How to Optimize Moisture Resistance in Cellophane?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Moisture Resistance Background and Objectives

Cellophane, a thin transparent sheet made from regenerated cellulose, has been widely used in packaging applications since its invention in the early 20th century. Its popularity stems from its excellent clarity, flexibility, and biodegradability. However, one of the major challenges faced by cellophane manufacturers and users is its susceptibility to moisture, which can significantly affect its performance and durability.

The optimization of moisture resistance in cellophane has been a focus of research and development efforts for decades. This ongoing pursuit aims to enhance the material's ability to withstand varying humidity conditions while maintaining its desirable properties. The evolution of cellophane technology has seen numerous advancements, from the initial uncoated sheets to the development of various moisture-resistant coatings and treatments.

Understanding the historical context of cellophane's moisture resistance is crucial for appreciating the current state of the technology and identifying future directions for improvement. Early cellophane products were highly hygroscopic, readily absorbing moisture from the environment, which led to dimensional instability and reduced barrier properties. This limitation prompted the development of moisture-resistant coatings, such as nitrocellulose and polyvinylidene chloride (PVDC), which significantly improved the material's performance in high-humidity conditions.

The objectives of optimizing moisture resistance in cellophane are multifaceted. Primarily, it aims to extend the shelf life of packaged products by maintaining a consistent barrier against moisture ingress or egress. This is particularly important for food packaging, where moisture control is critical for preserving freshness and preventing spoilage. Additionally, improved moisture resistance enhances the mechanical properties of cellophane, ensuring that it maintains its strength and flexibility under varying environmental conditions.

Another key objective is to develop environmentally friendly solutions for moisture resistance. As sustainability becomes increasingly important in packaging design, there is a growing demand for bio-based and biodegradable moisture barriers that align with cellophane's eco-friendly nature. This objective presents a significant challenge, as many traditional moisture-resistant coatings are derived from petroleum-based materials.

The pursuit of optimized moisture resistance in cellophane also aims to expand its applicability across various industries. By enhancing its performance in high-humidity environments, cellophane can become a viable option for a broader range of packaging applications, potentially replacing less sustainable materials in certain sectors.

As we delve deeper into the technical aspects of moisture resistance in cellophane, it is essential to consider the balance between performance, cost-effectiveness, and environmental impact. The ongoing research in this field continues to push the boundaries of what is possible, driving innovation in materials science and packaging technology.

The optimization of moisture resistance in cellophane has been a focus of research and development efforts for decades. This ongoing pursuit aims to enhance the material's ability to withstand varying humidity conditions while maintaining its desirable properties. The evolution of cellophane technology has seen numerous advancements, from the initial uncoated sheets to the development of various moisture-resistant coatings and treatments.

Understanding the historical context of cellophane's moisture resistance is crucial for appreciating the current state of the technology and identifying future directions for improvement. Early cellophane products were highly hygroscopic, readily absorbing moisture from the environment, which led to dimensional instability and reduced barrier properties. This limitation prompted the development of moisture-resistant coatings, such as nitrocellulose and polyvinylidene chloride (PVDC), which significantly improved the material's performance in high-humidity conditions.

The objectives of optimizing moisture resistance in cellophane are multifaceted. Primarily, it aims to extend the shelf life of packaged products by maintaining a consistent barrier against moisture ingress or egress. This is particularly important for food packaging, where moisture control is critical for preserving freshness and preventing spoilage. Additionally, improved moisture resistance enhances the mechanical properties of cellophane, ensuring that it maintains its strength and flexibility under varying environmental conditions.

Another key objective is to develop environmentally friendly solutions for moisture resistance. As sustainability becomes increasingly important in packaging design, there is a growing demand for bio-based and biodegradable moisture barriers that align with cellophane's eco-friendly nature. This objective presents a significant challenge, as many traditional moisture-resistant coatings are derived from petroleum-based materials.

The pursuit of optimized moisture resistance in cellophane also aims to expand its applicability across various industries. By enhancing its performance in high-humidity environments, cellophane can become a viable option for a broader range of packaging applications, potentially replacing less sustainable materials in certain sectors.

As we delve deeper into the technical aspects of moisture resistance in cellophane, it is essential to consider the balance between performance, cost-effectiveness, and environmental impact. The ongoing research in this field continues to push the boundaries of what is possible, driving innovation in materials science and packaging technology.

Market Demand for Improved Cellophane Packaging

The global packaging industry has witnessed a significant surge in demand for improved cellophane packaging, driven by the increasing need for sustainable and moisture-resistant materials. Cellophane, a biodegradable and renewable material derived from cellulose, has gained traction in various sectors due to its transparency, flexibility, and eco-friendly properties. However, its susceptibility to moisture has been a longstanding challenge, limiting its widespread adoption in certain applications.

The food and beverage industry, in particular, has shown a strong interest in enhanced cellophane packaging. With the growing consumer preference for fresh, minimally processed foods and the rise of convenience products, there is a pressing need for packaging solutions that can extend shelf life while maintaining product quality. Improved moisture resistance in cellophane would address these concerns, potentially revolutionizing food packaging and reducing food waste.

The pharmaceutical sector also presents a substantial market opportunity for moisture-resistant cellophane. Drug manufacturers require packaging materials that can protect sensitive medications from humidity and environmental factors. Enhanced cellophane could offer a cost-effective and environmentally friendly alternative to traditional synthetic materials, aligning with the industry's shift towards sustainable packaging solutions.

In the personal care and cosmetics industry, there is a growing demand for packaging that combines aesthetics with functionality. Moisture-resistant cellophane could provide an attractive option for packaging hygroscopic products such as bath salts, powders, and effervescent tablets, ensuring product integrity while offering visual appeal to consumers.

The e-commerce boom has further amplified the need for improved packaging materials. As online shopping continues to grow, retailers and logistics companies are seeking packaging solutions that can withstand varying environmental conditions during transit. Cellophane with enhanced moisture resistance could offer a lightweight, durable option for protecting goods from humidity and condensation during shipping and storage.

Market research indicates that the global biodegradable packaging market, which includes cellophane, is projected to experience substantial growth in the coming years. This growth is fueled by increasing environmental awareness, stringent regulations on plastic usage, and corporate sustainability initiatives. Improved moisture resistance in cellophane would position it as a viable alternative to conventional plastics in many applications, potentially capturing a larger share of this expanding market.

As industries strive to reduce their environmental footprint, the demand for bio-based and compostable packaging materials is expected to rise. Cellophane, with its inherent biodegradability, stands to benefit from this trend. By addressing its moisture sensitivity, cellophane could become a preferred choice for companies looking to balance performance with sustainability in their packaging solutions.

The food and beverage industry, in particular, has shown a strong interest in enhanced cellophane packaging. With the growing consumer preference for fresh, minimally processed foods and the rise of convenience products, there is a pressing need for packaging solutions that can extend shelf life while maintaining product quality. Improved moisture resistance in cellophane would address these concerns, potentially revolutionizing food packaging and reducing food waste.

The pharmaceutical sector also presents a substantial market opportunity for moisture-resistant cellophane. Drug manufacturers require packaging materials that can protect sensitive medications from humidity and environmental factors. Enhanced cellophane could offer a cost-effective and environmentally friendly alternative to traditional synthetic materials, aligning with the industry's shift towards sustainable packaging solutions.

In the personal care and cosmetics industry, there is a growing demand for packaging that combines aesthetics with functionality. Moisture-resistant cellophane could provide an attractive option for packaging hygroscopic products such as bath salts, powders, and effervescent tablets, ensuring product integrity while offering visual appeal to consumers.

The e-commerce boom has further amplified the need for improved packaging materials. As online shopping continues to grow, retailers and logistics companies are seeking packaging solutions that can withstand varying environmental conditions during transit. Cellophane with enhanced moisture resistance could offer a lightweight, durable option for protecting goods from humidity and condensation during shipping and storage.

Market research indicates that the global biodegradable packaging market, which includes cellophane, is projected to experience substantial growth in the coming years. This growth is fueled by increasing environmental awareness, stringent regulations on plastic usage, and corporate sustainability initiatives. Improved moisture resistance in cellophane would position it as a viable alternative to conventional plastics in many applications, potentially capturing a larger share of this expanding market.

As industries strive to reduce their environmental footprint, the demand for bio-based and compostable packaging materials is expected to rise. Cellophane, with its inherent biodegradability, stands to benefit from this trend. By addressing its moisture sensitivity, cellophane could become a preferred choice for companies looking to balance performance with sustainability in their packaging solutions.

Current Challenges in Cellophane Moisture Resistance

Cellophane, a versatile and widely used packaging material, faces significant challenges in maintaining optimal moisture resistance. The primary issue stems from its inherent hydrophilic nature, which makes it susceptible to water absorption and permeation. This characteristic compromises the material's barrier properties, potentially leading to degradation of packaged products, especially in high-humidity environments.

One of the key challenges is balancing moisture resistance with other desirable properties of cellophane, such as transparency, flexibility, and biodegradability. Efforts to enhance moisture resistance often result in trade-offs with these attributes, making it difficult to achieve an optimal solution without compromising the material's overall performance.

The current manufacturing process of cellophane also presents challenges in improving moisture resistance. The regeneration of cellulose into cellophane involves a complex series of chemical treatments and physical processes. Modifying these processes to incorporate moisture-resistant properties without significantly altering the production workflow or increasing costs remains a significant hurdle for manufacturers.

Another critical challenge lies in developing effective coating technologies. While various coatings have been explored to enhance moisture resistance, many struggle with adhesion issues, non-uniformity, or reduced flexibility of the final product. Additionally, some coatings may introduce environmental concerns or affect the recyclability of cellophane, conflicting with sustainability goals.

The dynamic nature of moisture interactions with cellophane under varying environmental conditions poses another challenge. Temperature fluctuations, relative humidity changes, and exposure to different types of moisture (liquid water, water vapor) can all affect the material's performance. Developing a solution that maintains consistent moisture resistance across diverse conditions is particularly challenging.

Furthermore, regulatory compliance and food safety considerations add another layer of complexity. Any modifications or additives used to enhance moisture resistance must meet stringent food contact material regulations, limiting the range of potential solutions and necessitating extensive testing and validation processes.

Lastly, the cost-effectiveness of moisture resistance improvements remains a significant challenge. Many potential solutions, while technically feasible, are economically prohibitive for large-scale implementation. Striking a balance between enhanced performance and cost-efficiency is crucial for widespread adoption in the packaging industry.

One of the key challenges is balancing moisture resistance with other desirable properties of cellophane, such as transparency, flexibility, and biodegradability. Efforts to enhance moisture resistance often result in trade-offs with these attributes, making it difficult to achieve an optimal solution without compromising the material's overall performance.

The current manufacturing process of cellophane also presents challenges in improving moisture resistance. The regeneration of cellulose into cellophane involves a complex series of chemical treatments and physical processes. Modifying these processes to incorporate moisture-resistant properties without significantly altering the production workflow or increasing costs remains a significant hurdle for manufacturers.

Another critical challenge lies in developing effective coating technologies. While various coatings have been explored to enhance moisture resistance, many struggle with adhesion issues, non-uniformity, or reduced flexibility of the final product. Additionally, some coatings may introduce environmental concerns or affect the recyclability of cellophane, conflicting with sustainability goals.

The dynamic nature of moisture interactions with cellophane under varying environmental conditions poses another challenge. Temperature fluctuations, relative humidity changes, and exposure to different types of moisture (liquid water, water vapor) can all affect the material's performance. Developing a solution that maintains consistent moisture resistance across diverse conditions is particularly challenging.

Furthermore, regulatory compliance and food safety considerations add another layer of complexity. Any modifications or additives used to enhance moisture resistance must meet stringent food contact material regulations, limiting the range of potential solutions and necessitating extensive testing and validation processes.

Lastly, the cost-effectiveness of moisture resistance improvements remains a significant challenge. Many potential solutions, while technically feasible, are economically prohibitive for large-scale implementation. Striking a balance between enhanced performance and cost-efficiency is crucial for widespread adoption in the packaging industry.

Existing Moisture Resistance Enhancement Techniques

01 Chemical modification of cellophane

Improving moisture resistance of cellophane through chemical modification techniques. This can involve treating the cellophane with various compounds or polymers to enhance its barrier properties against moisture. The modifications aim to alter the surface characteristics or internal structure of cellophane to reduce water absorption and permeability.- Chemical modification of cellophane: Improving moisture resistance of cellophane through chemical modification techniques. This can involve treating the cellophane with various compounds or polymers to enhance its barrier properties against moisture. The modifications aim to alter the surface characteristics or internal structure of cellophane to reduce water absorption and permeability.

- Coating applications for moisture resistance: Applying specialized coatings to cellophane to enhance its moisture resistance. These coatings can be made from various materials such as resins, waxes, or synthetic polymers. The coatings form a protective layer on the cellophane surface, effectively reducing moisture penetration and improving the overall barrier properties of the material.

- Multilayer structures incorporating cellophane: Developing multilayer structures that include cellophane as one of the layers to improve moisture resistance. These structures may combine cellophane with other moisture-resistant materials or films to create a composite with enhanced barrier properties. The layered approach allows for the combination of cellophane's desirable properties with the moisture resistance of other materials.

- Nanotechnology for cellophane moisture resistance: Utilizing nanotechnology to enhance the moisture resistance of cellophane. This can involve incorporating nanoparticles or nanostructures into the cellophane matrix or applying nanocoatings to the surface. These nano-scale modifications can significantly improve the moisture barrier properties of cellophane while maintaining its other desirable characteristics.

- Packaging designs for moisture-resistant cellophane: Developing innovative packaging designs that leverage moisture-resistant cellophane. This includes creating specialized packaging structures or configurations that maximize the moisture barrier properties of cellophane. The designs may incorporate features such as sealing techniques, moisture-absorbing components, or specific folding patterns to enhance the overall moisture resistance of the packaging.

02 Coating applications for moisture resistance

Applying specialized coatings to cellophane to enhance its moisture resistance. These coatings can be made from various materials such as resins, waxes, or synthetic polymers. The coatings form a protective layer on the cellophane surface, effectively reducing moisture penetration and improving the overall barrier properties of the material.Expand Specific Solutions03 Multilayer structures incorporating cellophane

Developing multilayer structures that include cellophane as one of the layers to improve moisture resistance. These structures can combine cellophane with other moisture-resistant materials or films to create a composite with enhanced barrier properties. The layered approach allows for the optimization of different material properties to achieve better moisture resistance.Expand Specific Solutions04 Nanotechnology for cellophane moisture resistance

Utilizing nanotechnology to enhance the moisture resistance of cellophane. This can involve incorporating nanoparticles or nanostructures into the cellophane matrix or surface to improve its barrier properties. Nanotechnology-based approaches can significantly alter the material's interaction with moisture at the molecular level.Expand Specific Solutions05 Packaging designs for moisture protection

Developing innovative packaging designs that utilize cellophane while addressing moisture resistance concerns. This can include creating specialized sealing methods, incorporating desiccants, or designing packaging structures that minimize moisture exposure to the cellophane components. The focus is on optimizing the overall package design to enhance moisture protection.Expand Specific Solutions

Key Players in Cellophane Manufacturing Industry

The moisture resistance optimization of cellophane is currently in a mature stage of development, with a global market size estimated to be in the billions of dollars. The technology has evolved significantly over the years, with major players like Mitsubishi Plastics, FUJIFILM, and Kuraray leading the innovation. These companies have developed advanced coating techniques and barrier materials to enhance cellophane's moisture resistance. The competitive landscape is characterized by ongoing research and development efforts, focusing on eco-friendly solutions and improved performance. Emerging players from China, such as Hainan Shiner Industrial and Guangdong Fumei New Material Technology, are also making strides in this field, potentially disrupting the market with cost-effective alternatives.

Mitsubishi Plastics, Inc.

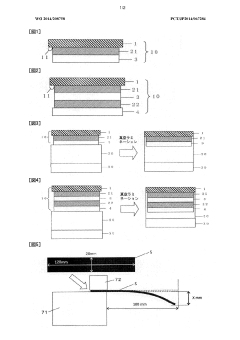

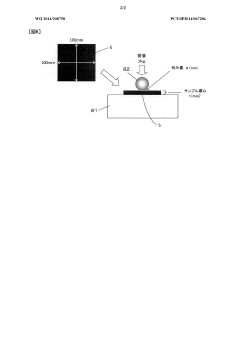

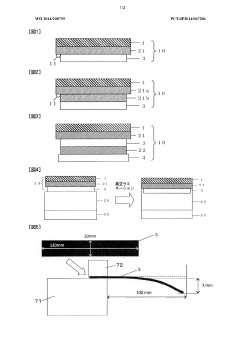

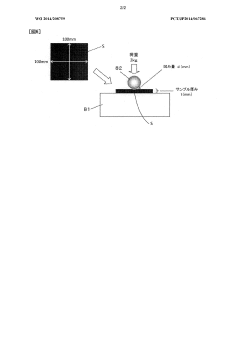

Technical Solution: Mitsubishi Plastics has developed a comprehensive approach to optimizing moisture resistance in cellophane through their DIAMIRON® technology. This involves a multi-step process that combines surface modification and coating techniques. First, the cellophane undergoes a plasma treatment to activate its surface, enhancing adhesion properties[10]. Then, a specially formulated moisture-resistant coating is applied using a high-precision roll-to-roll process. This coating is composed of a proprietary blend of polymers and inorganic particles, creating a highly effective barrier against water vapor[11]. Additionally, Mitsubishi has implemented a heat-treatment step that further improves the coating's performance by promoting cross-linking and reducing micro-defects in the barrier layer[12].

Strengths: Highly effective moisture barrier, improved adhesion properties, and potential for integration into existing production lines. Weaknesses: Multi-step process may increase production time and costs.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed an innovative approach to enhancing moisture resistance in cellophane through their EVAL™ EVOH (ethylene vinyl alcohol) technology. This method involves co-extruding a thin layer of EVAL™ EVOH with the cellophane base, creating a multi-layer structure with exceptional barrier properties[13]. The EVOH layer provides superior resistance to water vapor transmission while maintaining the transparency and flexibility of the cellophane. Kuraray has also implemented a proprietary surface treatment process that modifies the cellophane's surface energy, improving its compatibility with the EVOH layer and enhancing overall adhesion[14]. Furthermore, the company has explored the use of nanocomposite materials, incorporating moisture-resistant nanoparticles into the EVOH layer to further improve its barrier performance[15].

Strengths: Excellent moisture barrier properties, maintained transparency, and compatibility with existing cellophane production processes. Weaknesses: May require specialized co-extrusion equipment and potential increase in material costs due to the use of EVOH.

Innovative Approaches to Cellophane Moisture Barrier

Protective material for solar cell

PatentWO2014208758A1

Innovation

- A protective material configuration featuring a weather-resistant film, a resin layer, and an inorganic layer on a substrate, with a water vapor transmission rate of 0.1 g/m²/day, where the resin layer is formed from a thermoplastic resin composition without cross-linking agents and the width ratio of the protective material constituent layers is less than 1, ensuring excellent moisture resistance and flexibility.

Solar cell protective material

PatentWO2014208759A1

Innovation

- A solar cell protective material comprising a weather-resistant film, a resin layer, and a moisture-proof film with an inorganic layer, where the width of the resin layer is optimized relative to the weather-resistant and moisture-proof films to ensure effective sealing and adhesion, even after long-term storage, using a configuration where the width of the resin layer on the weather-resistant film side is wider than on the moisture-proof film side, and the moisture-proof film width is narrower than the weather-resistant film width.

Environmental Impact of Moisture-Resistant Cellophane

The environmental impact of moisture-resistant cellophane is a critical consideration in the development and application of this technology. As manufacturers strive to optimize moisture resistance in cellophane, it is essential to evaluate the ecological consequences of these improvements.

One of the primary environmental concerns associated with moisture-resistant cellophane is its biodegradability. Traditional cellophane is derived from renewable resources and is biodegradable. However, the addition of moisture-resistant coatings or treatments may alter its decomposition properties. Some moisture-resistant additives can significantly extend the time required for the material to break down in natural environments, potentially contributing to long-term pollution if not properly disposed of or recycled.

The production process of moisture-resistant cellophane also warrants scrutiny from an environmental perspective. The application of moisture-resistant coatings often involves the use of chemicals and solvents that may have negative impacts on air and water quality if not properly managed. Manufacturers must implement stringent emission control measures and waste treatment protocols to mitigate these risks.

Energy consumption is another factor to consider. The additional processing steps required to enhance moisture resistance in cellophane may increase the overall energy footprint of production. This could lead to higher greenhouse gas emissions if the energy sources used are not renewable or clean.

On the positive side, improved moisture resistance in cellophane can contribute to reduced food waste by extending the shelf life of packaged products. This indirect environmental benefit should be weighed against the potential drawbacks of the material itself. Additionally, the enhanced durability of moisture-resistant cellophane may reduce the need for double packaging or excessive material use in certain applications, potentially leading to a net reduction in packaging waste.

The recyclability of moisture-resistant cellophane is a crucial aspect of its environmental impact. While conventional cellophane can be composted or recycled, the addition of moisture-resistant properties may complicate these end-of-life processes. It is essential for researchers and manufacturers to develop moisture-resistant cellophane that maintains compatibility with existing recycling systems or to establish new recycling methods specifically designed for these materials.

Water usage in the production of moisture-resistant cellophane is another environmental consideration. The application of moisture-resistant coatings may require additional water-intensive processes, potentially straining local water resources in manufacturing regions. Implementing water-efficient technologies and closed-loop water systems can help mitigate this impact.

As the demand for sustainable packaging solutions grows, the environmental impact of moisture-resistant cellophane will likely face increased scrutiny. Future research and development efforts should focus on creating moisture-resistant cellophane that balances performance with environmental sustainability, exploring bio-based additives, and improving end-of-life management strategies to minimize ecological footprint.

One of the primary environmental concerns associated with moisture-resistant cellophane is its biodegradability. Traditional cellophane is derived from renewable resources and is biodegradable. However, the addition of moisture-resistant coatings or treatments may alter its decomposition properties. Some moisture-resistant additives can significantly extend the time required for the material to break down in natural environments, potentially contributing to long-term pollution if not properly disposed of or recycled.

The production process of moisture-resistant cellophane also warrants scrutiny from an environmental perspective. The application of moisture-resistant coatings often involves the use of chemicals and solvents that may have negative impacts on air and water quality if not properly managed. Manufacturers must implement stringent emission control measures and waste treatment protocols to mitigate these risks.

Energy consumption is another factor to consider. The additional processing steps required to enhance moisture resistance in cellophane may increase the overall energy footprint of production. This could lead to higher greenhouse gas emissions if the energy sources used are not renewable or clean.

On the positive side, improved moisture resistance in cellophane can contribute to reduced food waste by extending the shelf life of packaged products. This indirect environmental benefit should be weighed against the potential drawbacks of the material itself. Additionally, the enhanced durability of moisture-resistant cellophane may reduce the need for double packaging or excessive material use in certain applications, potentially leading to a net reduction in packaging waste.

The recyclability of moisture-resistant cellophane is a crucial aspect of its environmental impact. While conventional cellophane can be composted or recycled, the addition of moisture-resistant properties may complicate these end-of-life processes. It is essential for researchers and manufacturers to develop moisture-resistant cellophane that maintains compatibility with existing recycling systems or to establish new recycling methods specifically designed for these materials.

Water usage in the production of moisture-resistant cellophane is another environmental consideration. The application of moisture-resistant coatings may require additional water-intensive processes, potentially straining local water resources in manufacturing regions. Implementing water-efficient technologies and closed-loop water systems can help mitigate this impact.

As the demand for sustainable packaging solutions grows, the environmental impact of moisture-resistant cellophane will likely face increased scrutiny. Future research and development efforts should focus on creating moisture-resistant cellophane that balances performance with environmental sustainability, exploring bio-based additives, and improving end-of-life management strategies to minimize ecological footprint.

Cost-Benefit Analysis of Enhanced Moisture Resistance

Enhancing moisture resistance in cellophane packaging comes with both significant benefits and associated costs. The primary advantage lies in extended product shelf life, particularly for moisture-sensitive goods such as food items, pharmaceuticals, and electronics. Improved moisture barrier properties can reduce product spoilage, maintain quality, and potentially decrease overall waste. This enhancement can lead to increased customer satisfaction and brand loyalty, as products remain fresher for longer periods.

From a marketing perspective, enhanced moisture resistance can be a key differentiator in competitive markets. Packaging that offers superior protection against moisture can command premium pricing and attract quality-conscious consumers. This can result in higher profit margins and increased market share for companies that invest in such technologies.

However, the costs associated with improving moisture resistance in cellophane can be substantial. The development and implementation of new coating technologies or material modifications often require significant research and development investments. These may include expenses for specialized equipment, testing facilities, and skilled personnel. Additionally, the production process for enhanced cellophane may be more complex and time-consuming, potentially increasing manufacturing costs.

The use of advanced moisture-resistant additives or coatings can also impact the overall cost of raw materials. These specialized components are often more expensive than standard cellophane ingredients, which can drive up the per-unit cost of packaging. Companies must carefully evaluate whether the increased production costs can be offset by the benefits of improved product protection and potential market advantages.

Environmental considerations also play a role in the cost-benefit analysis. While enhanced moisture resistance can reduce food waste and extend product life, it may complicate recycling processes or increase the environmental footprint of the packaging. Companies must balance the benefits of moisture resistance with sustainability goals and potential regulatory compliance costs.

In conclusion, the decision to invest in optimizing moisture resistance in cellophane requires a comprehensive analysis of market demands, production capabilities, and long-term strategic goals. While the benefits of improved product protection and market differentiation are clear, companies must carefully weigh these against the increased costs and potential environmental impacts to determine the most advantageous approach for their specific product lines and target markets.

From a marketing perspective, enhanced moisture resistance can be a key differentiator in competitive markets. Packaging that offers superior protection against moisture can command premium pricing and attract quality-conscious consumers. This can result in higher profit margins and increased market share for companies that invest in such technologies.

However, the costs associated with improving moisture resistance in cellophane can be substantial. The development and implementation of new coating technologies or material modifications often require significant research and development investments. These may include expenses for specialized equipment, testing facilities, and skilled personnel. Additionally, the production process for enhanced cellophane may be more complex and time-consuming, potentially increasing manufacturing costs.

The use of advanced moisture-resistant additives or coatings can also impact the overall cost of raw materials. These specialized components are often more expensive than standard cellophane ingredients, which can drive up the per-unit cost of packaging. Companies must carefully evaluate whether the increased production costs can be offset by the benefits of improved product protection and potential market advantages.

Environmental considerations also play a role in the cost-benefit analysis. While enhanced moisture resistance can reduce food waste and extend product life, it may complicate recycling processes or increase the environmental footprint of the packaging. Companies must balance the benefits of moisture resistance with sustainability goals and potential regulatory compliance costs.

In conclusion, the decision to invest in optimizing moisture resistance in cellophane requires a comprehensive analysis of market demands, production capabilities, and long-term strategic goals. While the benefits of improved product protection and market differentiation are clear, companies must carefully weigh these against the increased costs and potential environmental impacts to determine the most advantageous approach for their specific product lines and target markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!