How to Reduce Maintenance Costs with Solar Inverters?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Maintenance Background and Objectives

Solar inverter maintenance has become a critical aspect of photovoltaic (PV) system management as the global adoption of solar energy continues to surge. The evolution of solar inverter technology has been marked by significant advancements in efficiency, reliability, and functionality over the past decades. From early central inverters to modern string and microinverters, the industry has witnessed a shift towards more sophisticated and intelligent devices.

The primary objective in reducing maintenance costs for solar inverters is to optimize the balance between system performance and operational expenses. This goal aligns with the broader industry trend of maximizing the return on investment for solar energy installations. By focusing on maintenance cost reduction, stakeholders aim to enhance the overall economic viability of solar power generation, making it more competitive with traditional energy sources.

A comprehensive understanding of solar inverter maintenance involves recognizing the various factors that contribute to maintenance needs. These include environmental conditions, system design, component quality, and operational practices. The industry has been moving towards predictive maintenance strategies, leveraging data analytics and remote monitoring capabilities to anticipate and prevent potential issues before they escalate into costly failures.

The technological trajectory in this field points towards the development of self-diagnostic and self-healing inverters. These advanced systems are designed to automatically detect anomalies, perform corrective actions, and optimize their performance without human intervention. This evolution is expected to significantly reduce the frequency and complexity of manual maintenance tasks, thereby lowering associated costs.

Another key aspect of the maintenance cost reduction objective is the standardization of maintenance protocols and the development of more efficient service models. This includes the creation of comprehensive maintenance guidelines, the training of specialized technicians, and the implementation of streamlined logistics for spare parts and replacements.

The goal of reducing maintenance costs is intrinsically linked to improving the overall reliability and longevity of solar inverters. Manufacturers are focusing on enhancing the durability of components, implementing more robust thermal management systems, and developing advanced protection mechanisms against environmental stressors. These improvements aim to extend the operational lifespan of inverters, reducing the frequency of replacements and major repairs.

In conclusion, the background and objectives of solar inverter maintenance cost reduction reflect a multifaceted approach to enhancing the sustainability and economic viability of solar energy systems. By addressing maintenance challenges through technological innovation, operational optimization, and strategic planning, the industry aims to make solar power an increasingly attractive and cost-effective energy solution for a wide range of applications.

The primary objective in reducing maintenance costs for solar inverters is to optimize the balance between system performance and operational expenses. This goal aligns with the broader industry trend of maximizing the return on investment for solar energy installations. By focusing on maintenance cost reduction, stakeholders aim to enhance the overall economic viability of solar power generation, making it more competitive with traditional energy sources.

A comprehensive understanding of solar inverter maintenance involves recognizing the various factors that contribute to maintenance needs. These include environmental conditions, system design, component quality, and operational practices. The industry has been moving towards predictive maintenance strategies, leveraging data analytics and remote monitoring capabilities to anticipate and prevent potential issues before they escalate into costly failures.

The technological trajectory in this field points towards the development of self-diagnostic and self-healing inverters. These advanced systems are designed to automatically detect anomalies, perform corrective actions, and optimize their performance without human intervention. This evolution is expected to significantly reduce the frequency and complexity of manual maintenance tasks, thereby lowering associated costs.

Another key aspect of the maintenance cost reduction objective is the standardization of maintenance protocols and the development of more efficient service models. This includes the creation of comprehensive maintenance guidelines, the training of specialized technicians, and the implementation of streamlined logistics for spare parts and replacements.

The goal of reducing maintenance costs is intrinsically linked to improving the overall reliability and longevity of solar inverters. Manufacturers are focusing on enhancing the durability of components, implementing more robust thermal management systems, and developing advanced protection mechanisms against environmental stressors. These improvements aim to extend the operational lifespan of inverters, reducing the frequency of replacements and major repairs.

In conclusion, the background and objectives of solar inverter maintenance cost reduction reflect a multifaceted approach to enhancing the sustainability and economic viability of solar energy systems. By addressing maintenance challenges through technological innovation, operational optimization, and strategic planning, the industry aims to make solar power an increasingly attractive and cost-effective energy solution for a wide range of applications.

Market Analysis for Low-Maintenance Solar Inverters

The market for low-maintenance solar inverters is experiencing significant growth, driven by the increasing adoption of solar energy systems worldwide. As the solar industry matures, there is a growing demand for more efficient and cost-effective solutions, particularly in terms of maintenance and operational expenses. This trend is especially pronounced in large-scale solar installations, where maintenance costs can significantly impact the overall return on investment.

The global solar inverter market is projected to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is fueled by the declining costs of solar panels, government incentives for renewable energy adoption, and the increasing awareness of environmental sustainability. Within this broader market, low-maintenance inverters are gaining traction due to their potential to reduce long-term operational costs.

Key market segments for low-maintenance solar inverters include utility-scale solar farms, commercial and industrial installations, and residential systems. Utility-scale projects, in particular, stand to benefit significantly from reduced maintenance requirements, as these large installations often incur substantial ongoing operational expenses. The commercial and industrial sector is also showing increased interest in low-maintenance solutions, driven by the need to optimize energy costs and minimize downtime.

Geographically, the market for low-maintenance solar inverters is seeing strong growth in regions with high solar energy potential and supportive regulatory environments. Countries like China, the United States, India, and several European nations are at the forefront of this trend. Emerging markets in Southeast Asia, Latin America, and Africa are also showing promising growth potential as they expand their renewable energy infrastructure.

The demand for low-maintenance solar inverters is influenced by several factors. Firstly, there is a growing emphasis on reducing the levelized cost of electricity (LCOE) for solar energy systems. By minimizing maintenance requirements, operators can significantly lower their operational expenses over the system's lifetime. Secondly, the increasing complexity and scale of solar installations necessitate more reliable and self-sustaining equipment to ensure optimal performance and reduce the need for frequent on-site interventions.

Moreover, the integration of advanced monitoring and diagnostic capabilities in modern inverters is driving the shift towards predictive maintenance strategies. This approach allows for more efficient resource allocation and helps prevent unexpected downtime, further reducing overall maintenance costs. The market is also seeing increased demand for modular and easily replaceable inverter designs, which simplify maintenance procedures and minimize system downtime during repairs or upgrades.

The global solar inverter market is projected to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is fueled by the declining costs of solar panels, government incentives for renewable energy adoption, and the increasing awareness of environmental sustainability. Within this broader market, low-maintenance inverters are gaining traction due to their potential to reduce long-term operational costs.

Key market segments for low-maintenance solar inverters include utility-scale solar farms, commercial and industrial installations, and residential systems. Utility-scale projects, in particular, stand to benefit significantly from reduced maintenance requirements, as these large installations often incur substantial ongoing operational expenses. The commercial and industrial sector is also showing increased interest in low-maintenance solutions, driven by the need to optimize energy costs and minimize downtime.

Geographically, the market for low-maintenance solar inverters is seeing strong growth in regions with high solar energy potential and supportive regulatory environments. Countries like China, the United States, India, and several European nations are at the forefront of this trend. Emerging markets in Southeast Asia, Latin America, and Africa are also showing promising growth potential as they expand their renewable energy infrastructure.

The demand for low-maintenance solar inverters is influenced by several factors. Firstly, there is a growing emphasis on reducing the levelized cost of electricity (LCOE) for solar energy systems. By minimizing maintenance requirements, operators can significantly lower their operational expenses over the system's lifetime. Secondly, the increasing complexity and scale of solar installations necessitate more reliable and self-sustaining equipment to ensure optimal performance and reduce the need for frequent on-site interventions.

Moreover, the integration of advanced monitoring and diagnostic capabilities in modern inverters is driving the shift towards predictive maintenance strategies. This approach allows for more efficient resource allocation and helps prevent unexpected downtime, further reducing overall maintenance costs. The market is also seeing increased demand for modular and easily replaceable inverter designs, which simplify maintenance procedures and minimize system downtime during repairs or upgrades.

Current Challenges in Solar Inverter Maintenance

Solar inverter maintenance presents several significant challenges that impact the overall efficiency and cost-effectiveness of solar energy systems. One of the primary issues is the complexity of inverter technology, which requires specialized knowledge and skills for proper maintenance. This complexity often leads to increased downtime during repairs and higher labor costs for skilled technicians.

Environmental factors pose another substantial challenge. Solar inverters are typically exposed to harsh outdoor conditions, including extreme temperatures, humidity, and dust. These elements can accelerate wear and tear, leading to more frequent maintenance needs and potentially shorter lifespans for the inverters. The need for weatherproofing and robust design adds to the overall cost of maintenance and replacement.

Reliability and performance degradation over time are also critical concerns. As inverters age, their efficiency may decrease, affecting the overall energy output of the solar system. This gradual decline necessitates regular monitoring and potential replacements, contributing to ongoing maintenance costs. Additionally, the rapid evolution of inverter technology means that older models may become obsolete, making it challenging to find compatible replacement parts or expertise for maintenance.

The distributed nature of solar installations, especially in residential and commercial settings, creates logistical challenges for maintenance. Technicians often need to travel to multiple sites, increasing response times and travel costs. This dispersed infrastructure also complicates remote monitoring and diagnostics, potentially delaying the identification and resolution of issues.

Preventive maintenance is crucial but often overlooked, leading to more frequent breakdowns and higher repair costs. Many system owners may not fully understand the importance of regular maintenance, resulting in neglect until a failure occurs. This reactive approach typically results in higher overall costs and reduced system efficiency.

Lastly, the lack of standardization across different inverter models and manufacturers adds complexity to maintenance procedures. Technicians need to be familiar with various proprietary technologies and software, which can lead to longer training periods and increased specialization costs. This diversity also complicates inventory management for spare parts, potentially leading to longer downtimes while waiting for specific components.

Addressing these challenges is crucial for reducing maintenance costs and improving the long-term viability of solar energy systems. Innovations in inverter design, improved remote monitoring capabilities, and the development of more standardized maintenance protocols are key areas that could significantly impact the efficiency and cost-effectiveness of solar inverter maintenance.

Environmental factors pose another substantial challenge. Solar inverters are typically exposed to harsh outdoor conditions, including extreme temperatures, humidity, and dust. These elements can accelerate wear and tear, leading to more frequent maintenance needs and potentially shorter lifespans for the inverters. The need for weatherproofing and robust design adds to the overall cost of maintenance and replacement.

Reliability and performance degradation over time are also critical concerns. As inverters age, their efficiency may decrease, affecting the overall energy output of the solar system. This gradual decline necessitates regular monitoring and potential replacements, contributing to ongoing maintenance costs. Additionally, the rapid evolution of inverter technology means that older models may become obsolete, making it challenging to find compatible replacement parts or expertise for maintenance.

The distributed nature of solar installations, especially in residential and commercial settings, creates logistical challenges for maintenance. Technicians often need to travel to multiple sites, increasing response times and travel costs. This dispersed infrastructure also complicates remote monitoring and diagnostics, potentially delaying the identification and resolution of issues.

Preventive maintenance is crucial but often overlooked, leading to more frequent breakdowns and higher repair costs. Many system owners may not fully understand the importance of regular maintenance, resulting in neglect until a failure occurs. This reactive approach typically results in higher overall costs and reduced system efficiency.

Lastly, the lack of standardization across different inverter models and manufacturers adds complexity to maintenance procedures. Technicians need to be familiar with various proprietary technologies and software, which can lead to longer training periods and increased specialization costs. This diversity also complicates inventory management for spare parts, potentially leading to longer downtimes while waiting for specific components.

Addressing these challenges is crucial for reducing maintenance costs and improving the long-term viability of solar energy systems. Innovations in inverter design, improved remote monitoring capabilities, and the development of more standardized maintenance protocols are key areas that could significantly impact the efficiency and cost-effectiveness of solar inverter maintenance.

Existing Cost-Reduction Strategies for Inverter Maintenance

01 Predictive maintenance for solar inverters

Implementing predictive maintenance strategies for solar inverters can significantly reduce maintenance costs. This approach uses data analytics and machine learning algorithms to predict potential failures before they occur, allowing for timely interventions and minimizing downtime. By monitoring key performance indicators and analyzing historical data, maintenance schedules can be optimized, reducing unnecessary inspections and replacements.- Predictive maintenance for solar inverters: Implementing predictive maintenance strategies for solar inverters can significantly reduce maintenance costs. This approach uses data analytics and machine learning algorithms to predict potential failures before they occur, allowing for timely interventions and minimizing downtime. By monitoring key performance indicators and analyzing historical data, maintenance schedules can be optimized, reducing unnecessary inspections and replacements.

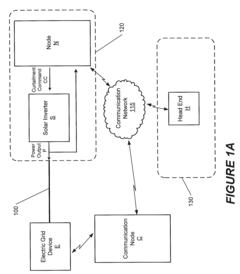

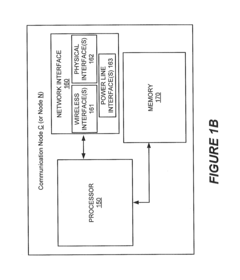

- Remote monitoring and diagnostics: Utilizing remote monitoring and diagnostic systems for solar inverters can help reduce maintenance costs by enabling real-time performance tracking and issue identification. These systems allow for quick detection of faults or inefficiencies, facilitating prompt resolution and minimizing the need for on-site inspections. Remote monitoring also enables proactive maintenance, potentially extending the lifespan of inverters and reducing overall maintenance expenses.

- Modular design for easy maintenance: Developing solar inverters with modular designs can significantly reduce maintenance costs. Modular components allow for easier replacement of faulty parts without the need to replace the entire inverter. This approach simplifies maintenance procedures, reduces downtime, and lowers the overall cost of repairs. Additionally, modular designs can facilitate upgrades to newer technologies without replacing the entire system.

- Automated cleaning and cooling systems: Incorporating automated cleaning and cooling systems into solar inverter designs can help reduce maintenance costs by minimizing manual interventions. These systems can include self-cleaning mechanisms for dust and debris removal, as well as advanced cooling technologies to maintain optimal operating temperatures. By reducing the need for manual cleaning and preventing overheating-related failures, these systems can extend the lifespan of inverters and reduce maintenance frequency.

- Cost-effective maintenance planning and scheduling: Implementing efficient maintenance planning and scheduling strategies can help optimize maintenance costs for solar inverters. This includes developing comprehensive maintenance plans that balance preventive and corrective maintenance activities, considering factors such as inverter age, performance history, and environmental conditions. By prioritizing maintenance tasks and coordinating them with other solar farm activities, overall maintenance costs can be reduced while maximizing system uptime and efficiency.

02 Remote monitoring and diagnostics

Utilizing remote monitoring and diagnostic systems for solar inverters can help reduce maintenance costs by enabling real-time performance tracking and issue identification. These systems allow for quick detection of faults or inefficiencies, facilitating prompt resolution without the need for frequent on-site inspections. Remote monitoring also enables proactive maintenance, reducing the likelihood of costly breakdowns and extending the lifespan of the inverters.Expand Specific Solutions03 Modular design for easy maintenance

Developing solar inverters with modular designs can significantly reduce maintenance costs. Modular components allow for easier replacement of faulty parts without the need to replace the entire inverter. This approach minimizes downtime, reduces labor costs, and extends the overall lifespan of the system. Additionally, modular designs facilitate upgrades and adaptations to new technologies without complete system overhauls.Expand Specific Solutions04 Automated cleaning and cooling systems

Incorporating automated cleaning and cooling systems into solar inverter designs can help reduce maintenance costs by minimizing manual interventions. Self-cleaning mechanisms can prevent dust and debris accumulation, which can impact inverter efficiency and lifespan. Efficient cooling systems can prevent overheating issues, reducing the frequency of temperature-related failures and extending the operational life of the inverters.Expand Specific Solutions05 Cost-effective maintenance planning and scheduling

Implementing efficient maintenance planning and scheduling strategies can significantly reduce the overall maintenance costs of solar inverters. This includes optimizing maintenance intervals based on equipment performance, environmental conditions, and historical data. By grouping maintenance activities and coordinating them with other solar farm operations, labor and logistics costs can be minimized. Additionally, using software tools for maintenance scheduling and resource allocation can improve efficiency and reduce human error.Expand Specific Solutions

Key Players in Solar Inverter Industry

The solar inverter market is in a growth phase, driven by increasing adoption of solar energy worldwide. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, solar inverters are evolving, with major players like Siemens, Sungrow, Enphase Energy, and SolarEdge Technologies leading innovation. These companies are focusing on developing more efficient, reliable, and cost-effective inverters. Emerging technologies such as microinverters and power optimizers are gaining traction, with companies like Enphase and SolarEdge at the forefront. Other key players like Huawei, Delta Electronics, and Fronius are also contributing to technological advancements, making the market highly competitive and dynamic.

Sungrow Power Supply Co., Ltd.

Technical Solution: Sungrow's string inverters incorporate advanced grid support features and smart O&M functions to reduce maintenance costs[1]. Their inverters use multi-MPPT technology to optimize power generation under various conditions, minimizing energy losses[2]. Sungrow's iSolarCloud platform provides comprehensive monitoring and analytics, enabling predictive maintenance and remote troubleshooting[3]. The company's inverters feature IP65 protection, reducing the risk of environmental damage and associated maintenance costs[4]. Sungrow also implements modular designs in their inverters, allowing for easier replacement of components and reducing repair times[5].

Strengths: Advanced grid support features, comprehensive monitoring platform, and modular design for easy maintenance. Weaknesses: May have a steeper learning curve for installers unfamiliar with the system.

Enphase Energy, Inc.

Technical Solution: Enphase's microinverter technology converts DC to AC at the individual panel level, enhancing system reliability and reducing maintenance needs[1]. Their Envoy communications gateway provides real-time monitoring and diagnostics, enabling quick identification of underperforming panels or faulty microinverters[2]. Enphase's IQ8 microinverters feature "Sunlight Jump Start" capability, allowing for system startup even during grid outages, reducing downtime and associated costs[3]. The company's Enlighten monitoring platform offers detailed performance data and automated alerts, facilitating proactive maintenance[4]. Enphase also implements over-the-air software updates, ensuring continuous improvement of system performance and features without on-site visits[5].

Strengths: Panel-level conversion improves system resilience, detailed monitoring, and remote update capabilities. Weaknesses: Higher upfront costs compared to string inverter systems.

Innovative Technologies for Reducing Maintenance Costs

Solar panel architecture

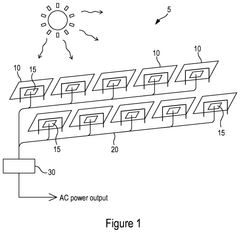

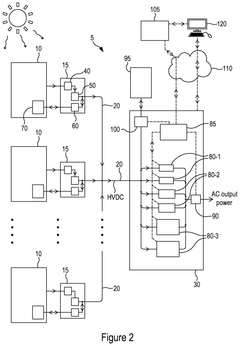

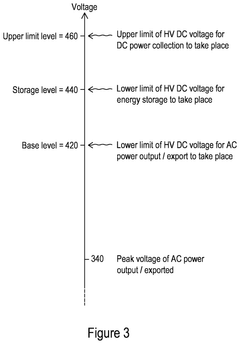

PatentPendingUS20250112469A1

Innovation

- The proposed system combines the benefits of string inverter and microinverter architectures by using a common inverter unit and power conditioning units connected in parallel, which raises the voltage of DC power to reduce cable losses and allows for efficient power conversion and storage.

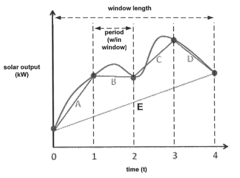

Methods for reducing solar inverter output volatility, and related nodes and solar inverters

PatentActiveUS9507364B2

Innovation

- A method that determines the likelihood of output fluctuations in solar inverters using real-time and past output data, allowing for preemptive curtailment of the solar inverter's output to reduce volatility, independent of cloud-cover sensors or other external measurements.

Economic Impact of Reduced Maintenance Costs

The economic impact of reduced maintenance costs associated with solar inverters is significant and multifaceted. By implementing advanced technologies and strategies to minimize maintenance requirements, solar energy systems can achieve substantial cost savings over their operational lifetime.

One of the primary economic benefits is the reduction in labor costs. Traditional solar inverter systems often require frequent on-site inspections and manual interventions. By incorporating smart monitoring systems and predictive maintenance algorithms, the need for regular physical inspections can be dramatically reduced. This translates to fewer man-hours spent on routine maintenance, allowing skilled technicians to focus on more critical tasks and reducing overall operational expenses.

The implementation of remote monitoring and diagnostics further enhances the economic advantages. Real-time data analysis enables early detection of potential issues, preventing costly breakdowns and minimizing downtime. This proactive approach not only reduces the frequency of emergency repairs but also extends the overall lifespan of the inverter systems, maximizing the return on investment for solar energy projects.

Reduced maintenance costs also contribute to improved cash flow for solar energy providers and system owners. Lower operational expenses translate to higher profit margins, making solar energy more competitive in the energy market. This improved financial performance can attract more investment in the sector, driving further innovation and cost reductions in solar technology.

From a broader economic perspective, the reduced maintenance costs of solar inverters can accelerate the adoption of solar energy on a larger scale. As the total cost of ownership decreases, solar power becomes more accessible to a wider range of consumers and businesses. This increased adoption can lead to job creation in the renewable energy sector, stimulating economic growth and contributing to the transition towards a more sustainable energy landscape.

Moreover, the economic benefits extend to the environmental sphere. By ensuring more efficient and reliable operation of solar inverters, the overall energy yield of solar installations can be optimized. This increased efficiency translates to a higher return on investment for system owners and a greater contribution to renewable energy goals, potentially reducing reliance on fossil fuels and associated economic costs.

In conclusion, the economic impact of reduced maintenance costs for solar inverters is far-reaching, affecting not only the immediate operational expenses but also broader market dynamics and environmental considerations. As technology continues to advance in this field, the economic benefits are likely to become even more pronounced, further solidifying solar energy's position as a cost-effective and sustainable power source.

One of the primary economic benefits is the reduction in labor costs. Traditional solar inverter systems often require frequent on-site inspections and manual interventions. By incorporating smart monitoring systems and predictive maintenance algorithms, the need for regular physical inspections can be dramatically reduced. This translates to fewer man-hours spent on routine maintenance, allowing skilled technicians to focus on more critical tasks and reducing overall operational expenses.

The implementation of remote monitoring and diagnostics further enhances the economic advantages. Real-time data analysis enables early detection of potential issues, preventing costly breakdowns and minimizing downtime. This proactive approach not only reduces the frequency of emergency repairs but also extends the overall lifespan of the inverter systems, maximizing the return on investment for solar energy projects.

Reduced maintenance costs also contribute to improved cash flow for solar energy providers and system owners. Lower operational expenses translate to higher profit margins, making solar energy more competitive in the energy market. This improved financial performance can attract more investment in the sector, driving further innovation and cost reductions in solar technology.

From a broader economic perspective, the reduced maintenance costs of solar inverters can accelerate the adoption of solar energy on a larger scale. As the total cost of ownership decreases, solar power becomes more accessible to a wider range of consumers and businesses. This increased adoption can lead to job creation in the renewable energy sector, stimulating economic growth and contributing to the transition towards a more sustainable energy landscape.

Moreover, the economic benefits extend to the environmental sphere. By ensuring more efficient and reliable operation of solar inverters, the overall energy yield of solar installations can be optimized. This increased efficiency translates to a higher return on investment for system owners and a greater contribution to renewable energy goals, potentially reducing reliance on fossil fuels and associated economic costs.

In conclusion, the economic impact of reduced maintenance costs for solar inverters is far-reaching, affecting not only the immediate operational expenses but also broader market dynamics and environmental considerations. As technology continues to advance in this field, the economic benefits are likely to become even more pronounced, further solidifying solar energy's position as a cost-effective and sustainable power source.

Environmental Benefits of Efficient Inverter Maintenance

Efficient maintenance of solar inverters not only reduces operational costs but also contributes significantly to environmental sustainability. By optimizing inverter performance, we can maximize energy production from solar panels, thereby reducing reliance on fossil fuels and decreasing greenhouse gas emissions. Regular maintenance ensures that inverters operate at peak efficiency, minimizing energy losses and maximizing the conversion of solar energy into usable electricity.

Proper maintenance of solar inverters extends their lifespan, reducing the need for premature replacements. This, in turn, decreases the environmental impact associated with manufacturing and disposing of electronic components. By prolonging the operational life of inverters, we reduce the demand for raw materials and energy required for producing new units, thus conserving natural resources and minimizing industrial waste.

Efficient inverter maintenance also plays a crucial role in grid stability and power quality. Well-maintained inverters provide more stable and reliable power output, reducing the need for grid operators to rely on fossil fuel-based backup power sources during periods of fluctuating solar generation. This stability contributes to a more efficient overall energy system, reducing waste and unnecessary emissions from conventional power plants.

Moreover, regular maintenance helps identify and address potential issues before they escalate, preventing catastrophic failures that could lead to hazardous waste or environmental contamination. By ensuring the proper functioning of safety features and monitoring systems, we can prevent electrical fires or other accidents that could have severe environmental consequences.

Efficient inverter maintenance also supports the broader adoption of solar energy systems. As maintenance costs decrease and system reliability improves, solar power becomes a more attractive option for a wider range of applications. This accelerates the transition to renewable energy sources, contributing to global efforts to mitigate climate change and reduce air pollution.

Furthermore, optimized inverter performance enhances the overall efficiency of solar energy systems, allowing for greater energy production from existing installations. This increased efficiency means that fewer solar panels are needed to meet energy demands, reducing the land use and environmental impact associated with large-scale solar farms.

In conclusion, the environmental benefits of efficient inverter maintenance extend far beyond the immediate cost savings. By ensuring optimal performance, extending equipment lifespan, improving grid stability, preventing accidents, and supporting the broader adoption of solar energy, efficient maintenance practices play a crucial role in maximizing the positive environmental impact of solar power technology.

Proper maintenance of solar inverters extends their lifespan, reducing the need for premature replacements. This, in turn, decreases the environmental impact associated with manufacturing and disposing of electronic components. By prolonging the operational life of inverters, we reduce the demand for raw materials and energy required for producing new units, thus conserving natural resources and minimizing industrial waste.

Efficient inverter maintenance also plays a crucial role in grid stability and power quality. Well-maintained inverters provide more stable and reliable power output, reducing the need for grid operators to rely on fossil fuel-based backup power sources during periods of fluctuating solar generation. This stability contributes to a more efficient overall energy system, reducing waste and unnecessary emissions from conventional power plants.

Moreover, regular maintenance helps identify and address potential issues before they escalate, preventing catastrophic failures that could lead to hazardous waste or environmental contamination. By ensuring the proper functioning of safety features and monitoring systems, we can prevent electrical fires or other accidents that could have severe environmental consequences.

Efficient inverter maintenance also supports the broader adoption of solar energy systems. As maintenance costs decrease and system reliability improves, solar power becomes a more attractive option for a wider range of applications. This accelerates the transition to renewable energy sources, contributing to global efforts to mitigate climate change and reduce air pollution.

Furthermore, optimized inverter performance enhances the overall efficiency of solar energy systems, allowing for greater energy production from existing installations. This increased efficiency means that fewer solar panels are needed to meet energy demands, reducing the land use and environmental impact associated with large-scale solar farms.

In conclusion, the environmental benefits of efficient inverter maintenance extend far beyond the immediate cost savings. By ensuring optimal performance, extending equipment lifespan, improving grid stability, preventing accidents, and supporting the broader adoption of solar energy, efficient maintenance practices play a crucial role in maximizing the positive environmental impact of solar power technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!