation

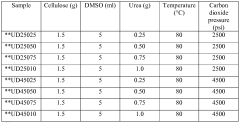

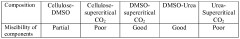

- Reducing cellulose crystallinity by mixing it with a solvent and a proppant, followed by treatment with supercritical fluids to facilitate solvation and disruption of hydrogen bonds, allowing for blending with other polymers.

Environmental Impact of Blended Cellophane Production

The environmental impact of blended cellophane production is a critical consideration in the development and innovation of this versatile packaging material. As manufacturers seek to improve the properties and performance of cellophane through blending, it is essential to evaluate the ecological consequences of these processes.

Blended cellophane formulations typically involve the incorporation of additional materials or chemicals to enhance specific characteristics such as barrier properties, strength, or flexibility. These additives can significantly alter the environmental footprint of the final product. For instance, the inclusion of synthetic polymers may improve certain functional aspects but could potentially increase the material's resistance to biodegradation.

The production process itself presents several environmental challenges. Energy consumption during manufacturing is a key concern, as the blending and extrusion of cellophane formulations often require high temperatures and specialized equipment. This energy demand contributes to greenhouse gas emissions and overall carbon footprint. Additionally, the use of solvents and other chemical agents in the blending process may lead to air and water pollution if not properly managed.

Water usage is another significant factor in the environmental impact assessment. The production of cellophane, particularly when incorporating water-soluble additives, can be water-intensive. Proper water treatment and recycling systems are crucial to minimize the strain on local water resources and prevent contamination of aquatic ecosystems.

Waste generation during production is an area that demands attention. Off-cuts, trimmings, and rejected batches of blended cellophane can accumulate, creating disposal challenges. Implementing efficient recycling and waste reduction strategies is essential to mitigate this impact. Some innovative approaches include the development of closed-loop systems where production waste is reincorporated into new batches or repurposed for other applications.

The end-of-life considerations for blended cellophane products are particularly important. While traditional cellophane is biodegradable, certain blended formulations may compromise this property. The addition of non-biodegradable components can lead to persistent environmental pollution, especially in marine environments where packaging waste often accumulates. Balancing performance enhancements with biodegradability is a key challenge for innovators in this field.

To address these environmental concerns, researchers and manufacturers are exploring various sustainable approaches. These include the use of bio-based additives, development of more energy-efficient production processes, and the creation of fully biodegradable blended formulations. Life cycle assessments are increasingly being employed to comprehensively evaluate the environmental impact of different blended cellophane formulations, from raw material extraction to disposal or recycling.

Blended cellophane formulations typically involve the incorporation of additional materials or chemicals to enhance specific characteristics such as barrier properties, strength, or flexibility. These additives can significantly alter the environmental footprint of the final product. For instance, the inclusion of synthetic polymers may improve certain functional aspects but could potentially increase the material's resistance to biodegradation.

The production process itself presents several environmental challenges. Energy consumption during manufacturing is a key concern, as the blending and extrusion of cellophane formulations often require high temperatures and specialized equipment. This energy demand contributes to greenhouse gas emissions and overall carbon footprint. Additionally, the use of solvents and other chemical agents in the blending process may lead to air and water pollution if not properly managed.

Water usage is another significant factor in the environmental impact assessment. The production of cellophane, particularly when incorporating water-soluble additives, can be water-intensive. Proper water treatment and recycling systems are crucial to minimize the strain on local water resources and prevent contamination of aquatic ecosystems.

Waste generation during production is an area that demands attention. Off-cuts, trimmings, and rejected batches of blended cellophane can accumulate, creating disposal challenges. Implementing efficient recycling and waste reduction strategies is essential to mitigate this impact. Some innovative approaches include the development of closed-loop systems where production waste is reincorporated into new batches or repurposed for other applications.

The end-of-life considerations for blended cellophane products are particularly important. While traditional cellophane is biodegradable, certain blended formulations may compromise this property. The addition of non-biodegradable components can lead to persistent environmental pollution, especially in marine environments where packaging waste often accumulates. Balancing performance enhancements with biodegradability is a key challenge for innovators in this field.

To address these environmental concerns, researchers and manufacturers are exploring various sustainable approaches. These include the use of bio-based additives, development of more energy-efficient production processes, and the creation of fully biodegradable blended formulations. Life cycle assessments are increasingly being employed to comprehensively evaluate the environmental impact of different blended cellophane formulations, from raw material extraction to disposal or recycling.

Regulatory Framework for Cellophane Innovations

The regulatory framework for cellophane innovations plays a crucial role in shaping the development and commercialization of blended cellophane formulations. As the industry explores new ways to innovate with these materials, it must navigate a complex landscape of regulations and standards.

At the forefront of regulatory considerations is the U.S. Food and Drug Administration (FDA), which oversees the use of cellophane in food packaging applications. The FDA's regulations, particularly those outlined in 21 CFR 177.1200, provide specific guidelines for the composition and manufacturing of cellophane intended for food contact. These regulations dictate the permissible raw materials, additives, and processing aids that can be used in cellophane production.

In the European Union, the European Food Safety Authority (EFSA) sets standards for food contact materials, including cellophane. The EU's Framework Regulation (EC) No 1935/2004 establishes general principles of safety and inertness for all food contact materials, while specific measures for cellophane are detailed in Commission Directive 2007/42/EC.

Environmental regulations also significantly impact cellophane innovation. As sustainability becomes increasingly important, regulations promoting biodegradability and recyclability are influencing formulation choices. The EU's Single-Use Plastics Directive, for instance, encourages the development of more environmentally friendly alternatives, potentially driving innovation in biodegradable cellophane blends.

Intellectual property regulations form another critical aspect of the regulatory framework. Patent laws in various jurisdictions provide protection for novel cellophane formulations and manufacturing processes, incentivizing innovation while also creating potential barriers to entry for new market players.

Safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, govern the manufacturing processes and workplace conditions in cellophane production facilities. These regulations ensure that new formulations and production methods meet stringent safety standards for workers and consumers alike.

As the industry moves towards more complex blended formulations, regulatory bodies are likely to adapt their frameworks to address emerging concerns. This may include new guidelines for assessing the safety and environmental impact of novel cellophane blends, as well as updated standards for testing and certification.

Innovators in the cellophane industry must therefore maintain a proactive approach to regulatory compliance, staying abreast of evolving standards and anticipating future regulatory trends. This forward-thinking stance not only ensures compliance but can also drive innovation by identifying opportunities within the regulatory framework to develop superior, more sustainable cellophane formulations.

At the forefront of regulatory considerations is the U.S. Food and Drug Administration (FDA), which oversees the use of cellophane in food packaging applications. The FDA's regulations, particularly those outlined in 21 CFR 177.1200, provide specific guidelines for the composition and manufacturing of cellophane intended for food contact. These regulations dictate the permissible raw materials, additives, and processing aids that can be used in cellophane production.

In the European Union, the European Food Safety Authority (EFSA) sets standards for food contact materials, including cellophane. The EU's Framework Regulation (EC) No 1935/2004 establishes general principles of safety and inertness for all food contact materials, while specific measures for cellophane are detailed in Commission Directive 2007/42/EC.

Environmental regulations also significantly impact cellophane innovation. As sustainability becomes increasingly important, regulations promoting biodegradability and recyclability are influencing formulation choices. The EU's Single-Use Plastics Directive, for instance, encourages the development of more environmentally friendly alternatives, potentially driving innovation in biodegradable cellophane blends.

Intellectual property regulations form another critical aspect of the regulatory framework. Patent laws in various jurisdictions provide protection for novel cellophane formulations and manufacturing processes, incentivizing innovation while also creating potential barriers to entry for new market players.

Safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, govern the manufacturing processes and workplace conditions in cellophane production facilities. These regulations ensure that new formulations and production methods meet stringent safety standards for workers and consumers alike.

As the industry moves towards more complex blended formulations, regulatory bodies are likely to adapt their frameworks to address emerging concerns. This may include new guidelines for assessing the safety and environmental impact of novel cellophane blends, as well as updated standards for testing and certification.

Innovators in the cellophane industry must therefore maintain a proactive approach to regulatory compliance, staying abreast of evolving standards and anticipating future regulatory trends. This forward-thinking stance not only ensures compliance but can also drive innovation by identifying opportunities within the regulatory framework to develop superior, more sustainable cellophane formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!