Life-Cycle Assessment of PCM Retrofits in Commercial Buildings

AUG 21, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Technology Background and Objectives

Phase Change Materials (PCMs) have emerged as a promising technology for enhancing energy efficiency in buildings through their unique thermal storage capabilities. The development of PCMs dates back to the 1940s, with significant advancements occurring in the 1980s when researchers began exploring their potential for building applications. Over the decades, PCM technology has evolved from simple salt hydrates to sophisticated microencapsulated materials and bio-based alternatives, demonstrating the field's continuous innovation trajectory.

The fundamental principle behind PCMs lies in their ability to absorb, store, and release large amounts of energy during phase transitions, particularly between solid and liquid states. This latent heat storage capacity allows PCMs to maintain stable temperatures within building environments, reducing heating and cooling loads and consequently decreasing energy consumption and associated carbon emissions.

Recent technological advancements have addressed historical challenges such as containment, thermal conductivity, and long-term stability, making PCMs increasingly viable for commercial building retrofits. The development of nano-enhanced PCMs and composite materials has significantly improved performance metrics, while innovations in encapsulation techniques have extended service life and reliability in building applications.

The primary objective of PCM retrofit technology is to enhance building energy performance while minimizing operational costs and environmental impacts throughout the building's life cycle. Specifically, PCM retrofits aim to reduce peak cooling loads by 10-30%, decrease annual energy consumption by 5-15%, and improve thermal comfort by maintaining temperature fluctuations within ±2°C of setpoints.

Additionally, PCM technology seeks to integrate seamlessly with existing building systems, requiring minimal modifications to structural elements and mechanical systems. This adaptability is crucial for widespread adoption in the commercial building sector, where retrofitting rather than new construction often represents the most economically viable path to improved energy efficiency.

The technology evolution trajectory suggests continued improvements in PCM formulations, with research focusing on bio-based materials, enhanced thermal properties, and cost-effective manufacturing processes. Future developments are expected to yield PCMs with higher energy density, improved cycling stability, and reduced environmental footprint, aligning with global sustainability goals and increasingly stringent building energy codes.

As climate change concerns intensify and energy efficiency standards become more demanding, PCM technology stands at a critical juncture, poised to transition from niche applications to mainstream building energy solutions. The successful realization of these technological objectives could significantly contribute to decarbonization efforts in the commercial building sector, which currently accounts for approximately 18% of global energy consumption and related greenhouse gas emissions.

The fundamental principle behind PCMs lies in their ability to absorb, store, and release large amounts of energy during phase transitions, particularly between solid and liquid states. This latent heat storage capacity allows PCMs to maintain stable temperatures within building environments, reducing heating and cooling loads and consequently decreasing energy consumption and associated carbon emissions.

Recent technological advancements have addressed historical challenges such as containment, thermal conductivity, and long-term stability, making PCMs increasingly viable for commercial building retrofits. The development of nano-enhanced PCMs and composite materials has significantly improved performance metrics, while innovations in encapsulation techniques have extended service life and reliability in building applications.

The primary objective of PCM retrofit technology is to enhance building energy performance while minimizing operational costs and environmental impacts throughout the building's life cycle. Specifically, PCM retrofits aim to reduce peak cooling loads by 10-30%, decrease annual energy consumption by 5-15%, and improve thermal comfort by maintaining temperature fluctuations within ±2°C of setpoints.

Additionally, PCM technology seeks to integrate seamlessly with existing building systems, requiring minimal modifications to structural elements and mechanical systems. This adaptability is crucial for widespread adoption in the commercial building sector, where retrofitting rather than new construction often represents the most economically viable path to improved energy efficiency.

The technology evolution trajectory suggests continued improvements in PCM formulations, with research focusing on bio-based materials, enhanced thermal properties, and cost-effective manufacturing processes. Future developments are expected to yield PCMs with higher energy density, improved cycling stability, and reduced environmental footprint, aligning with global sustainability goals and increasingly stringent building energy codes.

As climate change concerns intensify and energy efficiency standards become more demanding, PCM technology stands at a critical juncture, poised to transition from niche applications to mainstream building energy solutions. The successful realization of these technological objectives could significantly contribute to decarbonization efforts in the commercial building sector, which currently accounts for approximately 18% of global energy consumption and related greenhouse gas emissions.

Commercial Building Market Analysis

The commercial building sector represents a significant portion of global energy consumption, accounting for approximately 30% of total energy use in developed countries. This sector has been experiencing steady growth, with the global commercial building market valued at $1.1 trillion in 2022 and projected to reach $1.7 trillion by 2030, growing at a CAGR of 5.8%. Within this market, energy efficiency retrofits have emerged as a crucial segment, driven by increasing energy costs, stringent building codes, and corporate sustainability commitments.

Phase Change Materials (PCM) retrofits specifically address the thermal performance challenges in existing commercial buildings. The market for PCM in building applications was valued at $290 million in 2021 and is expected to grow at a CAGR of 16.2% through 2028, indicating strong market potential for these solutions. Office buildings represent the largest segment (38%) of potential PCM retrofit applications, followed by retail (27%), healthcare facilities (18%), and educational institutions (12%).

Regional analysis reveals varying adoption rates and market potential. North America currently leads the PCM retrofit market with 42% share, driven by stringent energy codes and incentive programs. Europe follows at 35%, with particularly strong adoption in countries with ambitious climate targets like Germany, France, and the UK. The Asia-Pacific region, while currently accounting for only 18% of the market, is projected to be the fastest-growing region with a CAGR of 19.7% through 2028.

Key market drivers include rising energy costs, with commercial buildings experiencing an average annual increase of 4.3% in energy expenditure over the past decade. Additionally, regulatory pressures continue to intensify, with 67% of developed nations implementing more stringent building energy performance standards since 2018. Corporate sustainability initiatives also play a significant role, as 78% of Fortune 500 companies have established net-zero targets that necessitate building energy performance improvements.

Market barriers include high initial investment costs for PCM retrofits, with payback periods typically ranging from 3-7 years depending on building type and climate zone. Limited awareness among building owners and facility managers regarding PCM technology benefits represents another significant barrier, with industry surveys indicating only 23% of decision-makers are familiar with PCM applications in buildings.

The retrofit market shows strong segmentation by building age, with structures built between 1970-2000 representing the prime target market (62% of potential applications) due to their suboptimal thermal performance and remaining service life that justifies investment in energy efficiency improvements.

Phase Change Materials (PCM) retrofits specifically address the thermal performance challenges in existing commercial buildings. The market for PCM in building applications was valued at $290 million in 2021 and is expected to grow at a CAGR of 16.2% through 2028, indicating strong market potential for these solutions. Office buildings represent the largest segment (38%) of potential PCM retrofit applications, followed by retail (27%), healthcare facilities (18%), and educational institutions (12%).

Regional analysis reveals varying adoption rates and market potential. North America currently leads the PCM retrofit market with 42% share, driven by stringent energy codes and incentive programs. Europe follows at 35%, with particularly strong adoption in countries with ambitious climate targets like Germany, France, and the UK. The Asia-Pacific region, while currently accounting for only 18% of the market, is projected to be the fastest-growing region with a CAGR of 19.7% through 2028.

Key market drivers include rising energy costs, with commercial buildings experiencing an average annual increase of 4.3% in energy expenditure over the past decade. Additionally, regulatory pressures continue to intensify, with 67% of developed nations implementing more stringent building energy performance standards since 2018. Corporate sustainability initiatives also play a significant role, as 78% of Fortune 500 companies have established net-zero targets that necessitate building energy performance improvements.

Market barriers include high initial investment costs for PCM retrofits, with payback periods typically ranging from 3-7 years depending on building type and climate zone. Limited awareness among building owners and facility managers regarding PCM technology benefits represents another significant barrier, with industry surveys indicating only 23% of decision-makers are familiar with PCM applications in buildings.

The retrofit market shows strong segmentation by building age, with structures built between 1970-2000 representing the prime target market (62% of potential applications) due to their suboptimal thermal performance and remaining service life that justifies investment in energy efficiency improvements.

PCM Implementation Challenges

Despite the promising potential of Phase Change Materials (PCMs) in commercial building retrofits, several significant implementation challenges persist that hinder widespread adoption. The integration of PCMs into existing building structures presents complex engineering hurdles, particularly regarding the containment systems required to prevent leakage and ensure long-term stability. Traditional encapsulation methods often add considerable weight to building elements, potentially necessitating structural reinforcements that increase installation costs and complexity.

Thermal conductivity limitations represent another critical challenge, as many PCMs exhibit relatively low heat transfer rates that can diminish their effectiveness in real-world applications. This characteristic often requires additional heat transfer enhancement mechanisms, such as metallic fins or graphite composites, which further complicate system design and increase implementation costs.

The durability and cycling stability of PCMs remain concerning for building stakeholders. Many materials experience performance degradation after repeated phase change cycles, with some studies indicating efficiency losses of 10-30% after 1000 cycles—equivalent to just 3-5 years of operation in many climates. This degradation profile significantly impacts the life-cycle assessment calculations and return on investment projections.

Fire safety and building code compliance present regulatory hurdles that vary significantly across jurisdictions. Many organic PCMs have relatively low flash points, requiring additional fire retardants or protective measures that may compromise their thermal performance or environmental credentials. The lack of standardized testing protocols specifically designed for PCM building applications further complicates regulatory approval processes.

Installation complexity and system integration challenges also impede adoption. Retrofitting existing buildings with PCM systems requires specialized knowledge that many contractors lack, creating implementation barriers and increasing labor costs. The interface between PCM systems and existing HVAC infrastructure often requires custom engineering solutions that are difficult to standardize across different building types.

Economic barriers remain perhaps the most significant challenge, with high initial costs and uncertain payback periods deterring investment. Current market prices for high-performance PCMs range from $4-15 per kg, resulting in material costs alone that can exceed $30-50 per square meter of treated building area. When installation and system integration costs are included, many PCM retrofit solutions struggle to demonstrate compelling financial returns within the 5-7 year payback periods typically demanded by commercial building owners.

Thermal conductivity limitations represent another critical challenge, as many PCMs exhibit relatively low heat transfer rates that can diminish their effectiveness in real-world applications. This characteristic often requires additional heat transfer enhancement mechanisms, such as metallic fins or graphite composites, which further complicate system design and increase implementation costs.

The durability and cycling stability of PCMs remain concerning for building stakeholders. Many materials experience performance degradation after repeated phase change cycles, with some studies indicating efficiency losses of 10-30% after 1000 cycles—equivalent to just 3-5 years of operation in many climates. This degradation profile significantly impacts the life-cycle assessment calculations and return on investment projections.

Fire safety and building code compliance present regulatory hurdles that vary significantly across jurisdictions. Many organic PCMs have relatively low flash points, requiring additional fire retardants or protective measures that may compromise their thermal performance or environmental credentials. The lack of standardized testing protocols specifically designed for PCM building applications further complicates regulatory approval processes.

Installation complexity and system integration challenges also impede adoption. Retrofitting existing buildings with PCM systems requires specialized knowledge that many contractors lack, creating implementation barriers and increasing labor costs. The interface between PCM systems and existing HVAC infrastructure often requires custom engineering solutions that are difficult to standardize across different building types.

Economic barriers remain perhaps the most significant challenge, with high initial costs and uncertain payback periods deterring investment. Current market prices for high-performance PCMs range from $4-15 per kg, resulting in material costs alone that can exceed $30-50 per square meter of treated building area. When installation and system integration costs are included, many PCM retrofit solutions struggle to demonstrate compelling financial returns within the 5-7 year payback periods typically demanded by commercial building owners.

Current PCM Retrofit Solutions

01 Environmental impact assessment of PCMs in building applications

Life-cycle assessment methodologies are applied to evaluate the environmental impacts of phase change materials used in building applications. These assessments consider the energy savings during building operation against the environmental costs of PCM production, installation, and disposal. The analysis typically includes metrics such as carbon footprint, embodied energy, and payback periods for different PCM types and applications in construction elements like walls, roofs, and floors.- Environmental impact assessment of PCMs in building applications: Life-cycle assessment methodologies are applied to evaluate the environmental impacts of phase change materials used in building applications. These assessments consider the energy savings during building operation against the environmental costs of PCM production, installation, and disposal. The analysis typically includes metrics such as embodied energy, carbon footprint, and payback periods for different PCM types and applications in various climate zones.

- PCM integration in energy storage systems: Phase change materials are evaluated throughout their life cycle for integration into energy storage systems. The assessment covers manufacturing processes, operational efficiency, and end-of-life considerations for PCMs in thermal energy storage applications. These evaluations help optimize PCM selection based on thermal properties, cycling stability, and overall environmental impact, particularly for renewable energy integration and grid stabilization applications.

- Sustainability analysis of PCMs in electronic cooling: Life-cycle assessments of phase change materials used in electronic cooling applications focus on their thermal management efficiency, material resource depletion, and disposal impacts. These analyses compare PCM-based cooling solutions with conventional approaches, considering factors such as cooling performance, device lifespan extension, and total environmental footprint. The assessments help identify optimal PCM formulations that balance thermal performance with environmental sustainability.

- PCM manufacturing process optimization: Life-cycle assessments are conducted to optimize the manufacturing processes of phase change materials, focusing on reducing environmental impacts during production. These assessments evaluate raw material sourcing, energy consumption during synthesis, chemical emissions, and waste generation. The analyses help identify more sustainable production pathways, including the use of bio-based precursors, green chemistry principles, and energy-efficient manufacturing techniques.

- Circular economy approaches for PCM lifecycle management: Life-cycle assessments of phase change materials incorporate circular economy principles to evaluate their full lifecycle from production to end-of-life. These assessments focus on material recovery strategies, recyclability, and potential for reuse or repurposing of PCMs after their primary application. The analyses help develop closed-loop systems that minimize waste and environmental impact while maximizing the value extracted from PCM materials throughout multiple life cycles.

02 PCM sustainability in energy storage systems

This category focuses on the life-cycle assessment of phase change materials used in thermal energy storage systems. The analysis evaluates the environmental performance of PCMs throughout their life cycle, from raw material extraction to end-of-life disposal. Key considerations include the energy efficiency improvements provided by PCMs, their durability and cycling stability, and the environmental impacts associated with their production and disposal. The assessment helps determine the overall sustainability of PCM-based energy storage solutions.Expand Specific Solutions03 PCM applications in electronic devices and thermal management

Life-cycle assessments of phase change materials used in electronic devices and thermal management systems evaluate their environmental impacts and benefits. These assessments consider factors such as the extended lifespan of electronic components due to improved thermal management, reduced energy consumption for cooling, and the environmental footprint of PCM manufacturing and disposal. The analysis helps determine whether PCMs provide a net environmental benefit in electronic applications despite their production impacts.Expand Specific Solutions04 Methodologies and frameworks for PCM life-cycle assessment

This category covers various methodologies, frameworks, and tools developed specifically for conducting life-cycle assessments of phase change materials. These approaches include standardized methods for evaluating environmental impacts, economic analyses, and social considerations throughout the PCM life cycle. The frameworks help researchers and industry professionals systematically assess and compare different PCM options based on their overall sustainability performance, enabling more informed decision-making in PCM selection and application.Expand Specific Solutions05 Bio-based and sustainable PCM development

Life-cycle assessments of bio-based and sustainable phase change materials evaluate their environmental performance compared to conventional PCMs. These assessments analyze the reduced environmental impact of using renewable raw materials, biodegradability aspects, and end-of-life considerations. The studies typically compare carbon footprints, resource depletion, and toxicity metrics between bio-based PCMs and petroleum-derived alternatives to determine their overall sustainability benefits and potential drawbacks throughout their life cycle.Expand Specific Solutions

Technical Innovations in PCM

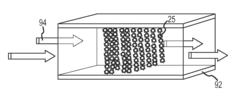

Thermal insulation unit

PatentInactiveEP2459669A1

Innovation

- A container comprising a film or sheet with a barrier layer and optional sealant layer, designed to be impermeable to PCMs, allowing for the use of PCM blends with polymers and forming a multilayer structure that can be processed into various shapes, including complex ones, to prevent leakage and maintain PCM retention.

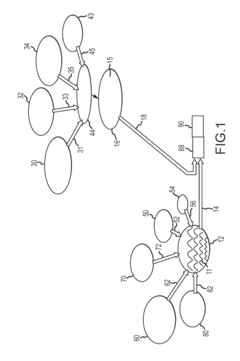

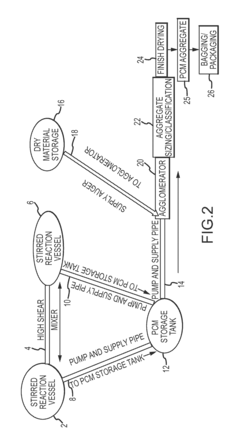

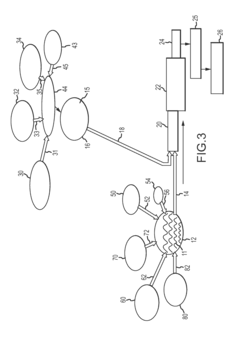

Phase change material-containing composition and related products and methods

PatentInactiveUS20130034732A1

Innovation

- A phase change material-containing composition comprising PCM, sorbent, and cement binder, which can be formulated into various forms such as aggregates or monolithic masses, providing high fire resistance and allowing for easier incorporation into building materials by bypassing costly drying processes, utilizing magnesium phosphate cement and clay sorbents to enhance fire resistance and handling safety.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the adoption and implementation of Phase Change Material (PCM) retrofits in commercial buildings. These regulations establish minimum performance standards and provide incentives for energy-efficient building technologies, directly influencing the market penetration of PCM solutions.

At the international level, frameworks such as the Paris Agreement have prompted countries to develop stringent building energy codes. The European Union's Energy Performance of Buildings Directive (EPBD) specifically recognizes thermal storage technologies like PCMs as viable solutions for improving building energy efficiency. This directive requires all new buildings to be nearly zero-energy buildings (nZEBs) by 2030, creating significant opportunities for PCM integration.

In the United States, the Department of Energy's Building Energy Codes Program establishes baseline requirements that vary by climate zone. ASHRAE Standard 90.1 and the International Energy Conservation Code (IECC) serve as model codes that many states adopt or adapt. Recent updates to these codes have begun to acknowledge thermal mass benefits, though explicit provisions for PCM technologies remain limited.

Regulatory incentives such as tax credits, rebates, and accelerated depreciation schedules further encourage PCM adoption. The Building Technologies Office within the U.S. Department of Energy offers financial support for demonstration projects featuring innovative thermal storage solutions, while utility companies provide demand-response programs that reward peak load reduction—a key benefit of PCM implementation.

Certification systems like LEED, BREEAM, and Green Star award points for thermal comfort optimization and energy efficiency improvements, indirectly benefiting PCM retrofits. These voluntary standards often drive market transformation ahead of mandatory regulations, creating early adoption pathways for innovative technologies.

Regulatory challenges persist, however, including inconsistent code enforcement, limited recognition of PCM benefits in energy modeling software approved for code compliance, and fragmented approaches across different jurisdictions. The lack of standardized testing protocols specifically designed for PCM performance evaluation in building applications creates additional market barriers.

Future regulatory trends indicate movement toward outcome-based energy codes that focus on actual building performance rather than prescriptive requirements. This shift could benefit PCM technologies by allowing greater flexibility in how energy efficiency targets are achieved, potentially accelerating market adoption of these innovative thermal storage solutions.

At the international level, frameworks such as the Paris Agreement have prompted countries to develop stringent building energy codes. The European Union's Energy Performance of Buildings Directive (EPBD) specifically recognizes thermal storage technologies like PCMs as viable solutions for improving building energy efficiency. This directive requires all new buildings to be nearly zero-energy buildings (nZEBs) by 2030, creating significant opportunities for PCM integration.

In the United States, the Department of Energy's Building Energy Codes Program establishes baseline requirements that vary by climate zone. ASHRAE Standard 90.1 and the International Energy Conservation Code (IECC) serve as model codes that many states adopt or adapt. Recent updates to these codes have begun to acknowledge thermal mass benefits, though explicit provisions for PCM technologies remain limited.

Regulatory incentives such as tax credits, rebates, and accelerated depreciation schedules further encourage PCM adoption. The Building Technologies Office within the U.S. Department of Energy offers financial support for demonstration projects featuring innovative thermal storage solutions, while utility companies provide demand-response programs that reward peak load reduction—a key benefit of PCM implementation.

Certification systems like LEED, BREEAM, and Green Star award points for thermal comfort optimization and energy efficiency improvements, indirectly benefiting PCM retrofits. These voluntary standards often drive market transformation ahead of mandatory regulations, creating early adoption pathways for innovative technologies.

Regulatory challenges persist, however, including inconsistent code enforcement, limited recognition of PCM benefits in energy modeling software approved for code compliance, and fragmented approaches across different jurisdictions. The lack of standardized testing protocols specifically designed for PCM performance evaluation in building applications creates additional market barriers.

Future regulatory trends indicate movement toward outcome-based energy codes that focus on actual building performance rather than prescriptive requirements. This shift could benefit PCM technologies by allowing greater flexibility in how energy efficiency targets are achieved, potentially accelerating market adoption of these innovative thermal storage solutions.

Cost-Benefit Analysis

The cost-benefit analysis of Phase Change Material (PCM) retrofits in commercial buildings reveals a complex economic landscape that requires careful consideration of multiple factors. Initial installation costs represent a significant investment, typically ranging from $5-15 per square foot depending on the specific PCM technology, installation method, and building characteristics. This upfront expenditure includes material costs, labor for installation, and potential system modifications to accommodate the PCM integration.

Energy savings constitute the primary financial benefit, with properly implemented PCM systems demonstrating potential reductions in HVAC energy consumption between 10-30% annually. These savings vary considerably based on climate zone, building usage patterns, and the thermal characteristics of the selected PCM. Buildings in regions with high diurnal temperature variations typically achieve greater returns on investment due to the PCM's ability to capture and release thermal energy during daily temperature cycles.

Operational cost impacts extend beyond direct energy savings. PCM installations can reduce peak demand charges by shifting cooling loads to off-peak hours, potentially decreasing utility bills by an additional 5-15% in regions with time-of-use pricing structures. Maintenance requirements for passive PCM systems are generally minimal, though encapsulated systems may require periodic inspection to ensure containment integrity.

The payback period analysis indicates considerable variation, with most commercial implementations achieving return on investment within 3-7 years. Buildings with high cooling demands, significant temperature fluctuations, or those located in regions with expensive electricity rates demonstrate faster payback periods, sometimes as short as 2-3 years. Conversely, buildings with minimal temperature swings or those in regions with inexpensive energy may see extended payback periods exceeding 8 years.

Life-cycle cost assessments reveal that PCM retrofits typically maintain effectiveness for 20-30 years, providing substantial long-term value beyond the initial payback period. When factoring in potential future energy price increases, the net present value of PCM implementations generally improves, enhancing the economic case for adoption.

Non-monetary benefits further enhance the value proposition. Improved thermal comfort can increase occupant productivity and satisfaction, potentially reducing absenteeism and improving tenant retention in commercial spaces. Additionally, PCM retrofits can contribute to sustainability goals and green building certifications, potentially increasing property values by 2-7% according to recent market analyses of energy-efficient commercial buildings.

Energy savings constitute the primary financial benefit, with properly implemented PCM systems demonstrating potential reductions in HVAC energy consumption between 10-30% annually. These savings vary considerably based on climate zone, building usage patterns, and the thermal characteristics of the selected PCM. Buildings in regions with high diurnal temperature variations typically achieve greater returns on investment due to the PCM's ability to capture and release thermal energy during daily temperature cycles.

Operational cost impacts extend beyond direct energy savings. PCM installations can reduce peak demand charges by shifting cooling loads to off-peak hours, potentially decreasing utility bills by an additional 5-15% in regions with time-of-use pricing structures. Maintenance requirements for passive PCM systems are generally minimal, though encapsulated systems may require periodic inspection to ensure containment integrity.

The payback period analysis indicates considerable variation, with most commercial implementations achieving return on investment within 3-7 years. Buildings with high cooling demands, significant temperature fluctuations, or those located in regions with expensive electricity rates demonstrate faster payback periods, sometimes as short as 2-3 years. Conversely, buildings with minimal temperature swings or those in regions with inexpensive energy may see extended payback periods exceeding 8 years.

Life-cycle cost assessments reveal that PCM retrofits typically maintain effectiveness for 20-30 years, providing substantial long-term value beyond the initial payback period. When factoring in potential future energy price increases, the net present value of PCM implementations generally improves, enhancing the economic case for adoption.

Non-monetary benefits further enhance the value proposition. Improved thermal comfort can increase occupant productivity and satisfaction, potentially reducing absenteeism and improving tenant retention in commercial spaces. Additionally, PCM retrofits can contribute to sustainability goals and green building certifications, potentially increasing property values by 2-7% according to recent market analyses of energy-efficient commercial buildings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!