How to Optimize PVDF Coatings for Durability?

PVDF Coating Evolution

PVDF (polyvinylidene fluoride) coatings have undergone significant evolution since their introduction in the 1960s. Initially developed as a protective coating for metal surfaces, PVDF quickly gained popularity due to its exceptional durability and resistance to weathering, chemicals, and UV radiation.

In the early stages, PVDF coatings were primarily used in architectural applications, particularly for metal roofing and siding. The focus was on improving color retention and chalk resistance, which were critical factors in maintaining the aesthetic appeal of buildings over extended periods.

As the technology progressed, researchers and manufacturers began to explore ways to enhance the coating's performance in more demanding environments. This led to the development of modified PVDF formulations that incorporated additional polymers and additives to improve specific properties such as flexibility, adhesion, and impact resistance.

The 1980s and 1990s saw a significant expansion in the use of PVDF coatings across various industries. The automotive sector, for instance, began adopting PVDF coatings for exterior trim components due to their superior weatherability and chemical resistance. Similarly, the aerospace industry recognized the potential of PVDF coatings for protecting aircraft exteriors from harsh environmental conditions.

Advancements in application techniques also played a crucial role in the evolution of PVDF coatings. The introduction of spray application methods and the development of liquid PVDF formulations allowed for more efficient and uniform coating processes, expanding the range of substrates that could be effectively coated.

In recent years, the focus has shifted towards improving the sustainability and environmental impact of PVDF coatings. Manufacturers have been working on developing water-based PVDF formulations to reduce volatile organic compound (VOC) emissions during application. Additionally, efforts have been made to incorporate recycled materials and improve the recyclability of PVDF-coated products at the end of their lifecycle.

The ongoing evolution of PVDF coatings has also seen advancements in nanotechnology integration. Researchers are exploring the use of nanoparticles and nanostructures to further enhance the coating's properties, such as self-cleaning capabilities, improved scratch resistance, and enhanced thermal management.

As the demand for more durable and high-performance coatings continues to grow, the evolution of PVDF coatings is expected to persist. Future developments are likely to focus on further improving durability, expanding application methods, and addressing emerging environmental concerns while maintaining the core benefits that have made PVDF coatings a preferred choice in various industries.

Market Demand Analysis

The market demand for optimized PVDF coatings with enhanced durability has been steadily increasing across various industries. This growth is primarily driven by the expanding construction and automotive sectors, where long-lasting protective coatings are essential for maintaining the integrity and appearance of structures and vehicles.

In the construction industry, there is a growing emphasis on sustainable and low-maintenance building materials. PVDF coatings have gained popularity due to their excellent resistance to weathering, UV radiation, and chemical corrosion. The global construction market is projected to reach $15.2 trillion by 2030, with a significant portion of this growth attributed to the demand for high-performance coatings. Architects and builders are increasingly specifying PVDF coatings for exterior applications, particularly in regions with harsh environmental conditions.

The automotive industry represents another major market for durable PVDF coatings. As consumers demand longer-lasting finishes and manufacturers seek to reduce warranty claims related to paint degradation, the adoption of advanced coating technologies has accelerated. The global automotive coatings market is expected to grow at a CAGR of 4.5% from 2021 to 2026, with PVDF coatings playing a crucial role in this expansion.

Additionally, the aerospace and marine industries have shown increased interest in optimized PVDF coatings. These sectors require coatings that can withstand extreme temperatures, high-altitude UV exposure, and saltwater corrosion. The aerospace coatings market alone is anticipated to reach $1.9 billion by 2025, with durability being a key factor driving innovation and demand.

Environmental regulations have also contributed to the market demand for optimized PVDF coatings. As governments worldwide implement stricter VOC emission standards, manufacturers are turning to PVDF coatings as a more environmentally friendly alternative to traditional solvent-based coatings. This shift is particularly evident in developed countries, where environmental concerns are at the forefront of industrial policies.

The electronics industry is another emerging market for durable PVDF coatings. With the increasing production of outdoor electronic devices and displays, there is a growing need for coatings that can protect sensitive components from environmental factors. This trend is expected to continue as smart city initiatives and outdoor digital signage become more prevalent.

Market analysis indicates that the Asia-Pacific region is poised to become the largest market for PVDF coatings, driven by rapid industrialization and urbanization in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance coatings for premium applications.

Current Challenges

PVDF (polyvinylidene fluoride) coatings have gained significant popularity in various industries due to their exceptional durability and resistance to harsh environmental conditions. However, optimizing these coatings for enhanced durability presents several challenges that researchers and manufacturers must address.

One of the primary challenges in optimizing PVDF coatings is achieving the right balance between flexibility and hardness. While increased hardness can improve scratch resistance, it may lead to reduced flexibility, potentially causing cracking or delamination under thermal stress or mechanical impact. Conversely, enhancing flexibility may compromise the coating's ability to withstand abrasion and chemical attack.

Another significant challenge lies in improving the adhesion of PVDF coatings to various substrates. The inherent low surface energy of PVDF can result in poor adhesion, especially on metals and certain polymers. This issue is particularly critical in applications where the coating is exposed to temperature fluctuations, humidity, or corrosive environments, as poor adhesion can lead to premature coating failure.

UV resistance remains a persistent challenge in PVDF coating optimization. Although PVDF coatings generally exhibit good UV stability, prolonged exposure to intense sunlight can still cause degradation, leading to color fading, chalking, and reduced protective properties. Enhancing UV resistance without compromising other performance attributes is a complex task that requires careful formulation and additive selection.

The incorporation of functional additives, such as pigments, UV stabilizers, and anti-corrosion agents, presents another challenge. These additives are essential for enhancing specific properties of the coating, but they can also affect the overall performance and durability of the PVDF system. Achieving the right balance and ensuring compatibility between the additives and the PVDF resin is crucial for optimizing coating performance.

Processing and application techniques also pose significant challenges in PVDF coating optimization. The high melting point of PVDF and its tendency to degrade at elevated temperatures require precise control of processing conditions. Achieving uniform thickness and coverage, especially on complex geometries, demands advanced application techniques and careful process optimization.

Environmental and regulatory considerations add another layer of complexity to PVDF coating optimization. As global regulations become more stringent, there is a growing need to develop PVDF coating formulations with reduced VOC content and improved environmental sustainability, without compromising durability and performance.

Lastly, the cost-effectiveness of PVDF coatings remains a challenge in certain applications. While their long-term durability often justifies the initial higher cost, optimizing the formulation and application process to reduce overall costs without sacrificing performance is an ongoing challenge for manufacturers and researchers in the field.

Existing Optimization

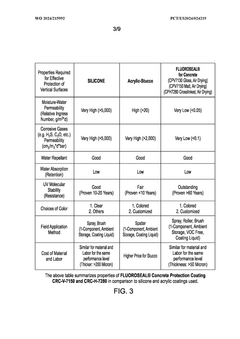

01 PVDF coating composition improvements

Enhancements to PVDF coating compositions to improve durability, including the addition of specific additives, nanoparticles, or modified polymer blends. These improvements can increase resistance to weathering, UV radiation, and chemical exposure, thereby extending the lifespan of the coating.- Improved PVDF coating formulations: Enhanced PVDF coating formulations are developed to increase durability. These formulations may include additives, modified polymer structures, or specialized blends to improve weather resistance, chemical resistance, and overall longevity of the coating.

- Surface treatment techniques: Various surface treatment methods are employed to enhance the adhesion and durability of PVDF coatings. These techniques may include plasma treatment, chemical etching, or application of primer layers to improve the bond between the coating and substrate.

- Nanocomposite PVDF coatings: Incorporation of nanoparticles or nanostructures into PVDF coatings to enhance their durability. These nanocomposites can improve mechanical strength, scratch resistance, and overall performance of the coating in harsh environments.

- Multi-layer coating systems: Development of multi-layer coating systems incorporating PVDF to improve overall durability. These systems may include specialized primer layers, intermediate coats, and topcoats designed to work synergistically for enhanced protection and longevity.

- Curing and application methods: Optimization of curing processes and application techniques to enhance the durability of PVDF coatings. This includes advancements in heat treatment, UV curing, and spray application methods to improve coating uniformity and adhesion.

02 Surface treatment techniques

Various surface treatment methods applied before PVDF coating application to enhance adhesion and durability. These techniques may include plasma treatment, chemical etching, or the application of primer layers, resulting in improved bonding between the substrate and the PVDF coating.Expand Specific Solutions03 Multi-layer coating systems

Development of multi-layer coating systems incorporating PVDF as one of the layers. These systems often include primer layers, intermediate layers, and topcoats, each serving specific functions to enhance overall durability, weather resistance, and longevity of the coating system.Expand Specific Solutions04 Application methods for improved durability

Innovative application techniques for PVDF coatings that result in enhanced durability. These may include specialized spray methods, electrostatic application, or heat treatment processes that optimize the coating's structure and properties during application and curing.Expand Specific Solutions05 Testing and evaluation methods

Development of advanced testing and evaluation methods to assess the durability of PVDF coatings. These include accelerated weathering tests, chemical resistance evaluations, and long-term performance studies that help in predicting and improving the coating's durability in various environmental conditions.Expand Specific Solutions

Key Industry Players

The optimization of PVDF coatings for durability is a rapidly evolving field in the advanced materials industry. The market is experiencing steady growth, driven by increasing demand in sectors such as construction, automotive, and electronics. While the technology is relatively mature, ongoing research and development efforts are focused on enhancing performance and longevity. Key players like Arkema, DuPont, and AGC are leading the innovation charge, with significant contributions from academic institutions such as Zhejiang University and Beijing University of Chemical Technology. Emerging companies like Ningde Zhuo High-tech Materials Technology are also making strides in this competitive landscape. The market is characterized by a mix of established global corporations and specialized regional players, indicating a diverse and dynamic competitive environment.

Arkema France SA

Arkema, Inc.

Innovative Approaches

- A method involving the application of a liquidous coating of modified polyvinylidene fluoride (PVDF) or polyvinylidene difluoride (PVDF) material in an air dryable solution, which is highly fluorinated and has high polymer crystallinity, allowing it to be applied in the field without specialized equipment, effectively blocking moisture and corrosive gases, and providing long-term protection against corrosion.

- A method involving the application of two layers of modified polyvinylidene fluoride (PVDF) coatings in air-dryable solutions, with the undercoating containing a PVDF co-polymer blended with acrylic and the overcoating highly fluorinated, allowing application in situ on large metal structures without specialized equipment, providing superior moisture and gas barrier properties.

Environmental Impact

The environmental impact of PVDF coatings is a critical consideration in optimizing their durability. These coatings have gained popularity due to their excellent weather resistance and long-lasting performance, but their environmental footprint must be carefully evaluated throughout their lifecycle.

PVDF coatings are known for their low volatile organic compound (VOC) emissions during application and curing, which contributes to improved air quality compared to some alternative coating systems. This characteristic aligns with increasingly stringent environmental regulations in many regions, making PVDF coatings an attractive option for environmentally conscious projects.

The durability of PVDF coatings also plays a significant role in their environmental impact. By extending the lifespan of coated surfaces, these coatings reduce the frequency of repainting or replacement, thereby minimizing waste generation and resource consumption over time. This longevity factor is particularly important in architectural applications, where coating replacement can be both costly and disruptive.

However, the production of PVDF resins involves fluoropolymers, which have raised environmental concerns due to their persistence in the environment. While PVDF itself is considered relatively inert, the manufacturing process of its precursors may contribute to the release of potentially harmful substances. Ongoing research is focused on developing more environmentally friendly production methods and exploring bio-based alternatives to reduce the ecological footprint of PVDF coatings.

End-of-life considerations for PVDF coatings are also crucial. While these coatings are highly durable, their eventual disposal or recycling presents challenges. The strong chemical bonds that provide PVDF with its exceptional resistance also make it difficult to break down or separate from substrates. Developing effective recycling methods for PVDF-coated materials is an area of active research, aiming to close the loop in the product lifecycle.

Optimizing PVDF coatings for durability must therefore balance performance enhancements with environmental considerations. Strategies may include improving the coating's resistance to UV degradation and chemical exposure, which could further extend its useful life. Additionally, incorporating self-cleaning or easy-to-clean properties could reduce the need for harsh cleaning agents and maintenance procedures, further minimizing environmental impact during the use phase.

Advancements in nanotechnology offer promising avenues for enhancing PVDF coating durability while potentially reducing material usage. Nanocomposite PVDF coatings, for instance, may provide improved barrier properties and mechanical strength with lower overall material requirements, potentially lessening environmental impact without compromising performance.

Performance Testing

Performance testing is a critical aspect of optimizing PVDF coatings for durability. This process involves subjecting the coatings to various environmental and mechanical stresses to evaluate their long-term performance and identify areas for improvement.

One of the primary performance tests for PVDF coatings is accelerated weathering. This test simulates prolonged exposure to sunlight, moisture, and temperature fluctuations using specialized equipment such as QUV accelerated weathering testers or xenon arc chambers. These tests can compress years of natural weathering into a matter of weeks or months, allowing researchers to quickly assess the coating's resistance to UV degradation, color fading, and chalking.

Corrosion resistance is another crucial factor in PVDF coating durability. Salt spray testing, as outlined in ASTM B117, exposes coated samples to a continuous salt fog environment, simulating coastal or marine conditions. This test evaluates the coating's ability to protect the underlying substrate from corrosion and maintain its integrity in harsh environments.

Mechanical properties are also essential for PVDF coating performance. Adhesion testing, such as cross-cut or pull-off tests, assesses the coating's ability to adhere to the substrate under various conditions. Flexibility and impact resistance tests, including mandrel bending and falling weight impact tests, evaluate the coating's ability to withstand deformation without cracking or delaminating.

Chemical resistance is another critical aspect of PVDF coating performance. Immersion tests in various solvents, acids, and alkalis help determine the coating's resistance to chemical attack and staining. These tests are particularly important for applications in industrial or chemical processing environments.

Abrasion resistance testing, using methods like the Taber abraser test, evaluates the coating's ability to withstand mechanical wear and maintain its protective properties over time. This is particularly important for applications where the coated surface may be subject to frequent cleaning or physical contact.

Thermal cycling tests subject the coated samples to repeated temperature fluctuations, simulating the expansion and contraction that occurs in real-world applications. This helps assess the coating's ability to maintain adhesion and prevent cracking under thermal stress.

To optimize PVDF coatings for durability, researchers analyze the results of these performance tests to identify weaknesses and areas for improvement. This may involve adjusting the coating formulation, modifying application techniques, or developing new additives to enhance specific properties. By iteratively refining the coating based on performance test results, manufacturers can develop more durable and long-lasting PVDF coatings that meet the demanding requirements of various industries.