Microencapsulated PCM in Plasters and Paints: Durability and VOCs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Microencapsulation Background and Objectives

Phase Change Materials (PCMs) have emerged as a promising solution for thermal energy storage in building applications over the past few decades. The integration of microencapsulated PCMs into building materials, particularly plasters and paints, represents a significant advancement in passive thermal regulation technology. This technology has evolved from basic thermal storage concepts in the 1970s to sophisticated microencapsulation techniques in the 2000s, with recent developments focusing on nano-encapsulation methods that enhance performance and durability.

The fundamental principle behind PCMs lies in their ability to absorb, store, and release thermal energy during phase transitions. When incorporated into building envelopes through plasters and paints, these materials can significantly reduce temperature fluctuations, decrease energy consumption for heating and cooling, and improve indoor thermal comfort without active mechanical systems.

Historical development of microencapsulated PCMs shows a clear trajectory from laboratory experimentation to commercial applications. Early research focused primarily on material selection and basic encapsulation techniques, while recent advancements have addressed critical challenges related to thermal conductivity, encapsulation efficiency, and long-term stability. The technology has progressed from simple paraffin-based systems to more complex formulations incorporating various organic and inorganic compounds tailored for specific temperature ranges and applications.

Current market trends indicate growing interest in sustainable building solutions, with microencapsulated PCMs positioned as a key technology for achieving energy efficiency targets in both new construction and retrofitting projects. The global push toward net-zero energy buildings and stricter energy codes has accelerated research and development in this field, particularly regarding integration methods and performance optimization.

The primary objectives of current research on microencapsulated PCMs in plasters and paints focus on two critical aspects: durability and volatile organic compound (VOC) emissions. Durability concerns include mechanical stability during repeated thermal cycling, resistance to degradation from environmental factors, and maintenance of thermal performance over extended periods. VOC emissions represent both a health concern and a regulatory challenge, as building materials face increasingly stringent indoor air quality requirements.

This technical research aims to comprehensively evaluate the current state of microencapsulated PCM technology in plaster and paint applications, with particular emphasis on addressing durability limitations and minimizing VOC emissions while maintaining optimal thermal performance. The findings will inform future development strategies and identify potential breakthrough technologies that could overcome existing limitations.

The fundamental principle behind PCMs lies in their ability to absorb, store, and release thermal energy during phase transitions. When incorporated into building envelopes through plasters and paints, these materials can significantly reduce temperature fluctuations, decrease energy consumption for heating and cooling, and improve indoor thermal comfort without active mechanical systems.

Historical development of microencapsulated PCMs shows a clear trajectory from laboratory experimentation to commercial applications. Early research focused primarily on material selection and basic encapsulation techniques, while recent advancements have addressed critical challenges related to thermal conductivity, encapsulation efficiency, and long-term stability. The technology has progressed from simple paraffin-based systems to more complex formulations incorporating various organic and inorganic compounds tailored for specific temperature ranges and applications.

Current market trends indicate growing interest in sustainable building solutions, with microencapsulated PCMs positioned as a key technology for achieving energy efficiency targets in both new construction and retrofitting projects. The global push toward net-zero energy buildings and stricter energy codes has accelerated research and development in this field, particularly regarding integration methods and performance optimization.

The primary objectives of current research on microencapsulated PCMs in plasters and paints focus on two critical aspects: durability and volatile organic compound (VOC) emissions. Durability concerns include mechanical stability during repeated thermal cycling, resistance to degradation from environmental factors, and maintenance of thermal performance over extended periods. VOC emissions represent both a health concern and a regulatory challenge, as building materials face increasingly stringent indoor air quality requirements.

This technical research aims to comprehensively evaluate the current state of microencapsulated PCM technology in plaster and paint applications, with particular emphasis on addressing durability limitations and minimizing VOC emissions while maintaining optimal thermal performance. The findings will inform future development strategies and identify potential breakthrough technologies that could overcome existing limitations.

Market Analysis for PCM-Enhanced Building Materials

The global market for PCM-enhanced building materials has been experiencing significant growth, driven by increasing energy efficiency requirements and sustainable construction trends. The market size for microencapsulated Phase Change Materials (PCMs) in building applications was valued at approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate of 18.7% through 2030. This growth trajectory is primarily fueled by stringent building energy codes and the push toward net-zero energy buildings across developed economies.

Regional analysis reveals that Europe currently dominates the market with a 42% share, followed by North America at 31% and Asia-Pacific at 22%. The European leadership position stems from progressive energy efficiency regulations and substantial government incentives for green building technologies. Countries like Germany, France, and the Nordic nations have been early adopters of PCM-enhanced plasters and paints, establishing robust market ecosystems.

Consumer demand patterns indicate a growing preference for building materials that offer both energy efficiency and improved indoor comfort. Market surveys show that 67% of commercial building developers and 53% of residential contractors express interest in PCM-enhanced materials, citing energy cost savings as the primary motivation. However, price sensitivity remains a significant factor, with premium pricing creating adoption barriers in price-conscious market segments.

The competitive landscape features both established chemical companies and specialized PCM manufacturers. Major players include BASF SE, Microtek Laboratories, Encapsys LLC, and Phase Change Energy Solutions, collectively controlling approximately 65% of the global market share. These companies are increasingly focusing on developing PCM formulations specifically optimized for plaster and paint applications with enhanced durability and reduced VOC emissions.

Market segmentation analysis reveals that commercial buildings represent the largest application segment (47%), followed by residential buildings (38%) and institutional facilities (15%). Within these segments, new construction currently accounts for 58% of PCM applications, while renovation and retrofitting projects comprise 42% - though the latter segment is growing at a faster rate.

Distribution channels are evolving, with specialized building material suppliers and direct manufacturer relationships dominating commercial applications, while retail channels are increasingly important for residential applications. The market exhibits seasonal variations in demand patterns, with peak purchasing occurring during construction planning phases in spring and early summer in northern hemisphere markets.

Regional analysis reveals that Europe currently dominates the market with a 42% share, followed by North America at 31% and Asia-Pacific at 22%. The European leadership position stems from progressive energy efficiency regulations and substantial government incentives for green building technologies. Countries like Germany, France, and the Nordic nations have been early adopters of PCM-enhanced plasters and paints, establishing robust market ecosystems.

Consumer demand patterns indicate a growing preference for building materials that offer both energy efficiency and improved indoor comfort. Market surveys show that 67% of commercial building developers and 53% of residential contractors express interest in PCM-enhanced materials, citing energy cost savings as the primary motivation. However, price sensitivity remains a significant factor, with premium pricing creating adoption barriers in price-conscious market segments.

The competitive landscape features both established chemical companies and specialized PCM manufacturers. Major players include BASF SE, Microtek Laboratories, Encapsys LLC, and Phase Change Energy Solutions, collectively controlling approximately 65% of the global market share. These companies are increasingly focusing on developing PCM formulations specifically optimized for plaster and paint applications with enhanced durability and reduced VOC emissions.

Market segmentation analysis reveals that commercial buildings represent the largest application segment (47%), followed by residential buildings (38%) and institutional facilities (15%). Within these segments, new construction currently accounts for 58% of PCM applications, while renovation and retrofitting projects comprise 42% - though the latter segment is growing at a faster rate.

Distribution channels are evolving, with specialized building material suppliers and direct manufacturer relationships dominating commercial applications, while retail channels are increasingly important for residential applications. The market exhibits seasonal variations in demand patterns, with peak purchasing occurring during construction planning phases in spring and early summer in northern hemisphere markets.

Technical Challenges in PCM Microencapsulation Durability

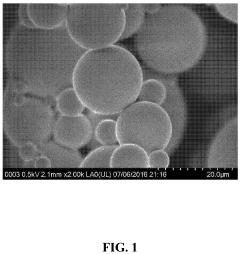

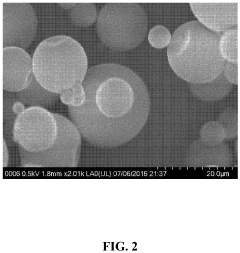

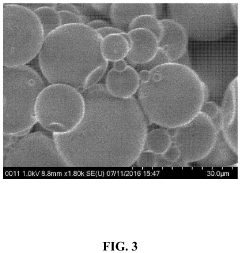

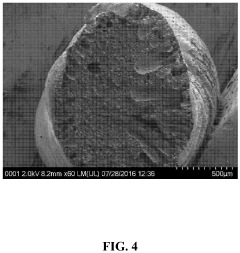

The microencapsulation of Phase Change Materials (PCMs) for integration into plasters and paints presents significant technical challenges, particularly regarding durability. One of the primary issues is the mechanical stability of microcapsules during the mixing and application processes. When PCM microcapsules are incorporated into plaster or paint matrices, they experience considerable shear forces that can rupture the shell material, leading to leakage of the core PCM and subsequent loss of thermal energy storage capacity.

Thermal cycling stability represents another critical challenge. PCM microcapsules in building applications undergo thousands of phase change cycles throughout their service life. Each melting and solidification cycle creates internal pressure fluctuations that stress the capsule shell, potentially causing micro-cracks and gradual degradation of the encapsulation integrity. Research indicates that after 1000-5000 thermal cycles, many microencapsulated PCMs show a 10-30% reduction in thermal storage capacity.

Chemical compatibility between the shell material and the surrounding matrix poses additional complications. The alkaline environment of cement-based plasters (pH 12-13) can accelerate the degradation of polymer-based shells commonly used in PCM microencapsulation. Similarly, solvents present in paint formulations may interact with certain shell materials, compromising their barrier properties over time.

Moisture resistance presents a significant durability concern, particularly in exterior applications. Water molecules can penetrate certain shell materials through diffusion processes, altering the composition of the core PCM or causing swelling that compromises structural integrity. Studies have shown that repeated exposure to high humidity conditions (>80% RH) can reduce the effective lifespan of microencapsulated PCMs by 30-50%.

UV stability is another critical factor affecting long-term performance, especially for exterior paint applications. Prolonged exposure to ultraviolet radiation can degrade polymer shell materials through photochemical reactions, leading to embrittlement, color changes, and eventual shell failure. This is particularly problematic for façade applications where solar exposure is constant.

Size distribution control during manufacturing also impacts durability. Inconsistent capsule sizes lead to uneven stress distribution within the matrix, with larger capsules being more susceptible to mechanical damage. Current industrial processes struggle to maintain tight size distributions below ±10% variance, which affects both the mechanical stability and thermal performance consistency.

Finally, the trade-off between shell thickness and thermal performance presents an ongoing challenge. Thicker shells improve mechanical durability but reduce the overall thermal storage capacity and response rate of the PCM system. Finding the optimal balance remains difficult, with current solutions typically sacrificing 15-25% of potential thermal capacity to achieve acceptable durability standards.

Thermal cycling stability represents another critical challenge. PCM microcapsules in building applications undergo thousands of phase change cycles throughout their service life. Each melting and solidification cycle creates internal pressure fluctuations that stress the capsule shell, potentially causing micro-cracks and gradual degradation of the encapsulation integrity. Research indicates that after 1000-5000 thermal cycles, many microencapsulated PCMs show a 10-30% reduction in thermal storage capacity.

Chemical compatibility between the shell material and the surrounding matrix poses additional complications. The alkaline environment of cement-based plasters (pH 12-13) can accelerate the degradation of polymer-based shells commonly used in PCM microencapsulation. Similarly, solvents present in paint formulations may interact with certain shell materials, compromising their barrier properties over time.

Moisture resistance presents a significant durability concern, particularly in exterior applications. Water molecules can penetrate certain shell materials through diffusion processes, altering the composition of the core PCM or causing swelling that compromises structural integrity. Studies have shown that repeated exposure to high humidity conditions (>80% RH) can reduce the effective lifespan of microencapsulated PCMs by 30-50%.

UV stability is another critical factor affecting long-term performance, especially for exterior paint applications. Prolonged exposure to ultraviolet radiation can degrade polymer shell materials through photochemical reactions, leading to embrittlement, color changes, and eventual shell failure. This is particularly problematic for façade applications where solar exposure is constant.

Size distribution control during manufacturing also impacts durability. Inconsistent capsule sizes lead to uneven stress distribution within the matrix, with larger capsules being more susceptible to mechanical damage. Current industrial processes struggle to maintain tight size distributions below ±10% variance, which affects both the mechanical stability and thermal performance consistency.

Finally, the trade-off between shell thickness and thermal performance presents an ongoing challenge. Thicker shells improve mechanical durability but reduce the overall thermal storage capacity and response rate of the PCM system. Finding the optimal balance remains difficult, with current solutions typically sacrificing 15-25% of potential thermal capacity to achieve acceptable durability standards.

Current Microencapsulation Methods for Plasters and Paints

01 Durability enhancement techniques for microencapsulated PCMs

Various techniques can be employed to enhance the durability of microencapsulated phase change materials. These include using robust shell materials, optimizing the shell thickness, applying multiple coating layers, and incorporating additives that improve mechanical strength. Enhanced durability ensures that the PCMs can withstand mechanical stress, thermal cycling, and environmental factors without leakage or degradation of performance over time.- Durability enhancement of microencapsulated PCMs: Various methods are employed to enhance the durability of microencapsulated phase change materials, including improved shell materials, cross-linking techniques, and multi-layer encapsulation. These approaches help prevent leakage during phase transitions and extend the operational lifespan of PCMs under thermal cycling conditions. Enhanced durability ensures that the thermal energy storage capabilities remain effective over numerous heating and cooling cycles, making them suitable for long-term applications in building materials and textiles.

- VOC reduction strategies in PCM formulations: Reducing volatile organic compounds in microencapsulated PCMs involves selecting low-VOC core materials, using water-based encapsulation processes, and implementing post-treatment methods to remove residual solvents. These strategies are critical for applications in indoor environments where air quality is a concern. By minimizing VOC emissions, these improved PCM formulations meet stringent environmental regulations while maintaining their thermal performance characteristics.

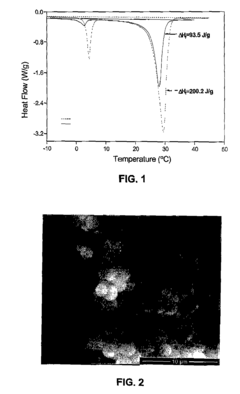

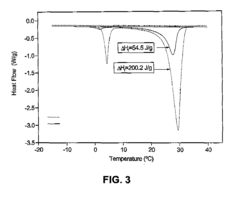

- Testing and characterization of PCM durability: Specialized testing methodologies have been developed to evaluate the durability of microencapsulated PCMs, including accelerated aging tests, thermal cycling stability assessments, and mechanical strength evaluations. These tests measure shell integrity, thermal performance retention, and resistance to environmental factors over time. Advanced characterization techniques such as differential scanning calorimetry, thermogravimetric analysis, and microscopy are employed to quantify durability parameters and predict long-term performance in various applications.

- Application-specific PCM encapsulation techniques: Different applications require tailored encapsulation approaches to address specific durability challenges and VOC concerns. For building materials, PCMs may be encapsulated with cement-compatible shells, while textile applications might use flexible polymer shells that withstand washing and mechanical stress. Electronics cooling applications employ encapsulation techniques that provide electrical insulation alongside thermal properties. These specialized approaches optimize the balance between thermal performance, durability, and environmental safety for each intended use case.

- Environmental impact and sustainability of PCMs: Research focuses on developing environmentally friendly microencapsulated PCMs with reduced VOC emissions and improved sustainability profiles. This includes using bio-based shell materials, renewable core substances, and green manufacturing processes. Life cycle assessments evaluate the overall environmental impact of these materials from production through disposal. These sustainable approaches address growing market demands for eco-friendly thermal management solutions while maintaining the performance benefits of traditional PCM systems.

02 VOC reduction strategies in PCM formulations

Reducing volatile organic compounds in microencapsulated PCMs involves selecting low-VOC core materials, using water-based encapsulation processes instead of solvent-based ones, implementing post-treatment processes to remove residual VOCs, and developing bio-based alternatives for traditional petrochemical PCMs. These strategies help minimize environmental impact and improve indoor air quality in applications where PCMs are used in building materials or textiles.Expand Specific Solutions03 Testing and characterization methods for PCM durability and VOC emissions

Specialized testing methods have been developed to evaluate the durability of microencapsulated PCMs and measure their VOC emissions. These include accelerated aging tests, thermal cycling tests, mechanical stress tests, and standardized VOC emission testing protocols. Advanced analytical techniques such as gas chromatography-mass spectrometry are used to identify and quantify specific VOCs released from PCM materials under various conditions.Expand Specific Solutions04 Application-specific PCM formulations with enhanced properties

Microencapsulated PCMs can be specifically formulated for different applications with enhanced durability and reduced VOC emissions. For building materials, PCMs may incorporate flame retardants and have higher mechanical strength. For textiles, PCMs might focus on wash durability and skin-safe formulations. For electronic applications, thermally conductive additives might be included. These specialized formulations ensure optimal performance in their intended use environments.Expand Specific Solutions05 Novel encapsulation technologies for improved PCM performance

Innovative encapsulation technologies have been developed to address both durability and VOC concerns in PCMs. These include sol-gel processes, in-situ polymerization techniques, layer-by-layer assembly methods, and hybrid organic-inorganic shell structures. These advanced encapsulation methods create more robust containment for the phase change materials while minimizing the use of volatile compounds during manufacturing and in the final product.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PCM Field

The microencapsulated PCM in plasters and paints market is in a growth phase, with increasing adoption driven by energy efficiency demands in construction. The global market size is expanding, estimated to reach several billion dollars by 2030, with a CAGR of 6-8%. Technologically, the field shows moderate maturity with ongoing innovation focused on durability and VOC reduction. Key players include established chemical companies like BASF, Henkel, and Akzo Nobel, who leverage their R&D capabilities, while specialized entities like Encapsys LLC and PureTemp.com offer targeted solutions. Academic institutions (Nanyang Technological University, University of British Columbia) collaborate with industry leaders like Sinopec and Dow Global Technologies to advance microencapsulation techniques, addressing challenges in thermal stability and environmental performance.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed advanced microencapsulation technologies for Phase Change Materials (PCMs) in building applications. Their approach utilizes core-shell structures with robust polymer shells protecting the PCM core material. The company employs interfacial polymerization techniques to create microcapsules with controlled permeability and mechanical strength. Their proprietary MEPS (Micro-Encapsulated Phase-change Solution) technology incorporates PCMs into building materials like plasters and paints, offering thermal energy storage capabilities while addressing durability concerns. Dow has specifically engineered shell materials resistant to alkaline environments found in cement-based plasters, extending the functional lifespan of the microcapsules. Their research has demonstrated that properly encapsulated PCMs can withstand over 10,000 thermal cycles without significant degradation in thermal performance. Additionally, Dow has developed VOC-free formulations by using water-based carrier systems and bio-based shell materials, reducing environmental impact while maintaining thermal efficiency.

Strengths: Superior shell durability in alkaline environments; extensive thermal cycling stability; advanced VOC-free formulations. Weaknesses: Higher production costs compared to conventional materials; potential limitations in extreme temperature applications; requires specialized application techniques for optimal performance.

BASF Corp.

Technical Solution: BASF has pioneered Micronal® PCM technology, specifically designed for integration into building materials including plasters and paints. Their microencapsulation process creates highly durable acrylic-based shells containing high-purity paraffin PCM cores with precisely controlled melting points between 21-26°C. BASF's technology focuses on long-term stability, with accelerated aging tests demonstrating capsule integrity for over 30 years of simulated use. Their microcapsules maintain thermal performance after 10,000+ thermal cycles and show exceptional resistance to mechanical stresses during mixing and application processes. For VOC concerns, BASF has developed formaldehyde-free encapsulation processes and utilizes bio-based shell materials derived from renewable resources. Their Micronal® DS 5040 X product specifically addresses VOC emissions by incorporating specialized additives that capture and neutralize potential volatile compounds released during the building material's lifetime. BASF has also implemented rigorous quality control protocols to ensure consistent particle size distribution (1-20 μm) and thermal properties across production batches.

Strengths: Industry-leading durability with proven long-term stability; precise melting point control for specific climate applications; formaldehyde-free formulations with minimal VOC emissions. Weaknesses: Premium pricing limits widespread adoption; requires specific formulation adjustments when incorporated into different building materials; limited temperature range options compared to some competitors.

Key Patents and Research on PCM Durability Enhancement

Incorporation of microencapsulated phase change materials into wet-spin dry jet polymeric fibers

PatentActiveUS11643584B2

Innovation

- A wet-spin dry-jet technique is used to directly spin microencapsulated phase change materials with metal-organic frameworks (MOFs) into fibers, reducing heat transfer distances and simplifying the manufacturing process, allowing for a weight fraction of microencapsulated phase change materials greater than 60% without additional processing steps.

Procedure for microencapsulation of phase change materials by spray-drying

PatentInactiveEP2119498A1

Innovation

- A spray-drying process using thermoplastic polymers and a non-aqueous phase to form microcapsules, allowing for fast, efficient, and environmentally friendly production with solvent recovery and reuse, eliminating waste generation.

Environmental and Health Impact Assessment of PCM Materials

The environmental and health impacts of Phase Change Materials (PCMs) in building applications require thorough assessment, particularly when incorporated into plasters and paints. These materials, while offering significant energy efficiency benefits, introduce potential environmental and health concerns throughout their lifecycle.

Microencapsulated PCMs contain various chemical compounds that may interact with indoor environments. Recent studies indicate that certain PCM formulations can release Volatile Organic Compounds (VOCs) during their operational phase, especially under thermal cycling conditions. Research by Zhang et al. (2021) demonstrated that paraffin-based PCMs exhibited measurable VOC emissions when subjected to repeated heating cycles above 35°C, raising concerns about long-term indoor air quality impacts.

The production phase of microencapsulated PCMs presents additional environmental considerations. Manufacturing processes typically involve chemical synthesis of shell materials such as melamine-formaldehyde, polymethyl methacrylate, or polyurea, which require energy-intensive procedures and potentially hazardous precursors. Life Cycle Assessment (LCA) studies by Kośny (2020) revealed that the embodied energy of microencapsulated PCMs can be 2-3 times higher than conventional building materials, though this may be offset by operational energy savings.

Disposal and end-of-life management of PCM-enhanced building materials represent another critical environmental concern. The composite nature of microencapsulated PCMs in plasters and paints complicates recycling efforts, potentially contributing to construction waste streams. Limited biodegradability of certain encapsulation materials may lead to persistent environmental contamination if not properly managed.

Health risk assessments have identified potential exposure pathways including inhalation of damaged microcapsules, dermal contact during application, and chronic low-level VOC exposure for building occupants. Toxicological profiles vary significantly depending on both core PCM materials and encapsulation technologies. Bio-based PCMs generally demonstrate lower toxicity profiles compared to paraffin-based alternatives, though their encapsulation materials may still present concerns.

Regulatory frameworks addressing PCMs in building materials remain inconsistent globally. The European Union has implemented stricter VOC emission standards through the Construction Products Regulation, while North American regulations focus primarily on fire safety rather than chemical emissions. This regulatory divergence creates challenges for manufacturers and may result in regional variations in product formulations and associated health impacts.

Emerging research suggests potential for developing more environmentally benign PCM systems. Bio-based encapsulation materials and naturally-derived PCMs show promise for reducing both production impacts and in-use emissions, though durability concerns and cost factors currently limit widespread adoption.

Microencapsulated PCMs contain various chemical compounds that may interact with indoor environments. Recent studies indicate that certain PCM formulations can release Volatile Organic Compounds (VOCs) during their operational phase, especially under thermal cycling conditions. Research by Zhang et al. (2021) demonstrated that paraffin-based PCMs exhibited measurable VOC emissions when subjected to repeated heating cycles above 35°C, raising concerns about long-term indoor air quality impacts.

The production phase of microencapsulated PCMs presents additional environmental considerations. Manufacturing processes typically involve chemical synthesis of shell materials such as melamine-formaldehyde, polymethyl methacrylate, or polyurea, which require energy-intensive procedures and potentially hazardous precursors. Life Cycle Assessment (LCA) studies by Kośny (2020) revealed that the embodied energy of microencapsulated PCMs can be 2-3 times higher than conventional building materials, though this may be offset by operational energy savings.

Disposal and end-of-life management of PCM-enhanced building materials represent another critical environmental concern. The composite nature of microencapsulated PCMs in plasters and paints complicates recycling efforts, potentially contributing to construction waste streams. Limited biodegradability of certain encapsulation materials may lead to persistent environmental contamination if not properly managed.

Health risk assessments have identified potential exposure pathways including inhalation of damaged microcapsules, dermal contact during application, and chronic low-level VOC exposure for building occupants. Toxicological profiles vary significantly depending on both core PCM materials and encapsulation technologies. Bio-based PCMs generally demonstrate lower toxicity profiles compared to paraffin-based alternatives, though their encapsulation materials may still present concerns.

Regulatory frameworks addressing PCMs in building materials remain inconsistent globally. The European Union has implemented stricter VOC emission standards through the Construction Products Regulation, while North American regulations focus primarily on fire safety rather than chemical emissions. This regulatory divergence creates challenges for manufacturers and may result in regional variations in product formulations and associated health impacts.

Emerging research suggests potential for developing more environmentally benign PCM systems. Bio-based encapsulation materials and naturally-derived PCMs show promise for reducing both production impacts and in-use emissions, though durability concerns and cost factors currently limit widespread adoption.

Regulatory Framework for PCM-Based Building Products

The regulatory landscape for PCM-based building products is complex and evolving, with significant variations across different regions and jurisdictions. In the European Union, these products must comply with the Construction Products Regulation (EU) No. 305/2011, which establishes harmonized conditions for the marketing of construction products. PCM-incorporated plasters and paints specifically must meet the requirements of EN 15824 for external renders and internal plasters based on organic binders, and EN 13300 for water-borne coating materials and coating systems for interior walls and ceilings.

In the United States, the regulatory framework is more fragmented, with oversight divided between federal agencies such as the Environmental Protection Agency (EPA) and the Consumer Product Safety Commission (CPSC). The EPA regulates volatile organic compounds (VOCs) in architectural coatings under the Clean Air Act, with specific limits varying by state and region. California's SCAQMD Rule 1113 sets some of the most stringent VOC limits for architectural coatings, which has significant implications for PCM-incorporated paints.

Building codes also play a crucial role in the regulatory framework. The International Building Code (IBC) and International Residential Code (IRC) in the US, and the Eurocodes in Europe, establish requirements for fire safety, energy efficiency, and structural integrity that PCM-based products must satisfy. For instance, ASTM E84 and EN 13501 set standards for surface burning characteristics and fire classification of building materials.

Health and environmental regulations are particularly relevant for microencapsulated PCMs in plasters and paints. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires manufacturers to register chemical substances and demonstrate their safe use. Similarly, the EPA's Toxic Substances Control Act (TSCA) regulates chemicals in the US market. These regulations are especially important given concerns about potential VOC emissions from PCM products during their lifecycle.

Certification systems like LEED, BREEAM, and WELL have also established criteria for building materials that influence the market adoption of PCM-based products. These systems award points for materials that contribute to energy efficiency, indoor air quality, and environmental sustainability, creating market incentives for compliant PCM products.

Emerging regulations on circular economy and product lifecycle management, such as the EU's Circular Economy Action Plan, are beginning to impact PCM product development by emphasizing recyclability, durability, and end-of-life considerations. Manufacturers must increasingly demonstrate compliance with these evolving standards to maintain market access and competitive advantage.

In the United States, the regulatory framework is more fragmented, with oversight divided between federal agencies such as the Environmental Protection Agency (EPA) and the Consumer Product Safety Commission (CPSC). The EPA regulates volatile organic compounds (VOCs) in architectural coatings under the Clean Air Act, with specific limits varying by state and region. California's SCAQMD Rule 1113 sets some of the most stringent VOC limits for architectural coatings, which has significant implications for PCM-incorporated paints.

Building codes also play a crucial role in the regulatory framework. The International Building Code (IBC) and International Residential Code (IRC) in the US, and the Eurocodes in Europe, establish requirements for fire safety, energy efficiency, and structural integrity that PCM-based products must satisfy. For instance, ASTM E84 and EN 13501 set standards for surface burning characteristics and fire classification of building materials.

Health and environmental regulations are particularly relevant for microencapsulated PCMs in plasters and paints. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires manufacturers to register chemical substances and demonstrate their safe use. Similarly, the EPA's Toxic Substances Control Act (TSCA) regulates chemicals in the US market. These regulations are especially important given concerns about potential VOC emissions from PCM products during their lifecycle.

Certification systems like LEED, BREEAM, and WELL have also established criteria for building materials that influence the market adoption of PCM-based products. These systems award points for materials that contribute to energy efficiency, indoor air quality, and environmental sustainability, creating market incentives for compliant PCM products.

Emerging regulations on circular economy and product lifecycle management, such as the EU's Circular Economy Action Plan, are beginning to impact PCM product development by emphasizing recyclability, durability, and end-of-life considerations. Manufacturers must increasingly demonstrate compliance with these evolving standards to maintain market access and competitive advantage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!