How to Size PCM for Peak-Shaving Under TOU Tariffs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Technology Background and Objectives

Phase Change Materials (PCM) have emerged as a promising technology for thermal energy storage, with applications spanning from building temperature regulation to industrial process optimization. The evolution of PCM technology can be traced back to the 1940s, with significant advancements occurring in the 1980s when researchers began exploring their potential for energy conservation. Over the past two decades, PCM technology has matured considerably, driven by increasing energy costs and growing environmental concerns.

PCM's unique ability to absorb, store, and release large amounts of energy during phase transitions makes them particularly valuable for peak-shaving applications under Time-of-Use (TOU) tariff structures. These materials can store thermal energy during off-peak periods when electricity rates are lower and release it during peak periods when rates are higher, effectively shifting energy consumption patterns and reducing operational costs.

The technical evolution of PCMs has followed several distinct pathways, including the development of organic PCMs (paraffins, fatty acids), inorganic PCMs (salt hydrates), and eutectic mixtures. Each category offers specific advantages in terms of latent heat capacity, phase change temperature range, thermal conductivity, and long-term stability. Recent innovations have focused on nano-enhanced PCMs and form-stable composites to address historical limitations related to thermal conductivity and containment.

For peak-shaving applications under TOU tariffs, the primary technical objective is to optimize PCM sizing to maximize economic benefits while ensuring reliable performance. This requires precise calculation of thermal storage capacity needed to offset peak demand charges, considering factors such as building thermal characteristics, occupancy patterns, HVAC system specifications, and the specific structure of applicable TOU tariffs.

Secondary objectives include enhancing PCM integration with existing building systems, improving prediction algorithms for optimal charging/discharging cycles, developing robust control strategies that respond dynamically to changing tariff structures, and extending PCM operational lifespan to improve return on investment. The ultimate goal is to create a technically sound and economically viable solution that can be widely deployed across commercial and industrial facilities.

Current research trends are moving toward machine learning approaches for PCM system optimization, hybrid storage solutions combining PCMs with other technologies, and the development of standardized sizing methodologies that can be applied across different building types and climate zones. These advancements aim to transform PCM from a niche technology to a mainstream solution for energy management under increasingly complex utility rate structures.

PCM's unique ability to absorb, store, and release large amounts of energy during phase transitions makes them particularly valuable for peak-shaving applications under Time-of-Use (TOU) tariff structures. These materials can store thermal energy during off-peak periods when electricity rates are lower and release it during peak periods when rates are higher, effectively shifting energy consumption patterns and reducing operational costs.

The technical evolution of PCMs has followed several distinct pathways, including the development of organic PCMs (paraffins, fatty acids), inorganic PCMs (salt hydrates), and eutectic mixtures. Each category offers specific advantages in terms of latent heat capacity, phase change temperature range, thermal conductivity, and long-term stability. Recent innovations have focused on nano-enhanced PCMs and form-stable composites to address historical limitations related to thermal conductivity and containment.

For peak-shaving applications under TOU tariffs, the primary technical objective is to optimize PCM sizing to maximize economic benefits while ensuring reliable performance. This requires precise calculation of thermal storage capacity needed to offset peak demand charges, considering factors such as building thermal characteristics, occupancy patterns, HVAC system specifications, and the specific structure of applicable TOU tariffs.

Secondary objectives include enhancing PCM integration with existing building systems, improving prediction algorithms for optimal charging/discharging cycles, developing robust control strategies that respond dynamically to changing tariff structures, and extending PCM operational lifespan to improve return on investment. The ultimate goal is to create a technically sound and economically viable solution that can be widely deployed across commercial and industrial facilities.

Current research trends are moving toward machine learning approaches for PCM system optimization, hybrid storage solutions combining PCMs with other technologies, and the development of standardized sizing methodologies that can be applied across different building types and climate zones. These advancements aim to transform PCM from a niche technology to a mainstream solution for energy management under increasingly complex utility rate structures.

Market Analysis for PCM in Energy Storage Applications

The global market for Phase Change Materials (PCM) in energy storage applications is experiencing robust growth, driven by increasing energy costs, growing environmental concerns, and the rising adoption of renewable energy sources. The market was valued at approximately $1.2 billion in 2022 and is projected to reach $2.8 billion by 2028, representing a compound annual growth rate of 15.2% during the forecast period.

The energy storage segment constitutes the largest application area for PCMs, accounting for roughly 38% of the total market share. Within this segment, peak-shaving applications under Time-of-Use (TOU) tariffs are gaining significant traction, particularly in commercial and industrial sectors where electricity costs represent a substantial operational expense.

North America currently leads the PCM market with approximately 35% market share, followed by Europe at 30% and Asia-Pacific at 25%. The remaining 10% is distributed across other regions. The United States, Germany, and China are the primary markets, with rapid growth observed in emerging economies like India and Brazil where energy infrastructure modernization is underway.

Key market drivers include the increasing implementation of demand-side management programs by utilities, rising electricity costs during peak hours, and stricter regulations on carbon emissions. The average peak-to-off-peak price ratio in developed markets has increased from 1.5:1 to 3:1 over the past decade, creating stronger economic incentives for peak-shaving solutions.

Market segmentation reveals that building and construction applications currently dominate PCM usage at 45%, followed by HVAC systems at 30%, and industrial processes at 15%. The remaining 10% encompasses various applications including electronics cooling and transportation. For peak-shaving specifically, commercial buildings represent the largest customer segment at 48%, followed by industrial facilities at 32% and data centers at 15%.

Customer demand patterns indicate growing interest in integrated solutions that combine PCMs with smart energy management systems. End-users increasingly seek PCM solutions that offer not only peak-shaving capabilities but also provide additional benefits such as improved thermal comfort, reduced HVAC equipment sizing, and integration with renewable energy systems.

Market barriers include high initial investment costs, limited awareness about PCM benefits, and technical challenges related to system integration. The average payback period for PCM-based peak-shaving systems currently ranges from 3 to 5 years, depending on local electricity rates and usage patterns.

The energy storage segment constitutes the largest application area for PCMs, accounting for roughly 38% of the total market share. Within this segment, peak-shaving applications under Time-of-Use (TOU) tariffs are gaining significant traction, particularly in commercial and industrial sectors where electricity costs represent a substantial operational expense.

North America currently leads the PCM market with approximately 35% market share, followed by Europe at 30% and Asia-Pacific at 25%. The remaining 10% is distributed across other regions. The United States, Germany, and China are the primary markets, with rapid growth observed in emerging economies like India and Brazil where energy infrastructure modernization is underway.

Key market drivers include the increasing implementation of demand-side management programs by utilities, rising electricity costs during peak hours, and stricter regulations on carbon emissions. The average peak-to-off-peak price ratio in developed markets has increased from 1.5:1 to 3:1 over the past decade, creating stronger economic incentives for peak-shaving solutions.

Market segmentation reveals that building and construction applications currently dominate PCM usage at 45%, followed by HVAC systems at 30%, and industrial processes at 15%. The remaining 10% encompasses various applications including electronics cooling and transportation. For peak-shaving specifically, commercial buildings represent the largest customer segment at 48%, followed by industrial facilities at 32% and data centers at 15%.

Customer demand patterns indicate growing interest in integrated solutions that combine PCMs with smart energy management systems. End-users increasingly seek PCM solutions that offer not only peak-shaving capabilities but also provide additional benefits such as improved thermal comfort, reduced HVAC equipment sizing, and integration with renewable energy systems.

Market barriers include high initial investment costs, limited awareness about PCM benefits, and technical challenges related to system integration. The average payback period for PCM-based peak-shaving systems currently ranges from 3 to 5 years, depending on local electricity rates and usage patterns.

PCM Technical Challenges and Limitations

Despite the promising potential of Phase Change Materials (PCM) for peak-shaving applications under Time-of-Use tariffs, several significant technical challenges and limitations must be addressed. The thermal conductivity of most PCMs is inherently low, typically ranging from 0.2 to 0.5 W/m·K, which restricts heat transfer rates during charging and discharging cycles. This limitation becomes particularly problematic when rapid response to peak demand periods is required, as the system may not be able to release stored thermal energy quickly enough to effectively shave peaks.

Supercooling presents another critical challenge, where PCMs fail to crystallize at their freezing point, instead remaining in liquid state below their theoretical phase change temperature. This phenomenon can reduce the effective energy storage capacity by up to 15-20% and introduces unpredictability in system performance, making precise sizing calculations difficult.

Long-term cycling stability remains a concern for many PCM applications. After repeated melting and solidification cycles, some materials exhibit phase separation, where components segregate, leading to degraded thermal properties. Studies have shown performance degradation of 5-15% after 1000 cycles for certain salt hydrates, which significantly impacts the economic viability of PCM installations intended for daily peak-shaving operations.

Volumetric expansion during phase transition poses design challenges, as most PCMs expand by 5-10% when melting. This necessitates additional containment volume, increasing system size and cost while potentially creating mechanical stress on containment structures over time.

The heterogeneous melting and solidification behavior of PCMs creates temperature gradients within the storage medium, resulting in non-uniform performance. This makes accurate modeling and sizing particularly challenging, as simplified calculations often fail to account for these complex thermodynamic behaviors.

Encapsulation technologies, while necessary to contain PCMs, introduce thermal resistance layers that further impede heat transfer. The encapsulation material must withstand thousands of thermal cycles without degradation while maintaining structural integrity against the PCM's volumetric changes.

Integration with building systems presents additional challenges, including space constraints, weight limitations, and compatibility with existing HVAC systems. The PCM system must be precisely sized not only for thermal performance but also to physically fit within available spaces, which may limit deployment options.

Cost-effectiveness remains perhaps the most significant barrier, with high-grade PCMs suitable for building applications typically costing $4-10 per kg. When factoring in containment systems, heat exchangers, and installation costs, the payback period under current TOU rate structures often exceeds 5-7 years, challenging the economic justification for many potential applications.

Supercooling presents another critical challenge, where PCMs fail to crystallize at their freezing point, instead remaining in liquid state below their theoretical phase change temperature. This phenomenon can reduce the effective energy storage capacity by up to 15-20% and introduces unpredictability in system performance, making precise sizing calculations difficult.

Long-term cycling stability remains a concern for many PCM applications. After repeated melting and solidification cycles, some materials exhibit phase separation, where components segregate, leading to degraded thermal properties. Studies have shown performance degradation of 5-15% after 1000 cycles for certain salt hydrates, which significantly impacts the economic viability of PCM installations intended for daily peak-shaving operations.

Volumetric expansion during phase transition poses design challenges, as most PCMs expand by 5-10% when melting. This necessitates additional containment volume, increasing system size and cost while potentially creating mechanical stress on containment structures over time.

The heterogeneous melting and solidification behavior of PCMs creates temperature gradients within the storage medium, resulting in non-uniform performance. This makes accurate modeling and sizing particularly challenging, as simplified calculations often fail to account for these complex thermodynamic behaviors.

Encapsulation technologies, while necessary to contain PCMs, introduce thermal resistance layers that further impede heat transfer. The encapsulation material must withstand thousands of thermal cycles without degradation while maintaining structural integrity against the PCM's volumetric changes.

Integration with building systems presents additional challenges, including space constraints, weight limitations, and compatibility with existing HVAC systems. The PCM system must be precisely sized not only for thermal performance but also to physically fit within available spaces, which may limit deployment options.

Cost-effectiveness remains perhaps the most significant barrier, with high-grade PCMs suitable for building applications typically costing $4-10 per kg. When factoring in containment systems, heat exchangers, and installation costs, the payback period under current TOU rate structures often exceeds 5-7 years, challenging the economic justification for many potential applications.

Current PCM Sizing Methodologies for Peak-Shaving

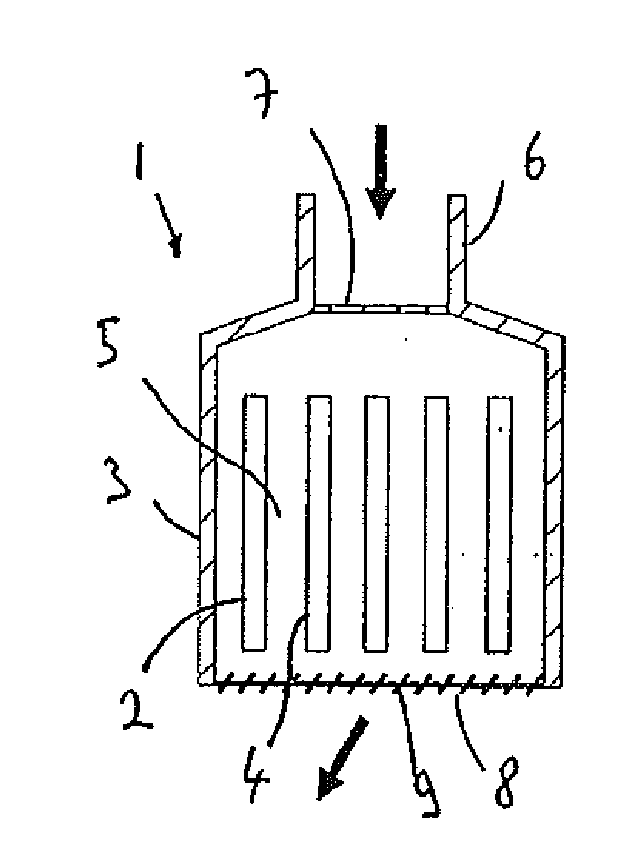

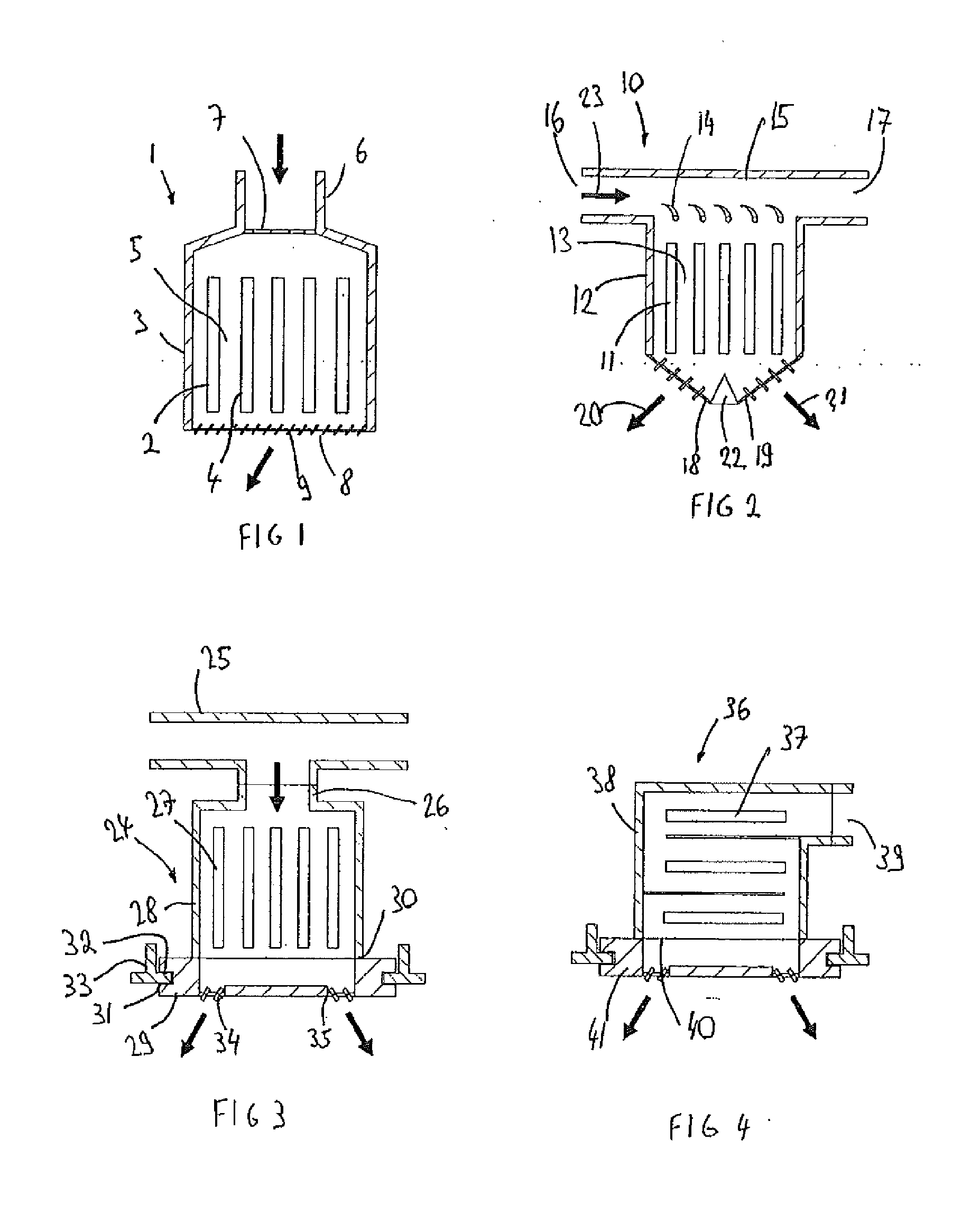

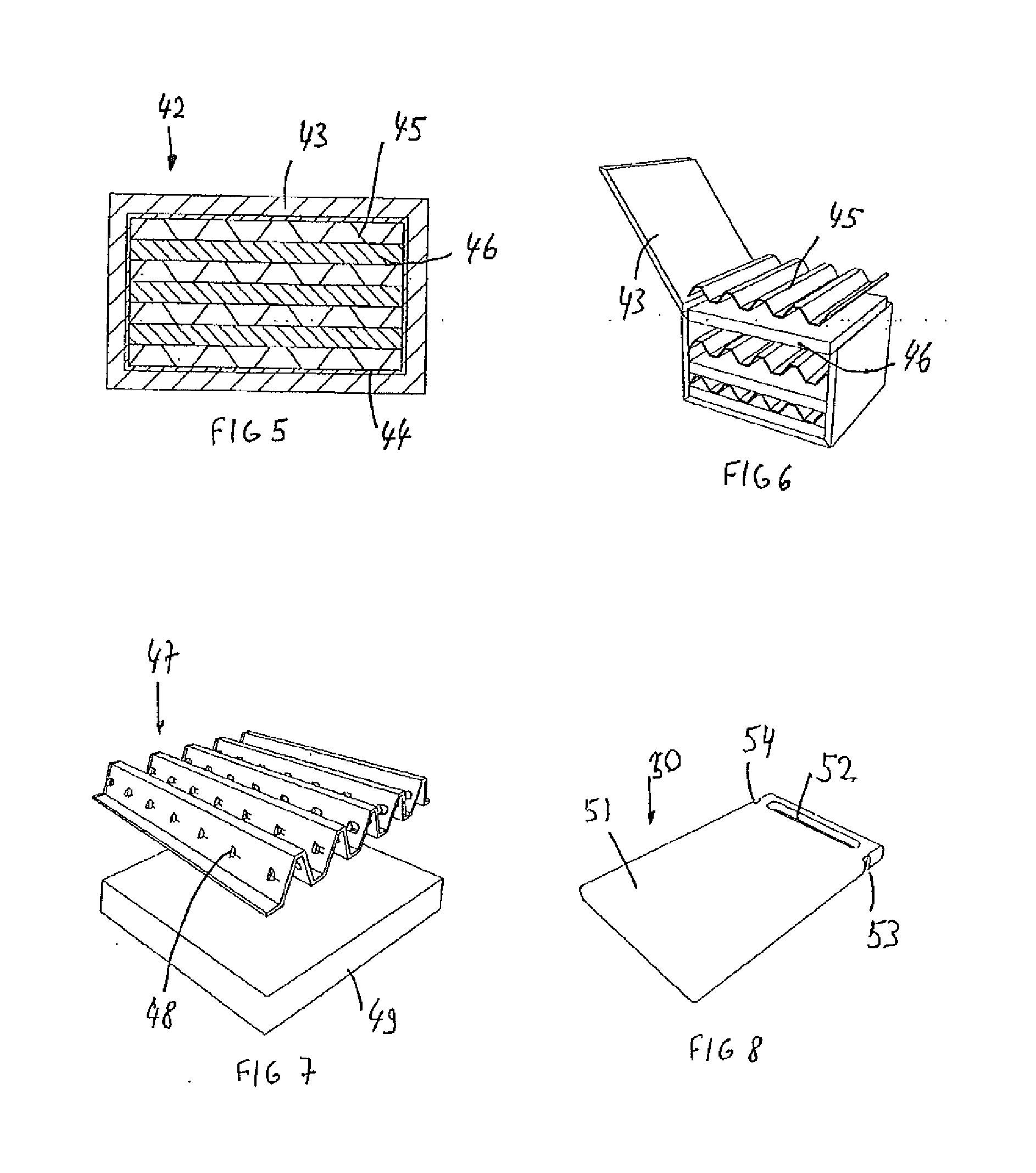

01 PCM sizing for thermal management in electronic devices

Phase change materials can be dimensioned specifically for thermal management in electronic devices. The sizing calculations consider heat generation rates, operating temperature ranges, and space constraints within the device. Proper dimensioning ensures efficient heat absorption during peak operation and subsequent release during idle periods, preventing overheating and maintaining optimal device performance. The PCM volume and distribution are critical factors in achieving effective thermal regulation.- PCM sizing for thermal management in electronic devices: Phase change materials can be dimensioned specifically for thermal management in electronic devices. The sizing calculations consider heat generation rates, operating temperature ranges, and space constraints within the device. Proper dimensioning ensures efficient heat absorption during peak operation and subsequent release during idle periods, preventing overheating and maintaining optimal device performance. The PCM volume and distribution are critical factors in achieving effective thermal regulation.

- PCM dimensioning for energy storage applications: The sizing of phase change materials for energy storage applications involves calculating the required PCM mass based on energy storage capacity needs, phase change temperature, and latent heat properties. Proper dimensioning ensures optimal energy density while considering spatial constraints. The calculations account for charging and discharging cycles, thermal conductivity, and system integration requirements to maximize energy storage efficiency and longevity.

- PCM sizing methodologies for building applications: Dimensioning phase change materials for building applications requires consideration of diurnal temperature fluctuations, building thermal mass, insulation properties, and occupancy patterns. The sizing calculations determine the optimal PCM thickness and distribution within building elements to maximize passive thermal regulation. These methodologies balance factors such as peak load shifting, energy consumption reduction, and indoor comfort maintenance while accounting for seasonal variations in external conditions.

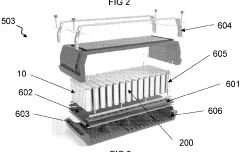

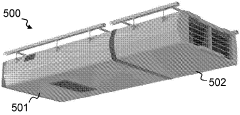

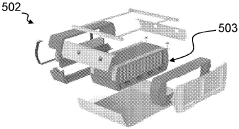

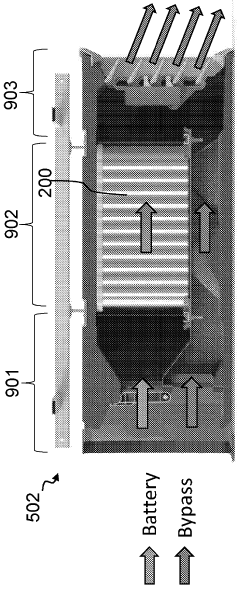

- PCM dimensioning for battery thermal management: The sizing of phase change materials for battery thermal management systems involves calculating the required PCM volume based on battery heat generation rates, operating temperature ranges, and safety margins. Proper dimensioning ensures that the PCM can absorb excess heat during charging and discharging cycles while maintaining battery cells within optimal temperature ranges. The calculations account for thermal conductivity enhancement, phase change temperature selection, and integration with battery pack geometry.

- PCM sizing for semiconductor and microelectronic applications: Dimensioning phase change materials for semiconductor and microelectronic applications requires precise calculations based on power density, thermal cycling requirements, and space constraints. The sizing methodologies account for the rapid thermal response needed in these applications, considering factors such as thermal interface resistance, heat spreading, and integration with existing cooling systems. Proper PCM dimensioning ensures reliable operation of sensitive electronic components while minimizing thermal gradients across the device.

02 PCM dimensioning for energy storage applications

The sizing of phase change materials for energy storage applications involves calculating the required PCM mass based on energy storage capacity needs, phase transition temperature, and latent heat properties. Proper dimensioning ensures optimal energy density while considering spatial constraints. The calculations account for charging and discharging cycles, thermal conductivity, and system integration requirements to maximize energy storage efficiency and system performance.Expand Specific Solutions03 PCM sizing methodologies for building applications

Dimensioning phase change materials for building applications requires consideration of diurnal temperature variations, building thermal mass, insulation properties, and desired indoor temperature stability. Calculations determine the optimal PCM thickness and distribution within building elements such as walls, ceilings, or floors. The sizing methodology accounts for seasonal variations, occupancy patterns, and integration with existing HVAC systems to enhance energy efficiency and thermal comfort.Expand Specific Solutions04 PCM dimensioning for semiconductor and battery applications

Phase change materials can be precisely sized for thermal management in semiconductor devices and battery systems. The dimensioning process considers the specific heat generation profiles, critical temperature thresholds, and space limitations. Calculations determine the optimal PCM volume and configuration to absorb heat during high-power operations and prevent thermal runaway in batteries. The sizing methodology accounts for charge-discharge cycles and varying operational conditions to ensure consistent thermal performance.Expand Specific Solutions05 Manufacturing techniques for precise PCM sizing

Various manufacturing techniques enable precise sizing and dimensioning of phase change materials for specific applications. These include microencapsulation, nanostructuring, and composite formation processes that control PCM particle size, distribution, and thermal properties. Advanced fabrication methods allow for tailored PCM geometries and integration into complex systems. The manufacturing approach significantly impacts the thermal response time, cycling stability, and overall performance of the PCM system.Expand Specific Solutions

Key Industry Players in PCM and TOU Solutions

The PCM sizing for peak-shaving under TOU tariffs market is in a growth phase, with increasing adoption driven by rising energy costs and grid stability concerns. The global thermal energy storage market, which includes PCM solutions, is projected to reach approximately $7-8 billion by 2025, growing at 10-12% CAGR. Technologically, the field is advancing from early commercial maturity toward standardization. Key players demonstrate varying levels of expertise: State Grid Corp. of China and Huawei focus on grid-level integration; specialized companies like Insolcorp and Stiesdal Storage offer dedicated PCM solutions; while materials manufacturers such as Stepan Co., Henry Co., and Mitsui Chemicals provide essential PCM components. Research institutions including Shanghai Dianji University and University of Minho are advancing fundamental PCM science, bridging the gap between laboratory innovations and commercial applications.

State Grid Corp. of China

Technical Solution: State Grid has developed a comprehensive PCM sizing methodology called "GridFlex" specifically designed for large-scale industrial and commercial applications under China's complex TOU tariff structures. Their approach begins with detailed load profiling and energy auditing to identify peak demand patterns and opportunities for load shifting. The GridFlex system employs advanced mathematical modeling that incorporates multiple variables including seasonal demand variations, TOU rate structures, and facility operational constraints to determine optimal PCM capacity. Their methodology includes sophisticated financial modeling that calculates the net present value of different PCM configurations over their expected lifecycle, accounting for installation costs, maintenance requirements, and projected energy savings. State Grid's solution also features a grid-interactive component that enables participation in demand response programs, providing additional revenue streams beyond basic peak shaving. The system includes real-time monitoring and predictive analytics that continuously optimize PCM operation based on current grid conditions and forecasted energy prices.

Strengths: Extensive experience with large-scale implementations across diverse industrial settings provides robust performance data. Their grid-interactive capabilities enable additional revenue streams through demand response participation. Weaknesses: The system is primarily designed for China's specific electricity market and regulatory environment, potentially requiring significant adaptation for international markets with different TOU structures.

Stiesdal Storage A/S

Technical Solution: Stiesdal Storage has developed an innovative PCM-based thermal energy storage system called "GridScale" specifically designed for peak-shaving applications under TOU tariffs. Their approach utilizes rock-based PCM materials that store energy as heat when electricity prices are low and release it during high-price periods. The system employs advanced algorithms that analyze historical TOU pricing patterns and energy consumption data to optimize charging and discharging cycles. Their proprietary sizing methodology incorporates multiple variables including peak demand profiles, local TOU rate structures, and seasonal variations to determine optimal PCM capacity. The GridScale system includes a sophisticated control system that continuously monitors grid conditions, energy prices, and facility demand to make real-time adjustments to the PCM operation schedule, maximizing economic benefits while ensuring reliable peak reduction.

Strengths: Uses abundant, low-cost rock materials as PCM medium, reducing system costs while maintaining good thermal performance. Their control algorithms adapt to changing TOU structures and consumption patterns over time. Weaknesses: The rock-based PCM system requires more physical space compared to more compact PCM solutions, potentially limiting deployment in space-constrained facilities.

Critical Patents and Research in PCM Sizing Optimization

Composition for a phase change material

PatentPendingGB2617056A

Innovation

- A composition comprising 55-80% Methyl palmitate and 15-35% Ethyl palmitate, with optional additives like thermal conductivity improvers and thickening agents, is developed to enhance thermal properties and safety, suitable for use in thermal batteries, heat exchanging devices, and ventilation systems.

Phase change material composition

PatentInactiveUS20120048768A1

Innovation

- A PCM composition comprising 50-99% salt hydrate and 0-45% carbon black, with optional additives like sodium chloride, potassium chloride, paraffin, thickening agents, and nucleating agents, enclosed in a thermally conductive envelope made of materials like aluminum or stainless steel, enhances conductivity and stability, reducing supercooling and manufacturing costs.

Economic Analysis of PCM Implementation under TOU Tariffs

The economic viability of implementing Phase Change Materials (PCM) for peak-shaving under Time-of-Use (TOU) tariffs requires comprehensive cost-benefit analysis. Initial capital expenditure for PCM systems includes material costs, installation expenses, and integration with existing building systems. These costs vary significantly based on PCM type, quantity, and installation complexity, typically ranging from $5-30 per kilogram of PCM depending on material specifications.

Operational cost savings derive primarily from reduced electricity consumption during peak-price periods. Under TOU tariff structures, peak electricity rates can be 2-5 times higher than off-peak rates, creating substantial arbitrage opportunities. PCM systems effectively shift cooling or heating loads from high-cost to low-cost periods, with potential bill reductions of 10-30% depending on building characteristics and local tariff structures.

Return on investment (ROI) calculations for PCM implementations typically show payback periods of 3-7 years in commercial applications. This timeframe varies based on climate zone, building usage patterns, and local utility rate differentials. Buildings with pronounced peak demands and those subject to demand charges often experience accelerated payback periods.

Life-cycle cost analysis reveals additional economic benefits beyond direct energy savings. PCM systems typically have operational lifespans of 15-20 years with minimal maintenance requirements, providing long-term value beyond the initial payback period. Furthermore, reduced peak demand can defer or eliminate the need for HVAC system upgrades, representing significant avoided capital costs.

Sensitivity analysis indicates that PCM economic performance is particularly dependent on three factors: the differential between peak and off-peak electricity rates, the frequency and duration of peak pricing periods, and the thermal characteristics of the building envelope. As utilities increasingly implement more aggressive TOU rate structures to manage grid demand, the economic case for PCM implementation strengthens accordingly.

Risk factors affecting economic performance include potential changes to utility rate structures, variations in building occupancy patterns, and climate change impacts on heating and cooling requirements. Modeling suggests that even with these uncertainties, PCM systems maintain positive economic returns across a wide range of scenarios, particularly in regions with pronounced seasonal temperature variations and steep peak/off-peak price differentials.

Financing options such as performance contracting, utility incentives, and green building tax credits can significantly improve the economic proposition of PCM implementations. These mechanisms can reduce initial capital requirements by 20-40%, further enhancing ROI metrics and accelerating adoption in commercial and institutional settings.

Operational cost savings derive primarily from reduced electricity consumption during peak-price periods. Under TOU tariff structures, peak electricity rates can be 2-5 times higher than off-peak rates, creating substantial arbitrage opportunities. PCM systems effectively shift cooling or heating loads from high-cost to low-cost periods, with potential bill reductions of 10-30% depending on building characteristics and local tariff structures.

Return on investment (ROI) calculations for PCM implementations typically show payback periods of 3-7 years in commercial applications. This timeframe varies based on climate zone, building usage patterns, and local utility rate differentials. Buildings with pronounced peak demands and those subject to demand charges often experience accelerated payback periods.

Life-cycle cost analysis reveals additional economic benefits beyond direct energy savings. PCM systems typically have operational lifespans of 15-20 years with minimal maintenance requirements, providing long-term value beyond the initial payback period. Furthermore, reduced peak demand can defer or eliminate the need for HVAC system upgrades, representing significant avoided capital costs.

Sensitivity analysis indicates that PCM economic performance is particularly dependent on three factors: the differential between peak and off-peak electricity rates, the frequency and duration of peak pricing periods, and the thermal characteristics of the building envelope. As utilities increasingly implement more aggressive TOU rate structures to manage grid demand, the economic case for PCM implementation strengthens accordingly.

Risk factors affecting economic performance include potential changes to utility rate structures, variations in building occupancy patterns, and climate change impacts on heating and cooling requirements. Modeling suggests that even with these uncertainties, PCM systems maintain positive economic returns across a wide range of scenarios, particularly in regions with pronounced seasonal temperature variations and steep peak/off-peak price differentials.

Financing options such as performance contracting, utility incentives, and green building tax credits can significantly improve the economic proposition of PCM implementations. These mechanisms can reduce initial capital requirements by 20-40%, further enhancing ROI metrics and accelerating adoption in commercial and institutional settings.

Regulatory Framework for Energy Storage Systems

The regulatory landscape for energy storage systems, including Phase Change Materials (PCM) for peak-shaving applications under Time-of-Use (TOU) tariffs, varies significantly across jurisdictions but follows several common frameworks. These frameworks directly impact how PCM systems can be sized, deployed, and monetized in different markets.

Energy storage regulations typically fall under the purview of public utility commissions or energy regulatory authorities that establish rules governing grid interconnection, market participation, and compensation mechanisms. For PCM implementations specifically, these regulations determine how peak-shaving applications can be valued and compensated under TOU rate structures.

In the United States, FERC Order 841 represents a landmark regulatory development that requires wholesale market operators to establish participation models allowing energy storage resources to provide all services they are technically capable of delivering. This has opened opportunities for PCM systems to participate in capacity markets, ancillary services, and energy arbitrage under TOU pricing schemes.

The regulatory treatment of behind-the-meter thermal storage solutions like PCM systems varies by state and utility territory. Some jurisdictions have implemented specific incentive programs that recognize the grid benefits of peak-shaving technologies. California's Self-Generation Incentive Program (SGIP) and New York's Value of Distributed Energy Resources (VDER) tariff are examples of frameworks that provide financial incentives for peak reduction capabilities.

Building codes and energy efficiency standards increasingly recognize thermal energy storage as compliance pathways. For instance, ASHRAE 90.1 and various state energy codes acknowledge thermal storage as an efficiency measure, which can influence PCM sizing decisions when designing systems to meet both regulatory compliance and economic optimization under TOU rates.

Safety regulations and standards also impact PCM system sizing and implementation. Standards such as NFPA 855 for stationary energy storage systems may apply to certain PCM installations, particularly when integrated with electrical systems or when exceeding specific capacity thresholds.

Environmental regulations regarding the materials used in PCM systems must be considered during the sizing process. Depending on the chemical composition of the PCM, different jurisdictions may impose restrictions or reporting requirements that affect system design and capacity.

The regulatory framework continues to evolve as energy markets recognize the value of flexible resources. Recent trends include the development of specific rules for aggregated distributed energy resources, which may allow smaller PCM installations to collectively participate in markets previously accessible only to larger systems, potentially changing the economic calculus for optimal PCM sizing under TOU tariffs.

Energy storage regulations typically fall under the purview of public utility commissions or energy regulatory authorities that establish rules governing grid interconnection, market participation, and compensation mechanisms. For PCM implementations specifically, these regulations determine how peak-shaving applications can be valued and compensated under TOU rate structures.

In the United States, FERC Order 841 represents a landmark regulatory development that requires wholesale market operators to establish participation models allowing energy storage resources to provide all services they are technically capable of delivering. This has opened opportunities for PCM systems to participate in capacity markets, ancillary services, and energy arbitrage under TOU pricing schemes.

The regulatory treatment of behind-the-meter thermal storage solutions like PCM systems varies by state and utility territory. Some jurisdictions have implemented specific incentive programs that recognize the grid benefits of peak-shaving technologies. California's Self-Generation Incentive Program (SGIP) and New York's Value of Distributed Energy Resources (VDER) tariff are examples of frameworks that provide financial incentives for peak reduction capabilities.

Building codes and energy efficiency standards increasingly recognize thermal energy storage as compliance pathways. For instance, ASHRAE 90.1 and various state energy codes acknowledge thermal storage as an efficiency measure, which can influence PCM sizing decisions when designing systems to meet both regulatory compliance and economic optimization under TOU rates.

Safety regulations and standards also impact PCM system sizing and implementation. Standards such as NFPA 855 for stationary energy storage systems may apply to certain PCM installations, particularly when integrated with electrical systems or when exceeding specific capacity thresholds.

Environmental regulations regarding the materials used in PCM systems must be considered during the sizing process. Depending on the chemical composition of the PCM, different jurisdictions may impose restrictions or reporting requirements that affect system design and capacity.

The regulatory framework continues to evolve as energy markets recognize the value of flexible resources. Recent trends include the development of specific rules for aggregated distributed energy resources, which may allow smaller PCM installations to collectively participate in markets previously accessible only to larger systems, potentially changing the economic calculus for optimal PCM sizing under TOU tariffs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!