PCM vs Ice Storage vs Chilled Water: Data Center Cooling Comparisons

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Data Center Cooling Evolution and Objectives

Data center cooling technologies have evolved significantly over the past decades, driven by the exponential growth in computing power and the corresponding increase in heat generation. In the 1970s and 1980s, data centers primarily relied on traditional computer room air conditioning (CRAC) units that utilized direct expansion cooling. These systems were inefficient by today's standards but adequate for the relatively low heat densities of early computing environments.

The 1990s saw the introduction of raised floor designs with underfloor air distribution, which became the industry standard for many years. As server densities increased in the early 2000s, chilled water cooling emerged as a more efficient alternative to direct expansion systems, offering greater cooling capacity and improved energy efficiency. This period also marked the beginning of hot aisle/cold aisle configurations to optimize airflow management.

Around 2010, as data center power densities continued to climb, more innovative cooling approaches gained traction. These included economizers that leverage outside air when conditions permit, evaporative cooling technologies, and the early implementations of liquid cooling for high-performance computing applications. The industry began focusing intensely on Power Usage Effectiveness (PUE) as a metric for data center efficiency.

The current technological landscape features three prominent cooling solutions: Phase Change Material (PCM) systems, Ice Storage systems, and traditional Chilled Water systems. Each represents a different approach to the fundamental challenge of removing heat efficiently from increasingly dense computing environments while minimizing energy consumption and operational costs.

The primary objectives of modern data center cooling technologies center around several key factors: maximizing energy efficiency to reduce operational expenses and environmental impact; ensuring reliability to maintain the required uptime levels; providing sufficient cooling capacity for high-density server environments; enabling scalability to accommodate growth; and minimizing water usage in response to sustainability concerns and water scarcity issues.

Looking forward, the industry is moving toward hybrid cooling approaches that combine multiple technologies to optimize performance across varying conditions. The ultimate goal is to develop cooling solutions that can support the next generation of high-performance computing and artificial intelligence workloads while simultaneously reducing environmental impact and total cost of ownership.

The 1990s saw the introduction of raised floor designs with underfloor air distribution, which became the industry standard for many years. As server densities increased in the early 2000s, chilled water cooling emerged as a more efficient alternative to direct expansion systems, offering greater cooling capacity and improved energy efficiency. This period also marked the beginning of hot aisle/cold aisle configurations to optimize airflow management.

Around 2010, as data center power densities continued to climb, more innovative cooling approaches gained traction. These included economizers that leverage outside air when conditions permit, evaporative cooling technologies, and the early implementations of liquid cooling for high-performance computing applications. The industry began focusing intensely on Power Usage Effectiveness (PUE) as a metric for data center efficiency.

The current technological landscape features three prominent cooling solutions: Phase Change Material (PCM) systems, Ice Storage systems, and traditional Chilled Water systems. Each represents a different approach to the fundamental challenge of removing heat efficiently from increasingly dense computing environments while minimizing energy consumption and operational costs.

The primary objectives of modern data center cooling technologies center around several key factors: maximizing energy efficiency to reduce operational expenses and environmental impact; ensuring reliability to maintain the required uptime levels; providing sufficient cooling capacity for high-density server environments; enabling scalability to accommodate growth; and minimizing water usage in response to sustainability concerns and water scarcity issues.

Looking forward, the industry is moving toward hybrid cooling approaches that combine multiple technologies to optimize performance across varying conditions. The ultimate goal is to develop cooling solutions that can support the next generation of high-performance computing and artificial intelligence workloads while simultaneously reducing environmental impact and total cost of ownership.

Market Demand Analysis for Efficient Cooling Solutions

The data center cooling market is experiencing unprecedented growth, driven by the rapid expansion of digital infrastructure worldwide. With global data center power consumption projected to reach 1,000 terawatt-hours by 2025, efficient cooling solutions have become critical for operational sustainability. Market research indicates that cooling systems account for approximately 40% of a data center's energy consumption, creating significant demand for more efficient alternatives to traditional air cooling methods.

Phase Change Material (PCM), Ice Storage, and Chilled Water systems represent three distinct approaches gaining traction in the market. The demand for PCM-based cooling solutions is growing at a compound annual growth rate of 12.8% through 2028, particularly in regions with high ambient temperatures where traditional cooling methods struggle with efficiency. This growth is supported by the technology's ability to reduce peak cooling loads by 15-30% compared to conventional systems.

Ice Storage systems have seen renewed interest, especially in markets with variable electricity pricing. These systems allow operators to shift cooling loads to off-peak hours, resulting in operational cost reductions of 20-35% in favorable markets. The technology is particularly attractive in regions with significant day-night electricity price differentials, such as parts of North America and Europe.

Chilled Water remains the dominant technology with approximately 65% market share in large-scale data centers, though this share is gradually decreasing as alternative technologies mature. Its established infrastructure and predictable performance continue to drive demand, particularly in hyperscale facilities where reliability concerns outweigh efficiency gains from newer technologies.

Regional market analysis reveals varying adoption patterns, with North American data centers leading in Ice Storage implementation, European facilities focusing on chilled water optimization with free cooling, and Asia-Pacific markets showing the fastest growth in PCM adoption due to challenging climate conditions and energy cost concerns.

Industry surveys indicate that 78% of data center operators consider cooling efficiency a "high" or "critical" priority for new facilities, with 63% actively evaluating alternative cooling technologies for implementation within the next three years. This trend is further reinforced by regulatory pressures, with several jurisdictions implementing energy efficiency requirements that indirectly mandate improvements in cooling system performance.

The market is also being shaped by sustainability initiatives, with 82% of Fortune 500 companies having established carbon reduction targets that directly impact their data center cooling strategy decisions. This has created a premium segment for cooling solutions that can demonstrate quantifiable sustainability benefits alongside operational cost advantages.

Phase Change Material (PCM), Ice Storage, and Chilled Water systems represent three distinct approaches gaining traction in the market. The demand for PCM-based cooling solutions is growing at a compound annual growth rate of 12.8% through 2028, particularly in regions with high ambient temperatures where traditional cooling methods struggle with efficiency. This growth is supported by the technology's ability to reduce peak cooling loads by 15-30% compared to conventional systems.

Ice Storage systems have seen renewed interest, especially in markets with variable electricity pricing. These systems allow operators to shift cooling loads to off-peak hours, resulting in operational cost reductions of 20-35% in favorable markets. The technology is particularly attractive in regions with significant day-night electricity price differentials, such as parts of North America and Europe.

Chilled Water remains the dominant technology with approximately 65% market share in large-scale data centers, though this share is gradually decreasing as alternative technologies mature. Its established infrastructure and predictable performance continue to drive demand, particularly in hyperscale facilities where reliability concerns outweigh efficiency gains from newer technologies.

Regional market analysis reveals varying adoption patterns, with North American data centers leading in Ice Storage implementation, European facilities focusing on chilled water optimization with free cooling, and Asia-Pacific markets showing the fastest growth in PCM adoption due to challenging climate conditions and energy cost concerns.

Industry surveys indicate that 78% of data center operators consider cooling efficiency a "high" or "critical" priority for new facilities, with 63% actively evaluating alternative cooling technologies for implementation within the next three years. This trend is further reinforced by regulatory pressures, with several jurisdictions implementing energy efficiency requirements that indirectly mandate improvements in cooling system performance.

The market is also being shaped by sustainability initiatives, with 82% of Fortune 500 companies having established carbon reduction targets that directly impact their data center cooling strategy decisions. This has created a premium segment for cooling solutions that can demonstrate quantifiable sustainability benefits alongside operational cost advantages.

Current Cooling Technologies and Implementation Challenges

Data center cooling technologies have evolved significantly over the past decade, with three primary approaches dominating the market: chilled water systems, ice storage solutions, and phase change material (PCM) implementations. Each technology presents distinct operational characteristics and implementation challenges that data center operators must carefully evaluate.

Chilled water cooling systems remain the most widely deployed solution in enterprise data centers. These systems utilize water chillers to remove heat from the facility, offering reliable performance and established engineering practices. However, they face significant challenges including high energy consumption during peak demand periods, substantial space requirements for equipment, and vulnerability to water-related failures such as leaks or condensation issues. Implementation typically requires specialized plumbing infrastructure and robust preventive maintenance protocols.

Ice storage cooling leverages thermal energy storage principles by freezing water during off-peak hours and using the stored cooling capacity during peak demand. While this approach enables beneficial load shifting and potential energy cost savings, implementation challenges include the need for large storage tanks, complex control systems to optimize charging and discharging cycles, and higher initial capital expenditure. The technology also presents operational risks related to system reliability during extended peak cooling demands.

PCM cooling represents the newest approach among these technologies, utilizing materials that absorb and release thermal energy during phase transitions. These systems offer promising energy efficiency benefits and can be deployed in more compact configurations than traditional solutions. However, PCM implementation faces challenges including limited commercial-scale deployment experience, integration complexities with existing cooling infrastructure, and concerns regarding long-term material stability and performance degradation over multiple thermal cycles.

Common implementation challenges across all three technologies include integration with existing data center designs, scalability limitations as computing densities increase, and operational complexity requiring specialized staff training. Water-based systems must address water availability and quality concerns, particularly in regions experiencing drought conditions. Additionally, all solutions must navigate the increasing thermal management demands of high-density computing environments, including AI accelerators and specialized hardware that can exceed 30kW per rack.

Regulatory compliance presents another significant challenge, with evolving energy efficiency standards and environmental regulations influencing technology selection. Data center operators must balance cooling performance with sustainability metrics, including water usage effectiveness (WUE) and carbon footprint considerations, which increasingly impact corporate environmental, social, and governance (ESG) reporting requirements.

Chilled water cooling systems remain the most widely deployed solution in enterprise data centers. These systems utilize water chillers to remove heat from the facility, offering reliable performance and established engineering practices. However, they face significant challenges including high energy consumption during peak demand periods, substantial space requirements for equipment, and vulnerability to water-related failures such as leaks or condensation issues. Implementation typically requires specialized plumbing infrastructure and robust preventive maintenance protocols.

Ice storage cooling leverages thermal energy storage principles by freezing water during off-peak hours and using the stored cooling capacity during peak demand. While this approach enables beneficial load shifting and potential energy cost savings, implementation challenges include the need for large storage tanks, complex control systems to optimize charging and discharging cycles, and higher initial capital expenditure. The technology also presents operational risks related to system reliability during extended peak cooling demands.

PCM cooling represents the newest approach among these technologies, utilizing materials that absorb and release thermal energy during phase transitions. These systems offer promising energy efficiency benefits and can be deployed in more compact configurations than traditional solutions. However, PCM implementation faces challenges including limited commercial-scale deployment experience, integration complexities with existing cooling infrastructure, and concerns regarding long-term material stability and performance degradation over multiple thermal cycles.

Common implementation challenges across all three technologies include integration with existing data center designs, scalability limitations as computing densities increase, and operational complexity requiring specialized staff training. Water-based systems must address water availability and quality concerns, particularly in regions experiencing drought conditions. Additionally, all solutions must navigate the increasing thermal management demands of high-density computing environments, including AI accelerators and specialized hardware that can exceed 30kW per rack.

Regulatory compliance presents another significant challenge, with evolving energy efficiency standards and environmental regulations influencing technology selection. Data center operators must balance cooling performance with sustainability metrics, including water usage effectiveness (WUE) and carbon footprint considerations, which increasingly impact corporate environmental, social, and governance (ESG) reporting requirements.

Comparative Analysis of PCM, Ice Storage, and Chilled Water Systems

01 Phase Change Material (PCM) cooling systems

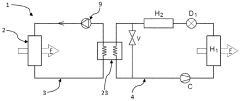

Phase Change Materials are used in data center cooling systems to absorb and release thermal energy during melting and freezing processes. PCM-based cooling solutions provide thermal energy storage capabilities, helping to maintain stable temperatures in data centers while reducing energy consumption during peak demand periods. These systems can operate passively and help improve overall cooling efficiency by reducing the reliance on mechanical cooling systems during certain periods.- Phase Change Material (PCM) cooling systems: Phase Change Materials are used in data center cooling systems to absorb and release thermal energy during melting and freezing processes. PCM-based cooling solutions provide thermal energy storage capabilities that help maintain stable temperatures in data centers, reducing the need for continuous mechanical cooling. These systems can absorb heat during peak loads and release it during off-peak periods, offering improved energy efficiency and temperature stability for sensitive IT equipment.

- Ice storage cooling technologies: Ice storage systems generate and store ice during off-peak hours when electricity costs are lower, then use the stored thermal energy for cooling during peak demand periods. This load-shifting capability allows data centers to reduce operational costs and peak power demands. The stored ice provides cooling capacity by absorbing heat as it melts, offering a reliable cooling solution that can supplement or temporarily replace mechanical cooling systems during high-demand periods or power outages.

- Chilled water cooling systems: Chilled water cooling systems circulate cold water through a network of pipes to remove heat from data center equipment. These systems typically include chillers, cooling towers, pumps, and heat exchangers to maintain optimal operating temperatures. Chilled water systems offer scalability and can be designed with redundancy for critical applications. They provide efficient cooling for high-density server environments and can be integrated with free cooling technologies to reduce energy consumption during favorable ambient conditions.

- Hybrid and integrated cooling solutions: Hybrid cooling solutions combine multiple cooling technologies such as PCM, ice storage, and chilled water systems to optimize energy efficiency and cooling performance. These integrated approaches allow data centers to leverage the advantages of each technology while minimizing their limitations. By intelligently switching between different cooling modes based on factors like ambient conditions, IT load, and electricity costs, hybrid systems can significantly reduce energy consumption while maintaining reliable cooling performance throughout varying operational conditions.

- Energy efficiency optimization techniques: Various techniques are employed to optimize the energy efficiency of data center cooling systems, including advanced control algorithms, variable speed drives, heat recovery systems, and free cooling. These approaches focus on minimizing the power usage effectiveness (PUE) ratio by reducing the energy consumed for cooling relative to IT equipment power. Optimization strategies may include dynamic load management, predictive cooling control, airflow management, and strategic equipment placement to maximize cooling efficiency while maintaining appropriate operating temperatures for IT infrastructure.

02 Ice storage cooling technologies

Ice storage systems generate and store ice during off-peak hours when electricity costs are lower, then use the stored thermal energy for cooling during peak demand periods. This load-shifting approach significantly reduces operational costs and energy consumption in data centers. The stored ice provides cooling capacity by absorbing heat as it melts, allowing chillers to be downsized or operated more efficiently. These systems are particularly effective for managing cooling loads in large data center facilities.Expand Specific Solutions03 Chilled water cooling systems

Chilled water cooling systems circulate cold water through a network of pipes to remove heat from data center equipment. These systems typically include chillers, cooling towers, pumps, and heat exchangers working together to maintain optimal operating temperatures. Chilled water systems offer high cooling capacity and efficiency for large-scale data centers, with the ability to precisely control temperature and humidity levels. Advanced control systems can optimize water flow rates and temperatures to match cooling demands while minimizing energy consumption.Expand Specific Solutions04 Hybrid cooling solutions

Hybrid cooling solutions combine multiple cooling technologies such as PCM, ice storage, and chilled water systems to optimize energy efficiency and cooling performance. These integrated approaches leverage the strengths of each technology while compensating for individual limitations. Hybrid systems can automatically switch between cooling modes based on external conditions, workload demands, and energy costs. This flexibility allows data centers to maintain optimal thermal conditions while significantly reducing energy consumption and operational costs throughout varying seasonal conditions.Expand Specific Solutions05 Energy efficiency optimization techniques

Various techniques are employed to optimize the energy efficiency of data center cooling systems, including advanced control algorithms, free cooling methods, and heat recovery systems. These approaches focus on minimizing power usage effectiveness (PUE) while maintaining required cooling performance. Techniques include variable speed drives for pumps and fans, intelligent temperature and airflow management, and predictive maintenance systems. By implementing these optimization strategies, data centers can achieve significant reductions in energy consumption while improving cooling system reliability and extending equipment lifespan.Expand Specific Solutions

Leading Providers in Data Center Cooling Industry

The data center cooling technology landscape is evolving rapidly, with PCM (Phase Change Materials), ice storage, and chilled water systems competing for market share in a growing sector. Currently in the growth phase, the data center cooling market is expanding due to increasing computing demands and sustainability concerns. Major technology players like Google, Microsoft, IBM, and NVIDIA are investing heavily in cooling innovations, while specialized cooling companies such as Green Revolution Cooling, CoolIT Systems, and Vertiv are developing advanced solutions. Traditional chilled water systems remain most mature, while PCM and ice storage technologies are gaining traction for their energy efficiency benefits. The competitive landscape shows established IT giants partnering with cooling specialists to develop hybrid solutions that balance performance, energy efficiency, and operational costs.

Google LLC

Technical Solution: Google has pioneered advanced data center cooling technologies with a comprehensive approach comparing PCM, ice storage, and chilled water systems. Their primary innovation focuses on AI-driven cooling optimization using machine learning algorithms that have reduced cooling energy by 40% in their facilities[1]. For PCM implementation, Google utilizes proprietary phase change materials integrated into server racks that absorb heat during peak loads and release it during lower demand periods. Their ice storage systems operate during off-peak hours to generate ice that provides cooling during peak demand, reducing both operational costs and grid strain. Google's chilled water systems employ advanced water-side economization with sophisticated temperature and flow controls that maximize free cooling opportunities. Their hybrid approach often combines these technologies based on facility-specific requirements and local climate conditions, with particular emphasis on water conservation techniques that have reduced water usage by up to 50% in some facilities[2].

Strengths: Industry-leading energy efficiency with documented 40% reduction in cooling energy; proprietary AI control systems; extensive global implementation experience across diverse climates. Weaknesses: Higher initial capital investment requirements; complex integration systems requiring specialized expertise; some solutions are highly customized and not easily transferable to other operators.

Green Revolution Cooling, Inc.

Technical Solution: Green Revolution Cooling (GRC) has developed innovative immersion cooling technology that fundamentally changes the comparison between traditional cooling methods like PCM, ice storage, and chilled water systems. Their flagship solution, ICEraQ™, utilizes single-phase immersion cooling where servers are submerged in ElectroSafe™ dielectric fluid that directly absorbs heat from components. This approach eliminates the need for traditional air cooling infrastructure while still interfacing with facility water systems. When compared to PCM systems, GRC's solution eliminates the cyclical efficiency limitations of phase change materials while providing consistent cooling regardless of computational load. Against ice storage systems, their technology reduces complexity by eliminating the need for thermal energy storage and associated control systems. When compared to traditional chilled water approaches, GRC's immersion cooling operates at significantly higher water temperatures (up to 40°C vs typical 18-22°C), enabling greater use of free cooling and reducing chiller energy consumption by up to 90%[7]. Their comparative analysis demonstrates that immersion cooling can achieve PUE values as low as 1.03-1.05, substantially outperforming even optimized traditional cooling methods. GRC's technology has been implemented in over 20 countries across various data center types, with documented cooling energy reductions of 90% and total facility energy reductions of 50% compared to air-cooled facilities[8].

Strengths: Revolutionary approach eliminating traditional cooling constraints; documented 90% reduction in cooling energy; compatibility with higher temperature water systems enabling free cooling; significantly reduced physical footprint. Weaknesses: Requires specialized server configurations or modifications; initial implementation requires operational paradigm shift; potential concerns regarding long-term fluid maintenance and replacement costs.

Technical Deep Dive: Patents and Innovations in Cooling Methods

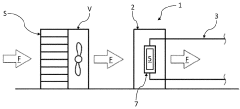

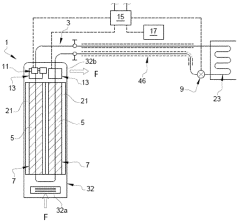

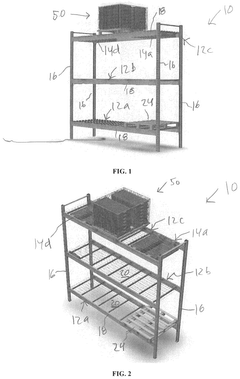

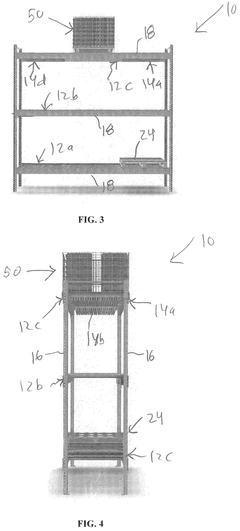

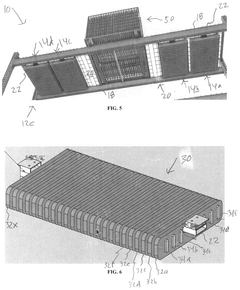

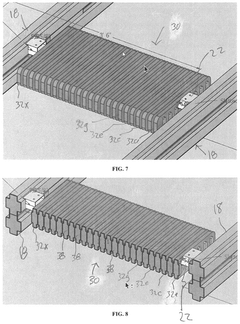

Device for cooling a data center computer server by using a phase change material

PatentWO2024047252A1

Innovation

- A cooling device utilizing a phase change material (PCM) that stores heat generated by server components and releases it via a heat exchanger, optimized for use with renewable energy sources, allowing for deferred energy use during more economical times and minimizing electrical energy consumption.

PCM Cell and System Technology

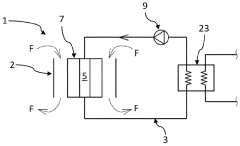

PatentPendingUS20250067522A1

Innovation

- The development of a Phase Change Material (PCM) cell apparatus and cooling system that integrates thermal energy storage directly into the existing refrigeration system, utilizing high-density PCM storage, modular design, and advanced monitoring systems to enhance efficiency and reliability.

Energy Efficiency Metrics and Environmental Impact Assessment

Energy efficiency metrics provide crucial benchmarks for evaluating data center cooling technologies. Power Usage Effectiveness (PUE), the ratio of total facility energy to IT equipment energy, remains the industry standard metric. Phase Change Material (PCM) cooling systems typically achieve PUE values between 1.15-1.25, outperforming traditional chilled water systems which average 1.4-1.8. Ice storage systems fall between these ranges at approximately 1.2-1.4, depending on implementation specifics.

Water Usage Effectiveness (WUE) has gained prominence as water conservation becomes increasingly critical. Chilled water systems consume significant water resources, with typical WUE values of 1.5-2.5 L/kWh. PCM systems substantially reduce water requirements, achieving WUE values as low as 0.2-0.5 L/kWh. Ice storage systems occupy a middle position with WUE values of approximately 0.8-1.2 L/kWh.

Carbon emissions represent another vital environmental consideration. PCM cooling technologies demonstrate the lowest carbon footprint, reducing emissions by up to 40% compared to conventional chilled water systems. This advantage stems from PCM's ability to operate efficiently during off-peak hours and maintain cooling without continuous energy input. Ice storage systems offer emissions reductions of 20-30% through similar load-shifting capabilities.

Life cycle assessment (LCA) reveals important distinctions between these cooling technologies. PCM systems utilize materials with varying environmental impacts—organic PCMs generally have lower environmental footprints than inorganic or salt-based alternatives. Chilled water systems require extensive piping infrastructure and refrigerants with high global warming potential. Ice storage systems necessitate substantial initial resource investment but demonstrate favorable long-term environmental performance through operational efficiency.

Refrigerant management presents significant environmental concerns. Modern PCM systems often eliminate traditional refrigerants entirely, while advanced chilled water systems still rely on hydrofluorocarbons (HFCs) with global warming potentials thousands of times greater than CO2. Ice storage systems typically require refrigerants for ice production, though in reduced quantities compared to conventional cooling.

Space efficiency metrics reveal that PCM systems require approximately 30-40% less physical space than equivalent chilled water infrastructure. Ice storage systems demand the largest footprint due to the substantial volume needed for ice production and storage tanks, typically 50-70% more space than chilled water systems of comparable capacity.

Water Usage Effectiveness (WUE) has gained prominence as water conservation becomes increasingly critical. Chilled water systems consume significant water resources, with typical WUE values of 1.5-2.5 L/kWh. PCM systems substantially reduce water requirements, achieving WUE values as low as 0.2-0.5 L/kWh. Ice storage systems occupy a middle position with WUE values of approximately 0.8-1.2 L/kWh.

Carbon emissions represent another vital environmental consideration. PCM cooling technologies demonstrate the lowest carbon footprint, reducing emissions by up to 40% compared to conventional chilled water systems. This advantage stems from PCM's ability to operate efficiently during off-peak hours and maintain cooling without continuous energy input. Ice storage systems offer emissions reductions of 20-30% through similar load-shifting capabilities.

Life cycle assessment (LCA) reveals important distinctions between these cooling technologies. PCM systems utilize materials with varying environmental impacts—organic PCMs generally have lower environmental footprints than inorganic or salt-based alternatives. Chilled water systems require extensive piping infrastructure and refrigerants with high global warming potential. Ice storage systems necessitate substantial initial resource investment but demonstrate favorable long-term environmental performance through operational efficiency.

Refrigerant management presents significant environmental concerns. Modern PCM systems often eliminate traditional refrigerants entirely, while advanced chilled water systems still rely on hydrofluorocarbons (HFCs) with global warming potentials thousands of times greater than CO2. Ice storage systems typically require refrigerants for ice production, though in reduced quantities compared to conventional cooling.

Space efficiency metrics reveal that PCM systems require approximately 30-40% less physical space than equivalent chilled water infrastructure. Ice storage systems demand the largest footprint due to the substantial volume needed for ice production and storage tanks, typically 50-70% more space than chilled water systems of comparable capacity.

Total Cost of Ownership and ROI Analysis

When evaluating cooling solutions for data centers, Total Cost of Ownership (TCO) and Return on Investment (ROI) analyses are critical for making informed decisions. PCM (Phase Change Material), Ice Storage, and Chilled Water systems each present distinct financial profiles that extend beyond initial capital expenditure.

The capital expenditure for PCM systems typically falls between ice storage and chilled water systems. While PCM modules require specialized encapsulation technology, they don't demand the extensive infrastructure of ice storage systems. Installation costs for PCM systems are moderate, with minimal site preparation requirements compared to ice storage solutions that often necessitate reinforced foundations due to weight considerations.

Operational expenditure analysis reveals significant differences among these cooling technologies. Chilled water systems operate continuously, resulting in consistent energy consumption patterns and higher peak-demand charges. Conversely, both PCM and ice storage systems enable load shifting to off-peak hours, potentially reducing electricity costs by 30-45% in regions with time-of-use pricing structures.

Maintenance requirements also impact long-term costs substantially. Ice storage systems require regular inspection of heat exchangers and glycol concentration monitoring, with major component replacement typically needed every 15-20 years. PCM systems generally demonstrate longer operational lifespans of 20-25 years with minimal maintenance requirements. Chilled water systems fall between these extremes, requiring regular maintenance but with well-established service protocols.

Space utilization efficiency affects indirect costs significantly. PCM solutions typically require 15-25% less physical space than equivalent ice storage systems, potentially freeing valuable real estate for revenue-generating IT equipment. This space efficiency can translate to approximately $1,000-2,500 per square meter in high-density data center environments.

ROI calculations indicate that while chilled water systems typically offer the fastest simple payback period of 2-3 years, PCM and ice storage systems demonstrate superior long-term ROI when factoring in energy arbitrage opportunities and operational savings. PCM systems generally achieve break-even within 3-5 years, while ice storage systems require 4-6 years but may offer greater total savings over a 20-year lifecycle.

Scalability considerations further impact long-term financial performance. PCM systems offer modular expansion capabilities, allowing for capital expenditure distribution over time as cooling needs increase. This phased investment approach can improve cash flow management compared to the larger upfront investments required for comprehensive chilled water or ice storage infrastructure.

The capital expenditure for PCM systems typically falls between ice storage and chilled water systems. While PCM modules require specialized encapsulation technology, they don't demand the extensive infrastructure of ice storage systems. Installation costs for PCM systems are moderate, with minimal site preparation requirements compared to ice storage solutions that often necessitate reinforced foundations due to weight considerations.

Operational expenditure analysis reveals significant differences among these cooling technologies. Chilled water systems operate continuously, resulting in consistent energy consumption patterns and higher peak-demand charges. Conversely, both PCM and ice storage systems enable load shifting to off-peak hours, potentially reducing electricity costs by 30-45% in regions with time-of-use pricing structures.

Maintenance requirements also impact long-term costs substantially. Ice storage systems require regular inspection of heat exchangers and glycol concentration monitoring, with major component replacement typically needed every 15-20 years. PCM systems generally demonstrate longer operational lifespans of 20-25 years with minimal maintenance requirements. Chilled water systems fall between these extremes, requiring regular maintenance but with well-established service protocols.

Space utilization efficiency affects indirect costs significantly. PCM solutions typically require 15-25% less physical space than equivalent ice storage systems, potentially freeing valuable real estate for revenue-generating IT equipment. This space efficiency can translate to approximately $1,000-2,500 per square meter in high-density data center environments.

ROI calculations indicate that while chilled water systems typically offer the fastest simple payback period of 2-3 years, PCM and ice storage systems demonstrate superior long-term ROI when factoring in energy arbitrage opportunities and operational savings. PCM systems generally achieve break-even within 3-5 years, while ice storage systems require 4-6 years but may offer greater total savings over a 20-year lifecycle.

Scalability considerations further impact long-term financial performance. PCM systems offer modular expansion capabilities, allowing for capital expenditure distribution over time as cooling needs increase. This phased investment approach can improve cash flow management compared to the larger upfront investments required for comprehensive chilled water or ice storage infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!