How to Manage Heat Production During Gel Electrophoresis?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gel Electrophoresis Heat Management Overview

Gel electrophoresis is a fundamental technique in molecular biology used for separating and analyzing DNA, RNA, and proteins based on their size and charge. The process involves applying an electric field to move molecules through a gel matrix. However, one of the significant challenges in this technique is managing the heat generated during the electrophoresis process.

The production of heat during gel electrophoresis is primarily due to the electrical current passing through the conductive buffer solution. This heat generation, known as Joule heating, can have detrimental effects on the separation process and the integrity of the samples being analyzed. Excessive heat can lead to band distortion, decreased resolution, and even sample degradation, particularly for sensitive biomolecules like proteins or RNA.

Effective heat management is crucial for maintaining the accuracy and reliability of gel electrophoresis results. Several strategies have been developed to address this issue. One common approach is the use of buffer systems with lower ionic strength, which reduces the current flow and, consequently, heat generation. Additionally, running gels at lower voltages or using pulsed-field gel electrophoresis can help minimize heat production.

Another important aspect of heat management is the design of electrophoresis apparatus. Modern systems often incorporate built-in cooling mechanisms, such as water jackets or Peltier-based cooling plates, to dissipate heat efficiently. These cooling systems help maintain a consistent temperature throughout the gel, preventing the formation of temperature gradients that can lead to uneven migration of molecules.

The choice of gel material and concentration also plays a role in heat management. Agarose gels, commonly used for DNA separation, have different heat dissipation properties compared to polyacrylamide gels used for protein analysis. Optimizing gel composition and concentration can contribute to better heat distribution and improved separation quality.

Monitoring and controlling the buffer temperature during the electrophoresis run is another critical factor. Some advanced systems include temperature sensors and feedback mechanisms to adjust power settings automatically, ensuring that the gel remains within an optimal temperature range throughout the separation process.

In recent years, the development of miniaturized and microfluidic electrophoresis systems has offered new possibilities for heat management. These systems typically operate with smaller volumes and have improved surface-to-volume ratios, allowing for more efficient heat dissipation. Such advancements have enabled faster separations with reduced heat-related issues, particularly beneficial for high-throughput applications.

The production of heat during gel electrophoresis is primarily due to the electrical current passing through the conductive buffer solution. This heat generation, known as Joule heating, can have detrimental effects on the separation process and the integrity of the samples being analyzed. Excessive heat can lead to band distortion, decreased resolution, and even sample degradation, particularly for sensitive biomolecules like proteins or RNA.

Effective heat management is crucial for maintaining the accuracy and reliability of gel electrophoresis results. Several strategies have been developed to address this issue. One common approach is the use of buffer systems with lower ionic strength, which reduces the current flow and, consequently, heat generation. Additionally, running gels at lower voltages or using pulsed-field gel electrophoresis can help minimize heat production.

Another important aspect of heat management is the design of electrophoresis apparatus. Modern systems often incorporate built-in cooling mechanisms, such as water jackets or Peltier-based cooling plates, to dissipate heat efficiently. These cooling systems help maintain a consistent temperature throughout the gel, preventing the formation of temperature gradients that can lead to uneven migration of molecules.

The choice of gel material and concentration also plays a role in heat management. Agarose gels, commonly used for DNA separation, have different heat dissipation properties compared to polyacrylamide gels used for protein analysis. Optimizing gel composition and concentration can contribute to better heat distribution and improved separation quality.

Monitoring and controlling the buffer temperature during the electrophoresis run is another critical factor. Some advanced systems include temperature sensors and feedback mechanisms to adjust power settings automatically, ensuring that the gel remains within an optimal temperature range throughout the separation process.

In recent years, the development of miniaturized and microfluidic electrophoresis systems has offered new possibilities for heat management. These systems typically operate with smaller volumes and have improved surface-to-volume ratios, allowing for more efficient heat dissipation. Such advancements have enabled faster separations with reduced heat-related issues, particularly beneficial for high-throughput applications.

Market Demand for Efficient Electrophoresis Systems

The market demand for efficient electrophoresis systems has been steadily growing, driven by the increasing need for precise and rapid separation of biomolecules in various fields of life sciences. Gel electrophoresis, particularly, has become an indispensable technique in molecular biology, genetics, and biochemistry research. As the complexity of biological samples and the demand for high-throughput analysis continue to rise, there is a growing emphasis on developing electrophoresis systems that can manage heat production effectively.

The global electrophoresis market has been experiencing significant growth, with a projected compound annual growth rate (CAGR) of over 5% in the coming years. This growth is primarily fueled by the expanding applications of electrophoresis in proteomics, genomics, and clinical diagnostics. The pharmaceutical and biotechnology industries, in particular, are major contributors to this market expansion, as they rely heavily on electrophoresis techniques for drug discovery and development processes.

One of the key drivers for efficient electrophoresis systems is the need for improved resolution and faster separation times. Researchers and clinicians are constantly seeking ways to enhance the quality of their results while reducing the time required for analysis. This demand has led to the development of advanced electrophoresis systems that can operate at higher voltages and currents, which in turn necessitates better heat management solutions.

The academic and research sector represents a significant portion of the market demand for efficient electrophoresis systems. Universities, research institutions, and government laboratories require state-of-the-art equipment to conduct cutting-edge research in fields such as molecular biology, genetics, and biochemistry. These institutions often seek systems that offer flexibility, reliability, and the ability to handle a wide range of sample types and sizes.

In the clinical diagnostics sector, there is a growing demand for electrophoresis systems that can provide rapid and accurate results for patient samples. Hospitals and diagnostic laboratories require systems that can efficiently manage heat production to ensure consistent and reliable results, especially when dealing with time-sensitive analyses. This has led to an increased focus on developing electrophoresis systems with advanced cooling mechanisms and temperature control features.

The biotechnology and pharmaceutical industries are also driving the demand for efficient electrophoresis systems. These sectors require high-throughput systems that can handle large numbers of samples while maintaining accuracy and reproducibility. The ability to manage heat production effectively is crucial in these applications, as it directly impacts the quality and reliability of the results obtained during drug development and quality control processes.

As the field of personalized medicine continues to advance, there is an emerging market for portable and miniaturized electrophoresis systems. These systems need to be capable of performing rapid and accurate analyses in point-of-care settings, which presents unique challenges in terms of heat management. The demand for such systems is expected to grow significantly in the coming years, particularly in regions with limited access to centralized laboratory facilities.

The global electrophoresis market has been experiencing significant growth, with a projected compound annual growth rate (CAGR) of over 5% in the coming years. This growth is primarily fueled by the expanding applications of electrophoresis in proteomics, genomics, and clinical diagnostics. The pharmaceutical and biotechnology industries, in particular, are major contributors to this market expansion, as they rely heavily on electrophoresis techniques for drug discovery and development processes.

One of the key drivers for efficient electrophoresis systems is the need for improved resolution and faster separation times. Researchers and clinicians are constantly seeking ways to enhance the quality of their results while reducing the time required for analysis. This demand has led to the development of advanced electrophoresis systems that can operate at higher voltages and currents, which in turn necessitates better heat management solutions.

The academic and research sector represents a significant portion of the market demand for efficient electrophoresis systems. Universities, research institutions, and government laboratories require state-of-the-art equipment to conduct cutting-edge research in fields such as molecular biology, genetics, and biochemistry. These institutions often seek systems that offer flexibility, reliability, and the ability to handle a wide range of sample types and sizes.

In the clinical diagnostics sector, there is a growing demand for electrophoresis systems that can provide rapid and accurate results for patient samples. Hospitals and diagnostic laboratories require systems that can efficiently manage heat production to ensure consistent and reliable results, especially when dealing with time-sensitive analyses. This has led to an increased focus on developing electrophoresis systems with advanced cooling mechanisms and temperature control features.

The biotechnology and pharmaceutical industries are also driving the demand for efficient electrophoresis systems. These sectors require high-throughput systems that can handle large numbers of samples while maintaining accuracy and reproducibility. The ability to manage heat production effectively is crucial in these applications, as it directly impacts the quality and reliability of the results obtained during drug development and quality control processes.

As the field of personalized medicine continues to advance, there is an emerging market for portable and miniaturized electrophoresis systems. These systems need to be capable of performing rapid and accurate analyses in point-of-care settings, which presents unique challenges in terms of heat management. The demand for such systems is expected to grow significantly in the coming years, particularly in regions with limited access to centralized laboratory facilities.

Current Challenges in Heat Control During Electrophoresis

Gel electrophoresis is a fundamental technique in molecular biology, but it faces significant challenges in heat control during operation. The primary issue stems from the Joule heating effect, where electrical current passing through the gel matrix generates heat. This heat production can lead to several problems that compromise the integrity and reliability of the electrophoresis process.

One of the main challenges is maintaining a uniform temperature across the gel. Uneven heat distribution can cause "smile effects" or distorted band patterns, reducing the accuracy of DNA or protein separation. The center of the gel often experiences higher temperatures than the edges, leading to inconsistent migration rates and potentially inaccurate size estimations of biomolecules.

Another critical challenge is preventing excessive overall temperature rise. High temperatures can denature proteins, melt DNA, and alter the physical properties of the gel matrix. This not only affects the separation quality but can also lead to complete failure of the experiment. In extreme cases, overheating can cause the gel to melt or break, resulting in loss of samples and time.

The buffer system used in electrophoresis also presents heat-related challenges. As the buffer heats up, its conductivity changes, potentially altering the electric field and affecting the migration of molecules. Moreover, excessive heat can cause buffer evaporation, leading to changes in concentration and pH, which further impacts the separation process.

Controlling heat production becomes even more challenging when working with high-percentage gels or when applying high voltages to achieve faster separation. These conditions inherently generate more heat, pushing the limits of traditional cooling methods. Balancing the need for rapid separation with effective heat management is a constant struggle for researchers.

The physical design of electrophoresis apparatus also contributes to heat control difficulties. Many systems have limited heat dissipation capabilities, relying primarily on the surrounding air or simple water baths for cooling. This passive approach often falls short in maintaining optimal temperature conditions, especially during extended run times or when processing multiple gels simultaneously.

Addressing these challenges requires innovative approaches to heat management. Some potential solutions include developing more efficient cooling systems, optimizing buffer compositions for better heat dissipation, and designing new gel materials with improved thermal properties. However, each of these solutions comes with its own set of technical and practical hurdles, highlighting the complexity of the heat control problem in gel electrophoresis.

One of the main challenges is maintaining a uniform temperature across the gel. Uneven heat distribution can cause "smile effects" or distorted band patterns, reducing the accuracy of DNA or protein separation. The center of the gel often experiences higher temperatures than the edges, leading to inconsistent migration rates and potentially inaccurate size estimations of biomolecules.

Another critical challenge is preventing excessive overall temperature rise. High temperatures can denature proteins, melt DNA, and alter the physical properties of the gel matrix. This not only affects the separation quality but can also lead to complete failure of the experiment. In extreme cases, overheating can cause the gel to melt or break, resulting in loss of samples and time.

The buffer system used in electrophoresis also presents heat-related challenges. As the buffer heats up, its conductivity changes, potentially altering the electric field and affecting the migration of molecules. Moreover, excessive heat can cause buffer evaporation, leading to changes in concentration and pH, which further impacts the separation process.

Controlling heat production becomes even more challenging when working with high-percentage gels or when applying high voltages to achieve faster separation. These conditions inherently generate more heat, pushing the limits of traditional cooling methods. Balancing the need for rapid separation with effective heat management is a constant struggle for researchers.

The physical design of electrophoresis apparatus also contributes to heat control difficulties. Many systems have limited heat dissipation capabilities, relying primarily on the surrounding air or simple water baths for cooling. This passive approach often falls short in maintaining optimal temperature conditions, especially during extended run times or when processing multiple gels simultaneously.

Addressing these challenges requires innovative approaches to heat management. Some potential solutions include developing more efficient cooling systems, optimizing buffer compositions for better heat dissipation, and designing new gel materials with improved thermal properties. However, each of these solutions comes with its own set of technical and practical hurdles, highlighting the complexity of the heat control problem in gel electrophoresis.

Existing Heat Management Solutions for Gel Electrophoresis

01 Heat generation in gel electrophoresis systems

Gel electrophoresis systems generate heat during operation due to electrical current passing through the gel. This heat production can affect the separation of molecules and the overall performance of the system. Various methods and designs are employed to manage and dissipate this heat to maintain optimal conditions for electrophoresis.- Heat management in gel electrophoresis systems: Gel electrophoresis systems often generate heat during operation, which can affect the separation of molecules. Various methods are employed to manage and dissipate this heat, including cooling systems, temperature control mechanisms, and buffer circulation. Effective heat management is crucial for maintaining the integrity of samples and ensuring accurate results.

- Temperature-controlled electrophoresis devices: Specialized electrophoresis devices incorporate temperature control features to regulate heat production during the separation process. These devices may include Peltier elements, thermostats, or other cooling mechanisms to maintain optimal temperature conditions. Temperature control helps prevent sample degradation and improves the resolution of separated molecules.

- Buffer systems for heat reduction: The composition and circulation of buffer solutions play a significant role in heat management during gel electrophoresis. Specialized buffer systems are designed to minimize heat generation and facilitate heat dissipation. Continuous buffer circulation or the use of low-conductivity buffers can help reduce overall heat production in the system.

- Gel composition and heat dissipation: The composition and structure of the gel matrix can influence heat production and dissipation during electrophoresis. Researchers develop gels with improved thermal properties to enhance heat transfer and maintain consistent temperatures across the gel. These advancements contribute to better separation quality and reduced thermal gradients.

- Power supply and voltage regulation for heat control: Advanced power supply systems and voltage regulation techniques are employed to minimize heat generation during gel electrophoresis. Pulsed field gel electrophoresis and other voltage modulation methods can help reduce overall heat production while maintaining effective separation of molecules. These approaches contribute to improved temperature stability and sample integrity.

02 Temperature control mechanisms in electrophoresis devices

Electrophoresis devices incorporate temperature control mechanisms to regulate heat production and maintain consistent conditions. These mechanisms may include cooling systems, heat sinks, or temperature sensors to monitor and adjust the temperature during the electrophoresis process, ensuring accurate and reproducible results.Expand Specific Solutions03 Buffer circulation and heat dissipation

Buffer circulation systems are used in gel electrophoresis to help dissipate heat and maintain uniform temperature throughout the gel. These systems may involve pumps or other mechanisms to circulate the buffer solution, which aids in heat removal and ensures consistent separation conditions across the gel.Expand Specific Solutions04 Gel composition and heat management

The composition of the gel used in electrophoresis can affect heat production and dissipation. Researchers develop and optimize gel formulations to improve heat management, enhance separation efficiency, and maintain gel integrity under various electrophoresis conditions.Expand Specific Solutions05 Power supply and heat generation control

Advanced power supply systems for gel electrophoresis are designed to control heat generation by regulating the applied voltage and current. These systems may incorporate pulsed or gradient voltage applications to minimize heat production while maintaining effective separation of molecules.Expand Specific Solutions

Key Players in Electrophoresis Equipment Industry

The management of heat production during gel electrophoresis is a critical issue in the mature field of molecular biology. The market for electrophoresis equipment and supplies is substantial, with key players like Life Technologies Corp., Bio-Rad Laboratories, and Sage Science dominating the landscape. These companies offer advanced solutions to address thermal challenges, indicating a high level of technological maturity. The industry is in a consolidation phase, with established firms continually innovating to maintain their market positions. Emerging players like Helena Laboratories and Hitachi High-Tech America are also contributing to the competitive dynamics, driving further advancements in heat management techniques for gel electrophoresis.

Life Technologies Corp.

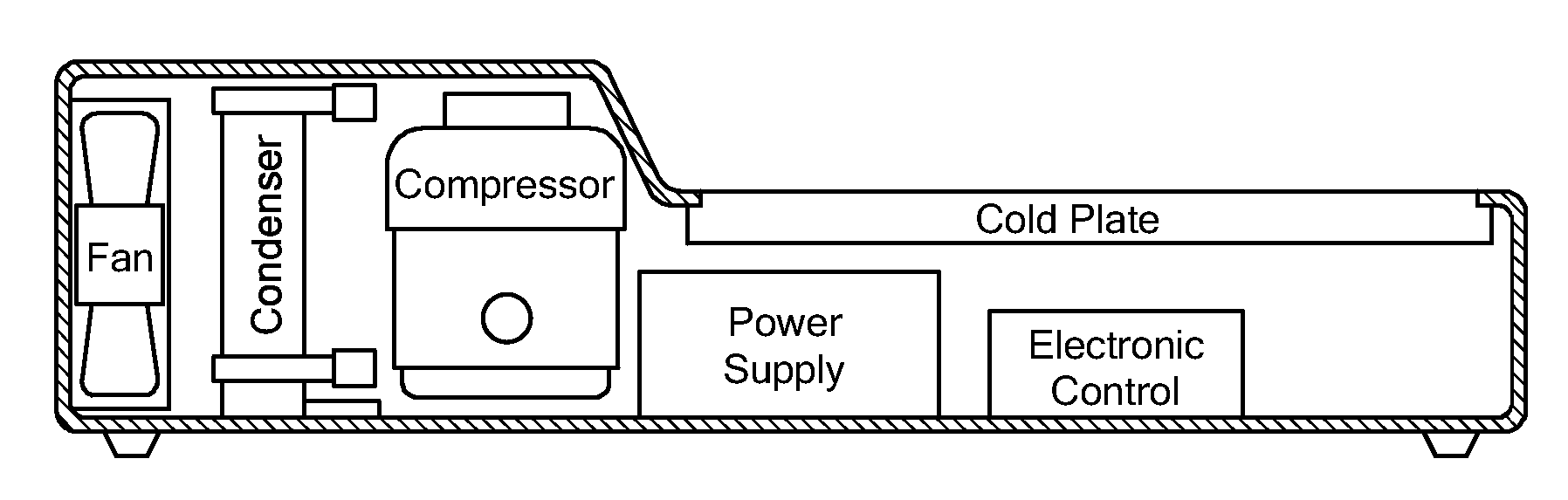

Technical Solution: Life Technologies (now part of Thermo Fisher Scientific) has developed innovative solutions for managing heat production in gel electrophoresis. Their systems incorporate a combination of passive and active cooling technologies to maintain optimal temperature conditions. The company's approach includes the use of high-thermal conductivity materials in the gel chamber construction to enhance heat dissipation[11]. Life Technologies has also implemented a buffer recirculation system that continuously cycles cooled buffer through the gel, effectively removing excess heat. Additionally, their systems feature programmable pulsed-field electrophoresis capabilities, allowing for intermittent cooling periods during long runs[12].

Strengths: Combination of passive and active cooling, versatile for various applications, and programmable run conditions. Weaknesses: Potential complexity for basic users, may require specialized buffers or consumables.

Bio-Rad Laboratories, Inc.

Technical Solution: Bio-Rad has developed advanced gel electrophoresis systems with integrated heat management solutions. Their systems utilize Peltier-based cooling technology to maintain precise temperature control during electrophoresis runs[1]. The company's innovative approach includes a buffer circulation system that continuously pumps cooled buffer through the gel chamber, effectively dissipating heat generated during the process[2]. Additionally, Bio-Rad has implemented adaptive power modulation algorithms that adjust the applied voltage based on real-time temperature measurements, preventing overheating while maintaining optimal separation conditions[3].

Strengths: Precise temperature control, efficient heat dissipation, and adaptive power management. Weaknesses: Higher cost compared to basic systems, potential complexity for novice users.

Innovative Approaches to Electrophoresis Heat Dissipation

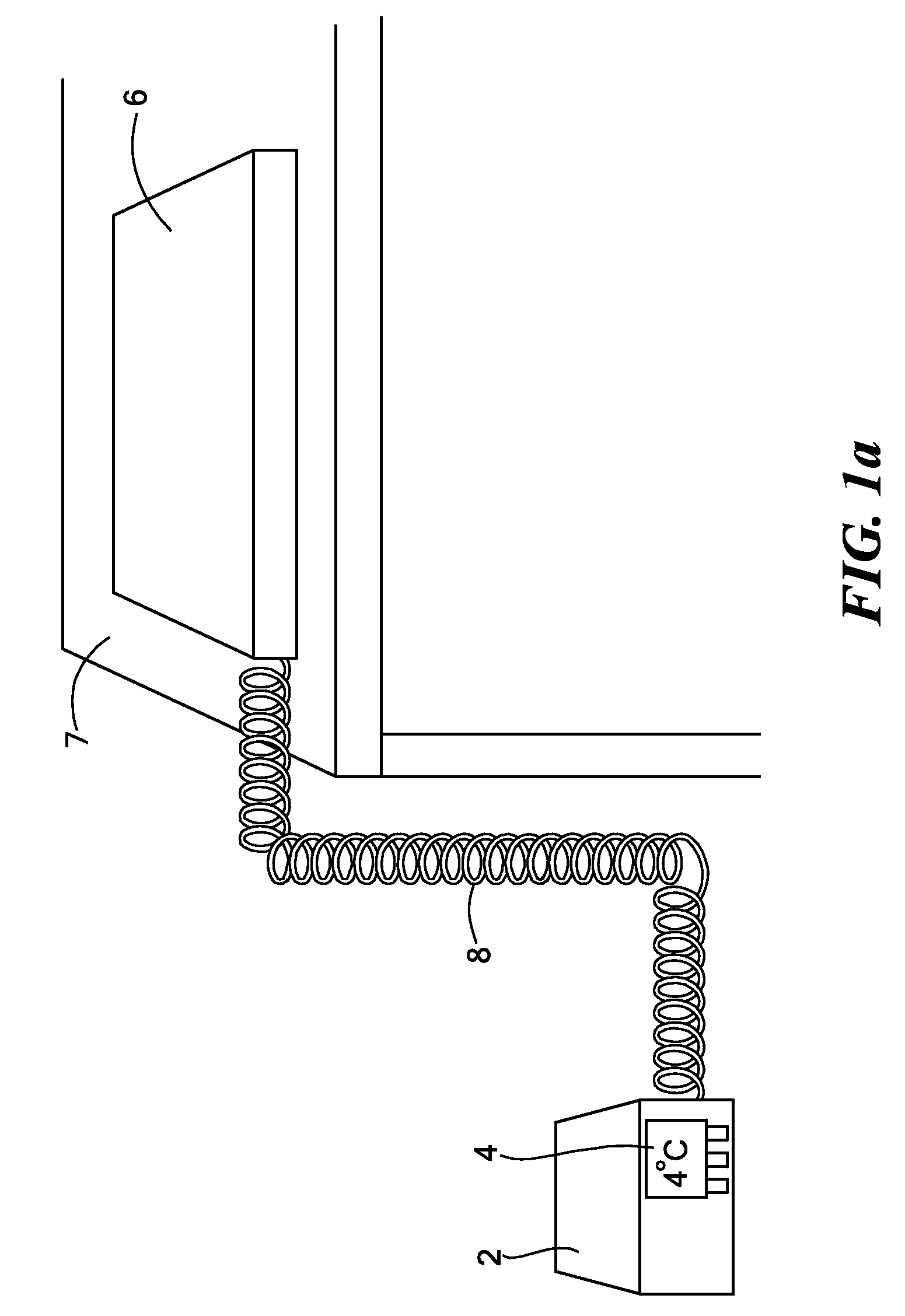

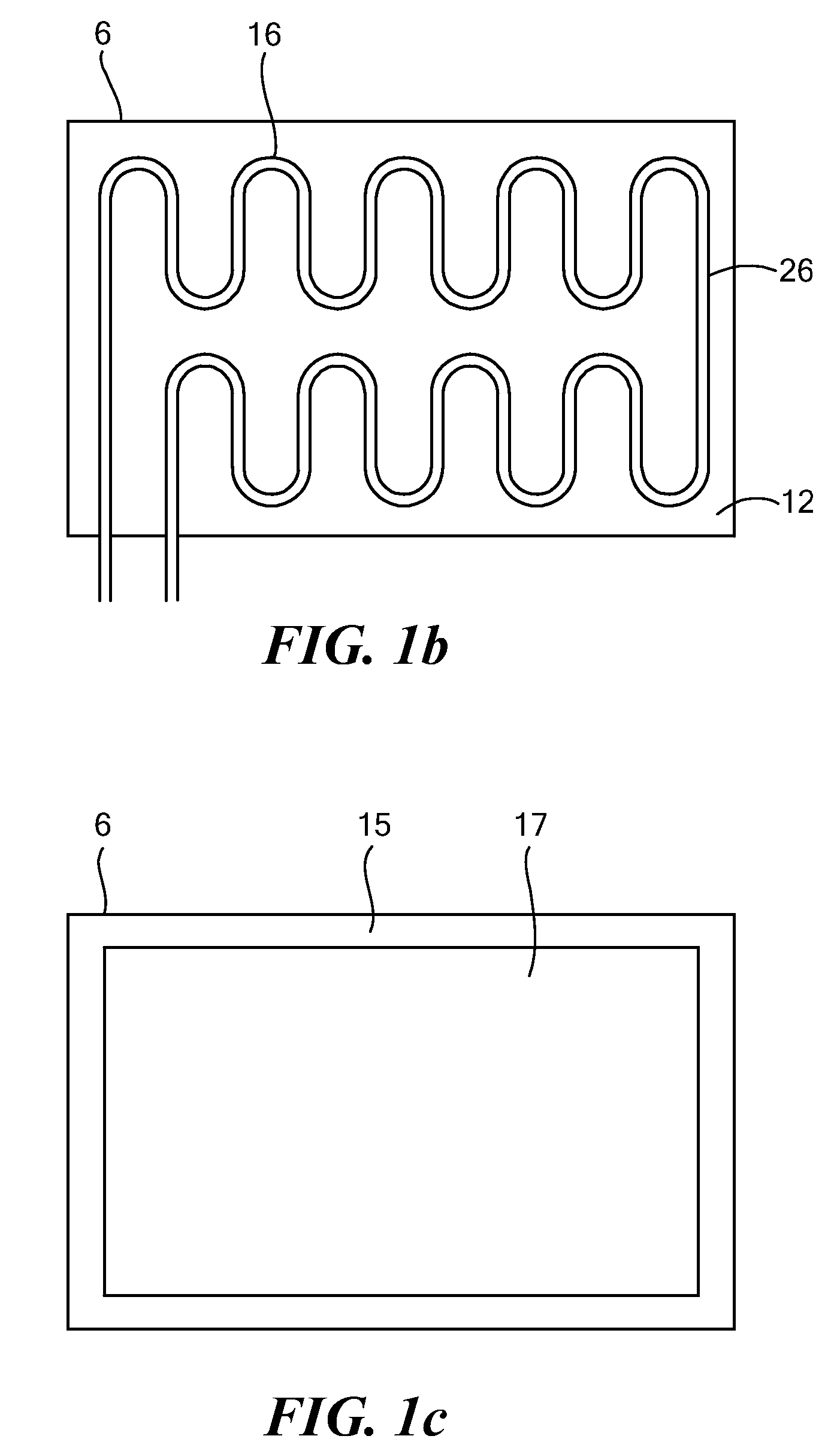

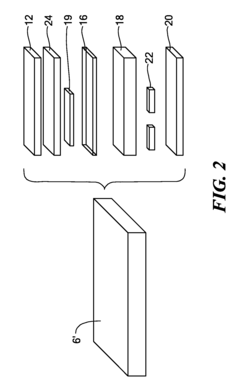

Laboratory Temperature Control With Ultra-Smooth Heat Transfer Surfaces

PatentInactiveUS20080029248A1

Innovation

- A temperature regulation system with a polished surface of low emissivity, integrated with a miniature rotary compressor and a refrigeration assembly, which circulates coolant fluid to efficiently transfer heat away from the electrophoresis buffer, maintaining a stable temperature and allowing higher voltage applications.

Multi-capillary electrophoresis apparatus

PatentInactiveUS7005053B2

Innovation

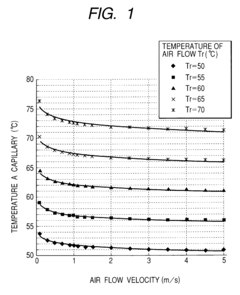

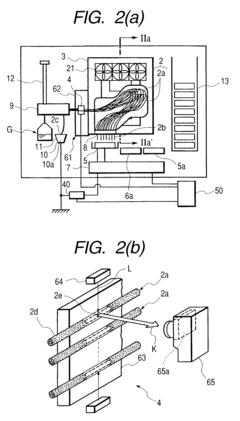

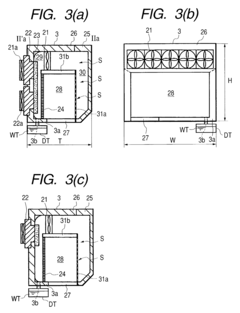

- A multi-capillary electrophoresis apparatus with a thermostat oven and air blower system, utilizing a straightening plate to ensure uniform air flow velocity and direction around the capillary array, which suppresses temperature differences and prevents vortex flow, thereby maintaining consistent temperature across all capillaries.

Safety Considerations in Electrophoresis Heat Control

Safety considerations in electrophoresis heat control are paramount to ensure the integrity of experiments and the well-being of laboratory personnel. The primary concern stems from the significant heat generation during gel electrophoresis, which can lead to various hazards if not properly managed. One of the most critical safety aspects is the prevention of buffer overheating, which can cause rapid evaporation and potential spills of hot liquid. To mitigate this risk, it is essential to monitor buffer temperature continuously and implement cooling systems when necessary.

Electrical safety is another crucial consideration in heat control during gel electrophoresis. The high voltages used in the process can pose serious risks of electric shock if equipment is not properly insulated or if there are any leaks in the system. Regular maintenance and inspection of electrophoresis apparatus, power supplies, and connecting cables are vital to prevent electrical accidents. Additionally, the use of ground fault circuit interrupters (GFCIs) can provide an extra layer of protection against electrical hazards.

The potential for burns from hot surfaces is a significant concern that requires attention. Buffer chambers, gel casting trays, and other components can become extremely hot during extended runs. Implementing clear warning signs and providing heat-resistant gloves for handling equipment can help prevent accidental burns. Moreover, allowing sufficient cooling time before attempting to remove or manipulate gels is essential to avoid injuries.

Proper ventilation is crucial in managing heat and potential fumes generated during electrophoresis. Adequate airflow helps dissipate heat and removes any potentially harmful vapors that may be produced. In some cases, the use of fume hoods or local exhaust systems may be necessary, especially when working with certain staining or visualization techniques that involve volatile chemicals.

Training and education play a vital role in ensuring safety during electrophoresis heat control. All laboratory personnel should be thoroughly instructed on the proper use of equipment, recognition of potential hazards, and appropriate emergency procedures. This includes understanding the importance of not leaving electrophoresis runs unattended for extended periods and knowing how to respond to equipment malfunctions or overheating incidents.

Implementing a comprehensive safety protocol that addresses heat management in gel electrophoresis is essential. This should include regular equipment checks, proper documentation of maintenance and incidents, and clear guidelines for safe operation. By prioritizing these safety considerations, laboratories can minimize risks associated with heat production during gel electrophoresis, ensuring a safer working environment and more reliable experimental results.

Electrical safety is another crucial consideration in heat control during gel electrophoresis. The high voltages used in the process can pose serious risks of electric shock if equipment is not properly insulated or if there are any leaks in the system. Regular maintenance and inspection of electrophoresis apparatus, power supplies, and connecting cables are vital to prevent electrical accidents. Additionally, the use of ground fault circuit interrupters (GFCIs) can provide an extra layer of protection against electrical hazards.

The potential for burns from hot surfaces is a significant concern that requires attention. Buffer chambers, gel casting trays, and other components can become extremely hot during extended runs. Implementing clear warning signs and providing heat-resistant gloves for handling equipment can help prevent accidental burns. Moreover, allowing sufficient cooling time before attempting to remove or manipulate gels is essential to avoid injuries.

Proper ventilation is crucial in managing heat and potential fumes generated during electrophoresis. Adequate airflow helps dissipate heat and removes any potentially harmful vapors that may be produced. In some cases, the use of fume hoods or local exhaust systems may be necessary, especially when working with certain staining or visualization techniques that involve volatile chemicals.

Training and education play a vital role in ensuring safety during electrophoresis heat control. All laboratory personnel should be thoroughly instructed on the proper use of equipment, recognition of potential hazards, and appropriate emergency procedures. This includes understanding the importance of not leaving electrophoresis runs unattended for extended periods and knowing how to respond to equipment malfunctions or overheating incidents.

Implementing a comprehensive safety protocol that addresses heat management in gel electrophoresis is essential. This should include regular equipment checks, proper documentation of maintenance and incidents, and clear guidelines for safe operation. By prioritizing these safety considerations, laboratories can minimize risks associated with heat production during gel electrophoresis, ensuring a safer working environment and more reliable experimental results.

Environmental Impact of Cooling Systems in Laboratories

The environmental impact of cooling systems in laboratories, particularly those used in gel electrophoresis, is a growing concern in the scientific community. These systems, while essential for managing heat production during experiments, can have significant ecological consequences. Traditional cooling methods often rely on energy-intensive processes and refrigerants that contribute to greenhouse gas emissions and climate change.

One of the primary environmental issues associated with laboratory cooling systems is their high energy consumption. Gel electrophoresis equipment requires constant temperature control to maintain optimal conditions for DNA separation. This continuous cooling demand leads to increased electricity usage, which, depending on the energy source, can result in substantial carbon emissions. In regions where electricity is primarily generated from fossil fuels, the carbon footprint of these cooling systems becomes even more pronounced.

Water consumption is another critical environmental factor to consider. Many cooling systems in laboratories use water as a heat transfer medium. This not only depletes local water resources but also raises concerns about water pollution when chemicals or biological materials contaminate the cooling water. Proper treatment and disposal of this water add another layer of environmental responsibility and potential impact.

The use of refrigerants in cooling systems presents additional environmental challenges. Many older systems still utilize hydrofluorocarbons (HFCs) or other synthetic refrigerants that have high global warming potential. While efforts are being made to phase out these substances, their continued use in existing laboratory equipment contributes to ozone depletion and climate change.

Noise pollution is an often-overlooked environmental impact of laboratory cooling systems. The constant operation of compressors and fans can create significant noise levels, affecting both the immediate laboratory environment and potentially the surrounding areas. This can have negative effects on wildlife and human well-being in nearby communities.

As laboratories strive for sustainability, there is a growing focus on developing more environmentally friendly cooling solutions. This includes the adoption of energy-efficient technologies, such as variable speed compressors and smart temperature control systems. Some facilities are exploring alternative cooling methods, like geothermal systems or the use of waste heat recovery, to reduce their environmental footprint.

The disposal of cooling equipment at the end of its lifecycle also poses environmental challenges. Many components contain hazardous materials that require special handling and recycling procedures. Improper disposal can lead to soil and water contamination, highlighting the need for comprehensive lifecycle management of laboratory equipment.

One of the primary environmental issues associated with laboratory cooling systems is their high energy consumption. Gel electrophoresis equipment requires constant temperature control to maintain optimal conditions for DNA separation. This continuous cooling demand leads to increased electricity usage, which, depending on the energy source, can result in substantial carbon emissions. In regions where electricity is primarily generated from fossil fuels, the carbon footprint of these cooling systems becomes even more pronounced.

Water consumption is another critical environmental factor to consider. Many cooling systems in laboratories use water as a heat transfer medium. This not only depletes local water resources but also raises concerns about water pollution when chemicals or biological materials contaminate the cooling water. Proper treatment and disposal of this water add another layer of environmental responsibility and potential impact.

The use of refrigerants in cooling systems presents additional environmental challenges. Many older systems still utilize hydrofluorocarbons (HFCs) or other synthetic refrigerants that have high global warming potential. While efforts are being made to phase out these substances, their continued use in existing laboratory equipment contributes to ozone depletion and climate change.

Noise pollution is an often-overlooked environmental impact of laboratory cooling systems. The constant operation of compressors and fans can create significant noise levels, affecting both the immediate laboratory environment and potentially the surrounding areas. This can have negative effects on wildlife and human well-being in nearby communities.

As laboratories strive for sustainability, there is a growing focus on developing more environmentally friendly cooling solutions. This includes the adoption of energy-efficient technologies, such as variable speed compressors and smart temperature control systems. Some facilities are exploring alternative cooling methods, like geothermal systems or the use of waste heat recovery, to reduce their environmental footprint.

The disposal of cooling equipment at the end of its lifecycle also poses environmental challenges. Many components contain hazardous materials that require special handling and recycling procedures. Improper disposal can lead to soil and water contamination, highlighting the need for comprehensive lifecycle management of laboratory equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!