How to Navigate Challenges in Cellophane Biodiversity Relations?

Cellophane Biodiversity Challenges and Objectives

The relationship between cellophane and biodiversity presents a complex challenge in the modern world. Cellophane, a thin transparent sheet made from regenerated cellulose, has been widely used in packaging and various industrial applications. However, its production and disposal have raised concerns about its impact on biodiversity and ecosystems.

The primary objective in addressing this challenge is to develop sustainable practices that minimize the negative effects of cellophane on biodiversity while maintaining its utility in various industries. This involves exploring alternative materials, improving production processes, and implementing effective waste management strategies.

One of the key challenges lies in the sourcing of raw materials for cellophane production. Traditionally, cellophane is derived from wood pulp or cotton linters, which can contribute to deforestation and habitat loss if not managed sustainably. The goal is to identify and utilize more environmentally friendly sources of cellulose that do not compromise biodiversity.

Another significant challenge is the disposal of cellophane waste. Although cellophane is biodegradable, it can take several months to decompose fully, potentially causing harm to wildlife and ecosystems in the interim. The objective here is to develop faster-degrading cellophane formulations or establish more efficient recycling systems to reduce its environmental impact.

The production process of cellophane also poses challenges to biodiversity. The use of chemicals and energy-intensive manufacturing methods can lead to pollution and greenhouse gas emissions, indirectly affecting ecosystems. The aim is to innovate cleaner production technologies that minimize these negative externalities.

Balancing the economic viability of cellophane production with environmental conservation is another crucial objective. The industry must find ways to maintain profitability while investing in sustainable practices and technologies that protect biodiversity.

Education and awareness form another critical aspect of this challenge. Both producers and consumers need to be informed about the environmental impacts of cellophane and the importance of responsible usage and disposal. The goal is to foster a culture of sustainability that supports biodiversity conservation efforts.

Lastly, there is a need for collaborative research and development initiatives involving industry, academia, and environmental organizations. These partnerships can drive innovation in biodegradable materials, eco-friendly production methods, and effective waste management strategies, all aimed at mitigating the impact of cellophane on biodiversity.

Market Analysis for Eco-Friendly Packaging

The eco-friendly packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global market for sustainable packaging is projected to reach $413.8 billion by 2027, growing at a CAGR of 6.1% from 2020 to 2027. This growth is primarily fueled by consumer demand for environmentally responsible products and corporate sustainability initiatives.

Cellophane, as a biodegradable material, has gained renewed interest in the eco-friendly packaging sector. However, its market share remains relatively small compared to other sustainable alternatives such as paper, bioplastics, and recycled plastics. The cellophane market is estimated to grow at a CAGR of 4.2% from 2021 to 2026, indicating steady but modest growth compared to the overall eco-friendly packaging market.

Key drivers for the eco-friendly packaging market include government regulations, such as the European Union's Single-Use Plastics Directive, which aims to reduce plastic waste. These regulations have prompted many companies to seek sustainable packaging solutions, creating opportunities for cellophane and other biodegradable materials. Additionally, consumer preferences are shifting towards brands that demonstrate environmental responsibility, with 74% of consumers willing to pay more for sustainable packaging.

The food and beverage industry represents the largest end-user segment for eco-friendly packaging, accounting for approximately 60% of the market share. This sector's demand is driven by the need for materials that can maintain food freshness while being environmentally friendly. Cellophane's properties, such as transparency and barrier protection, make it particularly suitable for this application.

However, challenges remain in the widespread adoption of cellophane for eco-friendly packaging. These include higher production costs compared to conventional plastics, limited scalability of production, and competition from other sustainable materials with established market presence. The price premium for cellophane packaging can range from 20% to 50% higher than traditional plastic alternatives, which may deter some cost-sensitive consumers and businesses.

Despite these challenges, the market for cellophane in eco-friendly packaging is expected to grow as manufacturers invest in research and development to improve its properties and reduce production costs. The Asia-Pacific region is anticipated to be the fastest-growing market for eco-friendly packaging, including cellophane, due to rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable practices.

Current State of Cellophane-Biodiversity Interactions

The relationship between cellophane and biodiversity presents a complex interplay of environmental concerns and industrial practices. Currently, the widespread use of cellophane in packaging and various consumer products has significant implications for biodiversity conservation efforts. While cellophane is derived from natural cellulose, typically sourced from wood pulp or cotton linters, its production process involves chemical treatments that can have detrimental effects on ecosystems.

One of the primary challenges in cellophane-biodiversity interactions is the impact of raw material sourcing. The demand for cellulose-based materials has led to increased pressure on forest resources, potentially contributing to deforestation and habitat loss for numerous species. This is particularly concerning in biodiversity hotspots where unique ecosystems are at risk.

The manufacturing process of cellophane also poses environmental challenges. The use of chemicals such as carbon disulfide and sodium hydroxide in the production of viscose, from which cellophane is derived, can result in harmful emissions and wastewater if not properly managed. These pollutants can adversely affect local biodiversity, particularly in aquatic ecosystems near production facilities.

Despite these concerns, recent advancements in cellophane production have shown promise in mitigating some of these negative impacts. Sustainable forestry practices and the use of alternative cellulose sources, such as agricultural waste, are being explored to reduce the pressure on natural forests. Additionally, closed-loop manufacturing systems and improved waste treatment technologies are being implemented to minimize environmental pollution.

The disposal of cellophane products presents another critical aspect of its interaction with biodiversity. While cellophane is biodegradable, the rate of decomposition can vary significantly depending on environmental conditions. In landfills or marine environments, cellophane may persist for extended periods, potentially harming wildlife through ingestion or entanglement.

Efforts to address these challenges include the development of more rapidly biodegradable cellophane variants and improved waste management systems. Some manufacturers are also exploring the potential for compostable cellophane products that break down more efficiently in industrial composting facilities, reducing their environmental footprint.

The current state of cellophane-biodiversity interactions also reflects growing consumer awareness and regulatory pressures. Many countries have implemented or are considering policies to reduce single-use plastics, including certain cellophane products. This shift is driving innovation in the industry, with a focus on creating more environmentally friendly alternatives that maintain the functional properties of traditional cellophane while minimizing ecological impact.

Existing Solutions for Biodiversity-Friendly Cellophane

01 Biodegradable cellophane alternatives

Development of biodegradable materials as alternatives to traditional cellophane, focusing on improving environmental sustainability while maintaining similar properties. These materials are designed to break down naturally in various ecosystems, reducing environmental impact and promoting biodiversity.- Biodegradable cellophane compositions: Development of biodegradable cellophane compositions that can contribute to environmental sustainability. These compositions may include modified cellulose or cellulose derivatives that enhance biodegradability while maintaining the desired properties of traditional cellophane.

- Cellophane-based packaging for biodiversity preservation: Innovative packaging solutions using cellophane that help preserve biodiversity. These may include specialized packaging for seeds, plant specimens, or other biological materials that require protection and controlled environments for storage or transportation.

- Cellophane alternatives from renewable resources: Research into alternative materials derived from renewable resources that can replace traditional cellophane while supporting biodiversity. These may include bio-based films or coatings that offer similar properties to cellophane but with a reduced environmental impact.

- Cellophane recycling and upcycling processes: Development of methods for recycling or upcycling cellophane to reduce waste and support biodiversity conservation efforts. These processes may involve chemical or mechanical treatments to repurpose used cellophane into new products or materials.

- Cellophane-based biodiversity monitoring tools: Creation of specialized tools or devices using cellophane for biodiversity monitoring and research. These may include transparent barriers, collection devices, or sampling equipment that utilize cellophane's unique properties to aid in ecological studies and conservation efforts.

02 Cellophane-based packaging for preserving biodiversity

Innovative packaging solutions using cellophane or similar materials to protect and transport biological samples, seeds, or other biodiversity-related items. These packaging methods aim to maintain the integrity of samples and contribute to biodiversity conservation efforts.Expand Specific Solutions03 Cellophane modifications for ecological applications

Modifications to cellophane or similar materials to enhance their suitability for ecological applications. This includes improvements in gas permeability, moisture resistance, or incorporation of biodegradable additives to make the material more environmentally friendly and supportive of biodiversity.Expand Specific Solutions04 Cellophane-based substrates for microbial growth

Development of cellophane-based or similar materials as substrates for microbial growth studies, particularly in biodiversity research. These substrates provide a controlled environment for studying various microorganisms, contributing to our understanding of microbial biodiversity.Expand Specific Solutions05 Cellophane in biodiversity sampling and analysis

Utilization of cellophane or similar materials in biodiversity sampling and analysis techniques. This includes the development of specialized tools or methods for collecting, preserving, or analyzing biological samples, contributing to biodiversity research and conservation efforts.Expand Specific Solutions

Key Players in Sustainable Packaging Industry

The field of cellophane biodiversity relations is in its early developmental stages, with a growing market driven by increasing environmental concerns. The technology's maturity is still evolving, with key players like The Regents of the University of California, Fraunhofer-Gesellschaft, and Stora Enso Oyj leading research efforts. Companies such as Corning, Inc. and Novozymes A/S are contributing to advancements in material science and bioinnovation, respectively. The market size is expanding as more industries seek sustainable packaging solutions. However, challenges remain in scaling production and improving biodegradability while maintaining performance, indicating a need for continued research and development across academic and industrial sectors.

The Regents of the University of California

Stora Enso Oyj

Core Innovations in Eco-Friendly Cellophane Production

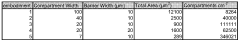

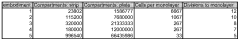

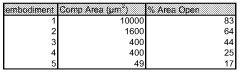

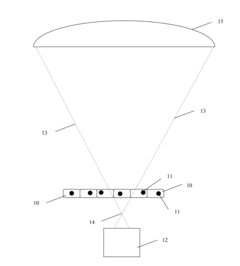

- A high-throughput method utilizing bio-chips with porous supports to analyze microorganisms, allowing for minimal disturbance of cells, enabling the determination of intrinsic heterogeneity and interactions by incubating microorganisms on a medium and using reporter compounds for phenotypic characterization.

- The proposal of attributing intelligence to cells, particularly eukaryotes, as a mechanism for rapid evolution and complexity increase, using molecular imaging techniques to study and understand cellular intelligence, which could involve developing probes and instruments to observe and communicate with cellular processes at a molecular level.

Environmental Regulations on Packaging Materials

Environmental regulations on packaging materials have become increasingly stringent in recent years, reflecting growing concerns about the environmental impact of cellophane and other packaging materials. These regulations aim to address issues such as waste reduction, recyclability, and biodegradability, which are crucial in navigating the challenges in cellophane biodiversity relations.

Many countries have implemented comprehensive packaging waste directives, setting targets for recovery and recycling of packaging materials. The European Union's Packaging and Packaging Waste Directive, for instance, requires member states to recover and recycle specific percentages of packaging waste. This directive has led to the development of extended producer responsibility schemes, where manufacturers are held accountable for the entire lifecycle of their packaging products.

In response to these regulations, the packaging industry has been compelled to innovate and develop more sustainable alternatives to traditional cellophane. Biodegradable and compostable materials have gained traction, with some countries introducing standards for these materials to ensure their environmental claims are substantiated. For example, the ASTM D6400 standard in the United States and the EN 13432 standard in Europe provide guidelines for compostable plastics.

The use of recycled content in packaging materials is another area of focus for regulators. Some jurisdictions have implemented minimum recycled content requirements for certain types of packaging, encouraging the development of closed-loop recycling systems. This approach not only reduces the demand for virgin materials but also helps to create a market for recycled cellophane and similar materials.

Regulations addressing single-use plastics have also impacted the cellophane industry. Many countries and municipalities have banned or restricted the use of certain single-use plastic items, prompting manufacturers to explore alternative materials or redesign their packaging to be reusable or more easily recyclable. These regulations have spurred innovation in packaging design and material science, leading to the development of novel biodegradable cellophane alternatives.

Chemical safety regulations, such as the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, have implications for cellophane production. These regulations require manufacturers to assess and manage the risks posed by chemicals used in their products, including additives and coatings used in cellophane production. This has led to increased scrutiny of the chemical composition of packaging materials and efforts to develop safer alternatives.

As environmental concerns continue to grow, it is likely that regulations on packaging materials will become even more stringent. Future regulations may focus on areas such as carbon footprint reduction, microplastic pollution prevention, and the promotion of circular economy principles in packaging design and production. The cellophane industry must stay ahead of these regulatory trends to remain competitive and environmentally responsible.

Life Cycle Assessment of Cellophane Products

Life Cycle Assessment (LCA) of cellophane products is a crucial step in understanding and mitigating the environmental impacts associated with their production, use, and disposal. This comprehensive analysis encompasses the entire lifecycle of cellophane, from raw material extraction to end-of-life management, providing valuable insights into its ecological footprint.

The production phase of cellophane begins with the sourcing of wood pulp, typically derived from sustainably managed forests. This raw material undergoes a series of chemical treatments, including dissolution in alkali and carbon disulfide, followed by regeneration in an acid bath. The environmental implications of these processes, such as energy consumption, water usage, and chemical emissions, are meticulously evaluated in the LCA.

During the manufacturing stage, the LCA focuses on the energy-intensive processes of casting, drying, and conditioning the cellophane film. The assessment quantifies the greenhouse gas emissions, water pollution, and resource depletion associated with these operations. Additionally, it examines the potential for optimization and the implementation of cleaner production technologies to reduce environmental impacts.

The use phase of cellophane products, primarily in packaging applications, is relatively short-lived but significant in terms of its biodiversity implications. The LCA evaluates the benefits of cellophane's barrier properties, which can extend the shelf life of food products and potentially reduce food waste. However, it also considers the challenges posed by improper disposal and littering, which can harm wildlife and ecosystems.

End-of-life management is a critical component of the cellophane LCA. While cellophane is biodegradable, the rate and conditions of decomposition vary widely depending on the disposal environment. The assessment examines different scenarios, including composting, landfilling, and incineration, to determine the most environmentally favorable options. It also explores the potential for recycling and the development of closed-loop systems to minimize waste.

The LCA of cellophane products provides a foundation for comparing its environmental performance with alternative materials, such as conventional plastics or other bioplastics. This comparative analysis helps inform decision-making processes for manufacturers, policymakers, and consumers, enabling them to make more environmentally conscious choices in packaging and product design.

By identifying hotspots of environmental impact throughout the cellophane lifecycle, the LCA guides targeted interventions and innovations. These may include improving production efficiencies, developing more sustainable sourcing practices, or enhancing end-of-life management strategies. Such insights are invaluable in navigating the complex relationship between cellophane production and biodiversity conservation, supporting the development of more sustainable and ecologically responsible practices in the packaging industry.