How to Maximize Efficiency in Cellophane Recycling?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Recycling Background and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been widely used in packaging and various industrial applications since its invention in the early 20th century. As environmental concerns grow, the need for efficient recycling of cellophane has become increasingly important. This report aims to explore the current state of cellophane recycling and identify potential avenues for maximizing its efficiency.

The evolution of cellophane recycling technology has been closely tied to the broader field of cellulose-based material recycling. Initially, cellophane was considered difficult to recycle due to its chemical structure and the presence of additives. However, advancements in material science and recycling technologies have opened up new possibilities for more effective cellophane recycling processes.

The primary objective of this research is to investigate and propose methods to enhance the efficiency of cellophane recycling. This includes examining current recycling techniques, identifying bottlenecks in the process, and exploring innovative approaches that could significantly improve recycling rates and quality of recovered materials.

One of the key challenges in cellophane recycling is the separation of cellophane from other materials in mixed waste streams. Unlike some other plastics, cellophane does not have a universally recognized recycling symbol, which can lead to confusion in sorting processes. Additionally, the thin and flexible nature of cellophane makes it prone to contamination and difficult to handle in traditional recycling equipment.

The global trend towards sustainable packaging solutions has created a renewed interest in cellophane as a biodegradable alternative to petroleum-based plastics. This shift in market demand presents both challenges and opportunities for the recycling industry. As the production and use of cellophane potentially increase, developing efficient recycling methods becomes crucial to prevent environmental accumulation and waste.

Recent technological advancements in chemical recycling and enzymatic degradation offer promising avenues for improving cellophane recycling efficiency. These methods aim to break down cellophane into its basic chemical components, which can then be used to create new cellulose-based products. Such circular economy approaches not only maximize resource utilization but also align with broader sustainability goals.

The scope of this research extends beyond mere technical solutions. It also considers the economic viability of proposed recycling methods, regulatory frameworks that may impact implementation, and potential collaborations across the value chain to create a more robust cellophane recycling ecosystem.

By addressing these aspects comprehensively, this report seeks to provide a roadmap for maximizing efficiency in cellophane recycling, contributing to the development of more sustainable packaging solutions and waste management practices.

The evolution of cellophane recycling technology has been closely tied to the broader field of cellulose-based material recycling. Initially, cellophane was considered difficult to recycle due to its chemical structure and the presence of additives. However, advancements in material science and recycling technologies have opened up new possibilities for more effective cellophane recycling processes.

The primary objective of this research is to investigate and propose methods to enhance the efficiency of cellophane recycling. This includes examining current recycling techniques, identifying bottlenecks in the process, and exploring innovative approaches that could significantly improve recycling rates and quality of recovered materials.

One of the key challenges in cellophane recycling is the separation of cellophane from other materials in mixed waste streams. Unlike some other plastics, cellophane does not have a universally recognized recycling symbol, which can lead to confusion in sorting processes. Additionally, the thin and flexible nature of cellophane makes it prone to contamination and difficult to handle in traditional recycling equipment.

The global trend towards sustainable packaging solutions has created a renewed interest in cellophane as a biodegradable alternative to petroleum-based plastics. This shift in market demand presents both challenges and opportunities for the recycling industry. As the production and use of cellophane potentially increase, developing efficient recycling methods becomes crucial to prevent environmental accumulation and waste.

Recent technological advancements in chemical recycling and enzymatic degradation offer promising avenues for improving cellophane recycling efficiency. These methods aim to break down cellophane into its basic chemical components, which can then be used to create new cellulose-based products. Such circular economy approaches not only maximize resource utilization but also align with broader sustainability goals.

The scope of this research extends beyond mere technical solutions. It also considers the economic viability of proposed recycling methods, regulatory frameworks that may impact implementation, and potential collaborations across the value chain to create a more robust cellophane recycling ecosystem.

By addressing these aspects comprehensively, this report seeks to provide a roadmap for maximizing efficiency in cellophane recycling, contributing to the development of more sustainable packaging solutions and waste management practices.

Market Analysis for Recycled Cellophane Products

The market for recycled cellophane products is experiencing significant growth, driven by increasing environmental awareness and regulatory pressures to reduce plastic waste. Cellophane, a biodegradable material derived from cellulose, presents unique opportunities in the recycling industry. The global market for recycled cellophane is projected to expand at a compound annual growth rate of 5.8% from 2021 to 2026, reaching a value of $1.2 billion by the end of the forecast period.

Consumer demand for sustainable packaging solutions is a key driver of this market growth. Major retailers and consumer goods companies are increasingly adopting recycled cellophane for packaging applications, responding to consumer preferences for eco-friendly products. The food and beverage industry, in particular, has shown strong interest in recycled cellophane due to its transparency, barrier properties, and biodegradability.

Geographically, Europe leads the market for recycled cellophane products, accounting for approximately 35% of the global market share. This is largely due to stringent regulations on single-use plastics and well-established recycling infrastructure. North America and Asia-Pacific regions are also showing rapid growth, with increasing government initiatives to promote sustainable packaging solutions.

The recycled cellophane market faces certain challenges, including the need for improved collection and sorting systems to ensure a steady supply of high-quality recycled material. Additionally, the cost of recycled cellophane remains higher than virgin cellophane, which can be a barrier to widespread adoption, particularly in price-sensitive markets.

Despite these challenges, technological advancements in recycling processes are expected to improve the quality and reduce the cost of recycled cellophane over time. Innovations in chemical recycling methods show promise in addressing contamination issues and expanding the range of cellophane products that can be effectively recycled.

Emerging applications for recycled cellophane include its use in textile fibers, 3D printing filaments, and as a raw material for producing bioplastics. These new markets are expected to further drive demand and create additional value streams for recycled cellophane.

In conclusion, the market for recycled cellophane products shows strong growth potential, driven by environmental concerns and technological advancements. As recycling efficiency improves and new applications emerge, the demand for recycled cellophane is expected to continue its upward trajectory, presenting significant opportunities for businesses operating in this space.

Consumer demand for sustainable packaging solutions is a key driver of this market growth. Major retailers and consumer goods companies are increasingly adopting recycled cellophane for packaging applications, responding to consumer preferences for eco-friendly products. The food and beverage industry, in particular, has shown strong interest in recycled cellophane due to its transparency, barrier properties, and biodegradability.

Geographically, Europe leads the market for recycled cellophane products, accounting for approximately 35% of the global market share. This is largely due to stringent regulations on single-use plastics and well-established recycling infrastructure. North America and Asia-Pacific regions are also showing rapid growth, with increasing government initiatives to promote sustainable packaging solutions.

The recycled cellophane market faces certain challenges, including the need for improved collection and sorting systems to ensure a steady supply of high-quality recycled material. Additionally, the cost of recycled cellophane remains higher than virgin cellophane, which can be a barrier to widespread adoption, particularly in price-sensitive markets.

Despite these challenges, technological advancements in recycling processes are expected to improve the quality and reduce the cost of recycled cellophane over time. Innovations in chemical recycling methods show promise in addressing contamination issues and expanding the range of cellophane products that can be effectively recycled.

Emerging applications for recycled cellophane include its use in textile fibers, 3D printing filaments, and as a raw material for producing bioplastics. These new markets are expected to further drive demand and create additional value streams for recycled cellophane.

In conclusion, the market for recycled cellophane products shows strong growth potential, driven by environmental concerns and technological advancements. As recycling efficiency improves and new applications emerge, the demand for recycled cellophane is expected to continue its upward trajectory, presenting significant opportunities for businesses operating in this space.

Current Challenges in Cellophane Recycling Processes

Cellophane recycling processes face several significant challenges that hinder their efficiency and widespread adoption. One of the primary obstacles is the lack of established infrastructure for collecting and sorting cellophane waste. Unlike more common plastics, cellophane is often mixed with other materials in consumer products, making it difficult to isolate and process separately.

The chemical composition of cellophane presents another major hurdle. As a regenerated cellulose material, it requires specialized recycling techniques that differ from those used for conventional plastics. The presence of additives and coatings in many cellophane products further complicates the recycling process, necessitating additional steps to remove these contaminants before the material can be effectively recycled.

Energy consumption during the recycling process is a significant concern. The current methods for breaking down cellophane into reusable components are often energy-intensive, reducing the overall sustainability of the recycling effort. This high energy requirement also impacts the economic viability of cellophane recycling, making it less attractive for recycling facilities to invest in the necessary equipment and processes.

Water usage is another critical challenge in cellophane recycling. The process typically involves substantial amounts of water for cleaning and processing the material, raising environmental concerns and increasing operational costs. Developing more water-efficient recycling methods is crucial for improving the sustainability of cellophane recycling.

The market for recycled cellophane products is still underdeveloped, creating uncertainty for recyclers. Without a stable demand for recycled cellophane, there is less incentive for companies to invest in the technology and infrastructure needed for efficient recycling. This chicken-and-egg problem slows down the development of more advanced recycling solutions.

Regulatory challenges also play a role in the current state of cellophane recycling. In many regions, there is a lack of clear guidelines or incentives for cellophane recycling, leading to inconsistent practices and limited investment in recycling technologies. Harmonizing regulations and providing incentives for cellophane recycling could help address this issue.

Lastly, consumer awareness and participation remain significant barriers. Many people are unaware that cellophane can be recycled or are unsure how to properly dispose of it. Improving public education and establishing clear recycling guidelines for consumers are essential steps in maximizing the efficiency of cellophane recycling processes.

The chemical composition of cellophane presents another major hurdle. As a regenerated cellulose material, it requires specialized recycling techniques that differ from those used for conventional plastics. The presence of additives and coatings in many cellophane products further complicates the recycling process, necessitating additional steps to remove these contaminants before the material can be effectively recycled.

Energy consumption during the recycling process is a significant concern. The current methods for breaking down cellophane into reusable components are often energy-intensive, reducing the overall sustainability of the recycling effort. This high energy requirement also impacts the economic viability of cellophane recycling, making it less attractive for recycling facilities to invest in the necessary equipment and processes.

Water usage is another critical challenge in cellophane recycling. The process typically involves substantial amounts of water for cleaning and processing the material, raising environmental concerns and increasing operational costs. Developing more water-efficient recycling methods is crucial for improving the sustainability of cellophane recycling.

The market for recycled cellophane products is still underdeveloped, creating uncertainty for recyclers. Without a stable demand for recycled cellophane, there is less incentive for companies to invest in the technology and infrastructure needed for efficient recycling. This chicken-and-egg problem slows down the development of more advanced recycling solutions.

Regulatory challenges also play a role in the current state of cellophane recycling. In many regions, there is a lack of clear guidelines or incentives for cellophane recycling, leading to inconsistent practices and limited investment in recycling technologies. Harmonizing regulations and providing incentives for cellophane recycling could help address this issue.

Lastly, consumer awareness and participation remain significant barriers. Many people are unaware that cellophane can be recycled or are unsure how to properly dispose of it. Improving public education and establishing clear recycling guidelines for consumers are essential steps in maximizing the efficiency of cellophane recycling processes.

Existing Cellophane Recycling Methods and Efficiency

01 Improved cellophane production methods

Various techniques have been developed to enhance the efficiency of cellophane production. These methods focus on optimizing the manufacturing process, including improvements in the viscose solution preparation, film formation, and regeneration steps. Such advancements lead to increased production speed, reduced energy consumption, and improved quality of the final cellophane product.- Cellophane production methods: Various methods for producing cellophane with improved efficiency have been developed. These methods may involve modifications to the manufacturing process, such as adjusting the composition of the cellulose solution, optimizing the regeneration process, or incorporating additives to enhance the properties of the final product. These techniques aim to increase production speed, reduce energy consumption, and improve the overall quality of the cellophane.

- Cellophane packaging applications: Cellophane's efficiency in packaging applications has been enhanced through innovations in film structure and composition. These improvements focus on increasing barrier properties, enhancing sealability, and improving printability. Advanced cellophane packaging solutions may incorporate additional layers or coatings to meet specific requirements for food preservation, moisture resistance, or oxygen barrier properties.

- Cellophane recycling and biodegradability: Efforts to improve the environmental efficiency of cellophane have led to advancements in recycling processes and biodegradability. These developments include the creation of more easily recyclable cellophane formulations, the implementation of efficient collection and processing systems, and the enhancement of cellophane's biodegradation properties to reduce environmental impact.

- Cellophane surface treatment and modification: Surface treatment and modification techniques have been developed to enhance cellophane's efficiency in various applications. These methods may include plasma treatment, chemical modification, or the application of specialized coatings to improve adhesion, printability, or other functional properties. Such modifications can expand the range of applications for cellophane and improve its performance in specific use cases.

- Cellophane in composite materials: The efficiency of cellophane has been improved through its incorporation into composite materials. By combining cellophane with other materials, such as polymers or natural fibers, novel composites with enhanced properties can be created. These composites may offer improved strength, flexibility, or barrier properties compared to traditional cellophane, expanding its potential applications in various industries.

02 Cellophane with enhanced barrier properties

Research has been conducted to improve the barrier properties of cellophane, making it more efficient for packaging applications. This includes developing cellophane films with enhanced moisture resistance, gas impermeability, and UV protection. These improvements extend the shelf life of packaged products and expand the range of applications for cellophane.Expand Specific Solutions03 Biodegradable cellophane alternatives

Efforts have been made to develop biodegradable alternatives to traditional cellophane, addressing environmental concerns while maintaining efficiency. These new materials aim to provide similar properties to cellophane in terms of transparency, flexibility, and barrier characteristics, while offering improved biodegradability and reduced environmental impact.Expand Specific Solutions04 Cellophane-based composite materials

Researchers have explored the development of composite materials incorporating cellophane to enhance its efficiency and functionality. These composites combine cellophane with other materials to create products with improved strength, durability, and specific properties tailored for various applications, such as packaging, electronics, and medical devices.Expand Specific Solutions05 Efficient cellophane packaging systems

Innovations in cellophane packaging systems have been introduced to improve efficiency in product packaging and handling. These advancements include automated packaging machines, smart dispensing systems, and improved sealing techniques specifically designed for cellophane. Such developments lead to faster packaging processes, reduced material waste, and enhanced product protection.Expand Specific Solutions

Key Players in Cellophane Recycling Industry

The cellophane recycling industry is in a growth phase, driven by increasing environmental concerns and sustainability initiatives. The market size is expanding, with a growing demand for efficient recycling solutions. Technologically, the field is advancing rapidly, with companies like Coperion GmbH and Wacker Chemie AG leading innovations in processing equipment and chemical solutions. Universities such as Sichuan University and South China University of Technology are contributing to research and development. The industry is seeing a blend of established players and new entrants, indicating a competitive and dynamic landscape. As the technology matures, we can expect more efficient and cost-effective recycling processes to emerge, potentially revolutionizing cellophane waste management.

Coperion GmbH

Technical Solution: Coperion GmbH has developed an advanced recycling system for cellophane that utilizes a combination of mechanical and chemical processes. Their technology employs a high-speed rotary cutter to reduce cellophane waste into small, uniform pieces, followed by a solvent-based dissolution process. This process separates cellulose from coatings and additives, allowing for the recovery of pure cellulose that can be used in new cellophane production or other applications. The system incorporates a closed-loop solvent recovery unit, minimizing environmental impact and reducing operational costs[1][3]. Coperion's approach also includes a proprietary filtration system that removes contaminants down to the micron level, ensuring high-quality recycled material[2].

Strengths: High purity of recovered cellulose, efficient solvent recovery, and adaptability to various cellophane types. Weaknesses: High initial investment cost and potential environmental concerns related to solvent use.

Air Liquide SA

Technical Solution: Air Liquide SA has pioneered a cryogenic recycling technology for cellophane that leverages the company's expertise in industrial gases and cryogenic processes. Their method involves flash-freezing cellophane waste using liquid nitrogen, which makes the material brittle and easy to pulverize into a fine powder[8]. This powder is then subjected to a series of separation processes, including electrostatic separation and density-based sorting, to remove contaminants and isolate pure cellulose particles. The company has also developed a proprietary surface modification technique that enhances the compatibility of the recycled cellulose with various polymer matrices, expanding its potential applications[9]. The cryogenic process preserves the molecular structure of cellulose, allowing for high-quality recycled material suitable for demanding applications.

Strengths: High purity of recovered cellulose, preservation of cellulose molecular structure, and versatility of recycled material. Weaknesses: High energy consumption for cryogenic cooling and potential safety concerns related to handling of cryogenic fluids.

Innovative Approaches to Enhance Recycling Efficiency

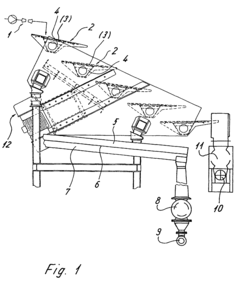

Method and device for separating pourable material

PatentInactiveEP0983803A1

Innovation

- A method involving a highly accelerated air stream to tear mat-like carrier materials into flakes, followed by vibration and screening to achieve precise separation, utilizing a device with adjustable frequency, amplitude, and inclination to optimize separation efficiency.

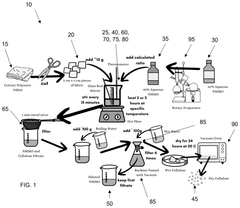

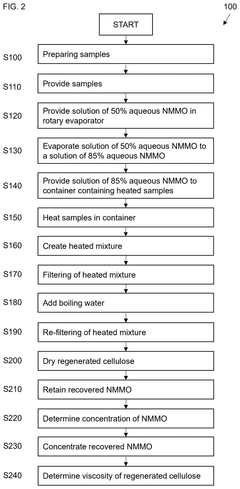

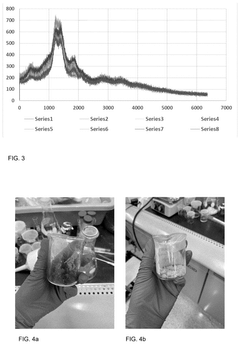

Regenerating cellulose from waste textile

PatentPendingUS20250198083A1

Innovation

- A system and method that uses a high concentration of N-methylmorpholine N-oxide (NMMO) to dissolve cellulose from blended fabrics, allowing for the detachment of polyester and cellulosic fibers from cotton, while maintaining the quality of the fibers and enabling the reuse of the NMMO solvent.

Environmental Impact Assessment of Recycling Processes

The environmental impact assessment of cellophane recycling processes is crucial for understanding the overall sustainability and efficiency of this practice. Cellophane, a biodegradable material derived from cellulose, presents unique challenges and opportunities in recycling.

The recycling process for cellophane typically involves collection, sorting, cleaning, and reprocessing. Each of these stages has its own environmental implications. During collection and transportation, the primary environmental concerns are fuel consumption and associated greenhouse gas emissions. The impact can be mitigated through optimized logistics and the use of low-emission vehicles.

Sorting and cleaning stages often require water and energy inputs. The water usage in cleaning cellophane can be substantial, potentially leading to increased wastewater production. However, implementing water recycling systems within the facility can significantly reduce freshwater consumption and minimize wastewater discharge. Energy consumption during sorting and cleaning processes contributes to indirect emissions, which can be addressed by incorporating renewable energy sources or improving energy efficiency in the recycling facilities.

The reprocessing stage, where cellophane is broken down and reformed into new products, typically has the most significant environmental impact. This stage often involves chemical treatments and high-temperature processes, resulting in direct emissions and energy consumption. However, compared to the production of virgin cellophane, recycling generally shows a lower environmental footprint in terms of energy use and greenhouse gas emissions.

One of the key environmental benefits of cellophane recycling is the reduction of waste sent to landfills or incineration. This not only conserves landfill space but also prevents the release of methane, a potent greenhouse gas, from decomposing cellophane in landfills. Additionally, recycling cellophane reduces the demand for raw materials, primarily wood pulp, thereby contributing to forest conservation and biodiversity protection.

The life cycle assessment (LCA) of cellophane recycling reveals that the environmental benefits often outweigh the impacts of the recycling process itself. However, the efficiency of recycling and its net environmental benefit can vary significantly based on factors such as transportation distances, recycling technology used, and the energy mix of the local grid.

To maximize the environmental benefits of cellophane recycling, it is essential to focus on improving process efficiency, reducing energy consumption, and minimizing water usage. Innovations in recycling technologies, such as advanced sorting systems and more efficient chemical processes, can further enhance the environmental performance of cellophane recycling.

In conclusion, while cellophane recycling does have environmental impacts, particularly in terms of energy and water usage, the overall environmental benefits of recycling this material are generally positive when compared to landfill disposal or incineration. Continuous improvement in recycling technologies and processes is key to further reducing the environmental footprint of cellophane recycling and enhancing its role in sustainable waste management.

The recycling process for cellophane typically involves collection, sorting, cleaning, and reprocessing. Each of these stages has its own environmental implications. During collection and transportation, the primary environmental concerns are fuel consumption and associated greenhouse gas emissions. The impact can be mitigated through optimized logistics and the use of low-emission vehicles.

Sorting and cleaning stages often require water and energy inputs. The water usage in cleaning cellophane can be substantial, potentially leading to increased wastewater production. However, implementing water recycling systems within the facility can significantly reduce freshwater consumption and minimize wastewater discharge. Energy consumption during sorting and cleaning processes contributes to indirect emissions, which can be addressed by incorporating renewable energy sources or improving energy efficiency in the recycling facilities.

The reprocessing stage, where cellophane is broken down and reformed into new products, typically has the most significant environmental impact. This stage often involves chemical treatments and high-temperature processes, resulting in direct emissions and energy consumption. However, compared to the production of virgin cellophane, recycling generally shows a lower environmental footprint in terms of energy use and greenhouse gas emissions.

One of the key environmental benefits of cellophane recycling is the reduction of waste sent to landfills or incineration. This not only conserves landfill space but also prevents the release of methane, a potent greenhouse gas, from decomposing cellophane in landfills. Additionally, recycling cellophane reduces the demand for raw materials, primarily wood pulp, thereby contributing to forest conservation and biodiversity protection.

The life cycle assessment (LCA) of cellophane recycling reveals that the environmental benefits often outweigh the impacts of the recycling process itself. However, the efficiency of recycling and its net environmental benefit can vary significantly based on factors such as transportation distances, recycling technology used, and the energy mix of the local grid.

To maximize the environmental benefits of cellophane recycling, it is essential to focus on improving process efficiency, reducing energy consumption, and minimizing water usage. Innovations in recycling technologies, such as advanced sorting systems and more efficient chemical processes, can further enhance the environmental performance of cellophane recycling.

In conclusion, while cellophane recycling does have environmental impacts, particularly in terms of energy and water usage, the overall environmental benefits of recycling this material are generally positive when compared to landfill disposal or incineration. Continuous improvement in recycling technologies and processes is key to further reducing the environmental footprint of cellophane recycling and enhancing its role in sustainable waste management.

Economic Viability of Advanced Recycling Technologies

The economic viability of advanced recycling technologies for cellophane is a critical factor in determining the feasibility of implementing more efficient recycling processes. As the demand for sustainable packaging solutions grows, the potential for cellophane recycling presents both opportunities and challenges from an economic perspective.

Advanced recycling technologies, such as chemical recycling and enzymatic depolymerization, offer promising avenues for maximizing efficiency in cellophane recycling. These methods can potentially yield higher-quality recycled materials and reduce the overall environmental impact compared to traditional mechanical recycling. However, the economic viability of these technologies depends on several key factors.

One crucial aspect is the initial investment required for implementing advanced recycling technologies. The cost of specialized equipment, research and development, and facility upgrades can be substantial. Companies must carefully evaluate the return on investment and payback period to justify the adoption of these technologies. Additionally, operational costs, including energy consumption, chemical inputs, and maintenance, play a significant role in determining long-term economic viability.

The market demand for recycled cellophane products is another essential consideration. As consumers and businesses increasingly prioritize sustainable packaging options, the potential for premium pricing of recycled cellophane materials may improve the economic outlook. However, this demand must be balanced against the availability and cost of virgin cellophane materials to ensure competitiveness in the market.

Scale of operations is a critical factor in achieving economic viability. Larger-scale recycling facilities can benefit from economies of scale, reducing per-unit costs and improving overall efficiency. However, the challenge lies in securing a consistent and sufficient supply of cellophane waste to maintain optimal operational capacity.

Government policies and regulations also significantly impact the economic viability of advanced recycling technologies. Incentives such as tax breaks, grants, or subsidies for sustainable packaging solutions can improve the financial attractiveness of investing in cellophane recycling. Conversely, stringent environmental regulations may increase compliance costs but could also drive demand for recycled materials.

The potential for value-added products from cellophane recycling processes can enhance economic viability. By-products or derivatives obtained during the recycling process may find applications in other industries, creating additional revenue streams and improving the overall economic proposition of advanced recycling technologies.

In conclusion, while advanced recycling technologies for cellophane show promise in maximizing efficiency, their economic viability depends on a complex interplay of factors. Careful analysis of costs, market dynamics, regulatory environment, and potential value creation is essential for businesses considering investment in this area. As technology continues to evolve and sustainability becomes increasingly important, the economic landscape for cellophane recycling is likely to shift, potentially opening up new opportunities for viable and efficient recycling solutions.

Advanced recycling technologies, such as chemical recycling and enzymatic depolymerization, offer promising avenues for maximizing efficiency in cellophane recycling. These methods can potentially yield higher-quality recycled materials and reduce the overall environmental impact compared to traditional mechanical recycling. However, the economic viability of these technologies depends on several key factors.

One crucial aspect is the initial investment required for implementing advanced recycling technologies. The cost of specialized equipment, research and development, and facility upgrades can be substantial. Companies must carefully evaluate the return on investment and payback period to justify the adoption of these technologies. Additionally, operational costs, including energy consumption, chemical inputs, and maintenance, play a significant role in determining long-term economic viability.

The market demand for recycled cellophane products is another essential consideration. As consumers and businesses increasingly prioritize sustainable packaging options, the potential for premium pricing of recycled cellophane materials may improve the economic outlook. However, this demand must be balanced against the availability and cost of virgin cellophane materials to ensure competitiveness in the market.

Scale of operations is a critical factor in achieving economic viability. Larger-scale recycling facilities can benefit from economies of scale, reducing per-unit costs and improving overall efficiency. However, the challenge lies in securing a consistent and sufficient supply of cellophane waste to maintain optimal operational capacity.

Government policies and regulations also significantly impact the economic viability of advanced recycling technologies. Incentives such as tax breaks, grants, or subsidies for sustainable packaging solutions can improve the financial attractiveness of investing in cellophane recycling. Conversely, stringent environmental regulations may increase compliance costs but could also drive demand for recycled materials.

The potential for value-added products from cellophane recycling processes can enhance economic viability. By-products or derivatives obtained during the recycling process may find applications in other industries, creating additional revenue streams and improving the overall economic proposition of advanced recycling technologies.

In conclusion, while advanced recycling technologies for cellophane show promise in maximizing efficiency, their economic viability depends on a complex interplay of factors. Careful analysis of costs, market dynamics, regulatory environment, and potential value creation is essential for businesses considering investment in this area. As technology continues to evolve and sustainability becomes increasingly important, the economic landscape for cellophane recycling is likely to shift, potentially opening up new opportunities for viable and efficient recycling solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!