PCM in Refrigerated Trucks and Containers: Design and Validation

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCM Technology Background and Objectives

Phase Change Materials (PCM) have emerged as a transformative technology in thermal management systems, particularly for refrigerated transportation. The evolution of PCM technology can be traced back to the 1940s when initial research on thermal energy storage materials began. However, significant advancements in PCM formulations specifically designed for cold chain applications only gained momentum in the late 1990s and early 2000s, coinciding with growing demands for energy-efficient and reliable temperature-controlled logistics.

The technological trajectory of PCM has been characterized by continuous improvements in material composition, encapsulation techniques, and system integration approaches. Early PCM solutions suffered from issues such as phase separation, supercooling, and limited cycle stability. Modern PCM formulations have largely overcome these limitations through advanced material engineering and innovative manufacturing processes, resulting in more reliable and efficient thermal management solutions for refrigerated transport.

Current market trends indicate a shift toward sustainable and environmentally friendly PCM solutions, driven by global regulations on refrigerants and increasing corporate sustainability commitments. This has accelerated research into bio-based PCMs and systems that can reduce the carbon footprint of refrigerated transportation while maintaining performance standards.

The primary objective of PCM technology in refrigerated trucks and containers is to maintain precise temperature control for perishable goods during transportation, particularly during power outages or when mechanical refrigeration systems are temporarily disabled. This capability is crucial for preserving product quality and extending shelf life while reducing energy consumption and operational costs.

Additional technical goals include developing PCM systems with faster charging rates, higher energy density, and improved thermal conductivity to enhance overall system efficiency. Research is also focused on creating adaptive PCM solutions that can accommodate varying ambient conditions and product requirements, providing more versatile temperature management across different geographic regions and seasons.

The integration of PCM technology with IoT sensors and predictive analytics represents another important objective, enabling real-time monitoring and optimization of thermal performance throughout the cold chain. This integration aims to create intelligent thermal management systems that can anticipate temperature fluctuations and proactively adjust to maintain optimal conditions.

Long-term technological aspirations include the development of multi-temperature PCM systems capable of simultaneously maintaining different temperature zones within a single container, addressing the growing need for mixed-load transportation. Researchers are also exploring hybrid systems that combine PCM with other emerging technologies such as thermoelectric cooling and advanced insulation materials to create next-generation refrigerated transport solutions with enhanced performance and sustainability profiles.

The technological trajectory of PCM has been characterized by continuous improvements in material composition, encapsulation techniques, and system integration approaches. Early PCM solutions suffered from issues such as phase separation, supercooling, and limited cycle stability. Modern PCM formulations have largely overcome these limitations through advanced material engineering and innovative manufacturing processes, resulting in more reliable and efficient thermal management solutions for refrigerated transport.

Current market trends indicate a shift toward sustainable and environmentally friendly PCM solutions, driven by global regulations on refrigerants and increasing corporate sustainability commitments. This has accelerated research into bio-based PCMs and systems that can reduce the carbon footprint of refrigerated transportation while maintaining performance standards.

The primary objective of PCM technology in refrigerated trucks and containers is to maintain precise temperature control for perishable goods during transportation, particularly during power outages or when mechanical refrigeration systems are temporarily disabled. This capability is crucial for preserving product quality and extending shelf life while reducing energy consumption and operational costs.

Additional technical goals include developing PCM systems with faster charging rates, higher energy density, and improved thermal conductivity to enhance overall system efficiency. Research is also focused on creating adaptive PCM solutions that can accommodate varying ambient conditions and product requirements, providing more versatile temperature management across different geographic regions and seasons.

The integration of PCM technology with IoT sensors and predictive analytics represents another important objective, enabling real-time monitoring and optimization of thermal performance throughout the cold chain. This integration aims to create intelligent thermal management systems that can anticipate temperature fluctuations and proactively adjust to maintain optimal conditions.

Long-term technological aspirations include the development of multi-temperature PCM systems capable of simultaneously maintaining different temperature zones within a single container, addressing the growing need for mixed-load transportation. Researchers are also exploring hybrid systems that combine PCM with other emerging technologies such as thermoelectric cooling and advanced insulation materials to create next-generation refrigerated transport solutions with enhanced performance and sustainability profiles.

Market Analysis for PCM in Cold Chain Logistics

The global cold chain logistics market has experienced substantial growth in recent years, with the Phase Change Materials (PCM) segment emerging as a critical component. Currently valued at approximately $5.2 billion in 2023, the PCM market for cold chain applications is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 8.4%. This growth is primarily driven by increasing demand for temperature-sensitive product transportation, particularly in pharmaceutical and food industries.

The pharmaceutical sector constitutes the largest market share for PCM applications in refrigerated transport, accounting for 42% of the total market. This dominance stems from stringent regulatory requirements for maintaining precise temperature conditions during medication and vaccine transportation. Following closely is the food and beverage industry at 38%, where PCM solutions help preserve product quality and reduce spoilage during distribution.

Regional analysis reveals North America as the current market leader with 35% market share, attributed to advanced cold chain infrastructure and early adoption of innovative technologies. Europe follows at 30%, with particularly strong growth in Nordic countries and Germany. The Asia-Pacific region, while currently representing 25% of the market, demonstrates the highest growth rate at 12.3% annually, fueled by rapid expansion of pharmaceutical manufacturing and increasing consumer demand for fresh produce in China and India.

Consumer behavior trends significantly impact market dynamics, with growing preference for fresh, minimally processed foods driving demand for efficient cold chain solutions. Additionally, the expansion of e-commerce grocery delivery services has created new opportunities for PCM applications in last-mile delivery, a segment growing at 15% annually.

Key market drivers include increasingly stringent regulatory frameworks governing temperature-controlled transportation, particularly GDP (Good Distribution Practice) guidelines in pharmaceuticals. Environmental regulations targeting refrigerant emissions have also accelerated adoption of passive cooling systems utilizing PCMs as alternatives to traditional mechanical refrigeration.

Market challenges include high initial implementation costs, with PCM systems typically requiring 20-30% higher upfront investment compared to conventional refrigeration. Technical limitations regarding PCM cycling stability and energy density also present barriers to wider adoption, particularly for long-haul transportation routes exceeding 72 hours.

The competitive landscape features both established refrigeration companies expanding into PCM solutions and specialized PCM manufacturers. Recent market consolidation through mergers and acquisitions indicates industry maturation, with five major players now controlling approximately 60% of the global market share.

The pharmaceutical sector constitutes the largest market share for PCM applications in refrigerated transport, accounting for 42% of the total market. This dominance stems from stringent regulatory requirements for maintaining precise temperature conditions during medication and vaccine transportation. Following closely is the food and beverage industry at 38%, where PCM solutions help preserve product quality and reduce spoilage during distribution.

Regional analysis reveals North America as the current market leader with 35% market share, attributed to advanced cold chain infrastructure and early adoption of innovative technologies. Europe follows at 30%, with particularly strong growth in Nordic countries and Germany. The Asia-Pacific region, while currently representing 25% of the market, demonstrates the highest growth rate at 12.3% annually, fueled by rapid expansion of pharmaceutical manufacturing and increasing consumer demand for fresh produce in China and India.

Consumer behavior trends significantly impact market dynamics, with growing preference for fresh, minimally processed foods driving demand for efficient cold chain solutions. Additionally, the expansion of e-commerce grocery delivery services has created new opportunities for PCM applications in last-mile delivery, a segment growing at 15% annually.

Key market drivers include increasingly stringent regulatory frameworks governing temperature-controlled transportation, particularly GDP (Good Distribution Practice) guidelines in pharmaceuticals. Environmental regulations targeting refrigerant emissions have also accelerated adoption of passive cooling systems utilizing PCMs as alternatives to traditional mechanical refrigeration.

Market challenges include high initial implementation costs, with PCM systems typically requiring 20-30% higher upfront investment compared to conventional refrigeration. Technical limitations regarding PCM cycling stability and energy density also present barriers to wider adoption, particularly for long-haul transportation routes exceeding 72 hours.

The competitive landscape features both established refrigeration companies expanding into PCM solutions and specialized PCM manufacturers. Recent market consolidation through mergers and acquisitions indicates industry maturation, with five major players now controlling approximately 60% of the global market share.

Current PCM Implementation Challenges in Transport Refrigeration

Despite the promising potential of Phase Change Materials (PCM) in transport refrigeration, several significant challenges impede their widespread implementation. The integration of PCM systems into refrigerated trucks and containers faces thermal management difficulties, particularly in maintaining consistent temperature control across varying ambient conditions. Current PCM solutions struggle to provide uniform cooling throughout cargo spaces, resulting in temperature gradients that can compromise perishable goods quality.

Weight considerations present another substantial obstacle. Most effective PCM systems add considerable mass to vehicles, reducing payload capacity and increasing fuel consumption. This trade-off between thermal efficiency and operational economics creates a significant barrier for fleet operators seeking to maximize profitability while maintaining cold chain integrity.

The selection of appropriate PCM compounds for specific transport applications remains problematic. Different cargo types require distinct temperature ranges, and no single PCM formulation can address the diverse needs of the transport refrigeration sector. Current materials often exhibit suboptimal phase transition temperatures or insufficient energy storage density for practical applications.

Durability and lifespan issues further complicate implementation. PCM systems in transport environments experience frequent thermal cycling, vibration, and mechanical stress, leading to accelerated degradation. Many existing solutions demonstrate performance deterioration after 500-1000 cycles, falling short of the multi-year service life required for commercial viability.

Economic factors also present significant barriers. The initial capital expenditure for PCM-equipped refrigeration systems typically exceeds conventional mechanical refrigeration by 30-45%. Despite potential operational savings, the extended return-on-investment timeline deters adoption, particularly among smaller fleet operators with limited capital resources.

System integration challenges persist in retrofitting existing refrigerated transport units. Current PCM solutions often require substantial modifications to vehicle architecture and cooling systems, creating compatibility issues with established refrigeration infrastructure. The lack of standardized design approaches complicates implementation across diverse vehicle platforms.

Regulatory uncertainty compounds these technical challenges. The absence of unified standards for PCM performance testing in transport applications creates market hesitation. Without clear certification pathways, manufacturers struggle to validate their solutions, while end-users lack confidence in product performance claims across varying operational conditions.

Weight considerations present another substantial obstacle. Most effective PCM systems add considerable mass to vehicles, reducing payload capacity and increasing fuel consumption. This trade-off between thermal efficiency and operational economics creates a significant barrier for fleet operators seeking to maximize profitability while maintaining cold chain integrity.

The selection of appropriate PCM compounds for specific transport applications remains problematic. Different cargo types require distinct temperature ranges, and no single PCM formulation can address the diverse needs of the transport refrigeration sector. Current materials often exhibit suboptimal phase transition temperatures or insufficient energy storage density for practical applications.

Durability and lifespan issues further complicate implementation. PCM systems in transport environments experience frequent thermal cycling, vibration, and mechanical stress, leading to accelerated degradation. Many existing solutions demonstrate performance deterioration after 500-1000 cycles, falling short of the multi-year service life required for commercial viability.

Economic factors also present significant barriers. The initial capital expenditure for PCM-equipped refrigeration systems typically exceeds conventional mechanical refrigeration by 30-45%. Despite potential operational savings, the extended return-on-investment timeline deters adoption, particularly among smaller fleet operators with limited capital resources.

System integration challenges persist in retrofitting existing refrigerated transport units. Current PCM solutions often require substantial modifications to vehicle architecture and cooling systems, creating compatibility issues with established refrigeration infrastructure. The lack of standardized design approaches complicates implementation across diverse vehicle platforms.

Regulatory uncertainty compounds these technical challenges. The absence of unified standards for PCM performance testing in transport applications creates market hesitation. Without clear certification pathways, manufacturers struggle to validate their solutions, while end-users lack confidence in product performance claims across varying operational conditions.

Current PCM Design Solutions for Refrigerated Transport

01 PCM integration in electronic devices for thermal management

Phase change materials can be integrated into electronic devices to manage heat generation during operation. These materials absorb excess heat when the device temperature rises, and release it when the device cools down, maintaining optimal operating temperatures. This approach is particularly useful in high-performance computing systems, mobile devices, and other electronics where thermal management is critical for performance and longevity.- PCM applications in electronic devices: Phase change materials are integrated into electronic devices for thermal management, helping to dissipate heat and maintain optimal operating temperatures. These materials can absorb excess heat during peak operation and release it when the device cools down, preventing overheating and extending the lifespan of electronic components. This application is particularly important in high-performance computing, mobile devices, and data storage systems where heat management is critical for performance and reliability.

- PCM compositions and formulations: Various compositions and formulations of phase change materials are developed to achieve specific thermal properties. These formulations may include organic compounds, inorganic salts, eutectic mixtures, or composite materials that can be tailored for different melting points, latent heat capacities, and thermal conductivities. Additives may be incorporated to enhance stability, prevent supercooling, or improve thermal conductivity, allowing for customized thermal management solutions across different applications.

- PCM integration in building materials: Phase change materials are incorporated into building materials and construction elements to enhance thermal comfort and energy efficiency. By absorbing heat during the day and releasing it at night, PCMs help maintain stable indoor temperatures, reducing the need for heating and cooling systems. These materials can be integrated into walls, ceilings, floors, or insulation materials, providing passive thermal regulation and contributing to sustainable building design and reduced energy consumption.

- PCM encapsulation technologies: Encapsulation technologies are developed to contain phase change materials and prevent leakage during the phase transition process. Microencapsulation and macroencapsulation techniques allow PCMs to be incorporated into various host materials while maintaining their thermal properties. These encapsulation methods also enhance the stability, durability, and handling of PCMs, making them suitable for integration into textiles, packaging, and other applications where direct contact with the PCM would be problematic.

- PCM for renewable energy storage: Phase change materials are utilized for thermal energy storage in renewable energy systems, particularly solar thermal applications. These materials can store excess thermal energy during periods of high solar radiation and release it when needed, improving the efficiency and reliability of renewable energy systems. PCM-based thermal storage solutions help address the intermittency issues of renewable energy sources by providing a means to store and utilize thermal energy on demand, contributing to more sustainable and reliable energy systems.

02 PCM-based building materials for energy efficiency

Phase change materials can be incorporated into building materials to enhance energy efficiency in construction. These materials absorb heat during the day and release it at night, helping to maintain consistent indoor temperatures and reduce heating and cooling costs. Applications include PCM-enhanced insulation, wallboards, concrete, and other construction materials that contribute to passive thermal regulation in buildings.Expand Specific Solutions03 PCM formulations for specific thermal properties

Specialized formulations of phase change materials can be developed to achieve specific thermal properties for different applications. These formulations may include organic compounds, inorganic salts, or eutectic mixtures with precisely controlled melting points and latent heat capacities. Additives can enhance thermal conductivity, stability, and encapsulation properties to optimize performance in various thermal management scenarios.Expand Specific Solutions04 PCM encapsulation techniques for improved performance

Encapsulation of phase change materials enhances their performance and usability in thermal management systems. Microencapsulation and macroencapsulation techniques prevent leakage during the phase change process and improve heat transfer efficiency. These methods also extend the lifespan of PCMs by protecting them from environmental degradation and allowing for easier integration into various host materials and systems.Expand Specific Solutions05 PCM applications in renewable energy systems

Phase change materials play a crucial role in renewable energy systems by providing thermal energy storage solutions. In solar thermal systems, PCMs store excess heat during peak sunlight hours for later use. In wind and other intermittent renewable energy sources, PCM-based thermal storage helps balance supply and demand. These applications improve the efficiency and reliability of renewable energy systems by addressing the inherent variability of renewable resources.Expand Specific Solutions

Leading Manufacturers and Suppliers in PCM Cold Chain Solutions

The PCM in refrigerated transport market is in a growth phase, with increasing demand driven by pharmaceutical and food supply chain needs. The market is characterized by a mix of established players like Thermo King, va-Q-tec, and Pelican BioThermal, alongside emerging specialists such as Tan90 Thermal Solutions and AeroSafe Global. Technical maturity varies, with companies like va-Q-tec and CSafe Global demonstrating advanced PCM integration in commercial solutions, while academic institutions (Chang'an University, Ghent University) continue fundamental research. The competitive landscape shows segmentation between pharmaceutical-focused providers (Fisher Clinical Services, Bristol Myers Squibb) and general refrigerated transport specialists (Hercules Manufacturing), with innovation centered on energy efficiency and temperature stability validation methodologies.

va-Q-tec AG

Technical Solution: va-Q-tec has developed advanced vacuum insulation panels (VIPs) integrated with PCM technology specifically for refrigerated transport. Their TempChain service utilizes passive thermal containers with PCM elements strategically positioned to maintain precise temperature ranges between -70°C and +25°C for up to 10 days without external energy. The company's va-Q-tainer product line incorporates multi-phase PCM configurations that adapt to varying ambient conditions, ensuring temperature stability during transport disruptions. Their PCM solutions feature proprietary phase change materials with customized melting points tailored to pharmaceutical and food transport requirements, achieving temperature deviation tolerances of less than ±0.5°C in their premium containers.

Strengths: Superior temperature stability without external power; exceptionally long hold times (up to 10 days); customizable PCM formulations for specific temperature ranges. Weaknesses: Higher initial investment compared to conventional solutions; containers have weight penalties due to PCM integration; requires specialized pre-conditioning infrastructure.

Pelican BioThermal LLC

Technical Solution: Pelican BioThermal has developed the Crēdo Cube system, which utilizes proprietary PCM technology specifically engineered for temperature-controlled shipping of pharmaceutical products in refrigerated transport. Their PCM panels feature TIC (Thermal Isolation Chamber) technology that creates multiple temperature-stabilizing barriers within a single container. The company's PCM formulations are designed with specific phase transition temperatures (2-8°C, 15-25°C, and -20°C ranges) to match pharmaceutical requirements. Their advanced vacuum insulation combined with PCM technology enables temperature maintenance for 120+ hours in extreme ambient conditions. Pelican's systems undergo rigorous qualification testing including thermal mapping with up to 15 temperature sensors to validate performance across various shipping lanes and seasonal profiles.

Strengths: Pharmaceutical-grade temperature precision; extensive validation data across global shipping lanes; modular design allows for scaling to different payload sizes. Weaknesses: Primarily focused on smaller payload sizes rather than full truck/container solutions; higher cost per cubic foot of payload compared to larger systems; requires specialized conditioning equipment.

Key PCM Materials and Thermal Properties Analysis

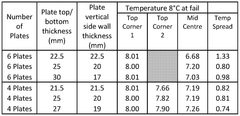

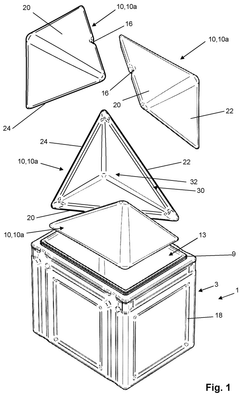

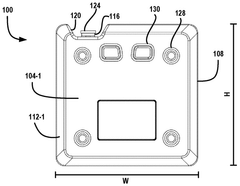

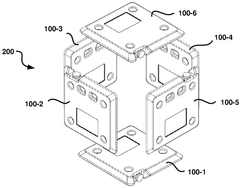

Phase change material elements for use in a thermally insulated trasportation container

PatentWO2025052115A1

Innovation

- The use of a set of phase change material (PCM) elements arranged to form a hollow cuboid structure within the thermally insulated transportation container, where each PCM element has a sealed or sealable receptacle with a unique side configuration to optimize thermal performance and reduce the number of joints aligned with less insulated areas.

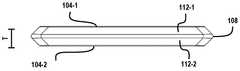

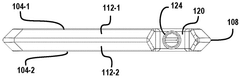

Phase change material panels and container with phase change material panels

PatentWO2025074277A1

Innovation

- A container design incorporating rectangular PCM panels with beveled perimeters, arranged at right angles to form a payload enclosure, combined with an inner tub and vacuum insulated panels (VIPs) for enhanced thermal performance and structural integrity.

Energy Efficiency and Sustainability Considerations

The integration of Phase Change Materials (PCM) in refrigerated transport systems presents significant opportunities for enhancing energy efficiency and sustainability across the cold chain. PCM-based solutions can reduce the overall energy consumption of refrigerated trucks and containers by up to 25-30% compared to conventional systems, primarily by minimizing the operational time of mechanical refrigeration units during transport and stationary periods.

From a sustainability perspective, PCM implementation contributes to substantial reductions in greenhouse gas emissions. Studies indicate that a medium-sized refrigerated truck fleet utilizing PCM technology can reduce carbon dioxide emissions by approximately 15-20 tons annually per vehicle. This reduction stems from decreased fuel consumption and the diminished need for environmentally harmful refrigerants commonly used in traditional cooling systems.

The life cycle assessment of PCM applications in transport refrigeration reveals favorable environmental metrics. Most commercial PCMs used in this context have operational lifespans exceeding 3,000 cycles, translating to 8-10 years of effective use before replacement becomes necessary. This extended lifespan significantly reduces waste generation and resource consumption associated with system maintenance and replacement.

Energy recovery capabilities represent another critical sustainability advantage of PCM systems. During braking and deceleration, kinetic energy can be captured and converted to power PCM regeneration processes, creating a partially self-sustaining cooling cycle. Advanced systems have demonstrated the ability to recover up to 15% of operational energy through these mechanisms, further enhancing overall efficiency.

The materials used in modern PCM formulations increasingly emphasize environmental compatibility. Bio-based PCMs derived from sustainable sources such as vegetable oils and sugar alcohols are gaining market share, offering comparable thermal performance to synthetic alternatives while presenting reduced environmental impact throughout their production and disposal phases.

Economic sustainability metrics also favor PCM implementation in refrigerated transport. Despite higher initial capital expenditure (typically 20-30% above conventional systems), the total cost of ownership analysis demonstrates break-even periods of 18-24 months for most commercial applications, with subsequent operational savings continuing throughout the system's lifespan. These economic benefits align with environmental advantages to create compelling sustainability cases for transportation companies seeking both financial and ecological improvements.

Future developments in PCM technology for refrigerated transport are focusing on smart energy management systems that optimize PCM charging and discharging cycles based on route planning, ambient conditions, and cargo requirements, potentially yielding additional 10-15% efficiency improvements over current implementations.

From a sustainability perspective, PCM implementation contributes to substantial reductions in greenhouse gas emissions. Studies indicate that a medium-sized refrigerated truck fleet utilizing PCM technology can reduce carbon dioxide emissions by approximately 15-20 tons annually per vehicle. This reduction stems from decreased fuel consumption and the diminished need for environmentally harmful refrigerants commonly used in traditional cooling systems.

The life cycle assessment of PCM applications in transport refrigeration reveals favorable environmental metrics. Most commercial PCMs used in this context have operational lifespans exceeding 3,000 cycles, translating to 8-10 years of effective use before replacement becomes necessary. This extended lifespan significantly reduces waste generation and resource consumption associated with system maintenance and replacement.

Energy recovery capabilities represent another critical sustainability advantage of PCM systems. During braking and deceleration, kinetic energy can be captured and converted to power PCM regeneration processes, creating a partially self-sustaining cooling cycle. Advanced systems have demonstrated the ability to recover up to 15% of operational energy through these mechanisms, further enhancing overall efficiency.

The materials used in modern PCM formulations increasingly emphasize environmental compatibility. Bio-based PCMs derived from sustainable sources such as vegetable oils and sugar alcohols are gaining market share, offering comparable thermal performance to synthetic alternatives while presenting reduced environmental impact throughout their production and disposal phases.

Economic sustainability metrics also favor PCM implementation in refrigerated transport. Despite higher initial capital expenditure (typically 20-30% above conventional systems), the total cost of ownership analysis demonstrates break-even periods of 18-24 months for most commercial applications, with subsequent operational savings continuing throughout the system's lifespan. These economic benefits align with environmental advantages to create compelling sustainability cases for transportation companies seeking both financial and ecological improvements.

Future developments in PCM technology for refrigerated transport are focusing on smart energy management systems that optimize PCM charging and discharging cycles based on route planning, ambient conditions, and cargo requirements, potentially yielding additional 10-15% efficiency improvements over current implementations.

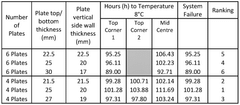

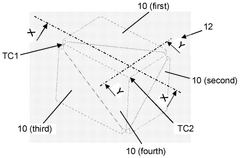

Validation Methodologies and Performance Standards

The validation of Phase Change Materials (PCM) in refrigerated transport systems requires rigorous methodologies and adherence to established performance standards to ensure reliability and effectiveness. Industry standards such as ASTM C1784 and ISO 11357 provide frameworks for thermal energy storage materials testing, specifically addressing the thermal properties and performance characteristics of PCMs under various conditions.

Temperature cycling tests represent a fundamental validation approach, subjecting PCM systems to repeated freeze-thaw cycles that simulate real-world operational conditions. These tests typically involve 500-1000 cycles to evaluate long-term stability and performance degradation over time. Thermal response measurements during these cycles provide critical data on the PCM's ability to maintain consistent phase change temperatures and latent heat storage capacity throughout its operational life.

Calorimetric analysis, particularly Differential Scanning Calorimetry (DSC), serves as a cornerstone validation technique for PCM applications in refrigerated transport. This method precisely quantifies the enthalpy of phase change, specific heat capacity, and phase transition temperatures. For transportation applications, DSC testing must be conducted across the expected operational temperature range (-30°C to +30°C) to ensure performance across varying ambient conditions encountered during transit.

Field testing protocols have evolved significantly, incorporating real-time monitoring systems that track temperature fluctuations throughout the cargo space during actual transport operations. These tests typically require minimum durations of 72-96 hours under varying external conditions to validate PCM performance in authentic scenarios. The ATP (Agreement on the International Carriage of Perishable Foodstuffs) standards provide specific guidelines for temperature maintenance in refrigerated transport that PCM systems must satisfy.

Computational Fluid Dynamics (CFD) modeling has emerged as a complementary validation approach, allowing for virtual simulation of thermal behavior before physical implementation. These models must be calibrated against experimental data with maximum deviation tolerances of ±1.5°C to be considered valid predictive tools for PCM performance in refrigerated containers.

Performance metrics for PCM validation in transport applications include temperature stabilization efficiency (ability to maintain target temperature ±0.5°C), thermal inertia (response to external temperature fluctuations), energy consumption reduction (minimum 15-20% compared to conventional systems), and operational resilience during power outages (maintaining safe temperatures for at least 4-6 hours). These metrics must be evaluated under standardized test conditions that replicate the challenging environments of long-haul transportation.

Temperature cycling tests represent a fundamental validation approach, subjecting PCM systems to repeated freeze-thaw cycles that simulate real-world operational conditions. These tests typically involve 500-1000 cycles to evaluate long-term stability and performance degradation over time. Thermal response measurements during these cycles provide critical data on the PCM's ability to maintain consistent phase change temperatures and latent heat storage capacity throughout its operational life.

Calorimetric analysis, particularly Differential Scanning Calorimetry (DSC), serves as a cornerstone validation technique for PCM applications in refrigerated transport. This method precisely quantifies the enthalpy of phase change, specific heat capacity, and phase transition temperatures. For transportation applications, DSC testing must be conducted across the expected operational temperature range (-30°C to +30°C) to ensure performance across varying ambient conditions encountered during transit.

Field testing protocols have evolved significantly, incorporating real-time monitoring systems that track temperature fluctuations throughout the cargo space during actual transport operations. These tests typically require minimum durations of 72-96 hours under varying external conditions to validate PCM performance in authentic scenarios. The ATP (Agreement on the International Carriage of Perishable Foodstuffs) standards provide specific guidelines for temperature maintenance in refrigerated transport that PCM systems must satisfy.

Computational Fluid Dynamics (CFD) modeling has emerged as a complementary validation approach, allowing for virtual simulation of thermal behavior before physical implementation. These models must be calibrated against experimental data with maximum deviation tolerances of ±1.5°C to be considered valid predictive tools for PCM performance in refrigerated containers.

Performance metrics for PCM validation in transport applications include temperature stabilization efficiency (ability to maintain target temperature ±0.5°C), thermal inertia (response to external temperature fluctuations), energy consumption reduction (minimum 15-20% compared to conventional systems), and operational resilience during power outages (maintaining safe temperatures for at least 4-6 hours). These metrics must be evaluated under standardized test conditions that replicate the challenging environments of long-haul transportation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!