How to Prevent Phase Separation and Supercooling in PCM Systems

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Technology Background and Objectives

Phase Change Materials (PCMs) have emerged as a pivotal technology in thermal energy storage systems over the past several decades. Initially developed for aerospace applications in the 1970s and 1980s, PCMs have evolved significantly to address broader energy efficiency challenges across multiple industries. The fundamental principle behind PCMs—their ability to absorb, store, and release large amounts of energy during phase transitions—makes them exceptionally valuable for thermal management and energy conservation applications.

The evolution of PCM technology has been marked by continuous improvements in material composition, encapsulation techniques, and system integration approaches. Early PCM systems primarily utilized simple salt hydrates and paraffin compounds, while contemporary solutions incorporate advanced eutectic mixtures, bio-based materials, and nano-enhanced composites to achieve superior performance characteristics.

Despite their promising attributes, PCM systems face persistent technical challenges that limit their widespread adoption. Phase separation and supercooling represent two of the most significant barriers to reliable PCM performance. Phase separation occurs when the components of a PCM mixture segregate during repeated thermal cycling, leading to degraded thermal properties and reduced operational lifespan. Supercooling, meanwhile, manifests as the delay in crystallization when a liquid PCM is cooled below its freezing point, resulting in unpredictable energy release patterns and diminished system efficiency.

The primary technical objective in this domain is to develop robust solutions that effectively mitigate both phase separation and supercooling phenomena without compromising the fundamental thermal storage capabilities of PCM systems. This includes exploring novel material formulations, innovative nucleation techniques, and advanced containment strategies that maintain homogeneity throughout numerous thermal cycles.

Secondary objectives include enhancing the overall energy density of PCM systems, improving their thermal conductivity to address heat transfer limitations, and developing cost-effective manufacturing processes that enable broader market penetration. Additionally, there is growing emphasis on developing environmentally sustainable PCM solutions that minimize ecological impact throughout their lifecycle.

The convergence of materials science, thermodynamics, and engineering design principles is driving rapid innovation in this field. Recent technological breakthroughs in nano-additives, microencapsulation techniques, and composite material development have opened promising pathways toward resolving the phase separation and supercooling challenges, potentially unlocking the full potential of PCM technology for next-generation energy storage and thermal management applications.

The evolution of PCM technology has been marked by continuous improvements in material composition, encapsulation techniques, and system integration approaches. Early PCM systems primarily utilized simple salt hydrates and paraffin compounds, while contemporary solutions incorporate advanced eutectic mixtures, bio-based materials, and nano-enhanced composites to achieve superior performance characteristics.

Despite their promising attributes, PCM systems face persistent technical challenges that limit their widespread adoption. Phase separation and supercooling represent two of the most significant barriers to reliable PCM performance. Phase separation occurs when the components of a PCM mixture segregate during repeated thermal cycling, leading to degraded thermal properties and reduced operational lifespan. Supercooling, meanwhile, manifests as the delay in crystallization when a liquid PCM is cooled below its freezing point, resulting in unpredictable energy release patterns and diminished system efficiency.

The primary technical objective in this domain is to develop robust solutions that effectively mitigate both phase separation and supercooling phenomena without compromising the fundamental thermal storage capabilities of PCM systems. This includes exploring novel material formulations, innovative nucleation techniques, and advanced containment strategies that maintain homogeneity throughout numerous thermal cycles.

Secondary objectives include enhancing the overall energy density of PCM systems, improving their thermal conductivity to address heat transfer limitations, and developing cost-effective manufacturing processes that enable broader market penetration. Additionally, there is growing emphasis on developing environmentally sustainable PCM solutions that minimize ecological impact throughout their lifecycle.

The convergence of materials science, thermodynamics, and engineering design principles is driving rapid innovation in this field. Recent technological breakthroughs in nano-additives, microencapsulation techniques, and composite material development have opened promising pathways toward resolving the phase separation and supercooling challenges, potentially unlocking the full potential of PCM technology for next-generation energy storage and thermal management applications.

Market Analysis for PCM Applications

The global Phase Change Material (PCM) market has demonstrated robust growth, valued at approximately $1.5 billion in 2022 and projected to reach $3.8 billion by 2030, with a compound annual growth rate (CAGR) of 12.4%. This growth trajectory is primarily driven by increasing demand for energy-efficient solutions across various sectors, particularly in building and construction, which currently accounts for nearly 40% of the total PCM market share.

The building and construction sector represents the largest application segment for PCMs, with thermal energy storage systems for heating and cooling applications being the primary use case. The integration of PCMs in building materials has shown potential to reduce energy consumption by 20-30% in residential and commercial buildings, offering significant cost savings and environmental benefits.

Cold chain logistics and transportation constitute the second-largest market segment, valued at approximately $380 million in 2022. This sector is experiencing accelerated growth due to expanding pharmaceutical and food industries requiring temperature-controlled environments. PCM-based passive cooling solutions are increasingly preferred over traditional mechanical refrigeration systems due to their reliability and reduced operational costs.

The electronics cooling segment is emerging as the fastest-growing application area with a CAGR of 15.7%. As electronic devices become more compact and powerful, thermal management challenges intensify, creating substantial market opportunities for PCM-based cooling solutions that can prevent overheating without consuming additional energy.

Geographically, North America and Europe currently dominate the PCM market, collectively accounting for approximately 65% of global revenue. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, increasing construction activities, and growing awareness about energy conservation in countries like China, Japan, and India.

A significant market challenge remains the higher initial cost of PCM systems compared to conventional alternatives, with price premiums ranging from 30-50%. However, this barrier is gradually diminishing as manufacturing scales up and technological advancements continue. The return on investment period for PCM systems has decreased from 7-8 years to 3-5 years over the past decade, enhancing their commercial viability.

The market is also witnessing a shift toward bio-based and sustainable PCMs, which currently represent about 15% of the market but are growing at nearly twice the rate of petroleum-based alternatives. This trend aligns with global sustainability initiatives and offers premium pricing opportunities for manufacturers focusing on environmentally friendly solutions.

The building and construction sector represents the largest application segment for PCMs, with thermal energy storage systems for heating and cooling applications being the primary use case. The integration of PCMs in building materials has shown potential to reduce energy consumption by 20-30% in residential and commercial buildings, offering significant cost savings and environmental benefits.

Cold chain logistics and transportation constitute the second-largest market segment, valued at approximately $380 million in 2022. This sector is experiencing accelerated growth due to expanding pharmaceutical and food industries requiring temperature-controlled environments. PCM-based passive cooling solutions are increasingly preferred over traditional mechanical refrigeration systems due to their reliability and reduced operational costs.

The electronics cooling segment is emerging as the fastest-growing application area with a CAGR of 15.7%. As electronic devices become more compact and powerful, thermal management challenges intensify, creating substantial market opportunities for PCM-based cooling solutions that can prevent overheating without consuming additional energy.

Geographically, North America and Europe currently dominate the PCM market, collectively accounting for approximately 65% of global revenue. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, increasing construction activities, and growing awareness about energy conservation in countries like China, Japan, and India.

A significant market challenge remains the higher initial cost of PCM systems compared to conventional alternatives, with price premiums ranging from 30-50%. However, this barrier is gradually diminishing as manufacturing scales up and technological advancements continue. The return on investment period for PCM systems has decreased from 7-8 years to 3-5 years over the past decade, enhancing their commercial viability.

The market is also witnessing a shift toward bio-based and sustainable PCMs, which currently represent about 15% of the market but are growing at nearly twice the rate of petroleum-based alternatives. This trend aligns with global sustainability initiatives and offers premium pricing opportunities for manufacturers focusing on environmentally friendly solutions.

Phase Separation Challenges in Current PCM Systems

Phase separation represents one of the most significant challenges in Phase Change Material (PCM) systems, particularly in salt hydrates and eutectic mixtures. This phenomenon occurs when the components of a PCM separate into distinct phases during repeated thermal cycling, severely compromising the material's thermal storage capacity and overall performance. The primary mechanism behind phase separation involves the difference in density between the solid and liquid phases, causing stratification where heavier components sink while lighter ones float.

In current commercial PCM systems, phase separation manifests in several critical ways. Salt hydrate PCMs, despite their high energy density and relatively low cost, frequently exhibit incongruent melting where the salt cannot be completely dissolved in its water of crystallization. This results in anhydrous salt precipitation at the bottom of containers, creating a non-homogeneous system that progressively loses thermal storage capacity with each cycle.

Eutectic mixtures of organic and inorganic compounds face similar challenges. These carefully formulated combinations, designed to melt and freeze at specific temperatures, gradually separate into their constituent components during operation. The separation disrupts the precise ratio required for the eutectic behavior, shifting the melting point and reducing the latent heat storage capacity.

Macro-encapsulated PCM systems demonstrate particularly severe phase separation issues. In larger volumes, the gravitational effects become more pronounced, accelerating component segregation. This has limited the scalability of many promising PCM formulations, restricting their application in large-scale thermal energy storage systems where they would otherwise offer significant advantages.

The consequences of phase separation extend beyond reduced thermal performance. The non-uniform distribution of components leads to localized overheating, thermal stress, and potential container damage. Additionally, the changing composition at different locations within the PCM volume creates unpredictable thermal behavior, making system control and optimization extremely difficult.

Current mitigation strategies include mechanical stirring, which adds complexity and energy consumption; thickening agents, which often reduce thermal conductivity; and container geometry modifications, which limit design flexibility. None of these approaches has provided a comprehensive solution that maintains performance while being economically viable at scale.

The persistence of phase separation issues has significantly hindered market adoption of PCM technologies in critical applications such as building thermal management, solar thermal storage, and industrial waste heat recovery. This technical barrier represents a major obstacle to the broader implementation of thermal energy storage solutions that could otherwise contribute substantially to energy efficiency and renewable energy integration.

In current commercial PCM systems, phase separation manifests in several critical ways. Salt hydrate PCMs, despite their high energy density and relatively low cost, frequently exhibit incongruent melting where the salt cannot be completely dissolved in its water of crystallization. This results in anhydrous salt precipitation at the bottom of containers, creating a non-homogeneous system that progressively loses thermal storage capacity with each cycle.

Eutectic mixtures of organic and inorganic compounds face similar challenges. These carefully formulated combinations, designed to melt and freeze at specific temperatures, gradually separate into their constituent components during operation. The separation disrupts the precise ratio required for the eutectic behavior, shifting the melting point and reducing the latent heat storage capacity.

Macro-encapsulated PCM systems demonstrate particularly severe phase separation issues. In larger volumes, the gravitational effects become more pronounced, accelerating component segregation. This has limited the scalability of many promising PCM formulations, restricting their application in large-scale thermal energy storage systems where they would otherwise offer significant advantages.

The consequences of phase separation extend beyond reduced thermal performance. The non-uniform distribution of components leads to localized overheating, thermal stress, and potential container damage. Additionally, the changing composition at different locations within the PCM volume creates unpredictable thermal behavior, making system control and optimization extremely difficult.

Current mitigation strategies include mechanical stirring, which adds complexity and energy consumption; thickening agents, which often reduce thermal conductivity; and container geometry modifications, which limit design flexibility. None of these approaches has provided a comprehensive solution that maintains performance while being economically viable at scale.

The persistence of phase separation issues has significantly hindered market adoption of PCM technologies in critical applications such as building thermal management, solar thermal storage, and industrial waste heat recovery. This technical barrier represents a major obstacle to the broader implementation of thermal energy storage solutions that could otherwise contribute substantially to energy efficiency and renewable energy integration.

Current Approaches to Mitigate Supercooling Effects

01 Prevention of phase separation in PCM systems

Various methods are employed to prevent phase separation in phase change material systems, which can compromise their thermal energy storage capabilities. These methods include using stabilizing additives, encapsulation techniques, and specialized material compositions that maintain homogeneity during phase transitions. By preventing the separation of components during melting and solidification cycles, these innovations ensure consistent thermal performance and extend the operational lifespan of PCM systems.- Prevention of phase separation in PCM systems: Phase separation in phase change materials can be prevented through various methods including the use of gelling agents, thickeners, or encapsulation techniques. These additives help maintain the homogeneity of the PCM composition during phase transitions, ensuring consistent thermal performance over multiple cycles. Preventing phase separation is crucial for maintaining the energy storage capacity and efficiency of PCM systems in applications such as thermal energy storage and temperature regulation.

- Supercooling reduction techniques in PCMs: Supercooling, where PCMs remain liquid below their freezing point, can be mitigated through the addition of nucleating agents that promote crystallization. These agents provide sites for crystal formation, triggering solidification at temperatures closer to the theoretical phase change temperature. Techniques such as surface modification of nucleating agents and optimized dispersion methods can enhance their effectiveness in reducing supercooling, thereby improving the reliability and performance of PCM-based thermal management systems.

- PCM encapsulation for stability enhancement: Encapsulation of phase change materials within protective shells or matrices helps maintain their physical integrity during phase transitions. This technique prevents leakage of the liquid phase and reduces interaction with surrounding materials. Various encapsulation methods include microencapsulation, shell structures, and matrix embedding, which can be tailored to specific application requirements. Properly encapsulated PCMs demonstrate improved cycling stability, reduced phase separation, and enhanced heat transfer characteristics.

- PCM composites for thermal energy storage: Composite PCM systems combine phase change materials with supporting matrices or additives to enhance thermal conductivity and structural stability. These composites often incorporate materials such as graphite, metal foams, or carbon nanostructures to improve heat transfer rates while maintaining high energy storage density. The composite structure helps prevent phase separation and reduces supercooling effects, resulting in more efficient and reliable thermal energy storage systems for applications in building climate control, electronics cooling, and renewable energy storage.

- PCM integration in electronic devices: Phase change materials are increasingly being integrated into electronic devices for thermal management purposes. These implementations include PCM layers in semiconductor packages, thermal interface materials, and dedicated heat sinks. Special formulations address the unique constraints of electronic applications, such as space limitations, reliability requirements, and compatibility with manufacturing processes. Advanced PCM systems for electronics feature reduced supercooling, minimal phase separation, and optimized thermal response characteristics to protect sensitive components from temperature fluctuations.

02 Supercooling reduction techniques in PCMs

Supercooling, where PCMs remain liquid below their freezing point, reduces energy storage efficiency. Various techniques address this issue, including nucleating agents that initiate crystallization, surface modifications that promote heterogeneous nucleation, and specialized additives that reduce the energy barrier for crystallization. These approaches ensure more reliable phase transitions at the desired temperature, improving the predictability and efficiency of thermal energy storage systems.Expand Specific Solutions03 PCM integration in battery thermal management

Phase change materials are increasingly integrated into battery thermal management systems to regulate temperature and prevent overheating. These systems utilize the latent heat absorption during phase transition to maintain optimal operating temperatures for batteries. Advanced designs incorporate PCMs with specific melting points matched to battery thermal requirements, along with enhanced heat transfer structures to improve thermal conductivity and response time, resulting in extended battery life and improved safety.Expand Specific Solutions04 Nanostructured PCMs for enhanced performance

Nanostructured and nanocomposite PCMs represent an advanced approach to addressing traditional PCM limitations. By incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles, these systems achieve significantly improved thermal conductivity, reduced supercooling, and enhanced phase stability. The nanostructures provide nucleation sites that promote consistent crystallization and prevent phase separation, while simultaneously improving heat transfer rates throughout the material.Expand Specific Solutions05 PCM systems with electrical energy storage integration

Innovative systems combine phase change materials with electrical energy storage components to create multifunctional energy management solutions. These hybrid systems leverage PCMs for thermal regulation while simultaneously incorporating electrical energy storage capabilities. The integration allows for more efficient energy utilization, with thermal energy from electrical components being captured by PCMs and either dissipated or repurposed. This approach is particularly valuable in applications requiring both thermal management and electrical energy storage.Expand Specific Solutions

Leading PCM Industry Players and Research Institutions

The phase change material (PCM) market is currently in a growth stage, with increasing adoption across thermal energy storage applications. The global PCM market is projected to expand significantly due to rising energy efficiency demands and sustainable building initiatives. Technologically, preventing phase separation and supercooling remains challenging, with companies pursuing different approaches. Sunamp has developed stable heat batteries using proprietary PCM formulations, while Merck Patent GmbH focuses on chemical additives to enhance nucleation. Pioneer Energy and Honeywell International are advancing microencapsulation techniques to prevent phase separation. Academic institutions like Dalian University of Technology and Monash University are researching novel nucleating agents. Schneider Electric and Whirlpool are integrating PCM solutions into consumer and industrial applications, focusing on reliability improvements through system design optimization.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced PCM systems utilizing their expertise in materials science and thermal management. Their approach to preventing phase separation and supercooling involves proprietary chemical stabilization techniques where carefully selected compatibilizers create strong intermolecular bonds between PCM components. Honeywell's technology incorporates specially engineered nucleating agents with crystallographic similarities to the PCM, significantly reducing the energy barrier for crystallization. Their systems feature gradient-density structures where components are strategically distributed to maintain stability during phase transitions. Additionally, Honeywell employs surface-modified nanoparticles that simultaneously enhance thermal conductivity while providing nucleation sites throughout the material. Their PCM formulations undergo extensive cycling tests under accelerated conditions to ensure long-term stability and performance reliability.

Strengths: Extensive industrial experience in materials engineering and thermal management systems with global manufacturing capabilities. Weaknesses: Their solutions may be optimized for specific industrial applications rather than offering versatility across different temperature ranges or applications.

Dalian University of Technology

Technical Solution: Dalian University of Technology has pioneered microencapsulation techniques for PCMs that effectively prevent both phase separation and supercooling. Their research team has developed core-shell microstructures where PCM materials are enclosed within polymer shells with precisely engineered surface properties. These microcapsules incorporate nucleating agents directly into the core material, while the shell provides physical constraint against component separation. Their innovation includes surface-modified nanoparticles that serve dual functions: enhancing thermal conductivity while simultaneously providing nucleation sites to trigger crystallization at minimal supercooling. The university has also developed composite PCM systems where the matrix material is chemically compatible with the PCM components, creating strong intermolecular interactions that resist separation during phase transitions.

Strengths: Strong fundamental research capabilities with numerous published studies on PCM behavior and modification techniques. Weaknesses: As an academic institution, may face challenges in scaling technologies to commercial production volumes and cost-effective manufacturing.

Key Patents in PCM Stability Enhancement

Phase change materials with enhanced thermal stability

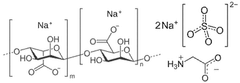

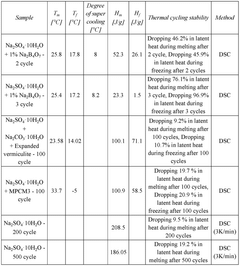

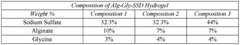

PatentWO2024215742A1

Innovation

- The use of glycine as a nucleating agent combined with sodium sulfate decahydrate and alginate forms a hydrogel with improved thermo-cyclic stability, reducing supercooling and promoting uniform solidification through a stable 3D network structure.

Phase change material composition and uses thereof

PatentWO2015176184A1

Innovation

- A PCM composition comprising an aqueous solution of lithium nitrate and nitric acid, potentially with additives like graphite or clay, which reduces supercooling and enhances stability, maintaining high latent heat absorption and thermal conductivity while being non-flammable, suitable for thermoregulation in fire-resistant garments.

Environmental Impact of PCM Materials

The environmental impact of Phase Change Materials (PCMs) is a critical consideration in their development and application, particularly when addressing challenges like phase separation and supercooling. PCMs offer significant potential for energy conservation through thermal energy storage, which can reduce reliance on conventional heating and cooling systems that consume substantial electricity or fossil fuels. This reduction in energy consumption directly translates to lower greenhouse gas emissions and decreased carbon footprint across various applications.

However, the environmental benefits of PCMs must be weighed against potential ecological concerns. Many commercial PCMs contain chemicals that may pose environmental risks if improperly disposed of or leaked into ecosystems. Paraffin-based PCMs, while effective for thermal storage, are petroleum derivatives with inherent sustainability issues. Salt hydrates, another common PCM category, may contain heavy metals or other compounds that could contaminate soil and water systems if released into the environment.

The manufacturing processes for PCMs also warrant environmental scrutiny. Energy-intensive production methods and the extraction of raw materials contribute to the overall environmental footprint of these materials. Life cycle assessments indicate that the environmental benefits of PCM applications must significantly outweigh these production impacts to justify their use from a sustainability perspective.

Recent innovations addressing phase separation and supercooling challenges have introduced new environmental considerations. Microencapsulation techniques, while effective for preventing phase separation, often utilize synthetic polymers as shell materials, which may not be biodegradable. Similarly, nucleating agents added to prevent supercooling may introduce additional chemical compounds into PCM systems with unknown long-term environmental effects.

Biodegradable alternatives are emerging as environmentally responsible solutions. Bio-based PCMs derived from vegetable oils, fatty acids, and other renewable resources offer promising environmental profiles. These materials typically feature lower toxicity, better biodegradability, and reduced carbon footprints compared to their petroleum-based counterparts. However, they often present greater technical challenges in preventing phase separation and supercooling.

Regulatory frameworks worldwide are increasingly emphasizing the environmental aspects of PCM systems. The European Union's REACH regulations and similar initiatives globally are driving manufacturers toward greener formulations with reduced environmental impact. This regulatory pressure is accelerating research into environmentally benign solutions for phase separation and supercooling issues, including the development of naturally derived stabilizers and nucleating agents.

However, the environmental benefits of PCMs must be weighed against potential ecological concerns. Many commercial PCMs contain chemicals that may pose environmental risks if improperly disposed of or leaked into ecosystems. Paraffin-based PCMs, while effective for thermal storage, are petroleum derivatives with inherent sustainability issues. Salt hydrates, another common PCM category, may contain heavy metals or other compounds that could contaminate soil and water systems if released into the environment.

The manufacturing processes for PCMs also warrant environmental scrutiny. Energy-intensive production methods and the extraction of raw materials contribute to the overall environmental footprint of these materials. Life cycle assessments indicate that the environmental benefits of PCM applications must significantly outweigh these production impacts to justify their use from a sustainability perspective.

Recent innovations addressing phase separation and supercooling challenges have introduced new environmental considerations. Microencapsulation techniques, while effective for preventing phase separation, often utilize synthetic polymers as shell materials, which may not be biodegradable. Similarly, nucleating agents added to prevent supercooling may introduce additional chemical compounds into PCM systems with unknown long-term environmental effects.

Biodegradable alternatives are emerging as environmentally responsible solutions. Bio-based PCMs derived from vegetable oils, fatty acids, and other renewable resources offer promising environmental profiles. These materials typically feature lower toxicity, better biodegradability, and reduced carbon footprints compared to their petroleum-based counterparts. However, they often present greater technical challenges in preventing phase separation and supercooling.

Regulatory frameworks worldwide are increasingly emphasizing the environmental aspects of PCM systems. The European Union's REACH regulations and similar initiatives globally are driving manufacturers toward greener formulations with reduced environmental impact. This regulatory pressure is accelerating research into environmentally benign solutions for phase separation and supercooling issues, including the development of naturally derived stabilizers and nucleating agents.

Standardization and Testing Protocols for PCM Systems

The standardization and testing protocols for Phase Change Material (PCM) systems represent a critical framework for ensuring consistent performance and reliability in thermal energy storage applications. Currently, the PCM industry faces significant challenges due to the lack of universally accepted testing methodologies and performance metrics, particularly for addressing phase separation and supercooling issues.

International standards organizations including ASTM International, ISO, and IEC have developed preliminary standards for PCM characterization, such as ASTM E2716 for enthalpy measurement and ISO 17498 for thermal performance assessment. However, these standards often lack specific protocols for evaluating long-term stability against phase separation or quantifying supercooling behavior under various operational conditions.

A comprehensive standardization framework should include accelerated aging tests that simulate thousands of thermal cycles to predict phase separation tendencies in PCM systems. These protocols typically involve subjecting samples to repeated heating and cooling cycles at varying rates while monitoring changes in thermal properties and physical composition. Differential Scanning Calorimetry (DSC) measurements before and after cycling can quantify degradation in thermal storage capacity.

For supercooling assessment, standardized protocols should establish consistent methodologies for measuring nucleation temperatures across different sample sizes and cooling rates. The degree of supercooling should be quantified as the temperature difference between the theoretical phase change temperature and the actual nucleation temperature under specified conditions.

Round-robin testing involving multiple laboratories has emerged as a valuable approach for validating these protocols. Recent collaborative efforts between research institutions and industry partners have demonstrated that interlaboratory variations can be significantly reduced through detailed procedural specifications and calibration requirements.

Certification systems based on these standardized tests would enable manufacturers to provide performance guarantees and allow designers to make informed material selections. Several industry associations have proposed certification frameworks that classify PCMs based on their resistance to phase separation and predictability of nucleation behavior.

The economic impact of standardization extends beyond technical considerations, potentially reducing market barriers and accelerating PCM adoption across various applications. By establishing clear performance metrics and testing methodologies, these protocols create a common language between material developers, system integrators, and end users, ultimately driving innovation in more stable and reliable PCM formulations.

International standards organizations including ASTM International, ISO, and IEC have developed preliminary standards for PCM characterization, such as ASTM E2716 for enthalpy measurement and ISO 17498 for thermal performance assessment. However, these standards often lack specific protocols for evaluating long-term stability against phase separation or quantifying supercooling behavior under various operational conditions.

A comprehensive standardization framework should include accelerated aging tests that simulate thousands of thermal cycles to predict phase separation tendencies in PCM systems. These protocols typically involve subjecting samples to repeated heating and cooling cycles at varying rates while monitoring changes in thermal properties and physical composition. Differential Scanning Calorimetry (DSC) measurements before and after cycling can quantify degradation in thermal storage capacity.

For supercooling assessment, standardized protocols should establish consistent methodologies for measuring nucleation temperatures across different sample sizes and cooling rates. The degree of supercooling should be quantified as the temperature difference between the theoretical phase change temperature and the actual nucleation temperature under specified conditions.

Round-robin testing involving multiple laboratories has emerged as a valuable approach for validating these protocols. Recent collaborative efforts between research institutions and industry partners have demonstrated that interlaboratory variations can be significantly reduced through detailed procedural specifications and calibration requirements.

Certification systems based on these standardized tests would enable manufacturers to provide performance guarantees and allow designers to make informed material selections. Several industry associations have proposed certification frameworks that classify PCMs based on their resistance to phase separation and predictability of nucleation behavior.

The economic impact of standardization extends beyond technical considerations, potentially reducing market barriers and accelerating PCM adoption across various applications. By establishing clear performance metrics and testing methodologies, these protocols create a common language between material developers, system integrators, and end users, ultimately driving innovation in more stable and reliable PCM formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!