PCM Thermal Pads for EV Battery Packs: Abuse Scenarios and Modeling

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Thermal Pads Background and Objectives

Phase Change Material (PCM) thermal pads represent a significant advancement in thermal management solutions for electric vehicle (EV) battery packs. These innovative materials have emerged over the past decade as manufacturers seek more efficient and reliable methods to control temperature fluctuations in high-capacity battery systems. PCM thermal pads incorporate materials that absorb and release thermal energy during phase transitions, providing a passive yet effective approach to temperature regulation.

The evolution of PCM technology for EV applications has progressed from simple paraffin-based compounds to sophisticated engineered materials with precisely tailored melting points and thermal properties. Early implementations focused primarily on general heat dissipation, while current generations address specific thermal challenges unique to lithium-ion battery packs used in electric vehicles.

Recent technological trends indicate a shift toward nano-enhanced PCMs that offer improved thermal conductivity and energy density. These advancements have been driven by the automotive industry's push for longer battery life, faster charging capabilities, and enhanced safety features in increasingly powerful EV platforms.

The primary technical objective for PCM thermal pads in EV battery applications is to maintain optimal operating temperatures (typically between 15-35°C) across all cells within a battery pack, even under extreme operating conditions or abuse scenarios. This temperature uniformity is critical for preventing thermal runaway events while maximizing battery performance and longevity.

Secondary objectives include minimizing system complexity by reducing or eliminating active cooling components, thereby improving overall reliability while decreasing weight, cost, and power consumption. The ideal PCM solution would provide sufficient thermal buffering to handle both normal operational heat generation and potential abuse scenarios without requiring additional intervention.

From a safety perspective, PCM thermal pads aim to provide critical time buffers during thermal incidents, allowing battery management systems to implement protective measures before catastrophic failure occurs. This capability becomes particularly important in abuse scenarios such as external fire exposure, internal short circuits, or overcharging events.

The development trajectory for PCM thermal solutions is increasingly focused on modeling capabilities that can accurately predict material behavior under various abuse conditions. These predictive models represent a crucial step toward designing optimized thermal management systems that can respond appropriately to the full spectrum of potential thermal challenges in real-world EV operations.

As the EV market continues its rapid expansion, PCM thermal pad technology stands at an inflection point where advances in material science, computational modeling, and manufacturing techniques converge to address one of the most significant challenges in electric vehicle design: safe, efficient, and reliable thermal management for high-energy battery systems.

The evolution of PCM technology for EV applications has progressed from simple paraffin-based compounds to sophisticated engineered materials with precisely tailored melting points and thermal properties. Early implementations focused primarily on general heat dissipation, while current generations address specific thermal challenges unique to lithium-ion battery packs used in electric vehicles.

Recent technological trends indicate a shift toward nano-enhanced PCMs that offer improved thermal conductivity and energy density. These advancements have been driven by the automotive industry's push for longer battery life, faster charging capabilities, and enhanced safety features in increasingly powerful EV platforms.

The primary technical objective for PCM thermal pads in EV battery applications is to maintain optimal operating temperatures (typically between 15-35°C) across all cells within a battery pack, even under extreme operating conditions or abuse scenarios. This temperature uniformity is critical for preventing thermal runaway events while maximizing battery performance and longevity.

Secondary objectives include minimizing system complexity by reducing or eliminating active cooling components, thereby improving overall reliability while decreasing weight, cost, and power consumption. The ideal PCM solution would provide sufficient thermal buffering to handle both normal operational heat generation and potential abuse scenarios without requiring additional intervention.

From a safety perspective, PCM thermal pads aim to provide critical time buffers during thermal incidents, allowing battery management systems to implement protective measures before catastrophic failure occurs. This capability becomes particularly important in abuse scenarios such as external fire exposure, internal short circuits, or overcharging events.

The development trajectory for PCM thermal solutions is increasingly focused on modeling capabilities that can accurately predict material behavior under various abuse conditions. These predictive models represent a crucial step toward designing optimized thermal management systems that can respond appropriately to the full spectrum of potential thermal challenges in real-world EV operations.

As the EV market continues its rapid expansion, PCM thermal pad technology stands at an inflection point where advances in material science, computational modeling, and manufacturing techniques converge to address one of the most significant challenges in electric vehicle design: safe, efficient, and reliable thermal management for high-energy battery systems.

EV Battery Market Demand Analysis

The global electric vehicle (EV) market is experiencing unprecedented growth, with battery technology serving as a critical component driving this expansion. As of 2023, the global EV battery market was valued at approximately $46.5 billion and is projected to grow at a CAGR of 18.9% through 2030, reaching over $120 billion. This growth is fueled by increasing consumer adoption of electric vehicles, with global EV sales surpassing 10 million units in 2022, representing a year-over-year growth of 55%.

Thermal management solutions, particularly PCM (Phase Change Material) thermal pads, are becoming increasingly vital in this expanding market. The demand for advanced thermal management systems in EV battery packs is expected to grow at a CAGR of 20.3% through 2028, outpacing the overall EV market growth. This accelerated demand stems from the critical need to address thermal runaway concerns, which remain a primary safety issue for consumers and manufacturers alike.

Consumer surveys indicate that 78% of potential EV buyers cite battery safety as a "very important" consideration in their purchasing decision. Additionally, 65% of consumers express specific concerns about battery fires and thermal incidents. These consumer sentiments are driving manufacturers to prioritize advanced thermal management solutions, creating a robust demand for PCM thermal pad technologies.

Regulatory frameworks are further accelerating market demand for thermal management solutions. The UN Global Technical Regulation No. 20 (GTR 20) and various regional standards now mandate specific thermal safety requirements for EV batteries. In the European Union, the upcoming Euro NCAP 2025 protocols will include enhanced battery safety assessments, while China's GB/T 31467.3 standard has already implemented stringent thermal runaway prevention requirements.

From a geographical perspective, the Asia-Pacific region dominates the EV battery thermal management market with a 45% share, followed by Europe (30%) and North America (20%). China leads global demand, accounting for 38% of the global market for EV battery thermal management solutions, driven by its position as the world's largest EV market.

The premium and luxury EV segments currently represent the highest adoption rate for advanced thermal management solutions, including PCM thermal pads. However, as production scales and costs decrease, mid-market vehicles are rapidly incorporating these technologies. Industry forecasts suggest that by 2026, over 70% of all new EVs will feature advanced thermal management systems, compared to approximately 40% in 2022.

Thermal management solutions, particularly PCM (Phase Change Material) thermal pads, are becoming increasingly vital in this expanding market. The demand for advanced thermal management systems in EV battery packs is expected to grow at a CAGR of 20.3% through 2028, outpacing the overall EV market growth. This accelerated demand stems from the critical need to address thermal runaway concerns, which remain a primary safety issue for consumers and manufacturers alike.

Consumer surveys indicate that 78% of potential EV buyers cite battery safety as a "very important" consideration in their purchasing decision. Additionally, 65% of consumers express specific concerns about battery fires and thermal incidents. These consumer sentiments are driving manufacturers to prioritize advanced thermal management solutions, creating a robust demand for PCM thermal pad technologies.

Regulatory frameworks are further accelerating market demand for thermal management solutions. The UN Global Technical Regulation No. 20 (GTR 20) and various regional standards now mandate specific thermal safety requirements for EV batteries. In the European Union, the upcoming Euro NCAP 2025 protocols will include enhanced battery safety assessments, while China's GB/T 31467.3 standard has already implemented stringent thermal runaway prevention requirements.

From a geographical perspective, the Asia-Pacific region dominates the EV battery thermal management market with a 45% share, followed by Europe (30%) and North America (20%). China leads global demand, accounting for 38% of the global market for EV battery thermal management solutions, driven by its position as the world's largest EV market.

The premium and luxury EV segments currently represent the highest adoption rate for advanced thermal management solutions, including PCM thermal pads. However, as production scales and costs decrease, mid-market vehicles are rapidly incorporating these technologies. Industry forecasts suggest that by 2026, over 70% of all new EVs will feature advanced thermal management systems, compared to approximately 40% in 2022.

PCM Thermal Management Challenges

The thermal management of Phase Change Material (PCM) thermal pads in electric vehicle battery packs presents significant challenges that must be addressed to ensure optimal performance and safety. One of the primary challenges is the limited thermal conductivity of most PCMs, which restricts their ability to rapidly dissipate heat during high-power operations. While PCMs excel at absorbing heat through their phase transition process, their inherent thermal conductivity often falls below 1 W/m·K, creating potential hotspots within battery modules.

Another critical challenge involves the volume expansion during phase transition. Most PCMs expand by 5-15% when changing from solid to liquid state, necessitating careful mechanical design to accommodate this expansion without creating mechanical stress on battery cells or allowing PCM leakage. This expansion characteristic complicates the integration of PCMs into the tightly packed architecture of modern EV battery systems.

The cycling stability of PCMs presents a long-term reliability concern. After repeated melting and solidification cycles, some PCMs exhibit performance degradation, including reduced latent heat capacity and phase separation in composite materials. This degradation can significantly reduce the thermal management efficiency over the vehicle's lifespan, which typically requires thousands of thermal cycles.

Temperature hysteresis between melting and solidification processes creates another challenge. Many PCMs solidify at temperatures several degrees below their melting point, creating a hysteresis effect that can complicate precise thermal control strategies. This phenomenon makes it difficult to maintain battery cells within their optimal temperature window during varying operational conditions.

The selection of appropriate phase transition temperatures presents a delicate balance. The ideal PCM must have a transition temperature slightly above the optimal battery operating temperature but well below critical safety thresholds. This narrow temperature window varies based on battery chemistry, making universal PCM solutions difficult to implement across different battery technologies.

Integration challenges also arise from the need to encapsulate PCMs effectively. Leakage prevention is paramount, as liquid PCM contact with battery components or electrical connections could cause serious system failures. Encapsulation solutions must maintain thermal performance while ensuring complete containment throughout the vehicle's operational life.

Finally, modeling the behavior of PCMs under abuse scenarios presents significant computational challenges. The non-linear thermal properties during phase transition, coupled with the complex geometries of battery packs, make accurate simulation of thermal runaway propagation particularly difficult. Current modeling approaches often struggle to capture the dynamic nature of PCM behavior during extreme thermal events.

Another critical challenge involves the volume expansion during phase transition. Most PCMs expand by 5-15% when changing from solid to liquid state, necessitating careful mechanical design to accommodate this expansion without creating mechanical stress on battery cells or allowing PCM leakage. This expansion characteristic complicates the integration of PCMs into the tightly packed architecture of modern EV battery systems.

The cycling stability of PCMs presents a long-term reliability concern. After repeated melting and solidification cycles, some PCMs exhibit performance degradation, including reduced latent heat capacity and phase separation in composite materials. This degradation can significantly reduce the thermal management efficiency over the vehicle's lifespan, which typically requires thousands of thermal cycles.

Temperature hysteresis between melting and solidification processes creates another challenge. Many PCMs solidify at temperatures several degrees below their melting point, creating a hysteresis effect that can complicate precise thermal control strategies. This phenomenon makes it difficult to maintain battery cells within their optimal temperature window during varying operational conditions.

The selection of appropriate phase transition temperatures presents a delicate balance. The ideal PCM must have a transition temperature slightly above the optimal battery operating temperature but well below critical safety thresholds. This narrow temperature window varies based on battery chemistry, making universal PCM solutions difficult to implement across different battery technologies.

Integration challenges also arise from the need to encapsulate PCMs effectively. Leakage prevention is paramount, as liquid PCM contact with battery components or electrical connections could cause serious system failures. Encapsulation solutions must maintain thermal performance while ensuring complete containment throughout the vehicle's operational life.

Finally, modeling the behavior of PCMs under abuse scenarios presents significant computational challenges. The non-linear thermal properties during phase transition, coupled with the complex geometries of battery packs, make accurate simulation of thermal runaway propagation particularly difficult. Current modeling approaches often struggle to capture the dynamic nature of PCM behavior during extreme thermal events.

Current PCM Thermal Pad Solutions

01 PCM thermal pad composition and structure

Phase Change Material (PCM) thermal pads are composed of materials that undergo phase transition at specific temperatures, allowing them to absorb and release thermal energy. These pads typically contain paraffin waxes, fatty acids, or salt hydrates embedded in a polymer matrix or carrier material. The structure of these pads can be engineered with different thicknesses, densities, and reinforcement materials to optimize thermal conductivity and mechanical stability for various applications.- PCM thermal pad composition and structure: Phase Change Material (PCM) thermal pads are composed of specific materials that undergo phase transition at predetermined temperatures, absorbing or releasing heat in the process. These pads typically contain paraffin waxes, fatty acids, or salt hydrates embedded in a polymer matrix or carrier material. The structure of these pads can be layered, with reinforcing materials to improve mechanical stability while maintaining thermal conductivity. The composition and structure directly influence the thermal management capabilities of the pad.

- Thermal interface applications in electronics: PCM thermal pads serve as thermal interface materials (TIMs) in electronic devices, creating efficient thermal pathways between heat-generating components and heat sinks. These pads conform to surface irregularities under minimal pressure, reducing thermal resistance at the interface. They are particularly valuable in applications such as processors, graphics cards, memory modules, and power electronics where efficient heat dissipation is critical for performance and longevity. The pads can be designed with specific thermal conductivity values to match application requirements.

- Enhanced thermal conductivity methods: Various methods are employed to enhance the thermal conductivity of PCM thermal pads. These include incorporating high thermal conductivity fillers such as metal particles, carbon-based materials (graphite, carbon nanotubes, graphene), or ceramic particles (aluminum oxide, boron nitride). Advanced manufacturing techniques can create aligned structures within the pad to create preferential heat flow paths. Surface treatments and coupling agents may be used to improve the interface between the fillers and the matrix material, reducing thermal boundary resistance.

- Temperature-responsive phase change behavior: The temperature-responsive behavior of PCM thermal pads is a key feature for thermal management. These materials are engineered to undergo phase transition at specific temperatures relevant to the operating conditions of electronic devices. During phase change, the material absorbs heat (endothermic process) without significant temperature rise, effectively buffering temperature spikes. This property helps maintain more consistent operating temperatures and prevents thermal cycling damage. The phase change temperature can be tailored by adjusting the composition of the PCM or by using mixtures of different PCMs.

- Manufacturing and integration techniques: Manufacturing and integration techniques for PCM thermal pads involve specialized processes to ensure consistent performance. These include encapsulation methods to prevent leakage during phase change, precision dispensing for controlled thickness and coverage, and integration with carrier materials or reinforcements. Some manufacturing approaches incorporate pre-applied adhesives for easier installation. Advanced techniques may include gradient structures where thermal properties vary across the pad to match specific heat flow requirements. These manufacturing considerations directly impact the reliability and effectiveness of the thermal management solution.

02 Thermal management in electronic devices

PCM thermal pads are extensively used in electronic devices to manage heat dissipation from components such as processors, graphics cards, and power modules. These pads conform to irregular surfaces, filling air gaps between heat sources and heat sinks to improve thermal transfer efficiency. The phase change property allows them to respond dynamically to temperature fluctuations, providing better thermal regulation during peak loads and preventing thermal throttling in high-performance computing applications.Expand Specific Solutions03 Advanced manufacturing techniques for PCM thermal solutions

Manufacturing innovations for PCM thermal pads include multi-layer construction, gradient density structures, and nano-particle enhanced formulations. Advanced production methods such as precision dispensing, controlled curing processes, and automated assembly techniques ensure consistent quality and performance. These manufacturing approaches allow for customization of thermal conductivity, phase transition temperature, and mechanical properties to meet specific application requirements.Expand Specific Solutions04 Integration with cooling systems and heat sinks

PCM thermal pads are designed to work in conjunction with other cooling components such as heat sinks, heat pipes, and liquid cooling systems. The integration of these pads with aluminum or copper heat spreaders enhances overall thermal management efficiency. Some advanced designs incorporate channels, grooves, or embedded heat pipes within the pad structure to facilitate directional heat flow and improve thermal dissipation in complex system architectures.Expand Specific Solutions05 Sustainability and environmental considerations

Recent developments in PCM thermal pad technology focus on environmentally friendly formulations using bio-based phase change materials and recyclable components. These sustainable alternatives aim to reduce the environmental impact while maintaining or improving thermal performance. Research is also directed toward extending the operational lifespan of these materials, enhancing their thermal cycling stability, and developing non-toxic formulations that comply with global environmental regulations.Expand Specific Solutions

Key Players in PCM Thermal Solutions

The PCM Thermal Pads for EV Battery Packs market is currently in a growth phase, driven by increasing EV adoption worldwide. The market size is expanding rapidly, projected to reach significant value as thermal management becomes critical for battery safety and performance. Technologically, the field shows moderate maturity with ongoing innovation in abuse scenario modeling. Key players include established battery manufacturers like Samsung SDI, LG Energy Solution, and SK On, who are advancing thermal management technologies. Automotive giants such as BYD, GM, and Chery are integrating these solutions into their battery packs. Research institutions including South China University of Technology and Tsinghua Shenzhen International Graduate School are contributing fundamental research, while specialized companies like Huating Power Technology and Honeycomb Battery are developing application-specific thermal solutions.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced PCM (Phase Change Material) thermal pads specifically designed for EV battery packs to manage thermal runaway scenarios. Their solution integrates microencapsulated PCM materials with high thermal conductivity graphite sheets to create a composite thermal interface material. This design allows for efficient heat absorption during normal operation while providing a critical safety buffer during abuse scenarios. Samsung's thermal management system includes a network of sensors that continuously monitor temperature distribution across the battery pack, triggering preventive measures before critical thresholds are reached. Their modeling approach combines computational fluid dynamics with machine learning algorithms to predict thermal behavior under various abuse conditions, including external fire, mechanical impact, and internal short circuits. The system has demonstrated the ability to delay thermal propagation between cells by up to 30 minutes in extreme testing scenarios, providing crucial evacuation time in emergency situations[1][3].

Strengths: Superior thermal conductivity and heat absorption capacity; integrated sensor network for real-time monitoring; proven delay in thermal runaway propagation. Weaknesses: Higher manufacturing costs compared to conventional solutions; added weight to the battery pack; potential long-term degradation of PCM effectiveness after multiple thermal cycles.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a multi-layered PCM thermal management system for EV battery packs designed to address various abuse scenarios. Their approach incorporates strategically placed PCM thermal pads between cells and modules with varying melting points (ranging from 45°C to 80°C) to create a cascading thermal buffer system. This design allows for staged heat absorption during different thermal events. The company has developed proprietary PCM formulations that maintain structural integrity even after multiple phase transitions, addressing a common failure point in PCM applications. Their thermal modeling platform integrates real-world abuse test data with finite element analysis to simulate thermal propagation pathways under extreme conditions. LG's system includes specialized PCM formulations at critical junctions within the pack where thermal runaway is most likely to initiate, creating firebreaks that significantly impede heat transfer between modules. Testing has shown their solution can contain thermal events to individual modules rather than allowing pack-wide propagation[2][4].

Strengths: Cascading thermal protection with multiple melting points; proprietary formulations with enhanced cycling stability; demonstrated containment of thermal events to individual modules. Weaknesses: Complex manufacturing process requiring precise placement of different PCM materials; higher initial cost compared to traditional cooling systems; additional validation required for new vehicle platforms.

Critical PCM Technology Patents

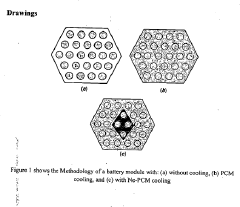

An hexagonal battery pack using nano-enhanced phase change material for thermal management in electric vehicles

PatentPendingIN202441023323A

Innovation

- A hexagonal battery pack design integrated with nano-enhanced phase change materials (PCMs) that strategically positions these materials in the central portion for enhanced thermal conductivity and mechanical stability, utilizing graphene, multi-walled carbon nanotubes (MWCNTs), and graphene nanoplatelets (GPN) to improve heat dissipation and mechanical integrity.

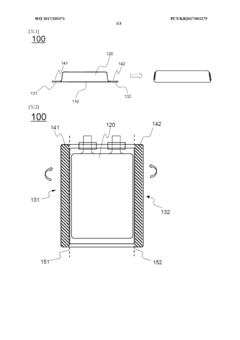

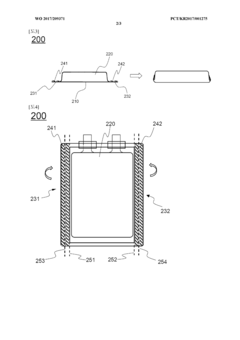

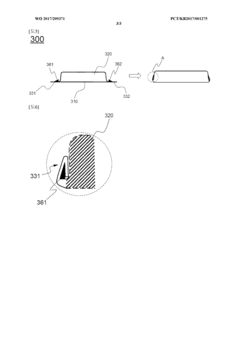

Battery cell including phase change material

PatentWO2017209371A1

Innovation

- Incorporating a phase change material (PCM) into the battery cell's sealing parts and surplus spaces, which undergoes phase transformation at specific temperatures to absorb or release heat, maintaining the battery's temperature within an optimal range and reducing rapid temperature changes.

Safety Standards and Regulations

The regulatory landscape governing Phase Change Material (PCM) thermal pads in electric vehicle battery packs has evolved significantly in response to high-profile thermal incidents. International standards such as ISO 6469-1:2019 specifically address the safety requirements for rechargeable energy storage systems (RESS) in electrically propelled road vehicles, including thermal management considerations that directly impact PCM implementation.

The UN ECE R100 regulation, widely adopted across Europe and many Asian markets, mandates specific thermal runaway protection measures that PCM thermal solutions must satisfy. These include requirements for thermal propagation prevention between cells and modules, with explicit temperature thresholds that must not be exceeded during various abuse scenarios.

In the United States, FMVSS 305 (Electric-Powered Vehicles: Electrolyte Spillage and Electrical Shock Protection) has been updated to incorporate thermal management requirements, while SAE J2929 provides detailed testing protocols for evaluating battery thermal management systems under abuse conditions. These standards specifically reference the need for thermal interface materials to maintain performance integrity during thermal excursions.

China's GB/T 31485-2015 standard outlines particularly stringent requirements for thermal management in EV batteries, including specific provisions for thermal interface materials used in battery packs. This standard requires PCM thermal pads to maintain functionality after exposure to temperatures exceeding 130°C for specified durations.

The UL 2580 standard for batteries in electric vehicles provides comprehensive safety requirements that thermal management solutions must meet, including specific provisions for PCM materials regarding flammability ratings and thermal stability. This standard requires PCM materials to undergo rigorous cycling tests to ensure long-term performance stability.

IEC 62660-2 and IEC 62660-3 standards focus on reliability and abuse testing of lithium-ion cells for vehicle applications, with explicit requirements for thermal management systems. These standards mandate that PCM thermal pads must maintain their thermal conductivity properties after exposure to specified abuse conditions, including overcharging and external short circuit scenarios.

Recent regulatory updates have increasingly focused on the modeling and simulation aspects of thermal management systems. The European Battery Directive revision now requires manufacturers to provide detailed thermal modeling data for battery systems, including the performance characteristics of thermal interface materials under various abuse scenarios.

The UN ECE R100 regulation, widely adopted across Europe and many Asian markets, mandates specific thermal runaway protection measures that PCM thermal solutions must satisfy. These include requirements for thermal propagation prevention between cells and modules, with explicit temperature thresholds that must not be exceeded during various abuse scenarios.

In the United States, FMVSS 305 (Electric-Powered Vehicles: Electrolyte Spillage and Electrical Shock Protection) has been updated to incorporate thermal management requirements, while SAE J2929 provides detailed testing protocols for evaluating battery thermal management systems under abuse conditions. These standards specifically reference the need for thermal interface materials to maintain performance integrity during thermal excursions.

China's GB/T 31485-2015 standard outlines particularly stringent requirements for thermal management in EV batteries, including specific provisions for thermal interface materials used in battery packs. This standard requires PCM thermal pads to maintain functionality after exposure to temperatures exceeding 130°C for specified durations.

The UL 2580 standard for batteries in electric vehicles provides comprehensive safety requirements that thermal management solutions must meet, including specific provisions for PCM materials regarding flammability ratings and thermal stability. This standard requires PCM materials to undergo rigorous cycling tests to ensure long-term performance stability.

IEC 62660-2 and IEC 62660-3 standards focus on reliability and abuse testing of lithium-ion cells for vehicle applications, with explicit requirements for thermal management systems. These standards mandate that PCM thermal pads must maintain their thermal conductivity properties after exposure to specified abuse conditions, including overcharging and external short circuit scenarios.

Recent regulatory updates have increasingly focused on the modeling and simulation aspects of thermal management systems. The European Battery Directive revision now requires manufacturers to provide detailed thermal modeling data for battery systems, including the performance characteristics of thermal interface materials under various abuse scenarios.

Thermal Runaway Prevention Strategies

Thermal runaway prevention in EV battery packs represents a critical safety challenge that requires multi-layered strategic approaches. The implementation of Phase Change Material (PCM) thermal pads offers a promising passive thermal management solution that can be integrated within comprehensive prevention frameworks.

Primary prevention strategies focus on early detection systems that can identify thermal anomalies before they escalate. Advanced Battery Management Systems (BMS) with sophisticated algorithms can monitor cell-level temperature gradients and voltage fluctuations, triggering protective measures when abnormal patterns emerge. These systems work synergistically with PCM thermal pads, which provide critical response time by absorbing excess heat during temperature spikes.

Structural isolation techniques form another crucial prevention layer, where PCM thermal pads serve as both thermal barriers and flame retardants between cells or modules. Strategic placement of these materials can compartmentalize thermal events, preventing propagation throughout the pack. Research indicates that properly engineered PCM barriers can delay cell-to-cell thermal runaway propagation by 15-30 minutes, providing crucial evacuation time.

Active cooling systems represent the third major prevention approach, where liquid cooling circuits work in conjunction with PCM thermal pads to create redundant thermal management. The PCM components provide immediate response to sudden temperature increases while active systems engage to remove heat from the system. This hybrid approach offers resilience against cooling system failures.

Material engineering advancements have yielded specialized PCM formulations with tailored phase transition temperatures matched to battery chemistry safety thresholds. These materials incorporate flame-retardant compounds and high thermal conductivity enhancers to optimize performance under abuse conditions. Recent developments include nanocomposite PCMs that maintain structural integrity even after multiple thermal cycles.

Predictive modeling and simulation tools have become essential for prevention strategy development. These computational approaches enable virtual testing of PCM thermal pad performance under various abuse scenarios, including mechanical impact, external heating, and internal short circuits. Simulation results guide optimal PCM placement, thickness determination, and composition selection for specific battery pack architectures.

Regulatory frameworks increasingly recognize the importance of thermal runaway prevention, with standards bodies developing specific testing protocols for thermal management systems including PCM solutions. These standards evaluate performance under controlled abuse conditions and establish minimum safety requirements for commercial deployment.

Primary prevention strategies focus on early detection systems that can identify thermal anomalies before they escalate. Advanced Battery Management Systems (BMS) with sophisticated algorithms can monitor cell-level temperature gradients and voltage fluctuations, triggering protective measures when abnormal patterns emerge. These systems work synergistically with PCM thermal pads, which provide critical response time by absorbing excess heat during temperature spikes.

Structural isolation techniques form another crucial prevention layer, where PCM thermal pads serve as both thermal barriers and flame retardants between cells or modules. Strategic placement of these materials can compartmentalize thermal events, preventing propagation throughout the pack. Research indicates that properly engineered PCM barriers can delay cell-to-cell thermal runaway propagation by 15-30 minutes, providing crucial evacuation time.

Active cooling systems represent the third major prevention approach, where liquid cooling circuits work in conjunction with PCM thermal pads to create redundant thermal management. The PCM components provide immediate response to sudden temperature increases while active systems engage to remove heat from the system. This hybrid approach offers resilience against cooling system failures.

Material engineering advancements have yielded specialized PCM formulations with tailored phase transition temperatures matched to battery chemistry safety thresholds. These materials incorporate flame-retardant compounds and high thermal conductivity enhancers to optimize performance under abuse conditions. Recent developments include nanocomposite PCMs that maintain structural integrity even after multiple thermal cycles.

Predictive modeling and simulation tools have become essential for prevention strategy development. These computational approaches enable virtual testing of PCM thermal pad performance under various abuse scenarios, including mechanical impact, external heating, and internal short circuits. Simulation results guide optimal PCM placement, thickness determination, and composition selection for specific battery pack architectures.

Regulatory frameworks increasingly recognize the importance of thermal runaway prevention, with standards bodies developing specific testing protocols for thermal management systems including PCM solutions. These standards evaluate performance under controlled abuse conditions and establish minimum safety requirements for commercial deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!